A Grain-Scale Study of Mojave Mars Simulant (MMS-1)

Abstract

:1. Introduction

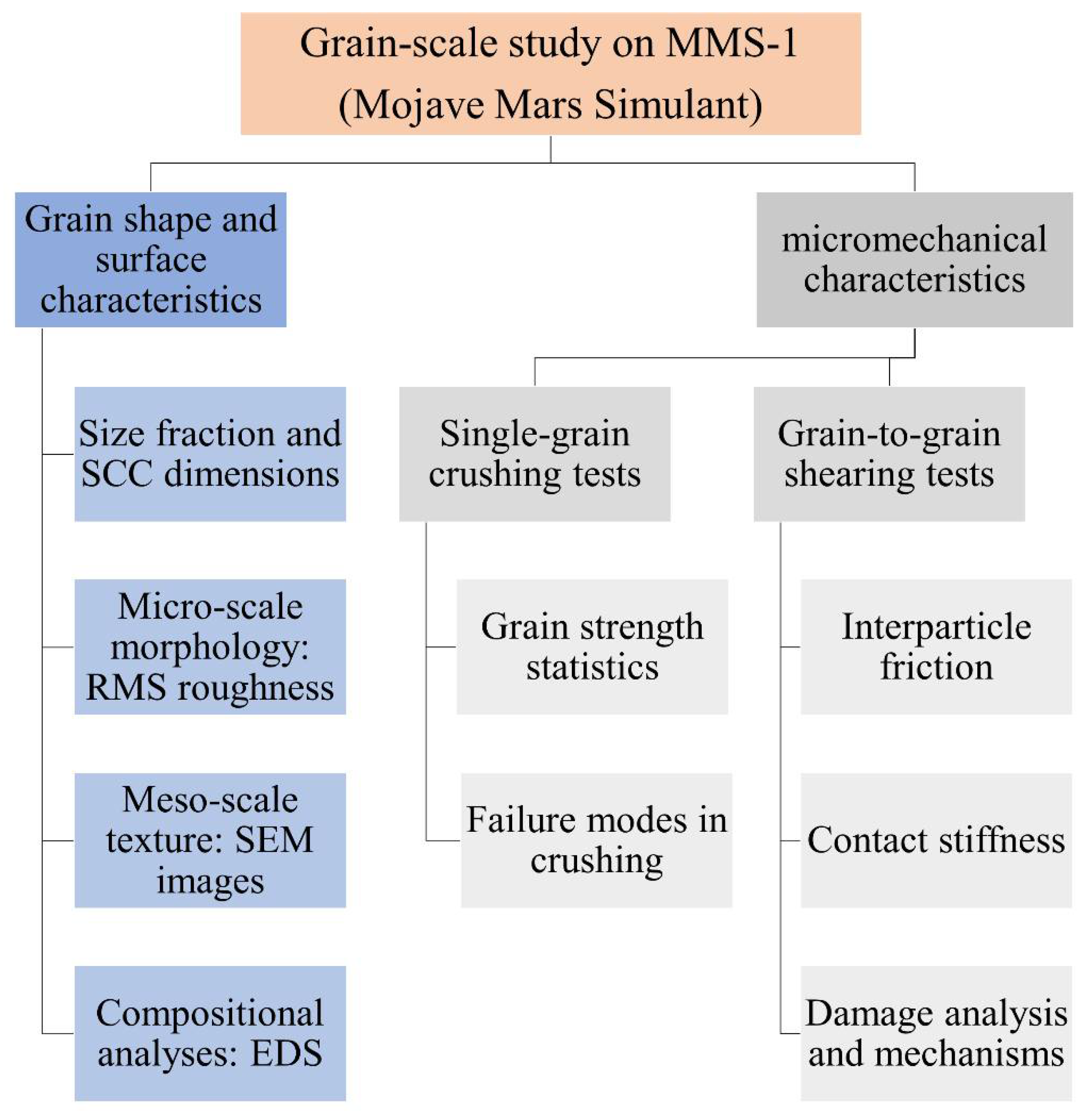

2. Material, Equipment and Methodology

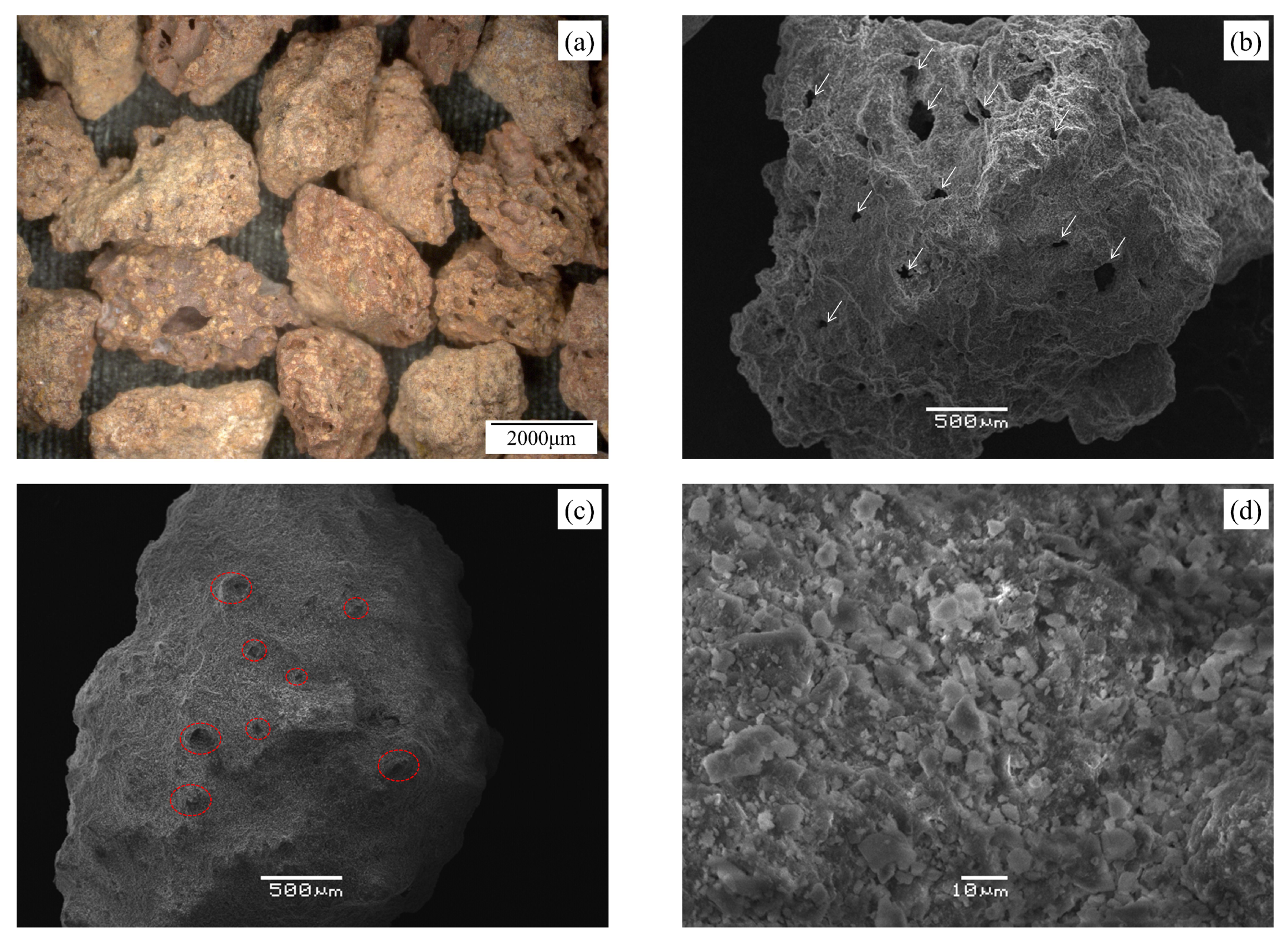

2.1. Material Description

2.2. Testing Apparatus and Methodology

3. Results and Discussion

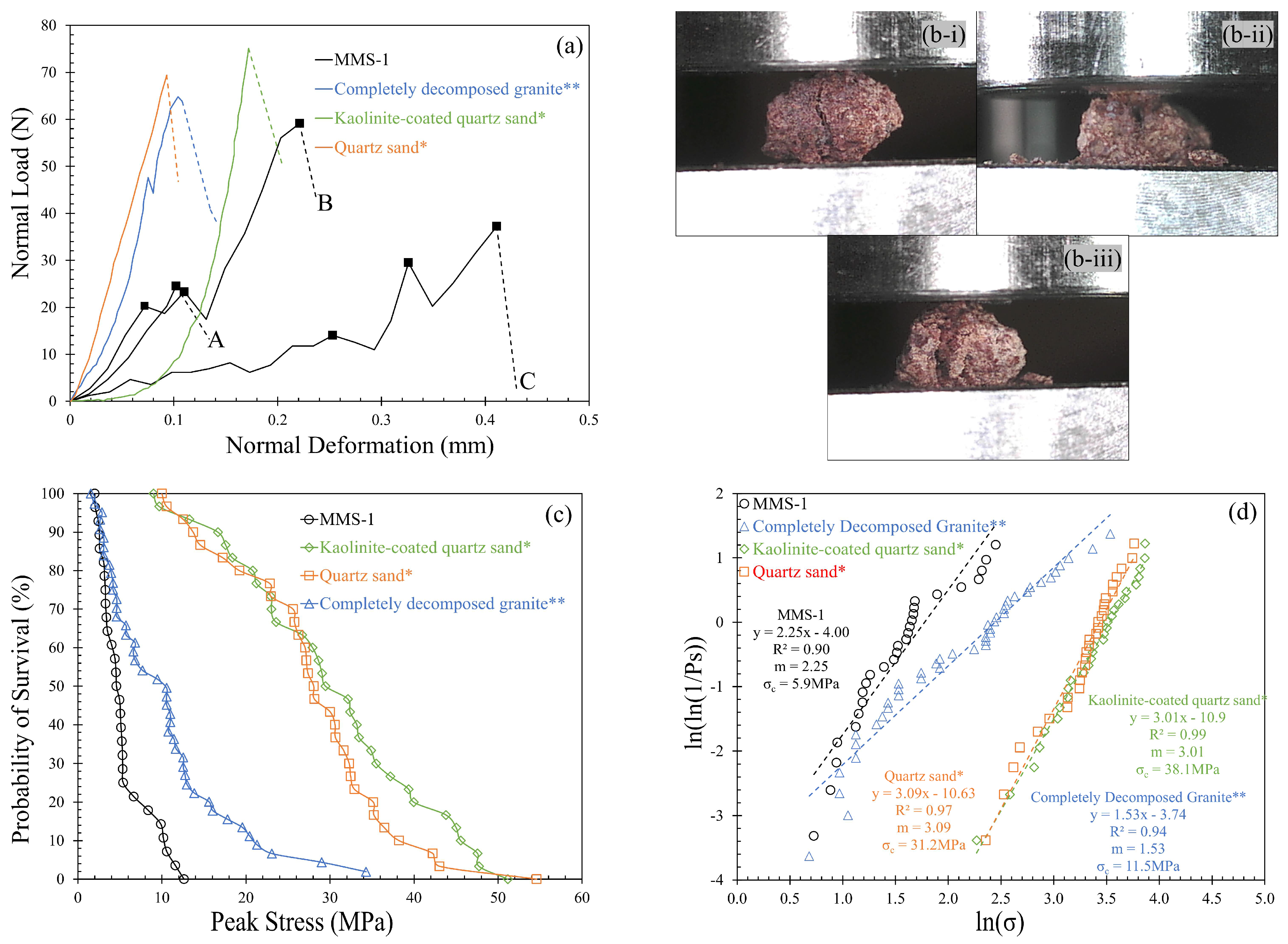

3.1. Single Grain Crushing Strength

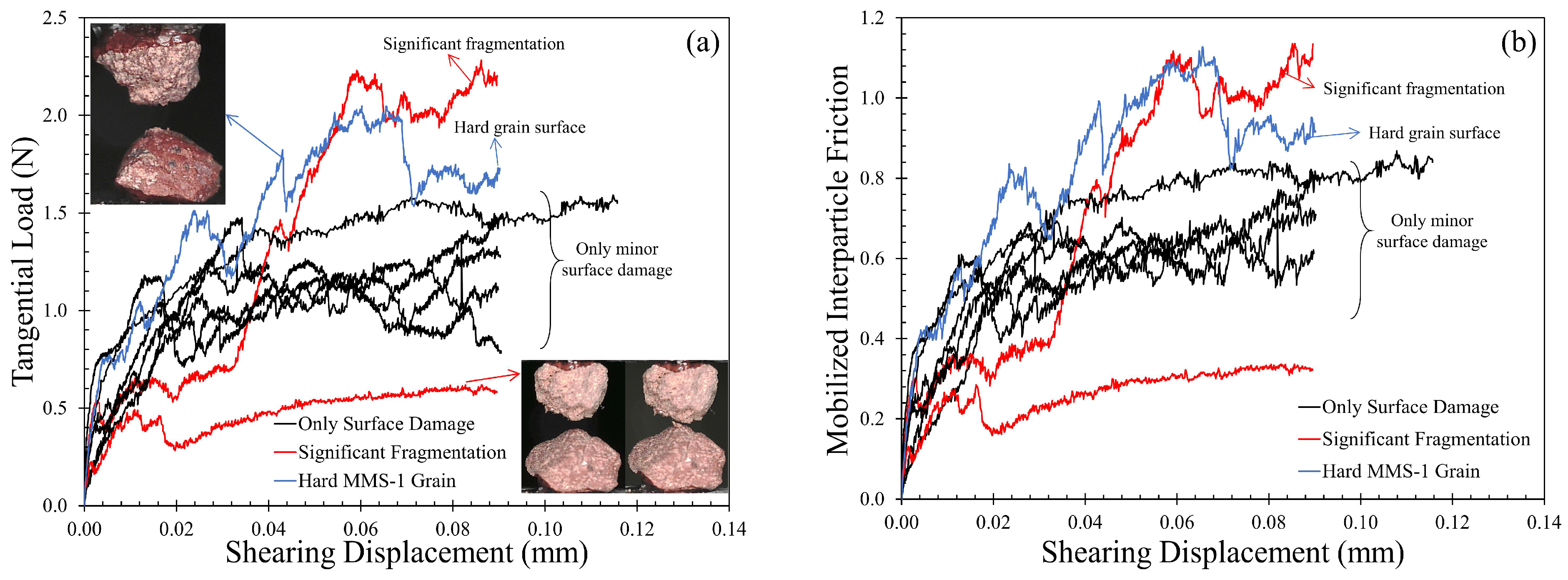

3.2. Normal and Tangential Contact Response of MMS-1 Grains

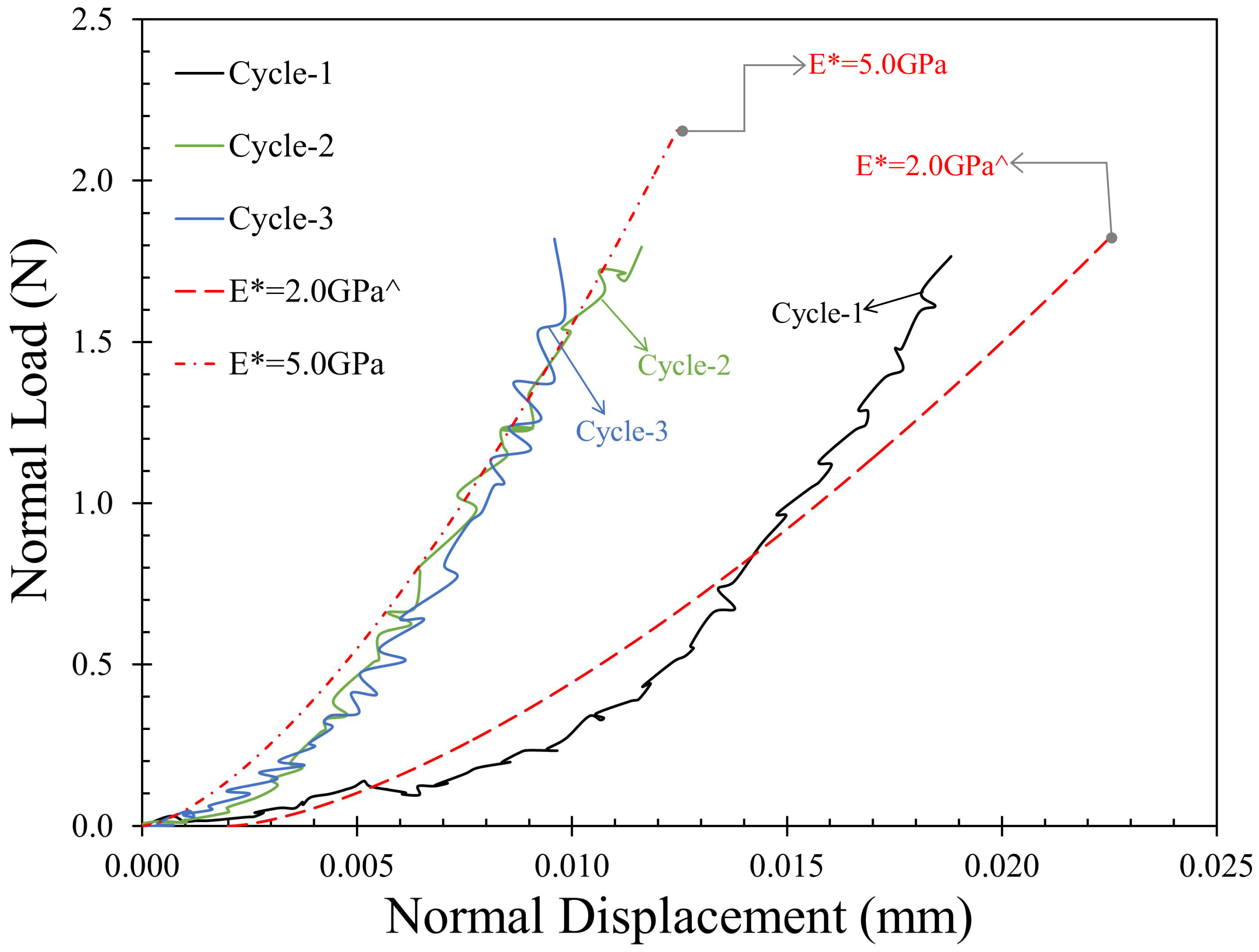

3.2.1. Normal Contact Response: Monotonic Loading

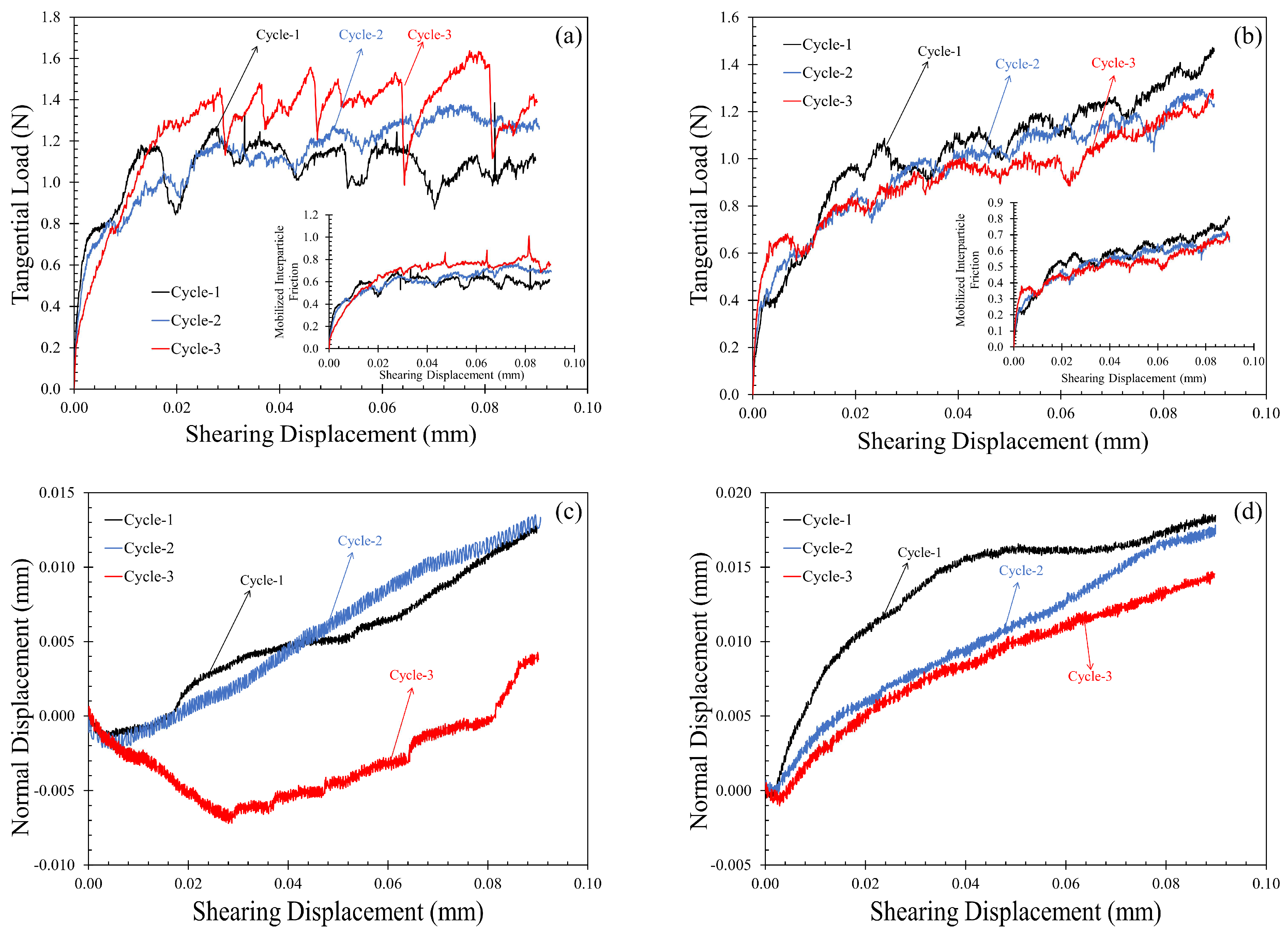

3.2.2. Tangential Contact Response: Monotonic Loading

3.2.3. Normal versus Shearing Displacement

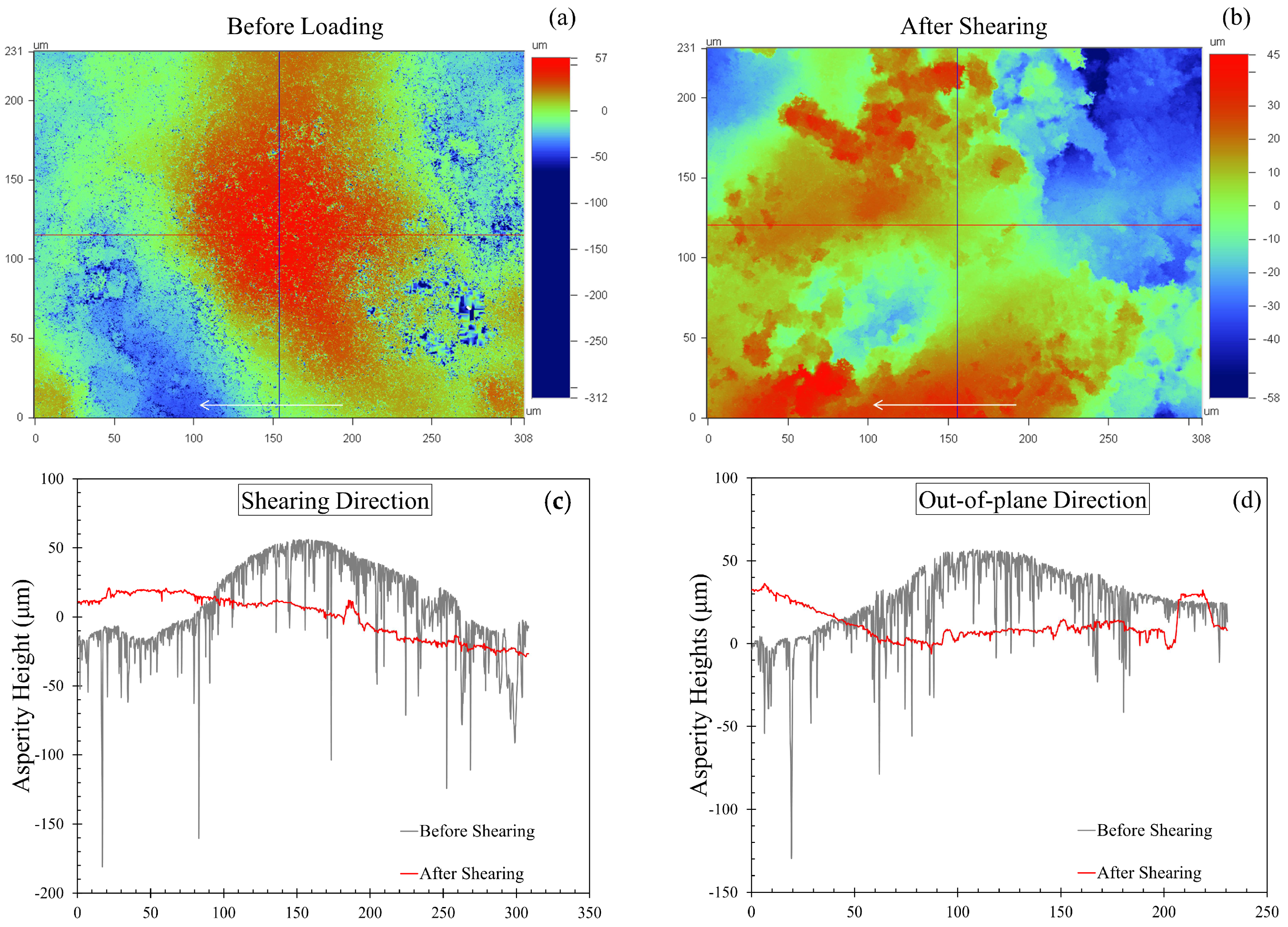

3.2.4. Damage Analysis

3.3. Repeated Monotonic Loading

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MMS | Mojave mars simulant |

| SEM | Scanning electron microscope |

| EDS | Energy dispersive X-ray Spectroscopy |

| FSO | Full scale output |

| FN | Normal Load |

| δN | Normal displacement |

| FT | Tangential Load |

| δT | Tangential displacement |

| δN,max | Normal displacement for a given normal load |

| δN,shear | Normal displacement during shearing |

| μSS | Steady state value of interparticle friction coefficient |

| φ | Interparticle friction angle. |

| μmob | Mobilized interparticle friction |

| FC | Crushing load |

| σc | Characteristic crushing strength |

| d | Geometric mean of smaller SCC dimensions |

| PS | Survival probability |

| σp | Peak stress |

| E* | Contact modulus |

| m | Weibull modulus |

| Sq | Surface roughness |

References

- Rannou, P.; Chassefiere, E.; Encrenaz, T.; Erard, S.; Genin, J.M.; Ingrin, J.; Jambon, A.; Jolivet, J.P.; Raulin, F.; Renault, P.; et al. EXOCAM: Mars in a Box to Simulate Soil-Atmosphere Interactions. Adv. Space Res. 2001, 27, 189–193. [Google Scholar] [CrossRef]

- Fraser, H.; Van Dishoeck, E. SURFRESIDE: A novel experiment to study surface chemistry under interstellar and protostellar conditions. Adv. Space Res. 2004, 33, 14–22. [Google Scholar] [CrossRef]

- Bullock, M.A.; Moore, J.M.; Mellon, M.T. Laboratory simulations of Mars aqueous geochemistry. Icarus 2004, 170, 404–423. [Google Scholar] [CrossRef]

- Kim, J.R.; Muller, J.-P.; van Gasselt, S.; Morley, J.G.; Neukum, G. Automated Crater Detection, A New Tool for Mars Cartography and Chronology. Photogramm. Eng. Remote. Sens. 2005, 71, 1205–1217. [Google Scholar] [CrossRef] [Green Version]

- Li, C.; Wang, C.; Wei, Y.; Lin, Y. China’s present and future lunar exploration program. Science 2019, 365, 238–239. [Google Scholar] [CrossRef]

- Schiboni, G.; Suarez, J.C.; Zhang, R.; Amft, O. DynDSE: Automated Multi-Objective Design Space Exploration for Context-Adaptive Wearable IoT Edge Devices. Sensors 2020, 20, 6104. [Google Scholar] [CrossRef] [PubMed]

- Ramachandran, A.V.; Nazarious, M.I.; Mathanlal, T.; Zorzano, M.-P.; Martín-Torres, J. Space Environmental Chamber for Planetary Studies. Sensors 2020, 20, 3996. [Google Scholar] [CrossRef]

- Martin-Torres, J.; Zorzano, M.-P.; Soria-Salinas, A.; Nazarious, M.I.; Konatham, S.; Mathanlal, T.; Ramachandran, A.V.; Ramirez-Luque, J.-A.; Mantas-Nakhai, R. The HABIT (HabitAbility: Brine Irradiation and Temperature) Environmental Instrument for the ExoMars 2022 Surface Platform. Planet. Space Sci. 2020, 190, 104968. [Google Scholar] [CrossRef]

- Yu, X.; Wang, P.; Zhang, Z. Learning-Based End-to-End Path Planning for Lunar Rovers with Safety Constraints. Sensors 2021, 21, 796. [Google Scholar] [CrossRef]

- Lu, Y.; Hu, Y.; Xiao, J.; Liu, L.; Zhang, L.; Wang, Y. Three-Dimensional Model of the Moon with Semantic Information of Craters Based on Chang’e Data. Sensors 2021, 21, 959. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Ling, Z.; Zhang, J.; Fu, X.; Liu, C.; Xin, Y.; Li, B.; Qiao, L. A Mars Environment Chamber Coupled with Multiple In Situ Spectral Sensors for Mars Exploration. Sensors 2021, 21, 2519. [Google Scholar] [CrossRef]

- Abrevaya, X.C.; Anderson, R.; Arney, G.; Atri, D.; Azua-Bustos, A.; Bowman, J.; Brazelton, W.J.; Brennecka, G.A.; Carns, R.; Chopra, A.; et al. The Astrobiology Primer v2.0. Astrobiology 2016, 16, 561–653. [Google Scholar] [CrossRef] [Green Version]

- Hill, E.; Mellin, M.J.; Deane, B.; Liu, Y.; Taylor, L.A. Apollo sample 70051 and high- and low-Ti lunar soil simulants MLS-1A and JSC-1A: Implications for future lunar exploration. J. Geophys. Res. Space Phys. 2007, 112, 02006. [Google Scholar] [CrossRef]

- Witte, L.; Richter, L.; Block, J.; Brucks, A.; Scharringhausen, M.; Sprowitz, T. A gravity compensating test facility for planetary surface mobility. In Proceedings of the 59th International astronautical congress, Glasgow, Scotland, 29 September–3 October 2008. [Google Scholar]

- Brunskill, C.; Patel, N.; Gouache, T.P.; Scott, G.P.; Saaj, C.M.; Matthews, M.; Cui, L. Characterization of martian soil simulants for ExoMars rover testbed. J. Terramechanics 2011, 48, 419–438. [Google Scholar] [CrossRef] [Green Version]

- McKay, D.S.; Carter, J.L.; Boles, W.W.; Allen, C.C.; Allton, J.H. JSC-1: A new lunar soil simulant. Eng. Constr. Oper. Space IV 1994, 2, 857–866. [Google Scholar]

- Allen, C.C.; Jager, K.M.; Morris, R.V.; Lindstrom, D.J.; Lindstrom, M.M.; Lockwood, J. JSC MARS-1: A Martian Soil Simulant. Space 98 1998, 98, 469–476. [Google Scholar] [CrossRef]

- Cesaretti, G.; Dini, E.; De Kestelier, X.; Colla, V.; Pambaguian, L. Building components for an outpost on the Lunar soil by means of a novel 3D printing technology. Acta Astronaut. 2014, 93, 430–450. [Google Scholar] [CrossRef]

- Marzulli, V.; Cafaro, F. Geotechnical Properties of Uncompacted DNA-1A Lunar Simulant. J. Aerosp. Eng. 2019, 32, 04018153. [Google Scholar] [CrossRef] [Green Version]

- Peters, G.H.; Abbey, W.; Bearman, G.H.; Mungas, G.S.; Smith, J.A.; Anderson, R.C.; Douglas, S.; Beegle, L.W. Mojave Mars simulant—Characterization of a new geologic Mars analog. Icarus 2008, 197, 470–479. [Google Scholar] [CrossRef]

- Scott, G.; Saaj, C. Measuring and Simulating the Effect of Variations in Soil Properties on Microrover Trafficability; American Institute of Aeronautics and Astronautics (AIAA): Pasadena, CA, USA, 2009; pp. 1–10. [Google Scholar]

- Zeng, X.; Li, X.; Wang, S.; Li, S.; Spring, N.; Tang, H.; Li, Y.; Feng, J. JMSS-1: A new Martian soil simulant. Earth Planets Space 2015, 67, 72. [Google Scholar] [CrossRef] [Green Version]

- Cannon, K.M.; Britt, D.T.; Smith, T.M.; Fritsche, R.F.; Batcheldor, D. Mars global simulant MGS-1: A Rocknest-based open standard for basaltic martian regolith simulants. Icarus 2019, 317, 470–478. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Liu, H.S.; Zhao, J.N.; Zhao, J.W.; Xiao, L. PSI HX: A new series of martian soil simulants. In Proceedings of the 52nd Lunar and Planetary Science Conference, Virtual Conference, 15–19 March 2021; p. 2479. [Google Scholar]

- Delage, P.; Karakostas, F.; Dhemaied, A.; Belmokhtar, M.; Lognonné, P.; Golombek, M.; De Laure, E.; Hurst, K.; Dupla, J.C.; Kedar, S.; et al. An Investigation of the Mechanical Properties of Some Martian Regolith Simulants with Respect to the Surface Properties at the InSight Mission Landing Site. Space Sci. Rev. 2017, 211, 191–213. [Google Scholar]

- Smith, C.L.; Manick, K.; Duvet, L.; Schroeven-Deceuninck, H. Starting a European Space Agency Sample Analogue Collection (ESA2C) and Curation Facility for Exploration Missions. In Proceedings of the European Planetary Science Congress, Riga, Latvia, 17–22 September 2017; p. 11. [Google Scholar]

- Kapui, Z.; Kereszturi, A.; Kiss, K.; Szalai, Z.; Ujvari, G.; Hickman-Lewis, K.; Foucher, F.; Westall, F. Fluvial or aeolian grains? Separation of transport agents on Mars using earth analogue observations. Planet. Space Sci. 2018, 163, 56–76. [Google Scholar] [CrossRef]

- Perko, H.A.; Nelson, J.D.; Green, J.R. Mars Soil Mechanical Properties and Suitability of Mars Soil Simulants. J. Aerosp. Eng. 2006, 19, 169–176. [Google Scholar] [CrossRef]

- Barreto, D.; O’Sullivan, C. The influence of inter-particle friction and the intermediate stress ratio on soil response under generalised stress conditions. Granul. Matter 2012, 14, 505–521. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Kwok, C.; Sandeep, C.; Senetakis, K. Sand type effect on the behaviour of sand-granulated rubber mixtures: Integrated study from micro-to macro-scales. Powder Technol. 2019, 342, 907–916. [Google Scholar] [CrossRef]

- Otsubo, M.; O’Sullivan, C. Experimental and DEM assessment of the stress-dependency of surface roughness effects on shear modulus. Soils Found. 2018, 58, 602–614. [Google Scholar] [CrossRef]

- Sazzad, M.M.; Suzuki, K. Effect of Interparticle Friction on the Cyclic Behavior of Granular Materials Using 2D DEM. J. Geotech. Geoenviron. Eng. 2011, 137, 545–549. [Google Scholar] [CrossRef]

- Mollon, G.; Quacquarelli, A.; Andò, E.; Viggiani, G. Can friction replace roughness in the numerical simulation of granular materials? Granul. Matter 2020, 22, 1–16. [Google Scholar] [CrossRef]

- Einav, I. Breakage mechanics—Part I: Theory. J. Mech. Phys. Solids 2007, 55, 1274–1297. [Google Scholar] [CrossRef]

- Einav, I. Breakage mechanics—Part II: Modelling granular materials. J. Mech. Phys. Solids 2007, 55, 1298–1320. [Google Scholar] [CrossRef]

- Wang, J.; Yan, H. DEM analysis of energy dissipation in crushable soils. Soils Found. 2012, 52, 644–657. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Yan, H. On the role of particle breakage in the shear failure behavior of granular soils by DEM. Int. J. Numer. Anal. Methods Géoméch. 2013, 37, 832–854. [Google Scholar] [CrossRef]

- Zhu, F.; Zhao, J. Multiscale modeling of continuous crushing of granular media: The role of grain microstructure. Comput. Part. Mech. 2020, 1–13. [Google Scholar] [CrossRef]

- Hanley, K.J.; O’Sullivan, C.; Huang, X. Particle-scale mechanics of sand crushing in compression and shearing using DEM. Soils Found. 2015, 55, 1100–1112. [Google Scholar] [CrossRef] [Green Version]

- Yimsiri, S.; Soga, K. Micromechanics-based stress–strain behaviour of soils at small strains. Géotechnique 2000, 50, 559–571. [Google Scholar] [CrossRef]

- Payan, M.; Khoshghalb, A.; Senetakis, K.; Khalili, N. Effect of particle shape and validity of Gmax models for sand: A critical review and a new model. Computers Geotech. 2016, 72, 28–41. [Google Scholar] [CrossRef]

- Payan, M.; Senetakis, K.; Khoshghalb, A.; Khalili, N. Influence of particle shape on small-strain material damping of dry sand. Geotechnique 2016, 66, 610–616. [Google Scholar] [CrossRef] [Green Version]

- Hurley, R.C.; Andrade, J.E. Friction in inertial granular flows: Competition between dilation and grain-scale dissipation rates. Granul. Matter 2015, 17, 287–295. [Google Scholar] [CrossRef]

- Zhang, L.; Nguyen, N.G.H.; Lambert, S.; Nicot, F.; Prunier, F.; Djeran-Maigre, I. The role of force chains in granular materials: From statics to dynamics. Eur. J. Environ. Civ. Eng. 2016, 21, 1–22. [Google Scholar] [CrossRef]

- Guillard, F.; Marks, B.; Einav, I. Dynamic X-ray radiography reveals particle size and shape orientation fields during granular flow. Sci. Rep. 2017, 7, 1–11. [Google Scholar] [CrossRef]

- Azéma, E.; Radjaï, F. Force chains and contact network topology in sheared packings of elongated particles. Phys. Rev. E 2012, 85, 031303. [Google Scholar] [CrossRef] [Green Version]

- Göncü, F.; Luding, S. Effect of particle friction and polydispersity on the macroscopic stress-strain relations of granular materials. Acta Geotech. 2013, 8, 629–643. [Google Scholar] [CrossRef]

- Kawamoto, R.; Andò, E.; Viggiani, G.; Andrade, J.E. All you need is shape: Predicting shear banding in sand with LS-DEM. J. Mech. Phys. Solids 2018, 111, 375–392. [Google Scholar] [CrossRef] [Green Version]

- Kumar, N.; Luding, S. Memory of jamming–multiscale models for soft and granular matter. Granul. Matter 2016, 18, 1–21. [Google Scholar] [CrossRef] [Green Version]

- Wiebicke, M.; Andò, E.; Herle, I.; Viggiani, G. On the metrology of interparticle contacts in sand from x-ray tomography images. Meas. Sci. Technol. 2017, 28, 124007. [Google Scholar] [CrossRef]

- Wiebicke, M.; Andò, E.; Šmilauer, V.; Herle, I.; Viggiani, G. A benchmark strategy for the experimental measurement of contact fabric. Granul. Matter 2019, 21, 54. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.; Zhou, B.; Wang, J. Exploring the effect of 3D grain shape on the packing and mechanical behaviour of sands. Géotechnique Lett. 2019, 9, 299–304. [Google Scholar] [CrossRef]

- Zhao, J.; Jiang, M.; Soga, K.; Luding, S. Micro origins for macro behavior in granular media. Granul. Matter 2016, 18, 59. [Google Scholar] [CrossRef]

- Zhao, C.-F.; Yin, Z.-Y.; Hicher, P.-Y. Integrating a micromechanical model for multiscale analyses. Int. J. Numer. Methods Eng. 2017, 114, 105–127. [Google Scholar] [CrossRef]

- Zhao, S.; Zhao, J.; Guo, N. Universality of internal structure characteristics in granular media under shear. Phys. Rev. E 2020, 101, 012906. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, J. A particle-tracking method for experimental investigation of kinematics of sand particles under triaxial compression. Powder Technol. 2018, 328, 436–451. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, J. Experimental investigation of inter-particle contact evolution of sheared granular materials using X-ray micro-tomography. Soils Found. 2018, 58, 1492–1510. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, J.; Coop, M.R.; Ye, G. A miniature triaxial apparatus for investigating the micromechanics of granular soils with in situ X-ray micro-tomography scanning. Front. Struct. Civ. Eng. 2020, 14, 357–373. [Google Scholar] [CrossRef]

- Sandeep, C.S.; Marzulli, V.; Cafaro, F.; Senetakis, K.; Poschel, T. Micromechanical Behavior of DNA-1A Lunar Regolith Simulant in Comparison to Ottawa Sand. J. Gephysical Res. Solid Earth 2019, 124, 8077–8100. [Google Scholar] [CrossRef]

- Marzulli, V.; Sandeep, C.; Senetakis, K.; Cafaro, F.; Pöschel, T. Scale and water effects on the friction angles of two granular soils with different roughness. Powder Technol. 2021, 377, 813–826. [Google Scholar] [CrossRef]

- Cavarretta, I.; Coop, M.; O’Sullivan, C. The influence of particle characteristics on the behaviour of coarse grained soils. Géotechnique 2010, 60, 413–423. [Google Scholar] [CrossRef] [Green Version]

- Krumbein, W.C.; Sloss, L.L. Stratigraphy and Sedimentation, 2nd ed.; Freeman and Company: San Francisco, CA, USA, 1963. [Google Scholar]

- Maroof, M.A.; Mahboubi, A.; Noorzad, A.; Safi, Y. A new approach to particle shape classification of granular materials. Transp. Geotech. 2020, 22, 100296. [Google Scholar] [CrossRef]

- Powers, M.C. Comparison chart for estimating roundness and sphericity. In AGI Data Sheet; American Geological Institute: Alexandria, VA, USA, 1982. [Google Scholar]

- Sandeep, C.S.; He, H.; Senetakis, K. An experimental micromechanical study of sand grain contacts behavior from different geological environments. Eng. Geol. 2018, 246, 176–186. [Google Scholar] [CrossRef]

- He, H.; Senetakis, K. An experimental study on the micromechanical behavior of pumice. Acta Geotech. 2019, 14, 1883–1904. [Google Scholar] [CrossRef]

- Sandeep, C.S.; Senetakis, K. Effect of Young’s Modulus and Surface Roughness on the Inter-Particle Friction of Granular Materials. Materials 2018, 11, 217. [Google Scholar] [CrossRef] [Green Version]

- Morris, R.V.; Golden, D.C.; Bell, J.F., III; Shelfer, T.D.; Scheinost, A.C.; Hinman, N.W.; Furniss, G.; Mertzman, S.A.; Bishop, J.L.; Ming, D.W.; et al. Mineralogy, composition, and alteration of Mars Pathfinder rocks and soils: Evidence from multispectral, elemental, and magnetic data on terrestrial analogue, SNC meteorite, and Pathfinder samples. J. Geophys. Res. Planets 2000, 105, 1757–1817. [Google Scholar] [CrossRef]

- Caporale, A.G.; Vingiani, S.; Palladino, M.; El-Nakhel, C.; Duri, L.G.; Pannico, A.; Rouphael, Y.; De Pascale, S.; Adamo, P. Geo-mineralogical characterisation of Mars simulant MMS-1 and appraisal of substrate physico-chemical properties and crop performance obtained with variable green compost amendment rates. Sci. Total. Environ. 2020, 720, 137543. [Google Scholar] [CrossRef] [PubMed]

- Noh, H.; Jang, H. Friction instability induced by iron and iron oxides on friction material surface. Wear 2018, 400–401, 93–99. [Google Scholar] [CrossRef]

- Kasyap, S.S.; Senetakis, K.; Coop, M.R.; Zhao, J. Micromechanical behaviour in shearing of reproduced flat LBS grains with strong and weak artificial bonds. Acta Geotech. 2021, 16, 1355–1376. [Google Scholar] [CrossRef]

- Senetakis, K.; Sandeep, C.S. Experimental study of sand grains behavior at their contacts with force- and displacement-controlled sliding tests. Undergr. Space 2017, 2, 38–44. [Google Scholar] [CrossRef]

- Senetakis, K.; Coop, M. The Development of a New Micro-Mechanical Inter-Particle Loading Apparatus. Geotech. Test. J. 2014, 37, 1028–1039. [Google Scholar] [CrossRef]

- Senetakis, K.; Coop, M.R. Micro-mechanical Experimental Investigation of Grain-to-Grain Sliding Stiffness of Quartz Minerals. Exp. Mech. 2015, 55, 1187–1190. [Google Scholar] [CrossRef]

- Sandeep, C.S.; Senetakis, K. Exploring the Micromechanical Sliding Behavior of Typical Quartz Grains and Completely Decomposed Volcanic Granules Subjected to Repeating Shearing. Energies 2017, 10, 370. [Google Scholar] [CrossRef] [Green Version]

- Sandeep, C.S.; Senetakis, K. Grain-scale mechanics of quartz sand under normal and tangential loading. Tribol. Int. 2018, 117, 261–271. [Google Scholar] [CrossRef]

- Kasyap, S.; Senetakis, K. Interface load–displacement behaviour of sand grains coated with clayey powder: Experimental and analytical studies. Soils Found. 2019, 59, 1695–1710. [Google Scholar] [CrossRef]

- Lim, W.L.; Mcdowell, G.R.; Collop, A.C. The application of Weibull statistics to the strength of railway ballast. Granul. Matter 2004, 6, 229–237. [Google Scholar] [CrossRef]

- Cavarretta, I.; O’Sullivan, C. The mechanics of rigid irregular particles subject to uniaxial compression. Géotechnique 2012, 62, 681–692. [Google Scholar] [CrossRef]

- Wang, W.; Coop, M.R. An investigation of breakage behaviour of single sand particles using a high-speed microscope camera. Géotechnique 2016, 66, 984–998. [Google Scholar] [CrossRef] [Green Version]

- Kasyap, S.; Senetakis, K. A micromechanical experimental study of kaolinite-coated sand grains. Tribol. Int. 2018, 126, 206–217. [Google Scholar] [CrossRef]

- Todisco, M.; Wang, W.; Coop, M.; Senetakis, K. Multiple contact compression tests on sand particles. Soils Found. 2017, 57, 126–140. [Google Scholar] [CrossRef]

- Orense, R.; Pender, M.; Hyodo, M.; Nakata, Y. Micro-mechanical properties of crushable pumice sands. Géotechnique Lett. 2013, 3, 67–71. [Google Scholar] [CrossRef]

- Weibull, W. A Statistical Distribution Function of Wide Applicability. J. Appl. Mech. 1951, 18, 293–297. [Google Scholar] [CrossRef]

- Kasyap, S.S.; Li, S.; Senetakis, K. Influence of natural coating type on the frictional and abrasion behaviour of siliciclastic-coated sedimentary sand grains. Eng. Geol. 2021, 281, 105983. [Google Scholar] [CrossRef]

- Ren, J.; Li, S.; He, H.; Senetakis, K. The tribological behavior of iron tailing sand grain contacts in dry, water and biopolymer immersed states. Granul. Matter 2021, 23, 1–23. [Google Scholar] [CrossRef]

- Sandeep, C.S.; Todisco, M.C.; Nardelli, V.; Senetakis, K.; Coop, M.R.; Lourenco, S.D.N. A micromechanical experimental study of highly/completely decomposed tuff granules. Acta Geotech. 2018, 13, 1355–1367. [Google Scholar] [CrossRef] [Green Version]

- Hertz, H. Uber die Beruhrang fester elastischer Korper (On the contacts of elastic solids). J. Der. Rennin. Angew. Math. 1882, 92, 156–171. [Google Scholar]

- Scott, A.; Oze, C.; Tang, Y.; O’Loughlin, A. Development of a Martian regolith simulant for in-situ resource utilization testing. Acta Astronaut. 2017, 131, 45–49. [Google Scholar] [CrossRef]

- Sullivan, R.; Anderson, R.; Biesiadecki, J.; Bond, T.; Stewart, H. Cohesions, friction angles, and other physical properties of Martian regolith from Mars Exploration Rover wheel trenches and wheel scuffs. J. Geophys. Res. Space Phys. 2011, 116. [Google Scholar] [CrossRef]

- Terzaghi, K.; Peck, R.B.; Mesri, G. Soil Mechanics in Engineering Practice; John Wiley & Sons: Hoboken, NJ, USA, 1996. [Google Scholar]

- Senetakis, K.; Todisco, M.C.; Coop, M.R. Tangential load–deflection behaviour at the contacts of soil particles. Géotechnique Lett. 2013, 3, 59–66. [Google Scholar] [CrossRef] [Green Version]

- Senetakis, K.; Sandeep, C.S.; Todisco, M. Dynamic inter-particle friction of crushed limestone surfaces. Tribol. Int. 2017, 111, 1–8. [Google Scholar] [CrossRef]

- Bristow, C.S.; Moller, T.H. Dust production by abrasion of aeolian basalt sands: Analogue for Martian dust. J. Geophys. Res. Planets 2018, 23, 2713–2731. [Google Scholar] [CrossRef]

- Kok, J.F. An improved parameterization of wind-blown sand flux on Mars that includes the effect of hysteresis. Geophys. Res. Lett. 2010, 37, 12202. [Google Scholar] [CrossRef] [Green Version]

| Element | JSC Mars-1 # | MMS * | MMS-1 ^ | Present Study on MMS-1 | ||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||||

| Si | 24.92 | 26.11 | 31.1 | 32.1 ± 1.2 | 32.6 ± 1.1 | 30.4 ± 1.5 | 28.5 ± 1.6 | 30.3 ± 1.4 |

| O | 46.08 | 45.68 | 43.3 | 31.0 ± 1.5 | 34.2 ± 1.4 | 31.3 ± 2.0 | 33.0 ± 2.3 | 31.8 ± 1.9 |

| Fe | 5.19 | 3.23 | 2.78 | 19.5 ± 1.9 | 16.6 ± 1.6 | 19.4 ± 2.5 | 17.8 ± 2.8 | 18.9 ± 2.4 |

| Al | 8.45 | 6.03 | 4.67 | 5.8 ± 0.5 | 5.7 ± 0.4 | 5.8 ± 0.6 | 7.3 ± 0.8 | 6.3 ± 0.6 |

| Ca | 5.68 | 9.05 | 4.36 | 4.5 ± 0.6 | 3.5 ± 0.5 | 4.7 ± 0.8 | 4.8 ± 0.9 | 4.7 ± 0.8 |

| K | 0.45 | 0.29 | 1.29 | 2.2 ± 0.4 | 2.5 ± 0.4 | 2.6 ± 0.6 | 2.9 ± 0.7 | 2.6 ± 0.6 |

| Mg | 4.65 | 6.18 | 4.28 | 2.1 ± 0.3 | 2.2 ± 0.3 | 1.9 ± 0.4 | 3.4 ± 0.5 | 2.5 ± 0.4 |

| Na | 2.06 | 2.67 | 3.51 | 0.9 ± 0.3 | 1.2 ± 0.3 | 1.5 ± 0.4 | 0.2 ± 0.4 | 0.9 ± 0.4 |

| Ti | 2.00 | 0.56 | 0.58 | 0.9 ± 0.5 | 0.4 ± 0.5 | 1.6 ± 0.8 | 1.8 ± 0.8 | 1.4 ± 0.7 |

| Mn | 0.21 | 0.13 | 0.08 | 0.5 ± 0.8 | 1.2 ± 0.8 | 0.0 ± 0.0 | 0.0 ± 0.0 | 0.2 ± 0.3 |

| P | 0.18 | 0.04 | 0.04 | 0.2 ± 0.2 | 0.0 ± 0.2 | 0.4 ± 0.3 | 0.2 ± 0.4 | 0.3 ± 0.3 |

| Cr | 0.01 | 0.02 | - | 0.1 ± 0.7 | 0.0 ± 0.0 | 0.1 ± 0.1 | 0.0 ± 0.0 | 0.1 ± 0.6 |

| S | 0.11 | 0.03 | - | 0.0 ± 0.2 | 0.0 ± 0.0 | 0.4 ± 0.3 | 0.0 ± 0.3 | 0.1 ± 0.3 |

| S.No | FN (N) # | δN,max @ (mm) | FT,SS (N) | μSS | φ (deg.) | δN,shear (μm) * | |

|---|---|---|---|---|---|---|---|

| Dilation | Compression | ||||||

| 1 | 2.06 | 0.065 | 1.47 | 0.70 | 35.0 | 0 | 24.5 |

| 2 | 1.90 | 0.014 | 2.28 & | 1.14 & | 47.7 & | −3.2 | 5.5 |

| 3 ^ | 1.84 | 0.024 | 1.39 | 0.61 | 31.4 | −1.4 | 13.4 |

| 1.85 | 0.012 | 1.38 | 0.60 | 30.9 | −2.3 | 13.5 | |

| 1.90 | 0.008 | 1.64 | 0.79 | 38.3 | −7.2 | 4.3 | |

| 4 | 1.83 | 0.084 | 1.26 | 0.70 | 35.0 | −0.9 | 20.5 |

| 5 | 1.83 | 0.020 | 1.51 | 0.81 | 39.0 | 0 | 22.7 |

| 6 | 1.82 | 0.014 | 0.95 | 0.52 | 27.5 | −0.1 | 24.4 |

| 7 ^ | 1.83 | 0.019 | - | - | - | −0.5 | 24.9 |

| 1.83 | 0.012 | - | - | - | −0.3 | 17.8 | |

| 1.83 | 0.010 | - | - | - | −1.1 | 14.7 | |

| 8 | 1.81 | 0.026 | 0.62 & | 0.34 & | 18.8 & | 0 | 27.9 |

| 9 | 1.84 | 0.048 | 1.45 | 0.79 | 38.3 | −7.6 | 4.4 |

| 10 | 1.86 | 0.026 | 1.59 | 0.87 | 41.0 | −0.1 | 22.1 |

| 11 | 1.95 | 0.035 | 1.64 | 0.84 | 40.0 | 0 | 19.7 |

| 12 | 1.85 | 0.022 | 1.55 | 0.84 | 40.0 | 0 | 23.4 |

| 13 | 1.87 | 0.029 | 1.27 | 0.68 | 34.2 | −0.1 | 21.9 |

| 14 | 1.91 | 0.041 | 1.44 | 0.75 | 36.9 | −0.1 | 17.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kasyap, S.S.; Senetakis, K. A Grain-Scale Study of Mojave Mars Simulant (MMS-1). Sensors 2021, 21, 4730. https://doi.org/10.3390/s21144730

Kasyap SS, Senetakis K. A Grain-Scale Study of Mojave Mars Simulant (MMS-1). Sensors. 2021; 21(14):4730. https://doi.org/10.3390/s21144730

Chicago/Turabian StyleKasyap, Sathwik S., and Kostas Senetakis. 2021. "A Grain-Scale Study of Mojave Mars Simulant (MMS-1)" Sensors 21, no. 14: 4730. https://doi.org/10.3390/s21144730

APA StyleKasyap, S. S., & Senetakis, K. (2021). A Grain-Scale Study of Mojave Mars Simulant (MMS-1). Sensors, 21(14), 4730. https://doi.org/10.3390/s21144730