A Method of Mining Truck Loading Volume Detection Based on Deep Learning and Image Recognition

Abstract

:1. Introduction

2. Research on Detection Method of Loading Volume of Mine Truck

2.1. Traditional Method

2.2. Data-Driven Approach

2.2.1. Deep Learning

2.2.2. Least Squares Regression

3. Mining Truck Loading Volume Detection Method Based on VGG16 and Least Square Algorithm

3.1. Image Preprocessing

3.2. Detection Model of Loading Volume of Mine Truck

3.2.1. VGG16 Model

3.2.2. Least Squares Mathematical Model

3.2.3. Mining Truck Loading Volume Detection Model Based on VGG16 and the Least Squares Algorithm

3.3. Evaluation Method

4. Experimental Process

4.1. Deep Learning Framework and Hardware Platform Environment

4.2. Image Acquisition and Preprocessing

4.3. Production of TFRecords Data Sets

- (1)

- Creation of TFRecords data

- (2)

- Reading TFRecords data

4.4. The Establishment of Model

4.4.1. VGG16 Deep Neural Network Model

4.4.2. Least Squares Mathematical Model

5. Experimental Results and Discussions

6. Conclusions

- (1)

- A method for detecting the loading volume of mining trucks based on image recognition is proposed. The main steps include using pixel value reduction and histogram equalization two image preprocessing strategies for the image. Then the VGG16 deep neural network model is used to pre-classify the images, and the classification results are displayed and the possibility of each category is determined. Finally, the loading volume of mining truck is calculated by the classification results and the least squares algorithm of a data-driven modeling method.

- (2)

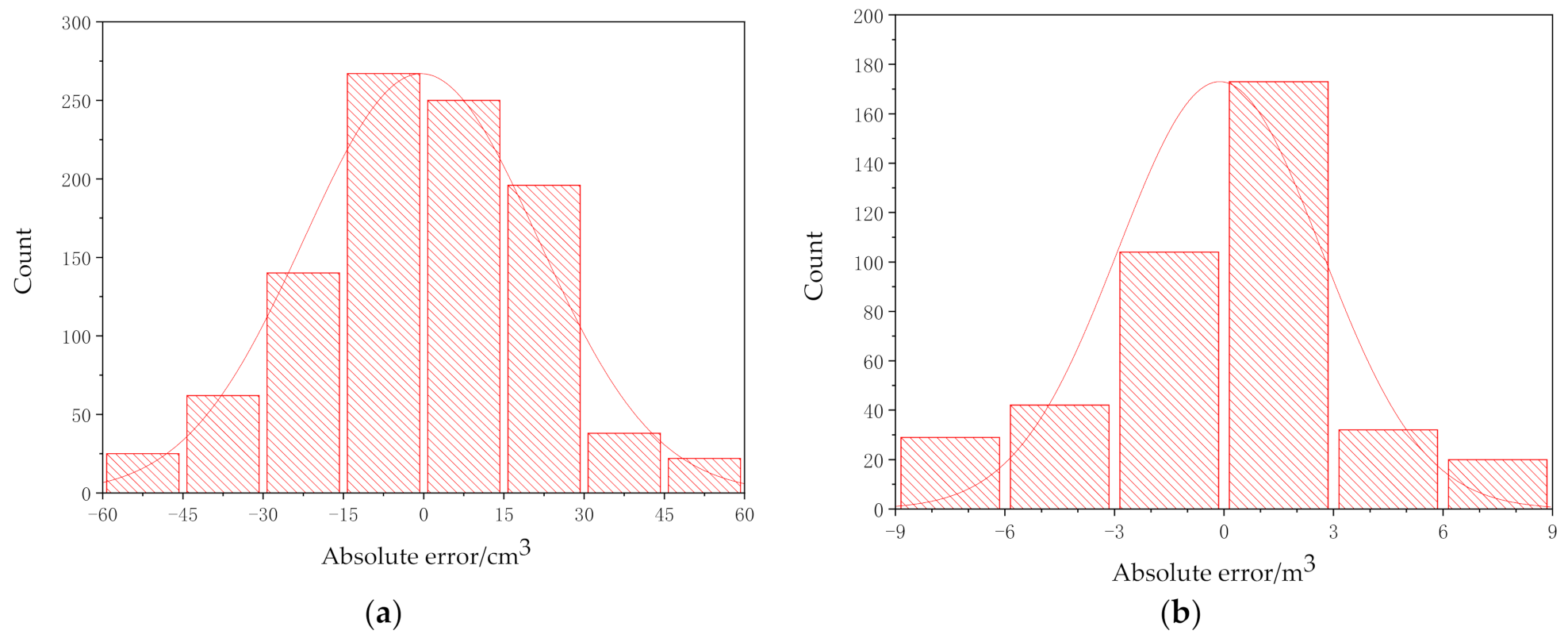

- The model is verified by using a large number of image data taken in the laboratory environment and real mine car images. The average error is 17.85 and 2.53 , respectively. The error is small, which proves that the proposed method has high prediction accuracy and versatility.

- (3)

- One of the innovative points of this paper is to combine the deep learning model with the mathematical model, using the labeled image data of five kinds of mining truck loading capacity, whereby the arbitrary loading capacity detection of mining truck is realized. It effectively solves the problem of a lack of labeled data types caused by the difficulty of data acquisition in mines.

- (4)

- The second innovation of this paper is that the artificial intelligence technology and image recognition technology are introduced into the detection of mining truck loading volume. This method has the advantages of low cost, greatly reducing the waste of resources and the use of human and material resources, and improving the degree of detection automation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bi, L.; Li, Y.L.; Guo, Z.H. Study on the estimation of ore loading quantity of truck based on deep convolutional neural network. Gold Sci. Technol. 2019, 27, 112–120. [Google Scholar]

- Jia, Y.H. Development and application of the truck-mounted self-measuring device on dump trucks. Min. Process. Equip. 2009, 37, 42–44. [Google Scholar]

- Li, F.B.; Lu, L.W.; Lu, C.W. Truck transport meteing system for open_pit mine based on RFID/BPRS. Metal Mine 2008, 04, 99–102. [Google Scholar]

- Yang, Z.S.; Hua, W. Meterial position measuring meter applied in weighting system in mine. Min. Eng. 2006, 4, 43–44. [Google Scholar]

- Wang, G.G.; Zhang, B.Y. Application of computer vision technology in mine production. Min. Technol. 2019, 19, 135–138. [Google Scholar]

- Tessier, J.; Duchesne, C.; Bartolacci, G. A machine vision approach to on-line estimation of run-of-mine ore composition on conveyor belts. Miner. Eng. 2007, 20, 1129–1144. [Google Scholar] [CrossRef]

- Dong, K.; Jing, D. Automated estimation of ore size distributions based on machine vision. In Unifying Electrical Engineering and Electronics Engineering; Springer: New York, NY, USA, 2014. [Google Scholar]

- Amankwash, A.; Aldrich, C. Automatic ore image segement using mean shift and watershed transform. In Proceedings of the 21st International Conference Radioelektronika 2011, Brno, Czech Republic, 4 April 2011. [Google Scholar] [CrossRef]

- Patel, A.K.; Chatterjee, S.; Gorai, A.K. Development of a machine vision system using the support vector machine regression (SVR) algorithm for the online prediction of iron ore grades. Earth Sci. Inform. 2018, 12, 197–210. [Google Scholar] [CrossRef]

- Singh, V.; Rao, S.M. Application of image precessing and radial basis neural network techniques foe ore sorting and ore classification. Miner. Eng. 2005, 18, 1412–1420. [Google Scholar] [CrossRef]

- Duan, J.X.; Liu, X.Y.; Wu, X.; Mao, C.G. Detection and segmentation of iron green pellets in images using lightweight U-net deep learning network. Neural. Comput. Appl. 2019, 2, 5775–5790. [Google Scholar] [CrossRef]

- Hu, H.; Golosinski, T.S. Early detection of mimning truck failure by modelling its operation with neural networks classification algorithms. Appl. Comput. Oper. Res. Miner. Ind. 2003, 1, 191–198. [Google Scholar]

- Li, L.L.; Ding, S.X.; Peng, X. Distributed data-driven optimal fault detection for large-scale systems. J. Process Control 2020, 96, 94–103. [Google Scholar] [CrossRef]

- Hassan, A.; Deka, D.; Chertkov, M. Data-Driven Learning and Load Ensemble Control. Electr. Power Syst. Res. 2020, 189, 106780. [Google Scholar] [CrossRef]

- Tan, H.Y.; Wang, D.H.; Guo, J.M.; Zhang, L. Application Prospect of Big Data Mining Technology in Early Warning Detection Information Processing. Mod. Radar. 2020, 42, 1–5. (In Chinese) [Google Scholar]

- Zhang, Y.; Li, M.C.; Han, S.; Ren, Q.B.; Shi, J. Intelligent Identification for Rock-Mineral Microscopic Images Using Ensemble Machine Learning Algorithms. Sensors 2019, 19, 3914. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Z.; Li, Y.S.; Wu, X.; Liu, G.; Lu, H.; Tang, M. Hollow Village Building Detection Method Using High Resolution Remote Sensing Image Based on CNN. Trans. Chin. Soc. Agric. Mach. 2017, 48, 160–165. [Google Scholar]

- Girshick, R.; Donahue, J.; Darrell, T.; Malik, J. Region-Based Convolutional Networks for Accurate Object Detection and Segmentation. IEEE Trans. Pattern Anal. Mach. Intell. 2016, 38, 142–158. [Google Scholar] [CrossRef]

- Simonyan, K.; Zisserman, A. Very Deep Convolutional Networks for Large-Scale Image Recognition. arXiv 2014, arXiv:1409.1556. [Google Scholar]

- Zhou, Y.; Xu, T.; Zheng, W.; Deng, H. Classification and recognition approaches of tomato main organs based on DCNN. Trans. Chin. Soc. Agric. Eng. 2017, 33, 219–226. [Google Scholar]

- Guo, S.; Luo, Y.; Song, Y. Random Forests and VGG-NET: An Algorithm for the ISIC 2017 Skin Lesion Classification Challenge. arXiv 2017, arXiv:1703.05148. [Google Scholar]

- Ke, H.; Chen, D.; Li, X.; Tang, Y.; Shah, T.; Ranjan, R. Towards Brain Big Data Classification: Epileptic EEG Identification with a Lightweight VGGNet on Global MIC. IEEE Access 2018, 6, 14722–14733. [Google Scholar] [CrossRef]

- Gao, C.H.; Jian, L.; Chen, J.M.; Sun, Y.X. Data-driven Modeling and Predictive Algorithm for Complex Blast Furnace Ironmaking Process. Acta Autom. Sin. 2009, 35, 725–730. [Google Scholar] [CrossRef]

- Mo, X.Q. Linear and nonlinear fitting based on least squares method. Wirel. Inter. Technol. 2019, 16, 128–129. [Google Scholar]

- Heathcote, C.R. Linear regression by functional least squares. J. Appl. Prob. 1982, 19, 225–239. [Google Scholar] [CrossRef]

- Fisher, G.W.; Huffel, S.V.; Vandewalle, J. The Total Least Squares Problem: Computational Aspects and Analysis. Math. Comput. 1991, 59, 724. [Google Scholar] [CrossRef]

- Rao, B.D. Unified Treatment of LS, TLS and Truncated SVD Methods Using a Weighted TLS Framework. In International Workshop on Recent Advances in Total Least Squares Techniques & Errors-in-Variables Modeling; Society for Industrial & Applied Mathematics-SIAM: Philadelphia, PN, USA, 1997. [Google Scholar]

- Sahaffrin, B.; Felus, Y.A. On Total Least-Squares Adjustment with Constraints. In A Window on the Future of Geodesy; Springer: Berlin/Heidelberg, Germany, 2005; pp. 417–421. [Google Scholar]

- Zhang, S.L.; Tong, X.H.; Zhang, K. A Solution to EIV Model with Inequality Constraints and Its Geodetic Applications. J. Geod. 2013, 87, 23–28. [Google Scholar] [CrossRef]

- Yang, Y.; Zhu, C.Q.; Sun, Q. Residential district block extraction and vectorization method in scanned topographic map. Sci. Surv. Mapp. 2007, 5, 88–90. [Google Scholar]

- Chen, Y.; Lu, J.; Zheng, B. Application of Total Least Squares to Space Resection. Geomat. Inf. Sci. Wuhan Univ. 2008, 12, 1271–1274. [Google Scholar]

- Yuan, B.; Yue, D.J.; Zhang, L.; Wang, L. Application of similarity transformation model based on total least-squares to map scanning digitization. Eng. Surv. Mapp. 2013, 22, 45–47. [Google Scholar]

- Chen, L.Y. Statistics. China Stat. Press 2015, 2, 128. [Google Scholar]

- Hou, H.F.; Wang, C.; Zeng, W.J. Management information system. China Railw. Press 2018, 6, 14. [Google Scholar]

| Convolution Core 3 × 3 | Convolution Core 3 × 3 | Convolution Core 3 × 3 | Pooling Layer | Output Size | |

|---|---|---|---|---|---|

| input | 224 × 224 × 3 | ||||

| Block 1 | Stride:1 Padding:1 Core size:3 Core num:64 | Stride:1 Padding:1 Core size:3 Core num:64 | ------ | Type:Max Stride:2 Core size:2 | 224 × 224 × 64 |

| Block 2 | Stride:1 Padding:1 Core size:3 Core num:128 | Stride:1 Padding:1 Core size:3 Core num:128 | ------ | Type:Max Stride:2 Core size:2 | 112 × 112 × 128 |

| Block 3 | Stride:1 Padding:1 Core size:3 Core num:256 | Stride:1 Padding:1 Core size:3 Core num:256 | Stride:1 Padding:1 Core size:3 Core num:256 | Type:Max Stride:2 Core size:2 | 56 × 56 × 256 |

| Block 4 | Stride:1 Padding:1 Core size:3 Core num:512 | Stride:1 Padding:1 Core size:3 Core num:512 | Stride:1 Padding:1 Core size:3 Core num:512 | Type:Max Stride:2 Core size:2 | 28 × 28 × 512 |

| Block 5 | Stride:1 Padding:1 Core size:3 Core num:512 | Stride:1 Padding:1 Core size:3 Core num:512 | Stride:1 Padding:1 Core size:3 Core num:512 | Type:Max Stride:2 Core size:2 | 14 × 14 × 512 7 × 7 × 512 |

| Fully connected layer-1 | Output node num: 4096 | 1 × 1 × 4096 | |||

| Fully connected layer-2 | Output node num: 4096 | 1 × 1 × 4096 | |||

| Fully connected layer-3 | Output node num: 1000 | 1 × 1 × 1000 | |||

| Softmax | |||||

| Learning Rate | R | RMSE |

|---|---|---|

| 0.001 | 0.9972 | 4.56 |

| 0.003 | 0.9990 | 2.70 |

| 0.005 | 0.2429 | 75.09 |

| 0.007 | 0.0064 | 86.28 |

| 0.01 | 0.2831 | 73.08 |

| 0.1 | −4.885 | 86.37 |

| Active Function | R | RMSE |

|---|---|---|

| Tanh | 0.7157 | 45.87 |

| Sigmoid | −3.7470 | 86.37 |

| Relu | 0.4576 | 63.57 |

| Elu | 0.999 | 2.70 |

| Leaky Relu | −4.885 | 86.37 |

| Selu | 0.7993 | 37.62 |

| BatchSize | R | RMSE |

|---|---|---|

| 10 | 0.9975 | 4.32 |

| 20 | 0.9990 | 2.70 |

| 30 | 0.9984 | 3.69 |

| 40 | 0.9956 | 5.70 |

| 50 | 0.9961 | 5.37 |

| 100 | 0.9980 | 3.90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Li, X.; Xiao, D.; Chen, Y.; Wang, B. A Method of Mining Truck Loading Volume Detection Based on Deep Learning and Image Recognition. Sensors 2021, 21, 635. https://doi.org/10.3390/s21020635

Sun X, Li X, Xiao D, Chen Y, Wang B. A Method of Mining Truck Loading Volume Detection Based on Deep Learning and Image Recognition. Sensors. 2021; 21(2):635. https://doi.org/10.3390/s21020635

Chicago/Turabian StyleSun, Xiaoyu, Xuerao Li, Dong Xiao, Yu Chen, and Baohua Wang. 2021. "A Method of Mining Truck Loading Volume Detection Based on Deep Learning and Image Recognition" Sensors 21, no. 2: 635. https://doi.org/10.3390/s21020635

APA StyleSun, X., Li, X., Xiao, D., Chen, Y., & Wang, B. (2021). A Method of Mining Truck Loading Volume Detection Based on Deep Learning and Image Recognition. Sensors, 21(2), 635. https://doi.org/10.3390/s21020635