Author Contributions

Conceptualization, T.K. and Z.B.; Investigation, T.K., D.H., I.V. and E.P.; Methodology, T.K. and Z.B.; Project administration, Z.B. and I.V.; Software, T.K.; Supervision, Z.B.; Validation, T.K., Z.B. and A.V.; Visualization, T.K.; Writing—original draft, T.K. and A.V.; Writing—review and editing, Z.B., D.H., A.V., I.V. and E.P. All authors have read and agreed to the published version of the manuscript.

Figure 1.

An example of a triangle mesh.

Figure 1.

An example of a triangle mesh.

Figure 2.

A ray intersecting four triangles of a concave mesh.

Figure 2.

A ray intersecting four triangles of a concave mesh.

Figure 3.

Ray-triangle intersection.

Figure 3.

Ray-triangle intersection.

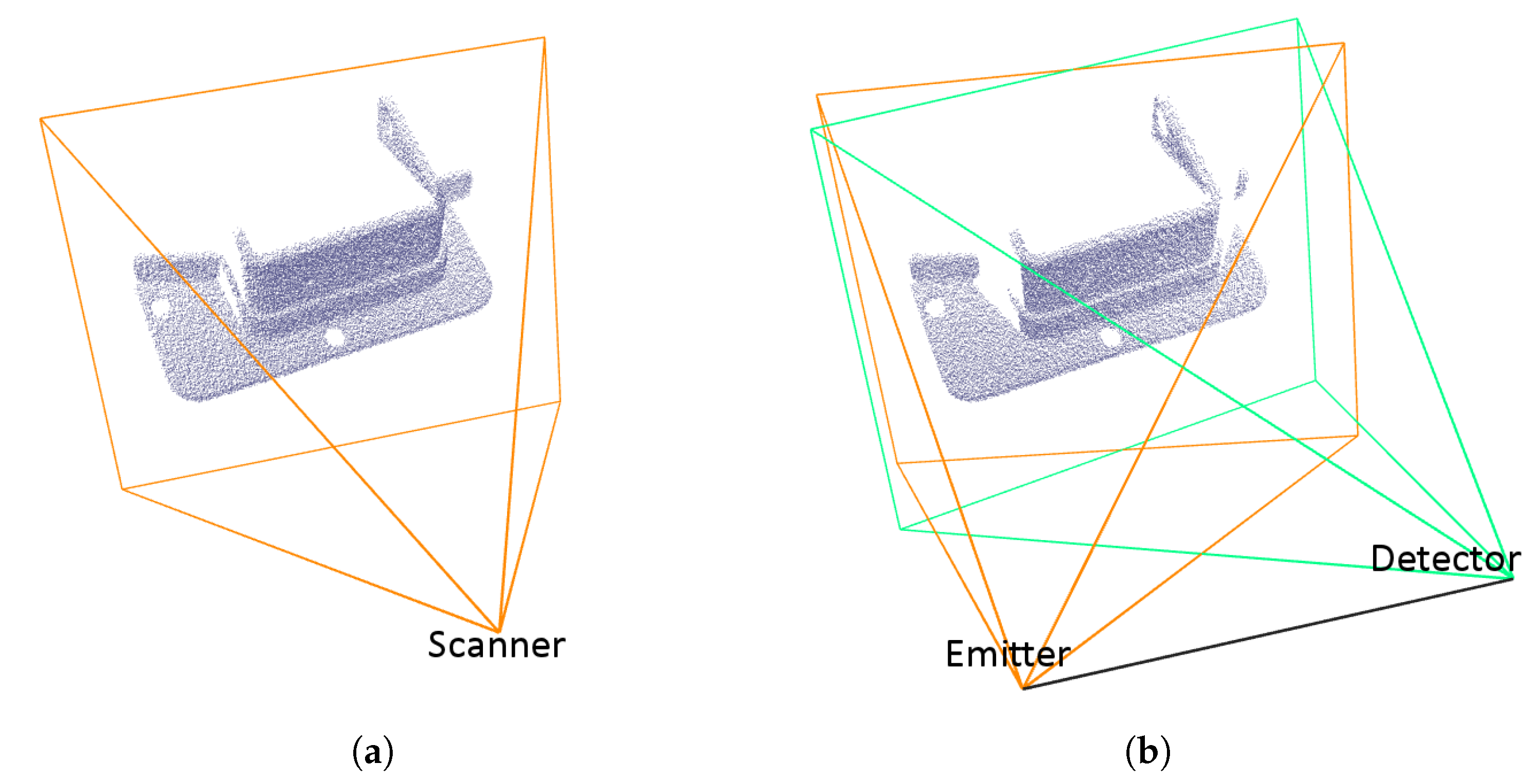

Figure 4.

A sample point cloud acquired by simulated 3D scanning and pyramids representing the view volumes of the simulated scanners: (a) a TOF scanner; (b) a triangulation scanner.

Figure 4.

A sample point cloud acquired by simulated 3D scanning and pyramids representing the view volumes of the simulated scanners: (a) a TOF scanner; (b) a triangulation scanner.

Figure 5.

Scan made by a single virtual scanner with various amount of simulated noise: (a) no noise; (b) low amount of noise (1 % of distance measurements); (c) high amount of noise (3 % of distance measurements).

Figure 5.

Scan made by a single virtual scanner with various amount of simulated noise: (a) no noise; (b) low amount of noise (1 % of distance measurements); (c) high amount of noise (3 % of distance measurements).

Figure 6.

Positions (blue crosses) and orientations (blue lines) of scanners rotated around the fixed turntable (30 steps). represents the elevation angle.

Figure 6.

Positions (blue crosses) and orientations (blue lines) of scanners rotated around the fixed turntable (30 steps). represents the elevation angle.

Figure 7.

Side view of the turntable with two example locations and horizontal viewing angles of scanners (elevation angles and , in this case ).

Figure 7.

Side view of the turntable with two example locations and horizontal viewing angles of scanners (elevation angles and , in this case ).

Figure 8.

The 16 selected sample models from the total number of 200 models used in the simulations.

Figure 8.

The 16 selected sample models from the total number of 200 models used in the simulations.

Figure 9.

A method of semi-even distribution of points on a single triangle.

Figure 9.

A method of semi-even distribution of points on a single triangle.

Figure 10.

An example of a reference point cloud covering evenly the whole surface of a model.

Figure 10.

An example of a reference point cloud covering evenly the whole surface of a model.

Figure 11.

Surface coverage (%) for different elevation angles (°) of a single scanner: (a) simulated TOF scanner; (b) simulated triangulation scanner.

Figure 11.

Surface coverage (%) for different elevation angles (°) of a single scanner: (a) simulated TOF scanner; (b) simulated triangulation scanner.

Figure 12.

Surface coverage (%) for different elevation angles (°) of a single scanner for six selected concrete models in

Figure 8: (

a) simulated TOF scanner; (

b) simulated triangulation scanner.

Figure 12.

Surface coverage (%) for different elevation angles (°) of a single scanner for six selected concrete models in

Figure 8: (

a) simulated TOF scanner; (

b) simulated triangulation scanner.

Figure 13.

Comparison of point clouds acquired by simulated scanning using a single scanner at elevation and elevation : (a) Model 11, better coverage for higher scanning angles; (b) Model 16, better coverage for higher scanning angles; (c) Model 7, better coverage for lower scanning angles.

Figure 13.

Comparison of point clouds acquired by simulated scanning using a single scanner at elevation and elevation : (a) Model 11, better coverage for higher scanning angles; (b) Model 16, better coverage for higher scanning angles; (c) Model 7, better coverage for lower scanning angles.

Figure 14.

Surface coverage (%) for different elevation angles (°) of a two-scanner setup. Elevation angle of the first scanner is constant for each colored group of graphs and is listed at the bottom.

Figure 14.

Surface coverage (%) for different elevation angles (°) of a two-scanner setup. Elevation angle of the first scanner is constant for each colored group of graphs and is listed at the bottom.

Figure 15.

Surface coverage (%) for various number of turntable rotation steps in a two-scanner setup. The colors are used to distinguish different step increments (2, 10).

Figure 15.

Surface coverage (%) for various number of turntable rotation steps in a two-scanner setup. The colors are used to distinguish different step increments (2, 10).

Figure 16.

Surface coverage (%) for different elevation angles (°) of a single TOF scanner for various placement offset values (percent of the object size) from the turntable axis of rotation.

Figure 16.

Surface coverage (%) for different elevation angles (°) of a single TOF scanner for various placement offset values (percent of the object size) from the turntable axis of rotation.

Figure 17.

Ellipsoid semi-axes difference between the scanned and reference point clouds for various number of turntable rotation steps in the single-scanner and two-scanner setups, averaged for all 200 models.

Figure 17.

Ellipsoid semi-axes difference between the scanned and reference point clouds for various number of turntable rotation steps in the single-scanner and two-scanner setups, averaged for all 200 models.

Figure 18.

Comparison of point clouds and their ellipsoids: (a) one scanner and two turntable rotations; (b) one scanner and three turntable rotations; (c) reference point cloud.

Figure 18.

Comparison of point clouds and their ellipsoids: (a) one scanner and two turntable rotations; (b) one scanner and three turntable rotations; (c) reference point cloud.

Figure 19.

The physical turntable with a Photoneo 3D scanner positioned for a low-angle scanning.

Figure 19.

The physical turntable with a Photoneo 3D scanner positioned for a low-angle scanning.

Figure 20.

A subset of the mechanical parts and sub-assemblies used in the physical experiment.

Figure 20.

A subset of the mechanical parts and sub-assemblies used in the physical experiment.

Figure 21.

A sample output from the real 3D scanner: (a) the overall view of the mesh; (b) a detail of the vertex grid of the generated triangle mesh.

Figure 21.

A sample output from the real 3D scanner: (a) the overall view of the mesh; (b) a detail of the vertex grid of the generated triangle mesh.

Figure 22.

Surface coverage (%) for different elevation angles (°) of a single triangulation scanner for selected 15 models: (a) results from simulated scanning (triangulation scanner); (b) results from the real 3D scanner.

Figure 22.

Surface coverage (%) for different elevation angles (°) of a single triangulation scanner for selected 15 models: (a) results from simulated scanning (triangulation scanner); (b) results from the real 3D scanner.

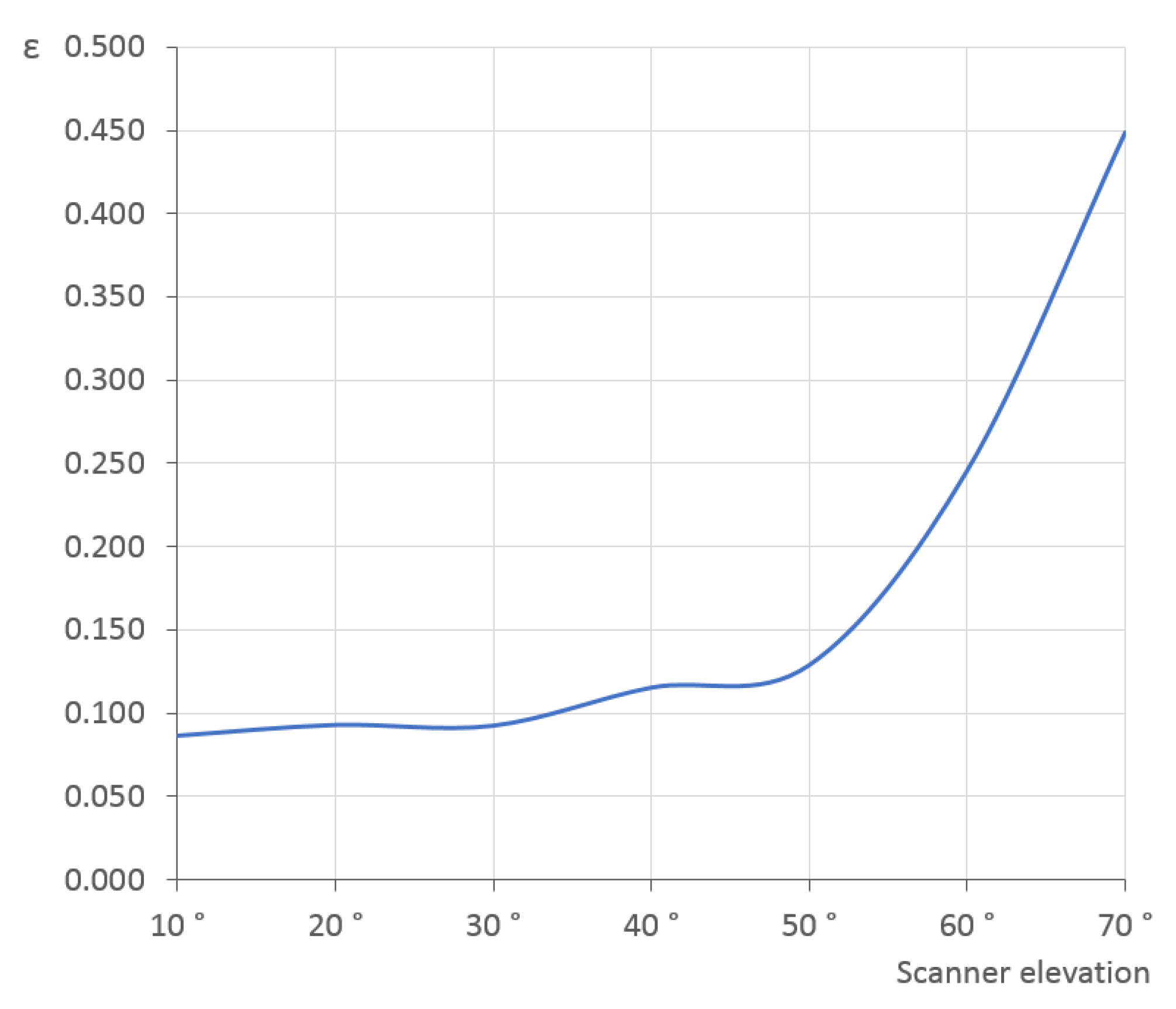

Figure 23.

Ellipsoid semi-axes difference between the scanned (by the real 3D scanner) and reference point clouds for various elevation angles (°) of a single scanner, averaged for the selected 15 models.

Figure 23.

Ellipsoid semi-axes difference between the scanned (by the real 3D scanner) and reference point clouds for various elevation angles (°) of a single scanner, averaged for the selected 15 models.

Figure 24.

Real (the top-most line) and simulated merged scans of the same mechanical part made by one scanner at various elevation angles (horizontal axis) and various threshold angles for simulated reflection errors (vertical axis).

Figure 24.

Real (the top-most line) and simulated merged scans of the same mechanical part made by one scanner at various elevation angles (horizontal axis) and various threshold angles for simulated reflection errors (vertical axis).

Figure 25.

Approximation of reflectivity errors—probability of a scanned point being retained in the point cloud based on the angle between the laser ray and the surface normal (threshold angle = 60°, spread angle = 10°).

Figure 25.

Approximation of reflectivity errors—probability of a scanned point being retained in the point cloud based on the angle between the laser ray and the surface normal (threshold angle = 60°, spread angle = 10°).

Figure 26.

Surface coverage (%) for different elevation angles (°) of a single simulated triangulation scanner for 15 selected models with approximate simulation of reflection errors ( = 60°, = 10°).

Figure 26.

Surface coverage (%) for different elevation angles (°) of a single simulated triangulation scanner for 15 selected models with approximate simulation of reflection errors ( = 60°, = 10°).

Table 1.

Minimal, averaged and maximal surface coverage (%) for different elevation angles of a single TOF scanner.

Table 1.

Minimal, averaged and maximal surface coverage (%) for different elevation angles of a single TOF scanner.

| Elevation | Minimum | Mean | Median | Maximum |

|---|

| 0 | 27.4% | 47.2% | 46.4% | 73.2% |

| 10 | 30.5% | 51.5% | 51.3% | 74.6% |

| 20 | 30.7% | 52.9% | 53.6% | 74.1% |

| 30 | 29.4% | 52.3% | 53.5% | 70.6% |

| 40 | 28.0% | 49.8% | 51.2% | 67.5% |

| 50 | 25.4% | 45.6% | 47.6% | 62.1% |

| 60 | 22.3% | 40.6% | 42.3% | 54.1% |

| 70 | 19.1% | 34.0% | 34.1% | 47.4% |

Table 2.

Minimal, averaged and maximal surface coverage (%) for various combinations of elevation angles and of two scanners.

Table 2.

Minimal, averaged and maximal surface coverage (%) for various combinations of elevation angles and of two scanners.

| Elevation | Elevation | Minimum | Mean | Median | Maximum |

|---|

| −20 | 10 | 46.5 % | 72.9 % | 73.4 % | 93.6 % |

| −20 | 20 | 48.2 % | 75.8 % | 77.0 % | 94.4 % |

| −20 | 30 | 48.8 % | 76.9 % | 78.4 % | 94.4 % |

| −20 | 40 | 49.1 % | 77.7 % | 79.8 % | 94.0 % |

| −20 | 50 | 48.8 % | 77.3 % | 79.5 % | 95.1 % |

| −20 | 60 | 48.4 % | 76.4 % | 78.2 % | 95.7 % |

| −20 | 70 | 47.7 % | 74.9 % | 77.2 % | 96.8 % |

| −10 | 20 | 43.6 % | 67.4 % | 67.3 % | 91.6 % |

| −10 | 30 | 45.4 % | 69.0 % | 68.7 % | 92.2 % |

| −10 | 40 | 46.2 % | 69.6 % | 69.3 % | 91.8 % |

| −10 | 50 | 43.6 % | 69.3 % | 69.0 % | 90.1 % |

| −10 | 60 | 42.9 % | 68.8 % | 68.8 % | 88.7 % |

| −10 | 70 | 41.3 % | 67.5 % | 67.1 % | 89.4 % |

| 0 | 30 | 40.0 % | 64.6 % | 64.8 % | 88.9 % |

| 0 | 40 | 40.5 % | 64.7 % | 64.3 % | 88.3 % |

| 0 | 50 | 39.4 % | 64.1 % | 64.3 % | 86.9 % |

| 0 | 60 | 38.0 % | 63.1 % | 63.6 % | 84.9 % |

| 0 | 70 | 36.5 % | 61.8 % | 62.5 % | 82.1 % |

| 10 | 40 | 39.1 % | 64.5 % | 65.7 % | 88.3 % |

| 10 | 50 | 38.8 % | 63.7 % | 64.9 % | 86.9 % |

| 10 | 60 | 37.8 % | 62.7 % | 64.0 % | 84.9 % |

| 10 | 70 | 36.5 % | 61.3 % | 62.5 % | 82.5 % |

| 20 | 50 | 37.4 % | 63.0 % | 64.0 % | 86.1 % |

| 20 | 60 | 36.1 % | 61.9 % | 63.4 % | 83.6 % |

| 20 | 70 | 35.3 % | 60.6 % | 62.3 % | 81.6 % |

| 30 | 60 | 34.2 % | 61.2 % | 62.4 % | 82.0 % |

| 30 | 70 | 33.0 % | 59.7 % | 61.2 % | 80.8 % |

| 40 | 70 | 31.2 % | 56.8 % | 59.3 % | 75.0 % |

Table 3.

Minimal, averaged and maximal surface coverage (%) for various number of rotation steps of the turntable, using two scanners with optimal elevations.

Table 3.

Minimal, averaged and maximal surface coverage (%) for various number of rotation steps of the turntable, using two scanners with optimal elevations.

| Steps | Minimum | Mean | Median | Maximum |

|---|

| 2 | 17.2% | 29.2% | 29.6% | 52.3% |

| 4 | 32.4% | 52.4% | 52.2% | 66.2% |

| 6 | 43.1% | 65.7% | 66.6% | 82.9% |

| 8 | 47.4% | 73.1% | 74.5% | 88.8% |

| 10 | 50.1% | 77.8% | 79.7% | 93.6% |

| 20 | 50.8% | 80.8% | 83.7% | 93.3% |

| 30 | 52.3% | 83.7% | 87.1% | 95.9% |

| 40 | 53.3% | 85.6% | 88.9% | 101.5% |

| 50 | 53.5% | 86.2% | 89.5% | 99.2% |

| 60 | 53.9% | 87.1% | 89.8% | 103.3% |

| 70 | 54.0% | 87.5% | 90.1% | 103.6% |

Table 4.

Minimal, averaged and maximal ellipsoid differences for various number of rotation steps of the turntable, using one (1) and two (2) scanners with optimal elevations.

Table 4.

Minimal, averaged and maximal ellipsoid differences for various number of rotation steps of the turntable, using one (1) and two (2) scanners with optimal elevations.

| Steps | Min 1 | Mean 1 | Max 1 | Min 2 | Mean 2 | Max 2 |

|---|

| 2 | 0.031 | 0.102 | 0.201 | 0.016 | 0.074 | 0.156 |

| 4 | 0.006 | 0.048 | 0.095 | 0.002 | 0.024 | 0.071 |

| 6 | 0.007 | 0.046 | 0.090 | 0.004 | 0.021 | 0.068 |

| 8 | 0.008 | 0.046 | 0.088 | 0.003 | 0.019 | 0.063 |

| 10 | 0.006 | 0.046 | 0.088 | 0.003 | 0.019 | 0.066 |

| 20 | 0.008 | 0.045 | 0.087 | 0.001 | 0.017 | 0.068 |

| 30 | 0.009 | 0.044 | 0.087 | 0.002 | 0.016 | 0.068 |

| 40 | 0.009 | 0.044 | 0.088 | 0.001 | 0.016 | 0.068 |

| 50 | 0.009 | 0.044 | 0.089 | 0.000 | 0.015 | 0.068 |

| 60 | 0.010 | 0.044 | 0.089 | 0.001 | 0.015 | 0.069 |

| 70 | 0.010 | 0.044 | 0.088 | 0.002 | 0.015 | 0.068 |