2.1. Thin Dielectric Grating on Thin MF (TDGTMF)-based Self-Referenced Sensor

A new technique for designing a self-referenced biosensor in the grating coupling geometry based on the combination of a thin dielectric grating (<200 nm) with a thin MF (<50 nm) is proposed in

Figure 3, which has been shown to exhibit the excitation of two optical modes [

21,

22]. The first optical mode is excited as a result of exciting the GMR supported by the dielectric grating, showing a reflection dip instead of peak due to the existence of the MF below the dielectric grating. Since the EMF associated with the excitation of the first mode, it exists mostly in the analyte medium side. This mode is called analyte mode. On the other hand, the second optical mode is ESP mode (ESPM), excited at the MF-substrate interface (called the substrate mode).

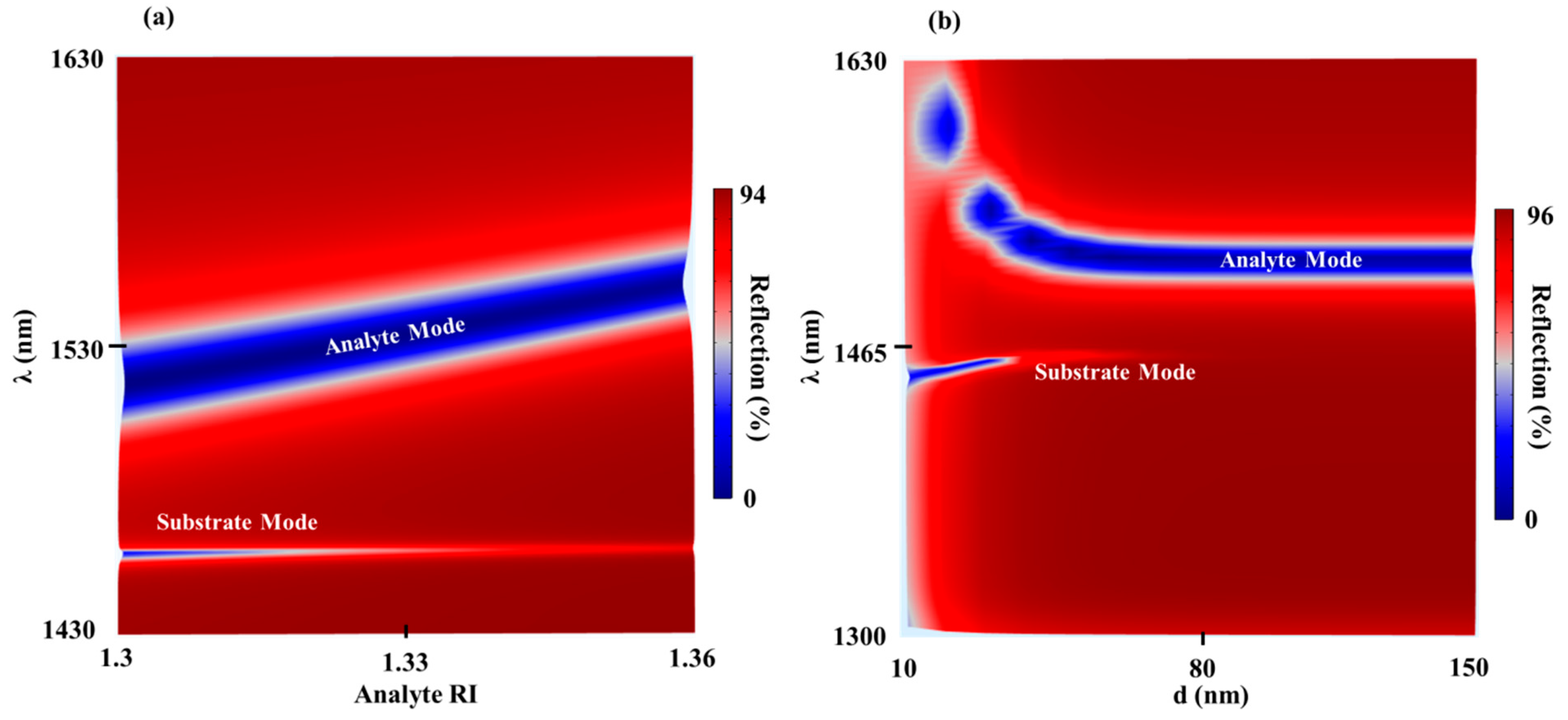

Because the substrate mode is not sensitive to the analyte RI, this mode was used as a reference for detecting variations in the analyte RI as shown in the reflection analyte RI–λ map of the TDGTMF geometry for h = 175 nm and d = 40 in

Figure 4a. It is interesting to note that, as the increased RI increases, the substrate mode started to disappear. Calculations showed that it almost disappeared at the analyte RI, close to the SiO

2 substrate RI (1.443–1.445 in the given spectral range). Reflection d–λ map from the TDGTMF geometry, with h = 175 nm, is shown in

Figure 4b. The MF thickness was shown to have a critical role in exciting the substrate mode (

Figure 4b), where, above a certain value (~80 nm), the field cannot penetrate through the MF and therefore cannot excite the ESP at the lower interface of the MF. Hence, the substrate mode disappears.

The analyte mode excitation wavelength, on the other hand, did not change when the MF thickness increased above ~ 60 nm, as shown in

Figure 4b. TM-polarized light under normal incidence was used in the simulations of the Si3N4 grating with Λ = 1000 nm and FF = 0.55 in

Figure 4,

Figure 5,

Figure 6 and

Figure 7. Water and SiO

2 were used for the superstrate (analyte) and substrate, respectively.

Although the TDGTMF was previously proposed by our group [

21,

22], there are some questions that still must be answered regarding this geometry. First, we strengthened our understanding of the nature of the resonant modes excited in the structure for different values of the grating parameters and MF thicknesses. New data are presented in

Figure 5, which show the reflection h–λ maps of the TDGTMF geometry for different values of d. Without the MF (

Figure 5a), the resonant branch is associated with the excitation of pure GMR. For d = 20 nm (

Figure 5b) and d = 40 nm (

Figure 5c), the TDGTMF geometry supports the excitation of both the photonic (GMR on MF) and plasmonic mode (ESP excited at the MF interface with the SiO

2 substrate). As can be observed from

Figure 5c for the case of d = 40 nm, the photonic branch splits around the horizontal dashed white line, which indicates the ESP wavelength of the substrate mode. The circled area indicates the region in which a strong coupling between the photonic and plasmonic modes is observed, which is associated with the FD of both the GMR on MF and the ESP modes, as in

Figure 6. At d = 100 nm in

Figure 5d, the ESP at the lower MF surface almost disappears. Therefore, a photonic mode branch is observed again. An important observation is shown at d = 20 nm, in which a gap in the continuous ESP substrate mode branch is observed. The origin of this gap requires more investigation, and we believe that it might be related to the bound state in the continuum (BIC) observed in several optical configurations.

To strengthen our understanding of the nature of the resonant modes in

Figure 5, FD calculations (|Hy| and |Ez|) are shown in

Figure 6 for at different combinations of h and d.

We started with the pure GMR at h = 450 nm and d = 0 nm. The resonant wavelength was λres = 1520 nm, and |Hy| was well confined within the grating line, since the grating was thick enough to be able to effectively support the GMR, as observed in

Figure 5a. On the other hand, at h = 250 nm and d = 0 nm, λres = 1452 nm, |Hy| was less confined within the grating line, and the field was leaky (leaky mode).

When involving the MF and at h = 450 nm and d = 40 nm, λres = 1690 nm, and |Hy| existed within the grating spaces and lines as expected from the GMR on MF geometry. On the other hand, at h = 175 nm and d = 40 nm, the coupling regime was still relatively far (see the circled area in

Figure 5c), and two resonant wavelengths were observed in

Figure 5c. At λres1 = 1525 nm, |Hy| was mainly concentrated within the grating spaces and lines, while at λres2 = 1458 nm, |Hy| existed almost only within the substrate medium as expected. The case of h = 129 nm and d = 40 nm fell with the coupled modes regime. Therefore, the resonant wavelengths λres1 = 1481 nm and λres1 = 1447 nm showed the signatures of both photonic and plasmonic FD nature. The case h = 116 nm and d = 40 nm was also close to the coupling regime, and therefore, both the photonic and plasmonic FD signature was observed (it was clearer at 1474 nm than at 1438 nm). Finally, at h = 60 nm and d = 40 nm, at λres1 = 1465 nm, the resonant branch returned to ESP branch behavior, as seen from the FD. Similarly, at λres1 = 1378 nm, the resonant branch returned to the photonic branch. The substrate mode has a larger penetration depth than the analyte mode [

21,

22], indicating long-range SP (LRSP) excitation. Thus, it can be used for large bioentity detection, such as cells and bacteria. To see this, field distribution (FD) for the case of h = 175 nm and d = 40 nm is shown in

Figure 6. Field distributions were λ = 1458 nm, indicating the substrate mode resonant wavelength, while λ = 1525 nm indicates the analyte mode resonant wavelength.

Phase detection has the advantage of having sharp response at resonance in comparison to intensity detection. Hence, the resonance wavelength can be easily determined in a high precision, as observed in

Figure 7.

Figure 7a shows the spectral reflection variation at different analyte RIs (1.33, 1.34, and 1.35) in which the width of the resonance (FWHM) is large, while in

Figure 7b, a sharper response was observed when detecting the phase for the same RIs in

Figure 7a. The spectral reflection sensitivity of the analyte mode is defined as the ratio between the shift in the resonant wavelength and the shift in the analyte RI, given by ∆λ/∆n = 580 (nm/RIU), as indicated in

Figure 7a. As can be observed in

Figure 7b, the spectral phase response of the analyte was much sharper than the one associated with the substrate mode. This is expected to be a result of the losses of the metal in the case of the ESP substrate mode, which significantly affects the sharpness of the phase response expected at resonance. Profiting from the sharp jump in phase function under ESPR excitation, an improved detection limit using phase over wavelength detection was demonstrated by the authors of [

28]. In particular, the polarimetric approach was applied at the spectral mode, and a clear advantage of the phase over the intensity or wavelength detection was shown both experimentally and theoretically using two different detection limit estimation algorithms. The system noise was also considered in the performance analysis. More details on the mathematical analysis of the detection limit have been presented by the authors of [

28].

The idea behind the proposed self-referenced sensor configuration was stimulated from a work performed by our group. Our previous work showed that showed that, using a thin enough metallic grating (~20–40 nm), the excitation of two EOT peaks is possible [

13,

29]. The EOT substrate mode was also used as a reference and showed a larger penetration depth than the analyte mode. A clear advantage of the proposed self-referenced sensor, previously described by our group in [

21], over the one based on the EOT in described in [

13] is the use of a thin dielectric grating with lateral features in the sub-micron scale and a thin MF instead of a thin metallic nanoslits (40–50 nm slits) array, which requires a fine lithography process. An important remark on the LRSP in the substrate medium in the TDGTFM geometry in the regard to sensing applications is that it can also be used for sensing with high sensitivity and large penetration depth, for example, by replacing the analyte medium (ambient) with a medium of low RI such as MgF2. On the other hand, the substrate is replaced with a liquid medium of RI close to that of SiO

2, for example, with blood or serum as the medium. To demonstrate this, numerical simulation was carried out and shown in

Figure 8 below.

In

Figure 8, the analyte medium (ambient or superstrate as shown in

Figure 3) was replaced with MgF2 (meaning that the Si3N4 grating spaces were filled with MgF2), while the substrate was replaced with an RI close to that of SiO

2 (1.42–1.47 RI), for example, with blood or serum as the medium.

Figure 8a shows reflection analyte RI–λ map of the TDGTMF geometry for h = 175 nm and d = 40 nm, where opposite behavior to that in

Figure 4a was observed. The bottom branch is now called the analyte mode branch, while the top one is related to the substrate mode, which almost did not change with the analyte RI. FD at the resonant wavelengths in

Figure 8a at 1.47 analyte RI is shown in

Figure 8b to verify the claim above, in which larger penetration depth was observed in the analyte medium. TM-polarized light under normal incidence was used in the simulations of the Si3N4 grating, with Λ = 1000 nm and FF = 0.55.

To summarize, this design proposed for water sensing in the infrared (IR) spectral range and the distance between the two dips (associated with the analyte and substrate modes excitation) in the reflection spectra is small. The design can be easily tuned to work in different types of analyte mediums by tuning the nano-scale features of the grating parameters as partially shown above, mainly by varying h. To work at the visible spectral range, the grating period can be reduced accordingly. Another important parameter that can help in the design is the FF.

2.2. Reflecting Nanograting-Based Multimodal Sensor

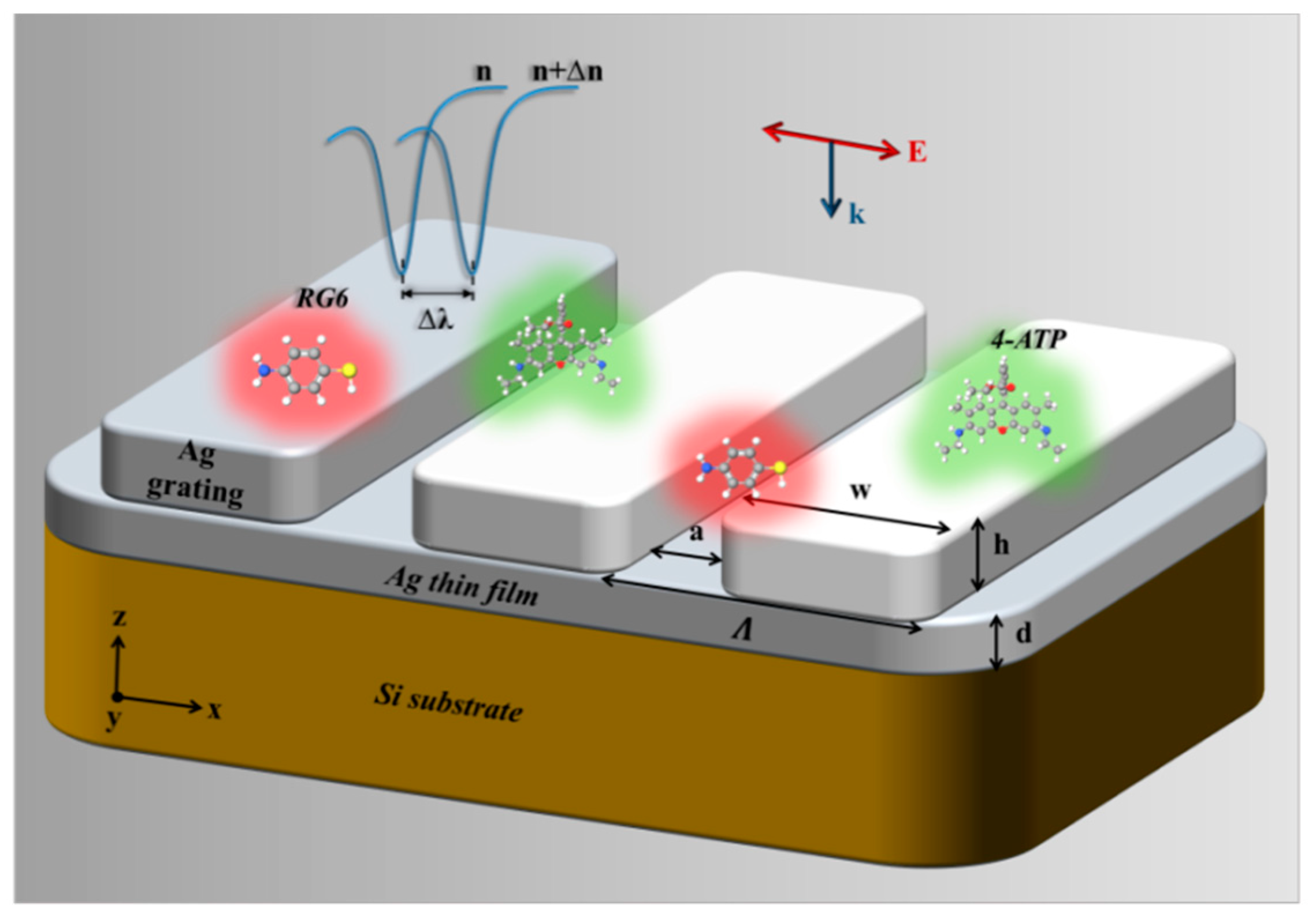

Metallic nanogratings can be effectively implemented for sensing applications due to the optical mode excitation they can support. The nature of the resonant modes of reflecting gratings (metallic grating on MF, as shown in

Figure 9) with nano-grooves was theoretically and experimentally investigated as a function of the λ, h, and Λ under normal incidence and TM polarization [

24].

Figure 9 shows the general scheme of the proposed geometry, consisting of a metallic grating on a thin MF of thickness d (>100 nm), which is thick enough to suppress transmission inside the silicon (Si) substrate under free-space excitation. The main conclusions arising from the mentioned work were as follows: For thin enough (20 nm) gratings, the resonant modes at the investigated λ range (500–1400 nm) were mainly attributed to ESPMs excitation. As mentioned in the theoretical background above, the resonant wavelength (assuming fixed incident angle) in the limit of shallow gratings can be simply determined by the RIs of the grating and the surrounding materials as well as by Λ, without much dependence on h [

24], and can be estimated using Equation (2) above. Increasing h (at which the plasmon momentum matching equation no longer accurately predicts the SP’s resonance position) allows the excitation of cavity modes (CMs) (excited within the grooves of the grating) that might also couple to ESPs in what we called ESP-cavity hybrid mode. Field calculations were performed expressing the nature of the three-mode field (ESP, CM, and ESP-cavity hybrid mode [

24]). Experimental verification (RI sensing in the visible and IR ranges and SEF experiments) of the observed phenomena was performed on a 154 nm-thick silver (Ag) nanograting with 1050 nm period fabricated using electron beam lithography. The whole issue of supporting the CMs is that the grating has very narrow grooves where the slit width is much smaller than the grating period and wavelength, as shown below in detail.

Since grating with nano-scale features is the topic of this work, the analysis of the reflecting grating at different grating grooves width (a) and thickness (h) at the nano scale is presented in

Figure 10. TM-polarized light under normal incidence was used in all simulations of the Ag grating. Air and Si were used for the superstrate and substrate, respectively. The behavior of the reflecting grating as a function of the groove width (a) varied significantly for different values of h and Λ. The reflection h-λ maps from the reflecting grating with Λ = 350 nm are shown in

Figure 10 for a = 227.5 nm (

Figure 10a) and a = 52.5 nm (

Figure 10b). For the narrow grooves in

Figure 9, four resonant branches were clearly observed and associated with the CMs excitation. On the other hand, for the wide grooves in

Figure 10a, the CMs were observed only for the short wavelengths. The special case in

Figure 10a,b with Λ = 350 nm was used to make sure that only CMs could be excited (ESPMs cannot be excited at the given spectral range).

In order to strengthen the importance of the groove width in the reflecting gratings, reflection a-λ maps from the reflecting grating with different combinations of the Λ and h are shown in

Figure 10c,d. In

Figure 10c, we used Λ = 1050 nm and h = 20 nm to make sure that only ESPMs were excited (the grating was too shallow to support cavity modes at the given spectral range). As expected for thin enough gratings, the resonant location was mainly determined by the materials and the grating period, not the groove width, as can be observed from Equation (3) (normal incidence). Therefore, we expected to observe two horizontal lines, as almost seen in

Figure 10c, associated with the first (top line) and second (bottom line) ESPMs. In

Figure 10d, Λ = 300 nm and h = 600 nm were used, and four CM branches were observed (in this case, Λ was too small to support ESPMs).

Figure 10 clearly demonstrates the effect of the grating grooves on the resonant behavior of the reflecting grating, which has strong dependence on the grating period and thickness as shown above.

Intensity versus phase detection using the reflecting grating is shown in

Figure 11.

Figure 11a shows the spectral reflection variation at different analyte RIs (1.33, 1.34, and 1.35), while

Figure 11b shows the spectral phase response for the same RIs in

Figure 11a. As can be observed in

Figure 11b, the phase response was not sharp as in the case of the analyte mode phase response in

Figure 7b. This is expected to be a result of the losses of the metal in the case of the plasmonic scheme (

Figure 9), supporting the excitation of ESP and cavity modes. The spectral reflection sensitivities of the ESPM and CM were 550 and 365 (nm/RIU), respectively, as indicated in

Figure 11a. The fact that the ESPM was more sensitive to the analyte RI than the CM is believed to be a result of the enhanced interaction of the EMF with the analyte in the case of the ESPM. In the case of the CM, the field was strongly confined within the narrow grooves of the grating, which reduced the interaction with the analyte material.

To summarize this section, using a simple setup, one can measure ESP, CM resonance shift, and SEF and SERS signals, thus forming a multimodal sensing or imaging system [

23]. To illustrate the concept of multimodal sensing geometry in

Figure 9, Λ = 390 nm, h = 436 nm, and FF = 0.9 were chosen, and three resonances were observed at the spectral range 450–900 nm (529 nm, 595 nm, and 785 nm) in

Figure 12a. At this point, our interest was to propose a geometry exhibiting resonances at 532 nm and 785 nm for SEF and SERS signals enhancement, respectively. Although the first resonance was observed at 529 nm, 532 nm was still included within the resonant spectral region.

Figure 12b shows the FD at the resonant wavelengths 529 nm and 785 nm as well as at 532 nm to verify the field confinement on the grating surface (at 529 nm and 532 nm) and grooves (at 529 nm, 532 nm, and 785 nm). Besides this, all the resonant dips can be also used for RI sensing.

Multimodal systems are important to provide as much information as possible on the measured samples, such as the concentration of analytes and characterization of cells and tissue. Reflecting nanogratings (having nano-grooves) can easily exhibit multiple resonant modes (ESP and cavity modes) appearing simultaneously at several wavelengths, making the proposed nanograting geometry a potential nanostructure with a simple setup for multiple sensing operations, such as RI or yes/no sensing in the visible and infrared (IR) ranges and SERS and SEF sensing modes. Since this scheme was pure plasmonic geometry, the phase response was less sensitive than in the previous case of the TDGTMF in

Figure 3. On the other hand, the ESPM sensitivity in the reflecting grating is comparable to the analyte mode sensitivity of the TDGTMF in which the CM was less sensitive.

2.4. CD-R-Based off-the-Shelf Plasmonics

Experimental and theoretical investigation on the SPR sensing using CDs with different track pitches, including BD, DVD, and CD-R, were shown by the authors of [

30]. In typical BDs, DVDs, and CDs, the standard track period is 320 nm, 740 nm, and 1600 nm, respectively [

30]. The authors of [

30] performed a treatment of the CD structures. In the study, the recording dye layer and reflective alloy layer of the BD were removed using a specific procedure. This procedure was followed by sputtering deposition of 2 nm chromium and 80 nm gold. On the other hand, the protective polycarbonate layer and the photosensitive dyes of DVD and CD-R were removed by following the procedures described by the authors of [

31,

32], and the exposed aluminum reflective layers were used directly in SPR sensing.

The authors of [

33] proposed a simple angular displacement measurement system with sub-micro radian resolution based on SPR excitation in CDs. The authors presented an AFM test and schematic of the layers forming the CD in which the protective lacquer layer was removed from the CD to enable the attachment of biological entities for sensing application. Removing the protective layer also efficiently excited the plasmon’s at the air-metal interface (after removing the lacquer layer).

The preliminary results found by the authors of [

34] showed SPR angle modification using a biomolecular layer on the CD-based biosensor structure. The authors of [

35] presented an SPR-based CD biosensor with a circular fluidic channel. In the AFM test before 50 nm gold layer sputtering, the authors showed a grating groove depth of 64 nm and width of 468 nm. After sputtering, a groove depth of 54 nm and groove width of 445 nm were shown in the AFM test.

Simpler treatment procedure was performed by the authors of [

36] to isolate the metal layer. First, the authors cut the DVD disc into slices by scissors. Then, they easily separated the glued metal layer and the organic dye layer, and they finally washed the side with the metal layer using isopropanol to remove the residual dye. AFM of the prepared metal grating showed a grating period of 740 nm and a peak-to-valley modulation depth of 86 nm [

36]. The structure was used for RI sensing. Additional works on SPR based DVD structures can be found in [

37,

38,

39,

40,

41]. Theoretical and experimental study of the SPR supported by CDs can be found in [

42], biosensing application of different types of CDs is discussed in [

43].

Many other applications can be implemented using CDs-based structures, for example, SERS-based CDs have been described by the authors of [

32,

44,

45]. Moreover, schematic, SEM, and AFM characterization of the CDs-based structures and the materials used to manufacture the different types of CDs have been described by the authors of [

30,

32,

33,

34,

35,

36,

37,

38,

39,

40,

41,

42,

43,

44,

45,

46,

47], including the treatment methods made on the sample to prepare them for sensing applications. The main treatment method is exposure to metallic film. Therefore, the sample can have direct contact with the analyte as much as possible to enhance the plasmonic response of the structure. Determination of the dye-recording layer thickness was shown by the authors of [

48]. The authors of [

49] transform a CD into a simple and cheap photocatalytic nanoreactor.

In the abovementioned works, many efforts were made on the optical recording discs to transform them into plasmonic substrates. In this experimental work, we have three main advantages. First, we proposed the use of the CD-R-based sensor with almost zero treatment. Second, we proposed measuring the TM response in relative to the TE one so the contrast of the measured reflection dips could be significantly improved. Finally, to the best of our knowledge, we implemented phase detection SPR-based sensing using off-the-shelf CDs for the first time.

Figure 15 shows the characterization of a prepared sample in which almost zero treatment was performed when preparing the substrates. When preparing the substrate, we only separated the top part, including the marketing sign, from the bottom part.

Figure 15a shows the cut piece from the CD.

Figure 15b,c show the extracted sample at different angles, where the colors verify the existence of the grating. The clear advantage of using off -the -shelf CDs is first the almost zero treatment as well as the possibility of preparing the sample at the desired size from the CD area. The grating height profile is shown in

Figure 15d with an estimated grating height of ~150 nm.

Figure 15d was extracted from the AFM characterization of the prepared sample shown in

Figure 15e, which also presents the grating period profile with an estimated periodicity of ~1500 nm. The AFM data and the different SEM characterization of the prepared sample (

Figure 15f–h) clearly verify the existence of the grating structure. According to the XPS test, the scratches on the grating lines shown in

Figure 15f are the remaining lacquer material used to connect the different parts of the CD-R.

Figure 16 shows experimental reflection spectra from the prepared sample extracted from the CD-R at different analytes in the visible range. The TE reflection spectrum when air was used is shown in the red curve without any signature of resonant behavior. On the other hand, the TM reflection spectrum showed two dips in the blue curve, as can be clearly seen in the zoomed sub-figure in the top part of

Figure 16. A shift of the left-side dip (called the first dip), observed when air was used (blue curve), occurred at the TM response measured at deionized water (DI) and ethanol analytes, as shown in the green and purple curves, respectively. The DI water and ethanol were simply introduced on the sample using a pipet and they covered the whole surface.

Important conclusions arising from the initial experiments are as follows: The resonances were only seen under TM-polarized light because the plasmonic excitation required this polarization. The sensitivity was determined by parameters of the structure, the materials, and the wavelength. Usually, the higher the interaction between the evanescent field and the analyte, the higher the sensitivity [

1], and this can be achieved by specific design. Here, as a metallic grating without extra layers, the sensitivity was expected to be high enough. Second, the contrast of the resonances was relatively low, and similar results have been reported in many other works on sensing using CD-R structures. Therefore, the first improvement we propose is that almost zero treatment is required to prepare the substrate. Additionally, we suggest measuring the TM response relative to the TE one. We also suggest mirroring the response (as the reflective sample), as significant improvement was observed in the contrast of the resonances. The results of the reflection spectra when normalizing the TM reflection spectrum to the TE one (RTM/RTE) are shown in the azure, orange, and gray curve for air, water, and ethanol analytes, respectively. The fact that RTM/RTE exceeded 100% reflection when air was used is because, near the second reflection dip and at the spectral range of 803–823 nm, the TM reflection was larger than the TE one. The spectral sensitivity of the first reflection dip was ~ 433 (nm/RIU) as indicated in

Figure 16.

It was important and necessary to verify the reliability of the results and that they can be easily reproduced at a high precision level. We performed reflection measurements from tens of prepared samples, and the reproduced measurements achieved always provided comparable results. This means that the resonances were observed at similar spectral position with only few nanometers shift between the different samples. In addition, a very comparable contrast of the reflection dips was observed for the different samples.

The schematic diagram of the prepared sample is shown in

Figure 17a. The geometrical parameters used in the simulation are written in the schematic diagram, where the grating profile parameters are close to those shown in the SEM and AFM data in

Figure 15. TM-polarized light and normal incidence were used in the reflection simulation and are shown in

Figure 17b. The simulation showed good agreement with the experimental results in

Figure 16 (blue curve) when comparing the right-hand reflection dip spectral position, contrast, and shape. On the other hand, the spectral position of the left-hand reflection dip in the simulation was different from the one observed in the experiment. This may be due to several reasons. First, the difference between the parameters used in the simulation and the real ones may have affected the position, as determining the real values of the different layers thicknesses is not an easy task. Second, the remained lacquer on the metallic grating can affect the reflectance.

Figure 17 is only a qualitative attempt to estimate the reflection of the structure. The most important component is that the experimental results are reproducible as discussed below.

Next, to the best of our knowledge, we present phase detection using the CD-R-based grating for the first time. Phase measurements can significantly improve the FOM as shown in the numerical simulations for the three different configurations above, except for the thick metallic gratings case.

Demonstration of phase detection using CD-R is shown in

Figure 18, where the polarimetric functions tan(ψ) and cos(Δ) were extracted using the equations and experimental setup as shown by the authors of [

28,

50,

51]. Briefly, the CD sample was inserted between two polarizers, while the optics axis (perpendicular to the grating lines) was oriented at 45° with respect to the first polarizer. The ellipsometric parameters tan(ψ) and cos(Δ) can be extracted by measuring the light intensity at three points based on three analyzer rotation angels—0°, 45°, and 90°—relative to the first polarizer [

28,

50,

51].

Figure 18 shows initial results to demonstrate the phase detection potential of the CD-R-based grating structure. The response for air and DI analytes are shown in the blue and red curves, respectively, under TM polarization.

To verify the reproducibility of the results, additional measurements of the polarimetric functions using different sample are presented in

Figure 19. It should be noted that, because the phase measurements were much more sensitive than intensity measurements, some noise was observed in the phase measurements. We plan to improve this, as the reported results are only initial results aimed to demonstrate the phase detection method in the CD-R-based gratings for sensing applications.

Figure 19a,b show the spectral response of tan(ψ) and cos(Δ,) respectively, for five types of analytes: Air, DI, 3 mL glucose in 1 mL DI (3% wt.), ethanol, and glycerol. The sensitivity of the first dip was detected, and a sensitivity of 442 (1/RIU) and 427 (1/RIU) was measured for tan(ψ) and cos(Δ) as indicated in Figs 19a and 19b, respectively. The sensitivity of tan(ψ) and cos(Δ) was calculated by extracting the resonant wavelengths in

Figure 19 as a function of wavelength and then calculating the slope of the curve.

The potential of sensing operation in the IR using CD-R is demonstrated in

Figure 20 in which new prepared CD-R sample was used. A spectral shift of the first and second dips was observed when changing the analyte from air to ethanol. On the other hand, the third dip position almost remained fixed, which might indicate the possibility of self-referenced sensing operation using CD-R. The results in

Figure 20 are only initial results, and more experiments are required for demonstration sensing in the IR range.

Table 1 summarizes the parameters and unique features of all the nano-scale grating configurations mentioned above. In addition, the data regarding the thin metallic nanoslits on dielectric substrate for enhanced optical transmission resonance excitation is also included and compared to the other grating-based sensing geometries.