Rapid Prototyping of Inertial MEMS Devices through Structural Optimization

Abstract

:1. Introduction

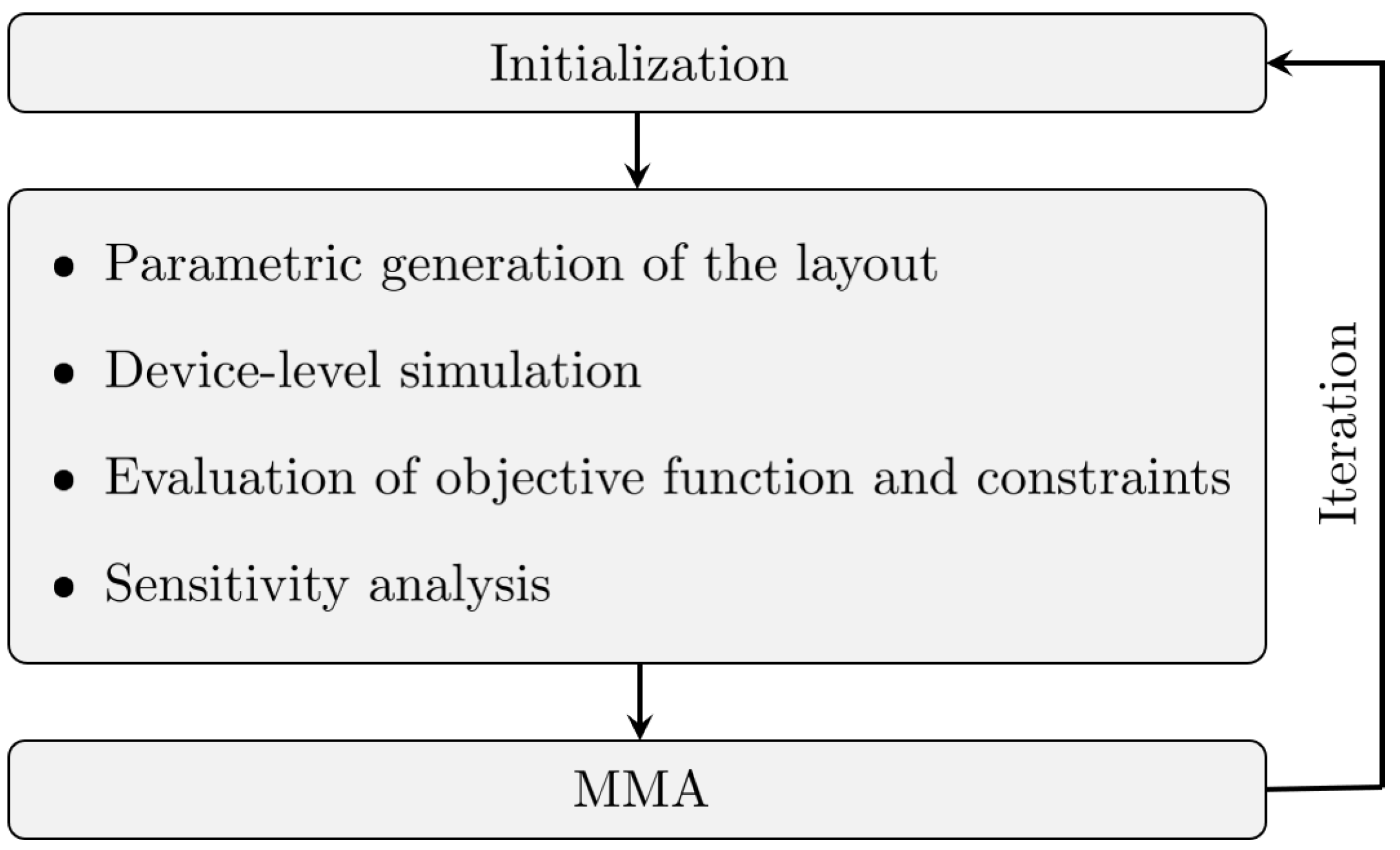

2. Introduction to feMEMSlite

3. Reference Design Case and Associated Design Variables

3.1. Reference Triaxial Beating Heart MEMS Gyroscope Layout and Design Requirements

3.2. Design Variables and Automatic Generation of the MEMS Geometry

4. Device-Level Simulation of the MEMS Structure Behavior

4.1. Discretization of the Structure at the Device Level

4.1.1. Out-of-Plane Variable-Gap Capacitance

4.1.2. In-Plane Variable-Gap Capacitance

4.1.3. Electrostatic Softening Effects

4.2. Equations of Motion and Dynamic Analyses

5. Definition of the Optimization Problem

5.1. Proposed Formulations

5.2. Sensitivity Analysis

6. Results and Discussion

6.1. Validation of the Proposed Device-Level Schematization

6.2. Optimization Results

6.3. Simulation of the Optimized Layouts at Physical Level

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kempe, V. Inertial MEMS: Principles and Practice; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar] [CrossRef]

- Acar, C.; Shkel, A. MEMS Vibratory Gyroscopes: Structural Approaches to Improve Robustness; Springer: Boston, MA, USA, 2009. [Google Scholar] [CrossRef]

- Xia, D.; Yu, C.; Kong, L. The development of micromachined gyroscope structure and circuitry technology. Sensors 2014, 14, 1394–1473. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sung, W.K.; Dalal, M.; Ayazi, F. A mode-matched 0.9 MHZ single proof-mass dual-axis gyroscope. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference, TRANSDUCERS’11, Beijing, China, 5–9 June 2011; pp. 2821–2824. [Google Scholar] [CrossRef]

- Vigna, B. Tri-axial MEMS gyroscopes and six degree-of-freedom motion sensors. In Proceedings of the Technical Digest—International Electron Devices Meeting, IEDM, Washington, DC, USA, 5–7 December 2011; pp. 662–664. [Google Scholar] [CrossRef]

- Sonmezoglu, S.; Taheri-Tehrani, P.; Valzasina, C.; Falorni, L.G.; Zerbini, S.; Nitzan, S.; Horsley, D.A. Single-Structure Micromachined Three-Axis Gyroscope With Reduced Drive-Force Coupling. IEEE Electron. Device Lett. 2015, 36, 953–956. [Google Scholar] [CrossRef]

- Guerinoni, L.; Falorni, L.G.; Gattere, G. Modelling Cross Axis Sensitivity in MEMS Coriolis Vibratory Gyroscopes. In Proceedings of the Eurosensors 2017, Paris, France, 3–6 September 2017; Volume 1, p. 281. [Google Scholar] [CrossRef] [Green Version]

- Iqbal, F.; Din, H.; Lee, B. Single Drive Multi-Axis Gyroscope with High Dynamic Range, High Linearity and Wide Bandwidth. Micromachines 2019, 10, 410. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Senturia, S. Microsystem Design; Springer: Berlin/Heidelberg, Germany, 2001. [Google Scholar]

- Benkhelifa, E.; Farnsworth, M.; Tiwari, A.; Bandi, G.; Zhu, M. Design and optimisation of microelectromechanical systems: A review of the state-of-the-art. Int. J. Des. Eng. 2010, 3, 41. [Google Scholar] [CrossRef]

- Farnsworth, M.; Tiwari, A.; Zhu, M. Multi-level and multi-objective design optimisation of a MEMS bandpass filter. Appl. Soft Comput. J. 2017, 52, 642–656. [Google Scholar] [CrossRef] [Green Version]

- Fedder, G.K.; Qi, J. NODAS 1.3—Nodal Design of Actuators and Sensors. 1998. Available online: https://research.ece.cmu.edu/~mems/pubs/pdfs/ieee/bmas/0033_jing-1998.pdf (accessed on 14 July 2021).

- Bindel, D.; Clark, J.; Zhou, N. SUGAR 3.0: A MEMS Simulation Program (User’s Guide). 2002. Available online: http://www-bsac.eecs.berkeley.edu/cadtools/sugar/Paper/user.pdf (accessed on 14 July 2021).

- Coventor. MEMS+ Webpage. Available online: https://www.coventor.com/products/coventormp/mems-plus/ (accessed on 14 July 2021).

- Haronian, D. Maximizing microelectromechanical sensor and actuator sensitivity by optimizing geometry. Sens. Actuators A Phys. 1995, 50, 223–236. [Google Scholar] [CrossRef]

- Xia, D.; Kong, L.; Gao, H. Design and analysis of a novel fully decoupled tri-axis linear vibratory gyroscope with matched modes. Sensors 2015, 15, 16929–16955. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Benkhelifa, E.; Farnsworth, M.; Tiwari, A.; Zhu, M. Evolutionary Algorithms for Planar MEMS Design Optimisation: A Comparative Study. In Nature Inspired Cooperative Strategies for Optimization (NICSO 2010); Springer: Berlin/Heidelberg, Germany, 2010; pp. 199–210. [Google Scholar] [CrossRef]

- Hoffmann, D.; Bechtold, T.; Hohlfeld, D. Design optimization of MEMS piezoelectric energy harvester. In Proceedings of the 2016 17th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE), Montpellier, France, 18–20 April 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Li, L.; Polunin, P.; Dou, S.; Shoshani, O.; Strachan, B.; Jensen, J.; Shaw, S.; Foster, K. Tailoring the nonlinear response of MEMS resonators using shape optimization. Appl. Phys. Lett. 2017, 110, 081902. [Google Scholar] [CrossRef]

- Zega, V.; Guercilena, A.; Gattere, G. Analysis of Frequency Stability and Thermoelastic Effects for Slotted Tuning Fork MEMS Resonators. Sensors 2018, 18, 2157. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bendsoe, M.P.; Sigmund, O. Topology Optimization; Springer: Berlin/Heidelberg, Germany, 2004; Volume 95, p. 261101. [Google Scholar] [CrossRef]

- He, W.; Bindel, D.; Govindjee, S. Topology optimization in micromechanical resonator design. Optim. Eng.-Optim. Eng. 2012, 13, 1–22. [Google Scholar] [CrossRef] [Green Version]

- Wein, F.; Kaltenbacher, M.; Stingl, M. Topology optimization of a cantilevered piezoelectric energy harvester using stress norm constraints. Struct. Multidiscip. Optim. 2013, 48. [Google Scholar] [CrossRef]

- Philippine, M.A.; Sigmund, O.; Rebeiz, G.M.; Kenny, T.W. Topology optimization of stressed capacitive RF MEMS switches. J. Microelectromech. Syst. 2013, 22, 206–215. [Google Scholar] [CrossRef]

- Bruggi, M.; Zega, V.; Corigliano, A. Optimization of auxetic structures for MEMS applications. In Proceedings of the 2016 17th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems, EuroSimE 2016, Montpellier, France, 18–20 April 2016; pp. 1–5. [Google Scholar] [CrossRef]

- Gerrard, D.D.; Chen, Y.; Chandorkar, S.A.; Yu, G.; Rodriguez, J.; Flader, I.B.; Shin, D.D.; Meinhart, C.D.; Sigmund, O.; Kenny, T.W. Topology optimization for reduction of thermo-elastic dissipation in MEMS resonators. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017; pp. 794–797. [Google Scholar] [CrossRef]

- Giannini, D.; Braghin, F.; Aage, N. Topology optimization of 2D in-plane single mass MEMS gyroscopes. Struct. Multidiscip. Optim. 2020. [Google Scholar] [CrossRef]

- Xia, D.; Kong, L.; Gao, H. A mode matched triaxial vibratory wheel gyroscope with fully decoupled structure. Sensors 2015, 15, 28979–29002. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Giannini, D.; Bonaccorsi, G.; Braghin, F. Size optimization of MEMS gyroscopes using substructuring. Eur. J. Mech. A/Solids 2020, 84, 104045. [Google Scholar] [CrossRef]

- Izadi, M.; Braghin, F.; Giannini, D.; Milani, D.; Resta, F.; Brunetto, M.F.; Falorni, L.G.; Gattere, G.; Guerinoni, L.; Valzasina, C. A comprehensive model of beams’ anisoelasticity in MEMS gyroscopes, with focus on the effect of axial non-vertical etching. In Proceedings of the 2018 IEEE International Symposium on Inertial Sensors and Systems (INERTIAL), Lake Como, Italy, 26–29 March 2018; pp. 1–4. [Google Scholar]

- Svanberg, K. The method of moving asymptotes—A new method for structural optimization. Int. J. Numer. Methods Eng. 1987, 24, 359–373. [Google Scholar] [CrossRef]

- Prandi, L.; Caminada, C.; Coronato, L.; Cazzaniga, G.; Biganzoli, F.; Antonello, R.; Oboe, R. A low-power 3-axis digital-output MEMS gyroscope with single drive and multiplexed angular rate readout. In Proceedings of the 2011 IEEE International Solid-State Circuits Conference, San Francisco, CA, USA, 20–24 February 2011; pp. 104–106. [Google Scholar] [CrossRef]

- Cook, R.D.; Malkus, D.S.; Plesha, M.E.; Witt, R.J. Concepts and Applications of Finite Element Analysis, 4th ed.; Wiley: Hoboken, NJ, USA, 2001. [Google Scholar]

- Svanberg, K. MMA and GCMMA—Two methods for nonlinear optimization. In Optimization and Systems Theory; KTH: Stockholm, Sweden, 2007. [Google Scholar]

- Gray, J.S.; Hwang, J.T.; Martins, J.R.; Moore, K.T.; Naylor, B.A. OpenMDAO: An open-source framework for multidisciplinary design, analysis, and optimization. Struct. Multidiscip. Optim. 2019, 59, 1075–1104. [Google Scholar] [CrossRef]

| Abaqus [29] | feMEMS [29] | feMEMSlite | |

|---|---|---|---|

| Geom. creation time | (user dependent, s) | 0.2 s | 0.2 s |

| Assembly time | 8.4 s | 17.3 s | 0.003 s |

| Modal analysis time | 46.3 s | 0.001 s | 0.005 s |

| Harm. analysis time | 89.4 s × 3 | 0.001 s × 3 | 0.005 s × 3 |

| Total time | 322.8 s | 17.5 s | 0.25 s |

| Number of dofs | 672,765 | 416,089 (full), 246 (red.) | 354 |

| Abaqus [29] | feMEMS [29] | feMEMSlite (no soft.) | feMEMSlite (+soft.) | |

|---|---|---|---|---|

| 31,975 Hz | 31,931 Hz (−0.14%) | 34,108 Hz (+6.67%) | 34,108 Hz | |

| 43,018 Hz | 42,980 Hz (−0.09%) | 47,780 Hz (+11.07%) | 47,679 Hz | |

| 38,761 Hz | 38,718 Hz (−0.11%) | 43,187 Hz (+11.42%) | 43,045 Hz | |

| 30,796 Hz | 30,772 Hz (−0.08%) | 31,694 Hz (+2.92%) | 31,605 Hz | |

| 34,478 Hz | 34,440 Hz (−0.11%) | 35,775 Hz (+3.76%) | 35,775 Hz | |

| 0.9866 | 0.9874 (+0.08%) | 0.9922 (+0.57%) | 0.9922 | |

| 1.4136 nm | 1.3954 nm (−1.29%) | 1.2266 nm (−13.23%) | 1.2295 nm | |

| 1.7863 nm | 1.7648 nm (−1.20%) | 1.5828 nm (−11.39%) | 1.5885 nm | |

| 2.1082 nm | 2.0534 nm (−2.60%) | 2.0620 nm (−2.19%) | 2.0970 nm |

| Layout (a) | Layout (b) | Layout (c) | |

|---|---|---|---|

| Formulation | - (initial guess) | (P1) | (P2) |

| 31,605 Hz (yaw) | 20,100 Hz (drive) | 20,099 Hz (drive) | |

| 34,108 Hz (drive) | 21,153 Hz (pitch) | 21,139 Hz (pitch) | |

| 35,775 Hz (spurious) | 21,213 Hz (yaw) | 21,211 Hz (yaw) | |

| 36,312 Hz (spurious) | 21,213 Hz (roll) | 21,212 Hz (roll) | |

| 39,715 Hz (spurious) | 24,213 Hz (spurious) | 24,761 Hz (spurious) | |

| 43,045 Hz (roll) | 24,214 Hz (spurious) | 24,761 Hz (spurious) | |

| 46,259 Hz (spurious) | 28,993 Hz (spurious) | 24,770 Hz (spurious) | |

| 47,047 Hz (spurious) | 30,064 Hz (spurious) | 28,090 Hz (spurious) | |

| 0.9922 | 1.010 | 0.9949 | |

| 0.7154 | 0.9525 | 0.9502 | |

| 0.7924 | 0.9525 | 0.9475 | |

| 1.0792 | 0.9525 | 0.9475 | |

| 1.2295 nm | 2.9509 nm | 2.3950 nm | |

| 1.5885 nm | 2.9509 nm | 2.9725 nm | |

| 2.0970 nm | 3.5064 nm | 3.1257 nm |

| Layout | (b) feMEMSlite | (b) Abaqus HEX20 | (c) feMEMSlite | (c) Abaqus HEX20 |

|---|---|---|---|---|

| 20,100 Hz (drive) | 19,416 Hz (drive) | 20,099 Hz (drive) | 19,383 Hz (drive) | |

| 21,153 Hz (pitch) | 19,912 Hz (pitch) | 21,139 Hz (pitch) | 19,581 Hz (pitch) | |

| 21,213 Hz (yaw) | 20,125 Hz (roll) | 21,211 Hz (yaw) | 19,810 Hz (roll) | |

| 21,213 Hz (roll) | 20,790 Hz (yaw) | 21,212 Hz (roll) | 20,837 Hz (yaw) | |

| 24,213 Hz (spur.) | 23,677 Hz (spur.) | 24,761 Hz (spur.) | 23,964 (spur.) | |

| 0.9922 | 1.0090 | 0.9949 | 0.9927 | |

| 2.9509 nm | 3.0498 nm | 2.3950 nm | 2.5316 nm | |

| 2.9509 nm | 3.0630 nm | 2.9725 nm | 2.9406 nm | |

| 3.5064 nm | 3.4003 nm | 3.1257 nm | 3.0543 nm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giannini, D.; Bonaccorsi, G.; Braghin, F. Rapid Prototyping of Inertial MEMS Devices through Structural Optimization. Sensors 2021, 21, 5064. https://doi.org/10.3390/s21155064

Giannini D, Bonaccorsi G, Braghin F. Rapid Prototyping of Inertial MEMS Devices through Structural Optimization. Sensors. 2021; 21(15):5064. https://doi.org/10.3390/s21155064

Chicago/Turabian StyleGiannini, Daniele, Giacomo Bonaccorsi, and Francesco Braghin. 2021. "Rapid Prototyping of Inertial MEMS Devices through Structural Optimization" Sensors 21, no. 15: 5064. https://doi.org/10.3390/s21155064

APA StyleGiannini, D., Bonaccorsi, G., & Braghin, F. (2021). Rapid Prototyping of Inertial MEMS Devices through Structural Optimization. Sensors, 21(15), 5064. https://doi.org/10.3390/s21155064