Vibration Sensor Based on Hollow Biconical Fiber

Abstract

:1. Introduction

2. Principle and Fabrication

3. Experiments and Discussions

3.1. Bending Response

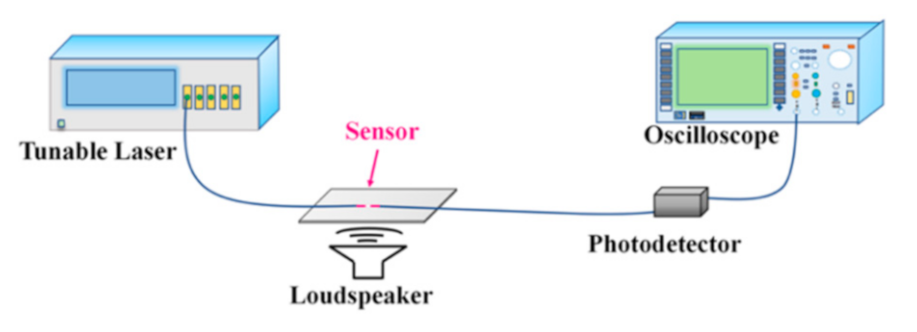

3.2. Acoustic Vibration Testing

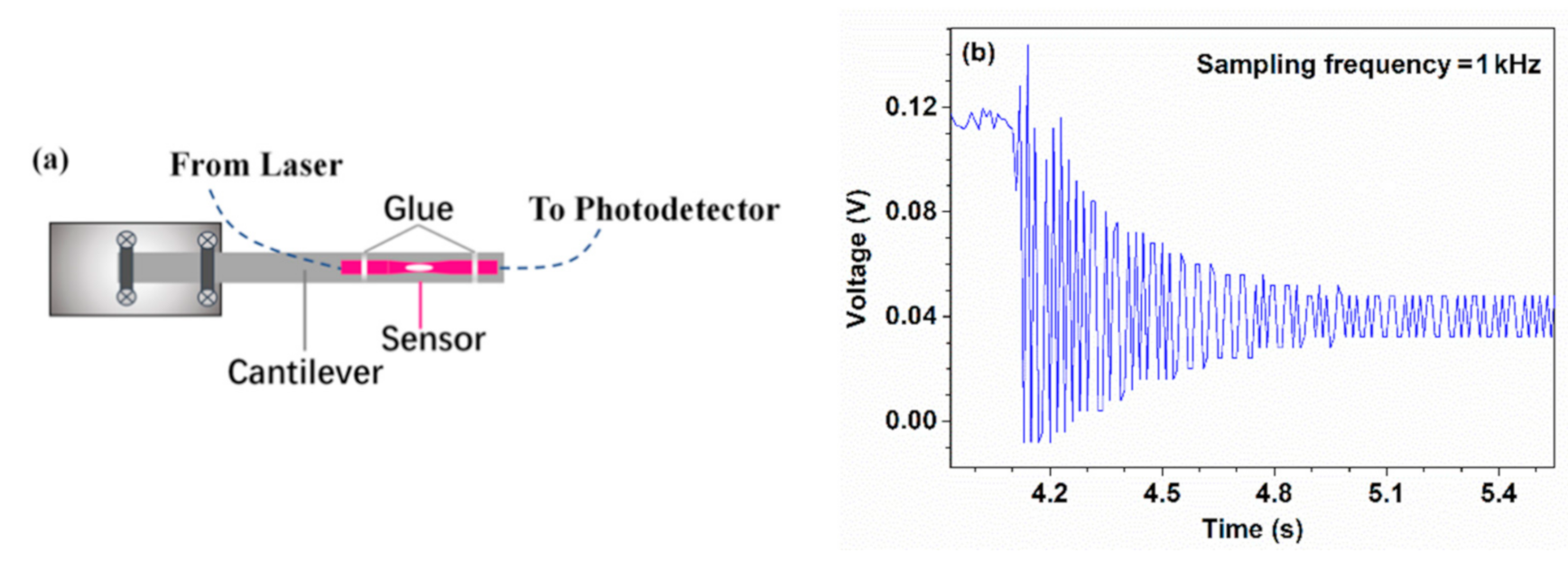

3.3. Cantilever Beam Testing

3.4. Temperature Response

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Doebling, S.W.; Farrar, C.R.; Prime, M.B. A summary review of vibration-based damage identification methods. Shock Vib. Dig. 1998, 30, 91–105. [Google Scholar] [CrossRef] [Green Version]

- García, I.; Zubia, J.; Durana, G.; Aldabaldetreku, G.; Illarramendi, M.A.; Villatoro, J. Optical Fiber Sensors for Aircraft Structural Health Monitoring. Sensors 2015, 15, 15494–15519. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ma, Z.; Chen, X. Fiber Bragg Gratings Sensors for Aircraft Wing Shape Measurement: Recent Applications and Technical Analysis. Sensors 2018, 19, 55. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- XYe, W.; Su, Y.H.; Han, J.P. Structural health monitoring of civil infrastructure using optical fiber sensing technology: A comprehensive review. Sci. World J. 2014, 2014, 652329. [Google Scholar]

- Li, H.N.; Li, D.S.; Song, G.B. Recent applications of fiber optic sensors to health monitoring in civil engineering. Eng. Struct. 2004, 26, 1647–1657. [Google Scholar] [CrossRef]

- Majumder, M.; Gangopadhyay, T.K.; Chakraborty, A.K.; Dasgupta, K.; Bhattacharya, D.K. Fibre Bragg gratings in structural health monitoring—Present status and applications. Sens. Actuators A Phys. 2008, 147, 150–164. [Google Scholar] [CrossRef]

- Joe, H.E.; Yun, H.; Jo, S.H.; Jun, M.B.; Min, B.K. A review on optical fiber sensors for environmental monitoring. Int. J. Precis. Eng. Manuf. Green Technol. 2018, 5, 173–191. [Google Scholar] [CrossRef]

- Yang, C.; Chen, S.; Yang, G. Fiber optical liquid level sensor under cryogenic environment. Sens. Actuators A Phys. 2001, 94, 69–75. [Google Scholar] [CrossRef]

- Xiao, H. Fiber optic pressure sensor with self-compensation capability for harsh environment applications. Opt. Eng. 2005, 44, 054403. [Google Scholar] [CrossRef]

- Nishino, Z.T.; Chen, K.; Gupta, N. Power Modulation-Based Optical Sensor for High-Sensitivity Vibration Measurements. IEEE Sens. J. 2014, 14, 2153–2158. [Google Scholar] [CrossRef]

- Zhou, C.; Tian, T.; Qian, L.; Fan, D.; Liang, W.; Ou, Y. Doppler Effect-Based Optical Fiber Vibration Sensor Using Frequency-Shifted Interferometry Demodulation. J. Lightwave Technol. 2017, 35, 3483–3488. [Google Scholar] [CrossRef]

- An, J.; Liu, T.; Jin, Y. Fiber Optic Vibration Sensor Based on the Tilted Fiber Bragg Grating. Adv. Mater. Sci. Eng. 2013, 2013, 545013. [Google Scholar] [CrossRef] [Green Version]

- Zhou, W.; Dong, X.; Shen, C.; Zhao, C.L.; Chan, C.C.; Shum, P. Temperature-independent vibration sensor with a fiber Bragg grating. Microw. Opt. Technol. Lett. 2010, 52, 2282–2285. [Google Scholar] [CrossRef]

- Chen, D.; Qian, J.; Liu, J.; Chen, B.; An, G.; Hong, Y.; Jia, P.; Xiong, J. An In-Line Fiber Optic Fabry-Perot Sensor for High-Temperature Vibration Measurement. Micromachines 2020, 11, 252. [Google Scholar] [CrossRef] [Green Version]

- Corres, J.M.; Bravo, J.; Arregui, F.J.; Matias, I.R. Vibration monitoring in electrical engines using an in-line fiber etalon. Sens. Actuators A Phys. 2006, 132, 506–515. [Google Scholar] [CrossRef]

- Yu, H.; Luo, Z.; Zheng, Y.; Ma, J.; Jiang, X.; Jiang, D. Vibration Sensing Using Liquid-Filled Photonic Crystal Fiber With a Central Air-Bore. J. Lightwave Technol. 2019, 37, 4625–4633. [Google Scholar] [CrossRef]

- He, T.; Ran, Y.; Liu, T.; Li, H.; Fan, C.; Zhou, W.; Yan, Z.; Liu, D.; Sun, Q. Distributed Temperature/Vibration Fiber Optic Sensor With High Precision and Wide Bandwidth. IEEE Photonics J. 2019, 11, 1–11. [Google Scholar] [CrossRef]

- Villatoro, J.; Antonio-Lopez, E.; Schülzgen, A.; Amezcua-Correa, R. Miniature multicore optical fiber vibration sensor. Opt. Lett. 2017, 42, 2022–2025. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, Y.; Jia, J.; Wang, P.; Wang, S.; Jiang, L. Fiber-optic micro vibration sensors fabricated by a femtosecond laser. Opt. Lasers Eng. 2018, 110, 207–210. [Google Scholar] [CrossRef]

- Zhao, Y.; Xia, F.; Chen, M.Q.; Lv, R.Q. Optical fiber low-frequency vibration sensor based on Butterfly-Shape Mach-Zehnder Interferometer. Sens. Actuators A Phys. 2018, 273, 107–112. [Google Scholar] [CrossRef]

- Xu, Y.; Lu, P.; Qin, Z.; Harris, J.; Baset, F.; Bhardwaj, V.R.; Bao, X. Vibration sensing using a tapered bend-insensitive fiber based Mach-Zehnder interferometer. Opt. Express 2013, 21, 3031–3042. [Google Scholar] [CrossRef] [PubMed]

- Jenkins, F.A.; White, H.E. Fundamentals of Optics; Tata McGraw-Hill Education: New York, NY, USA, 1937. [Google Scholar]

- Wang, Y.; Richardson, D.; Brambilla, G.; Feng, X.; Petrovich, M.; Ding, M.; Song, Z. Intensity measurement bend sensors based on periodically tapered soft glass fibers. Opt. Lett. 2011, 36, 558–560. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nguyen, L.V.; Hwang, D.; Moon, S.; Moon, D.S.; Chung, Y. High temperature fiber sensor with high sensitivity based on core diameter mismatch. Opt. Express 2008, 16, 11369–11375. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Xu, B.; Wang, D.; Guo, Y.; Chen, M.; Chen, W.; Guo, P.; Peng, X.; Li, J. Vibration Sensor Based on Hollow Biconical Fiber. Sensors 2021, 21, 1023. https://doi.org/10.3390/s21041023

Zhang Y, Xu B, Wang D, Guo Y, Chen M, Chen W, Guo P, Peng X, Li J. Vibration Sensor Based on Hollow Biconical Fiber. Sensors. 2021; 21(4):1023. https://doi.org/10.3390/s21041023

Chicago/Turabian StyleZhang, Yingfang, Ben Xu, Dongning Wang, Yun Guo, Min Chen, Weicheng Chen, Penglai Guo, Xiaoling Peng, and Jianqing Li. 2021. "Vibration Sensor Based on Hollow Biconical Fiber" Sensors 21, no. 4: 1023. https://doi.org/10.3390/s21041023

APA StyleZhang, Y., Xu, B., Wang, D., Guo, Y., Chen, M., Chen, W., Guo, P., Peng, X., & Li, J. (2021). Vibration Sensor Based on Hollow Biconical Fiber. Sensors, 21(4), 1023. https://doi.org/10.3390/s21041023