An Integrated Compensation Method for the Force Disturbance of a Six-Axis Force Sensor in Complex Manufacturing Scenarios

Abstract

:1. Introduction

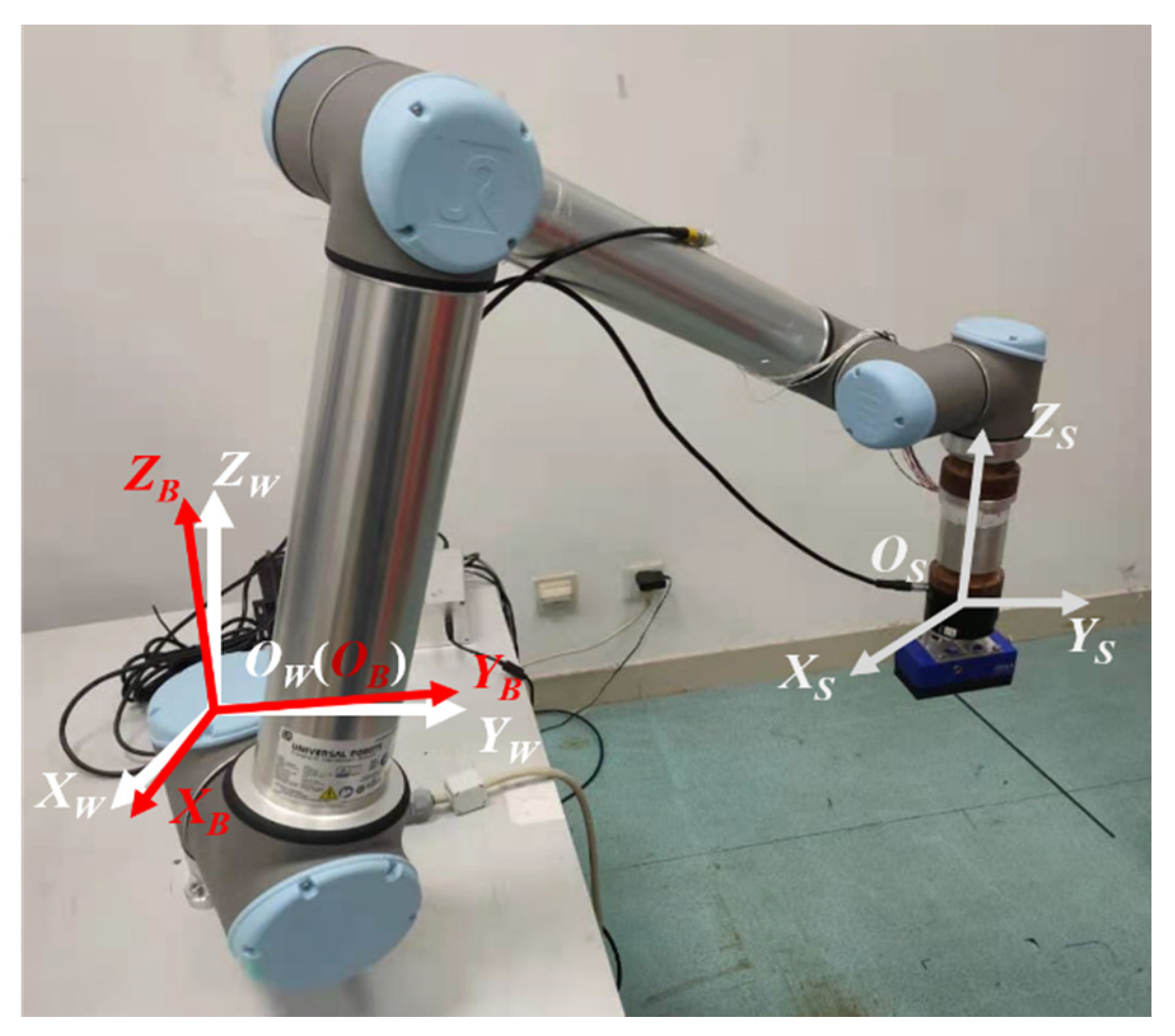

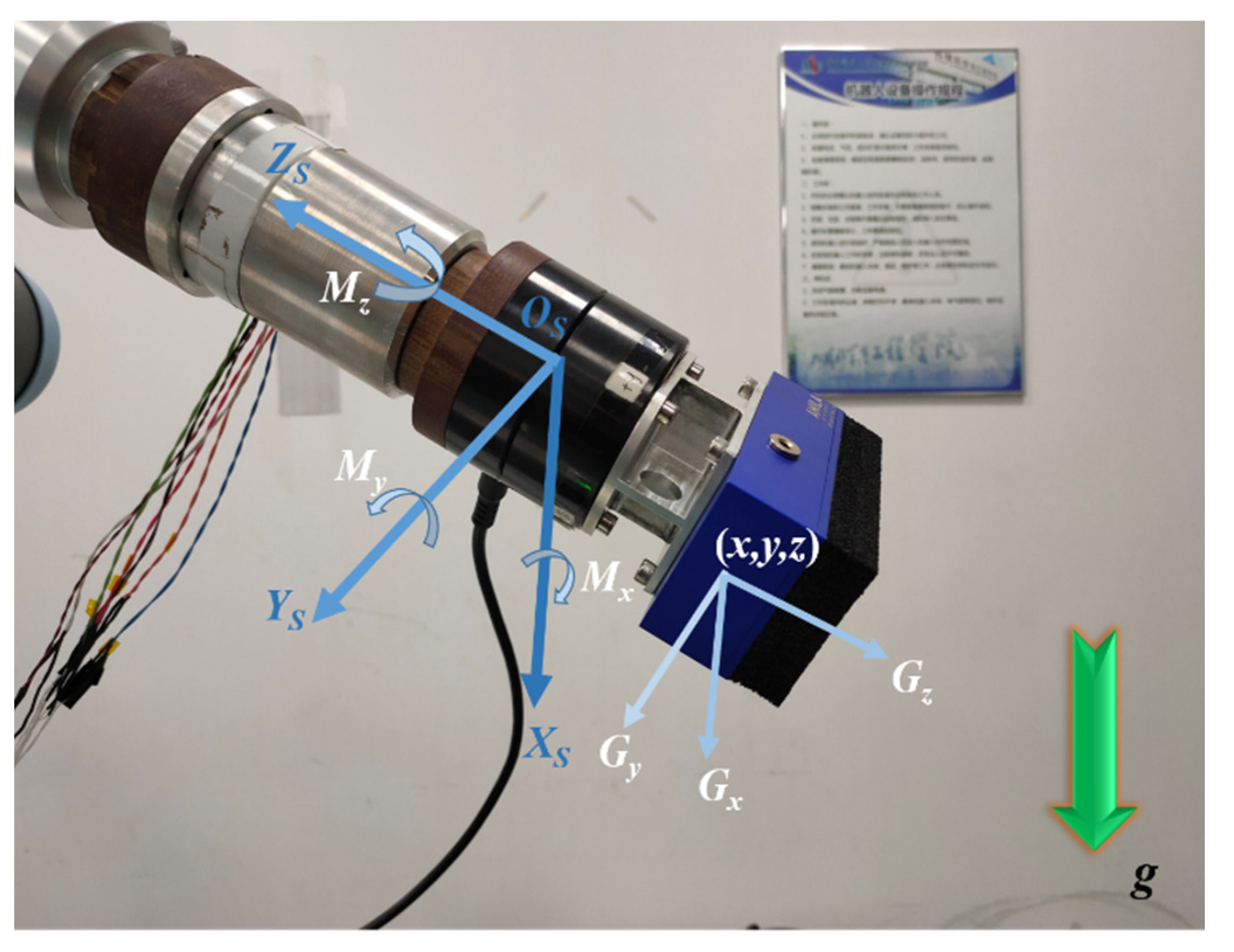

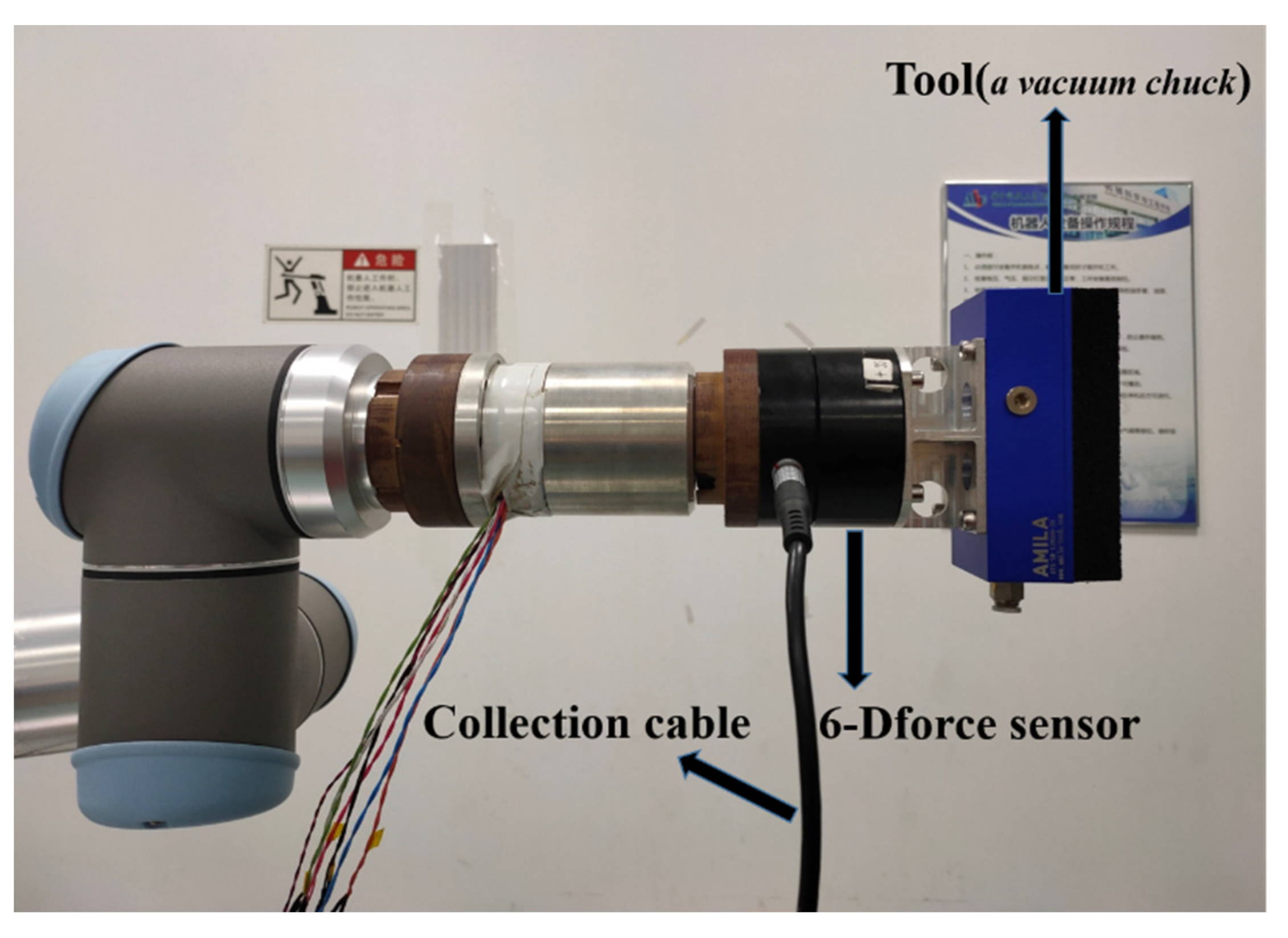

2. Problem Statement

3. Integrated Compensation Method

3.1. Zero-Point Estimation of a Six-Axis Force Sensor Based on Deep Learning

3.2. Tool Load Identification Based on Least Squares Method

3.3. Compensation of Force Disturbance

4. Experimental Results

4.1. Zero-Point Estimation of a Six-Axis Force Sensor Based on Deep Learning

4.2. Tool Load Identification by Least Squares Method

4.3. Compensation Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Algorithm A1: Integrated compensation method. |

| Input:: Current pose of the force sensor. : Set of robot poses to be moved. : Weight’s file generated by deep learning in Section 3.1. Output:: In the pose , the pure contact force applied to the end-effector. repeat if end-effector is replaced then for i to length () do Control the robot move to the pose in ; Save current pose information in ; Save current output of the force sensor in ; Save current zero-point in ; end for ; ; Calculate from ; ; end if while p is changed do Current output of the force sensor Get the rotation matrix at this pose ; Zero-point of the force sensor at this pose ; Effect of the end-effector: Calculate from end while until end of manufacturing task. |

Appendix B

| Data Size | Type | NN | DM | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 1000 | Fx | 0.006 | 0.224 | 0.841 | 0.678 | −0.010 | 0.418 | 1.027 | 1.244 |

| Fy | −0.001 | 0.255 | 0.808 | 0.764 | 0.051 | 0.618 | 1.158 | 1.905 | |

| Fz | −0.019 | 0.205 | 0.531 | 0.596 | −0.006 | 0.368 | 0.951 | 1.098 | |

| Mx | 0.038 | 0.144 | 1.493 | 0.470 | −0.040 | 0.540 | 1.509 | 1.580 | |

| My | 0.028 | 0.571 | 1.783 | 1.741 | 0.001 | 0.983 | 1.841 | 2.950 | |

| 3000 | Fx | −0.008 | 0.208 | 0.682 | 0.616 | −0.024 | 0.418 | 1.043 | 1.230 |

| Fy | −0.018 | 0.273 | 0.925 | 0.801 | 0.038 | 0.619 | 1.146 | 1.895 | |

| Fz | −0.006 | 0.211 | 0.585 | 0.627 | 0.316 | 0.367 | 0.953 | 1.417 | |

| Mx | 0.062 | 0.449 | 1.526 | 1.409 | 0.452 | 0.536 | 1.488 | 2.060 | |

| My | −0.003 | 0.541 | 1.493 | 1.620 | 0.837 | 0.985 | 1.812 | 3.792 | |

| 5000 | Fx | −0.006 | 0.197 | 0.602 | 0.585 | −0.027 | 0.418 | 1.041 | 1.227 |

| Fy | −0.019 | 0.256 | 0.892 | 0.749 | 0.031 | 0.619 | 1.139 | 1.888 | |

| Fz | −0.139 | 0.198 | 0.592 | 0.455 | 0.004 | 0.367 | 0.960 | 1.105 | |

| Mx | 0.048 | 0.435 | 1.331 | 1.353 | −0.045 | 0.535 | 1.483 | 1.560 | |

| My | −0.005 | 0.537 | 1.363 | 1.606 | −0.041 | 0.984 | 1.810 | 2.911 | |

| 7000 | Fx | 0.019 | 0.182 | 0.616 | 0.565 | −0.031 | 0.418 | 1.045 | 1.223 |

| Fy | 0.004 | 0.245 | 0.858 | 0.739 | 0.028 | 0.619 | 1.147 | 1.885 | |

| Fz | −0.019 | 0.191 | 0.550 | 0.554 | 0.002 | 0.367 | 0.956 | 1.103 | |

| Mx | 0.020 | 0.413 | 1.159 | 1.259 | −0.044 | 0.535 | 1.487 | 1.561 | |

| My | 0.045 | 0.487 | 1.675 | 1.506 | −0.051 | 0.984 | 1.819 | 2.901 | |

Appendix C

| Number | RX | RY | RZ |

|---|---|---|---|

| 1 | 2.0592 | 0.6381 | −0.0558 |

| 2 | 0.6526 | −2.7875 | 0.2766 |

| 3 | 1.8874 | −2.0127 | −0.2661 |

| 4 | 0.4880 | 2.1373 | 0.2597 |

| 5 | 0.4232 | −1.8506 | −0.6033 |

| 6 | −1.9615 | 1.9499 | 0.2685 |

| 7 | 1.5291 | −1.1463 | −1.6160 |

| 8 | −2.6872 | −0.6012 | −0.4095 |

| 9 | −1.2868 | 1.6152 | 0.1995 |

| 10 | −0.7769 | 2.4489 | 1.6684 |

| 11 | −1.9852 | 0.5888 | 0.2570 |

| 12 | −0.5084 | −2.1222 | −1.6644 |

| 13 | −0.4566 | −1.9525 | −1.8284 |

| 14 | −0.7513 | −0.2524 | 0.6352 |

| 15 | −0.8525 | −2.4366 | 0.7001 |

References

- Brogardh, T. Present and future robot control development—An industrial perspective. Annu. Rev. Control 2007, 31, 69–79. [Google Scholar] [CrossRef]

- Hua, J.; Zeng, L.; Li, G.; Ju, Z. Learning for a Robot: Deep Reinforcement Learning, Imitation Learning, Transfer Learning. Sensors 2021, 21, 1278. [Google Scholar] [CrossRef] [PubMed]

- Kemp, C.; Edsinger, A.; Torres-Jara, E. Challenges for robot manipulation in human environments [grand challenges of robotics]. IEEE Robot. Autom. Mag. 2007, 14, 20–29. [Google Scholar] [CrossRef]

- Villani, V.; Pini, F.; Leali, F.; Secchi, C. Survey on human–robot collaboration in industrial settings: Safety, intuitive interfaces and applications. Mechatronics 2018, 55, 248–266. [Google Scholar] [CrossRef]

- Bonci, A.; Cen Cheng, P.D.; Indri, M.; Nabissi, G.; Sibona, F. Human-Robot Perception in Industrial Environments: A Survey. Sensors 2021, 21, 1571. [Google Scholar] [CrossRef]

- Semini, C.; Barasuol, V.; Goldsmith, J.; Frigerio, M.; Focchi, M.; Gao, Y.; Caldwell, D. Design of the hydraulically actuated, torque-controlled quadruped robot HyQ2Max. IEEE/ASME Trans. Mechatron. 2016, 22, 635–646. [Google Scholar] [CrossRef]

- Campeau-Lecours, A.; Otis, J.; Gosselin, C. Modeling of physical human-robot interaction: Admittance controllers applied to intelligent assist devices with large payload. Int. J. Adv. Robot. Syst. 2016, 13, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Yang, C.; Wang, G.; Zhang, H.; Cui, H.; Zhang, Y. Research on the parallel load sharing principle of a novel self-decoupled piezoelectric six-dimensional force sensor. ISA Trans. 2017, 70, 447–457. [Google Scholar] [CrossRef]

- He, X.; Cai, P. Design and analysis of a low-range 6-D force sensor. Transducer Microsyst. Technol. 2012, 1, 20–22. [Google Scholar]

- Ma, J.; Song, A. Fast Estimation of Strains for Cross-Beams Six-Axis Force/Torque Sensors by Mechanical Modeling. Sensors 2013, 13, 6669–6686. [Google Scholar] [CrossRef] [Green Version]

- Oh, H.; Kim, U.; Kang, G.; Seo, J.; Choi, H. Multi-Axial Force/Torque Sensor Calibration Method Based on Deep-Learning. IEEE Sens. J. 2018, 18, 5485–5496. [Google Scholar] [CrossRef]

- Lin, C.-Y.; Ahmad, A.R.; Kebede, G.A. Novel Mechanically Fully Decoupled Six-Axis Force-Moment Sensor. Sensors 2020, 20, 395. [Google Scholar] [CrossRef] [Green Version]

- Raibert, M.; Craig, J. Hybrid position/force control of manipulators. ASME J. Dyn. Syst. Meas. Control 1981, 102, 126–133. [Google Scholar] [CrossRef]

- Luo, J.; Solowjow, E.; Wen, C.; Ojea, J.; Agogino, A.; Tamar, A.; Abbeel, P. Reinforcement learning on variable impedance controller for high-precision robotic assembly. In Proceedings of the 2019 International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 3080–3087. [Google Scholar]

- Shetty, B.R.; Ang, M.H. Active compliance control of a PUMA 560 robot. In Proceedings of the IEEE International Conference on Robotics and Automation, Minneapolis, MN, USA, 22–28 April 1996; pp. 3720–3725. [Google Scholar]

- Tian, F.; Li, Z.; Lv, C.; Liu, G. Polishing pressure investigations of robot automatic polishing on curved surfaces. Int. J. Adv. Manuf. Technol. 2016, 87, 639–646. [Google Scholar] [CrossRef]

- Xu, X.; Zhu, D.; Zhang, H.; Yan, S.; Ding, H. Application of novel force control strategies to enhance robotic abrasive belt grinding quality of aero-engine blades. Chin. J. Aeronaut. 2019, 32, 2368–2382. [Google Scholar] [CrossRef]

- Loske, J.; Biesenbach, R. Force-torque sensor integration in industrial robot control. In Proceedings of the 15th International Workshop on Research and Education in Mechatronics (REM), El Gouna, Egypt, 9–11 September 2014; pp. 1–5. [Google Scholar]

- Lin, J. Research on Active Compliant Assembly System of Industrial Robot Based on Force Sensor. Ph.D. Thesis, South China University of technology, Guangzhou, China, 2013. [Google Scholar]

- Cai, M. Research on Homogeneous Hand Controller Based on Force Fusion Control for Telerobot. Master’s Thesis, Jilin University, Changchun, China, 2015. [Google Scholar]

- Li, S.; Zhang, Y.; Cao, Y.; Dai, X. Experiment research of gravity compensation for haptic device. Mech. Des. Res. 2007, 1, 95–97. [Google Scholar]

- Vougioukas, S. Bias estimation and gravity compensation for force-torque sensors. In Proceedings of the 3rd WSEAS Symposium on Mathematical Methods and Computational Techniques in Electrical Engineering, Athens, Greece, 17–23 December 2001; pp. 82–85. [Google Scholar]

- Zhang, L.; Hu, R.; Yi, W. Research on force sensing for the end-load of industrial robot based on a 6-axis force/torque sensor. Acta Autom. Sin. 2017, 43, 439–447. [Google Scholar]

- Zhang, Z.; Chen, Y.; Zhang, D.; Tong, Q. Research on numerical compensation method of tandem force sensor installed at the end of industrial robot. In Proceedings of the 5th International Conference on Automation, Control and Robotics Engineering, Dalian, China, 19–20 September 2020; pp. 725–731. [Google Scholar]

- El, D.; Kamal, M.; Sanchez, J.; Corrales, J.A.; Mezouar, Y. FaForce-torque sensor disturbance observer using deep learning. In International Symposium on Experimental Robotics; Springer: Cham, Switzerland, 2018. [Google Scholar]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Banerjee, I.; Ling, Y.; Chen, M.; Hasan, S.; Langlotz, C.; Moradzadeh, N.; Chapman, B.; Amrhein, T.; Mong, D.; Rubin, D.; et al. Comparative effectiveness of convolutional neural network (CNN) and recurrent neural network (RNN) architectures for radiology text report classification. Artif. Intell. Med. 2019, 97, 79–88. [Google Scholar] [CrossRef]

- Ciregan, D.; Meier, U.; Schmidhuber, J. Multi-column deep neural networks for image classification. In Proceedings of the 2012 IEEE Conference on Computer vision and Pattern Recognition, Providence, RI, USA, 16–21 June 2012; pp. 13642–13649. [Google Scholar]

- Litjens, G.; Kooi, T.; Bejnordi, B.; Setio, A.; Ciompi, F.; Ghafoorian, M.; Laak, J.; Ginneken, B.; Sanchez, C. A survey on deep learning in medical image analysis. Med. Image Anal. 2017, 42, 60–88. [Google Scholar] [CrossRef] [Green Version]

- Jiang, C.; Chen, S.; Chen, Y.; Bo, Y.; Han, L.; Guo, J.; Feng, Z.; Zhou, H. Performance Analysis of a Deep Simple Recurrent Unit Recurrent Neural Network (SRU-RNN) in MEMS Gyroscope De-Noising. Sensors 2018, 18, 4471. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hu, J.; Hua, F.; Tian, W. Robot Positioning Error Compensation Method Based on Deep Neural Network. In Proceedings of the 2020 4th International Conference on Control Engineering and Artificial Intelligence (CCEAI 2020), Singapore, 17–19 January 2020; Volume 1487, p. 12045. [Google Scholar]

- Yegnanarayana, B. Artificial Neural Networks, 1st ed.; PHI Learning Pvt. Ltd.: New Delhi, India, 2009. [Google Scholar]

- Zhang, Z.; Chen, Y.; Zhang, D. Development and Application of a Tandem Force Sensor. Sensors 2020, 20, 6042. [Google Scholar] [CrossRef] [PubMed]

- Xiong, Y. Robotics: Modeling, Control and Vision, 1st ed.; Huazhong University of Science and Technology Press: Wuhan, China, 2018. [Google Scholar]

| Type | Fx (N) | Fy (N) | Fz (N) | Mx (Ncm) | My (Ncm) | Mz (Ncm) |

|---|---|---|---|---|---|---|

| Range | ±100 | ±100 | ±200 | ±500 | ±500 | ±500 |

| Type I error | ≤1%F.S. | |||||

| Type II error | ≤2%F.S. | |||||

| Overload | 120%F.S. | |||||

| Resolution | 16-bit AD | |||||

| Temperature | −10~40 °C | |||||

| Humidity | 20%~70% RH | |||||

| Number of Iterations | Learning Rate |

|---|---|

| 0th–10,000th | 0.005 |

| 10,000th–30,000th | 0.001 |

| 30,000th–50,000th | 0.0005 |

| 50,000th–100,000th | 0.0001 |

| Type | NN | DM | ||||

|---|---|---|---|---|---|---|

| Fx | −0.009 | 0.193 | 0.607 | −0.030 | 0.418 | 1.041 |

| Fy | 0.002 | 0.221 | 0.987 | 0.023 | 0.619 | 1.152 |

| Fz | −0.009 | 0.165 | 0.549 | 0.003 | 0.368 | 0.958 |

| Mx | 0.037 | 0.405 | 1.040 | −0.043 | 0.537 | 1.493 |

| My | 0.022 | 0.473 | 1.458 | −0.054 | 0.984 | 1.823 |

| Types | Fx (N) | Fy (N) | Fz (N) | Mx (Ncm) | My (Ncm) | Mz (Ncm) | |

|---|---|---|---|---|---|---|---|

| MAX | Bias + LSM [22] | 1.368 | 1.826 | 1.735 | 3.340 | 5.721 | 1.036 |

| Double-LSM [23] | 1.273 | 1.764 | 1.629 | 3.191 | 5.591 | 0.899 | |

| NN + LSM | 0.834 | 1.390 | 1.418 | 2.235 | 4.215 | 0.932 | |

| MAE | Bias + LSM [22] | 0.502 | 0.583 | 0.724 | 1.211 | 2.356 | 0.430 |

| Double-LSM [23] | 0.473 | 0.571 | 0.656 | 1.092 | 2.141 | 0.246 | |

| NN + LSM | 0.301 | 0.465 | 0.502 | 0.652 | 1.104 | 0.247 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, L.; Gao, Q.; Zhang, D.; Zhang, W.; Chen, Y. An Integrated Compensation Method for the Force Disturbance of a Six-Axis Force Sensor in Complex Manufacturing Scenarios. Sensors 2021, 21, 4706. https://doi.org/10.3390/s21144706

Yao L, Gao Q, Zhang D, Zhang W, Chen Y. An Integrated Compensation Method for the Force Disturbance of a Six-Axis Force Sensor in Complex Manufacturing Scenarios. Sensors. 2021; 21(14):4706. https://doi.org/10.3390/s21144706

Chicago/Turabian StyleYao, Lei, Qingguang Gao, Dailin Zhang, Wanpeng Zhang, and Youping Chen. 2021. "An Integrated Compensation Method for the Force Disturbance of a Six-Axis Force Sensor in Complex Manufacturing Scenarios" Sensors 21, no. 14: 4706. https://doi.org/10.3390/s21144706

APA StyleYao, L., Gao, Q., Zhang, D., Zhang, W., & Chen, Y. (2021). An Integrated Compensation Method for the Force Disturbance of a Six-Axis Force Sensor in Complex Manufacturing Scenarios. Sensors, 21(14), 4706. https://doi.org/10.3390/s21144706