Lightweight Thermal Compensation Technique for MEMS Capacitive Accelerometer Oriented to Quasi-Static Measurements

Abstract

1. Introduction

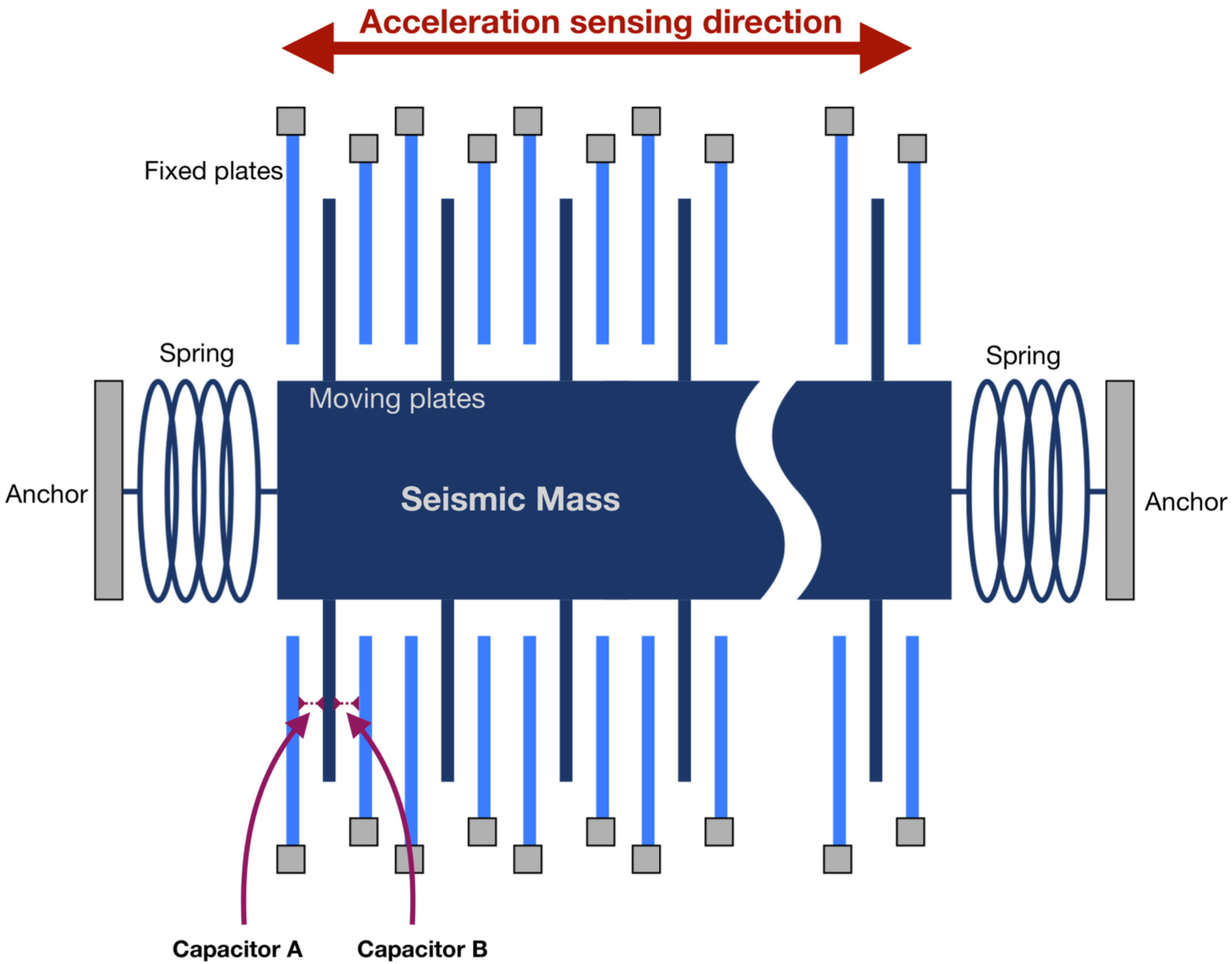

2. The MEMS Accelerometer

2.1. Working Principle

2.2. Triaxial Accelerometer Calibration

2.3. Tilt Measurement Techniques for Accelerometers

2.4. Thermal Behavior

Thermal Compensation

- = Bias in s at 0 °C.

- = Data variation proportional to temperature in s/°C. Same as .

- = Sensibility of the acceleration in s. Same as in Equation (1).

- = Second order . It does not have much effect, since it is three orders lower than .

- = Sensitivity change because of temperature. Same as .

- = Second order non-linearity sensibility in s. Typical order of .

3. Methodology

3.1. The Accelerometer—Device under Test

3.2. Hardware—TestBench

3.3. Tests Conditions

3.4. Signal Processing

4. Results

4.1. Thermal Drift

4.2. Self-Heating

4.3. Temporal Drift

4.4. System Noise

5. Analysis

Temperature Drift of Bias and Temperature Drift of Scale Factor

6. Compensation

6.1. Thermal Drift

6.2. Self-Heating Drift

6.3. Improvement as Inclinometer

7. Discussion

7.1. Methods Comparison

7.2. Application of the Thermal Calibration Algorithm

7.3. Typical Drifts

7.4. Self-Heating

7.5. Computing Time

8. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| MEMS | MicroElectroMechanical System |

| TDB | Temperature Drift of Bias |

| TDSF | Temperature Drift of Scale Factor |

| MCU | Microcontroller Unit |

| DUT | Device Under Test |

Appendix A

| Second Order Surface | Proposed Method | Goodness of Fit | Relative Maximum | ||||

|---|---|---|---|---|---|---|---|

| , , | , , | TDB | TDSF | RMSE | Error | ||

| Case 1 | −1.64 | −70.7 | 0.9848 | 4.904 | 0.575% | ||

| Case 2 | −1.61 | −70.5 | 0.9893 | 4.045 | 0.557% | ||

| 354 | |||||||

| Case 3 | −0.86 | −183.8 | 0.9990 | 0.663 | 0.135% | ||

| Case 4 | −0.91 | −154.4 | 0.9936 | 1.789 | 0.237% | ||

Appendix A

- Place the accelerometer with a pitch and roll of approximately 35°. In this way, the accelerations in the 3 axes are about 577 mg, achieving the maximum study range for the three axes.

- Generate a temperature of 25 °C and record the acceleration measurements. This is the for each axis.

- Generate a thermal variation, for example, 20 °C.

- Use these new accelerations to compute the with Equation (11) for each axis.

- Without lowering the temperature, invert the accelerometer: pitch and roll angles at approximately −35°.

- Record acceleration.

- Generate again the temperature of 25 °C, these accelerations are .

- Use these accelerations to obtain the .

- is calculated as the difference of and divided between the difference of and (see Equation (A1)).

References

- Shaeffer, D.K. MEMS inertial sensors: A tutorial overview. IEEE Commun. Mag. 2013, 51, 100–109. [Google Scholar] [CrossRef]

- Wang, S.; Chen, C.; Ma, J. Accelerometer based transportation mode recognition on mobile phones. In Proceedings of the 2010 Asia-Pacific Conference on Wearable Computing Systems, Shenzhen, China, 17–18 April 2010; pp. 44–46. [Google Scholar]

- Sugimori, D.; Iwamoto, T.; Matsumoto, M. A study about identification of pedestrian by using 3-axis accelerometer. In Proceedings of the 2011 IEEE 17th International Conference on Embedded and Real-Time Computing Systems and Applications, Toyama, Japan, 28–31 August 2011; Volume 2, pp. 134–137. [Google Scholar]

- Feng, M.; Fukuda, Y.; Mizuta, M.; Ozer, E. Citizen sensors for SHM: Use of accelerometer data from smartphones. Sensors 2015, 15, 2980–2998. [Google Scholar] [CrossRef]

- Milne, D.; Le Pen, L.; Watson, G.; Thompson, D.; Powrie, W.; Hayward, M.; Morley, S. Proving MEMS technologies for smarter railway infrastructure. Procedia Eng. 2016, 143, 1077–1084. [Google Scholar] [CrossRef]

- Li, C.; Fernnandez-Steeger, T.M.; Link, J.A.B.; May, M.; Azzam, R. Use of MEMS accelerometers/inclinometers as a geotechnical monitoring method for ground subsidence. Acta Geodyn. Geomater. 2014, 11, 337–349. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, D.; Ayyub, B. An integrated risk sensing system for geo-structural safety. J. Rock Mech. Geotech. Eng. 2017, 9, 226–238. [Google Scholar] [CrossRef]

- Uchimura, T.; Towhata, I.; Wang, L.; Nishie, S.; Yamaguchi, H.; Seko, I.; Qiao, J. Precaution and early warning of surface failure of slopes using tilt sensors. Soils Found. 2015, 55, 1086–1099. [Google Scholar] [CrossRef]

- Bedon, C.; Bergamo, E.; Izzi, M.; Noè, S. Prototyping and validation of MEMS accelerometers for structural health monitoring—The case study of the Pietratagliata cable-stayed bridge. J. Sens. Actuator Netw. 2018, 7, 30. [Google Scholar] [CrossRef]

- Van Emmerik, T.; Steele-Dunne, S.; Hut, R.; Gentine, P.; Guerin, M.; Oliveira, R.S.; Wagner, J.; Selker, J.; Van de Giesen, N. Measuring tree properties and responses using low-cost accelerometers. Sensors 2017, 17, 1098. [Google Scholar] [CrossRef] [PubMed]

- STMicroelectronics. LIS3DSH MEMS Digital Output Motion Sensor: Ultra-Low-Power High-Performance Three-Axis “Nano” Accelerometer. 2017. Available online: https://cdn.sparkfun.com/assets/learntutorials/5/9/6/LIS3DHAppNoteDocID18198rev1.pdf (accessed on 3 March 2021).

- Ruzza, G.; Guerriero, L.; Revellino, P.; Guadagno, F.M. A Low-Cost Chamber Prototype for Automatic Thermal Analysis of MEMS IMU Sensors in Tilt Measurements Perspective. Sensors 2019, 19, 2705. [Google Scholar] [CrossRef]

- He, L.; Xu, Y.P.; Qiu, A. Folded silicon resonant accelerometer with temperature compensation. In Proceedings of the 2004 IEEE SENSORS, Vienna, Austria, 24–27 October 2004; pp. 512–515. [Google Scholar]

- Tan, S.S.; Liu, C.Y.; Yeh, L.K.; Chiu, Y.H.; Lu, M.S.C.; Hsu, K.Y. Design of low-noise CMOS MEMS accelerometer with techniques for thermal stability and stable DC biasing. In Proceedings of the IEEE Custom Integrated Circuits Conference 2010, San Jose, CA, USA, 19–22 September 2010; pp. 1–4. [Google Scholar]

- Dong, Y.; Zwahlen, P.; Nguyen, A.; Frosio, R.; Rudolf, F. Ultra-high precision MEMS accelerometer. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference, Beijing, China, 5–9 June 2011; pp. 695–698. [Google Scholar]

- Coultate, J.K.; Fox, C.H.; McWilliam, S.; Malvern, A.R. Application of optimal and robust design methods to a MEMS accelerometer. Sens. Actuators A Phys. 2008, 142, 88–96. [Google Scholar] [CrossRef]

- He, J.; Zhou, W.; Yu, H.; He, X.; Peng, P. Structural designing of a MEMS capacitive accelerometer for low temperature coefficient and high linearity. Sensors 2018, 18, 643. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Rhim, J. Temperature compensation method for the resonant frequency of a differential vibrating accelerometer using electrostatic stiffness control. J. Micromechan. Microeng. 2012, 22, 095016. [Google Scholar] [CrossRef]

- Ko, H.; Cho, D.-i.D. Highly programmable temperature compensated readout circuit for capacitive microaccelerometer. Sens. Actuators A Phys. 2010, 158, 72–83. [Google Scholar] [CrossRef]

- Aggarwal, P.; Syed, Z.; Niu, X.; El-Sheimy, N. A standard testing and calibration procedure for low cost MEMS inertial sensors and units. J. Navig. 2008, 61, 323. [Google Scholar] [CrossRef]

- Liu, M.; Chi, B.; Liu, Y.; Dong, J. A closed-loop MEMS accelerometer with capacitive sensing interface ASIC. Int. J. Electron. 2013, 100, 21–35. [Google Scholar] [CrossRef]

- Yang, D.; Woo, J.K.; Lee, S.; Mitchell, J.; Challoner, A.D.; Najafi, K. A micro oven-control system for inertial sensors. J. Microelectromechan. Syst. 2017, 26, 507–518. [Google Scholar] [CrossRef]

- Ruzza, G.; Guerriero, L.; Revellino, P.; Guadagno, F.M. Thermal compensation of low-cost MEMS accelerometers for tilt measurements. Sensors 2018, 18, 2536. [Google Scholar] [CrossRef]

- Niu, X.; Li, Y.; Zhang, H.; Wang, Q.; Ban, Y. Fast thermal calibration of low-grade inertial sensors and inertial measurement units. Sensors 2013, 13, 12192–12217. [Google Scholar] [CrossRef]

- Zhu, M.; Pang, L.; Xiao, Z.; Shen, C.; Cao, H.; Shi, Y.; Liu, J. Temperature Drift Compensation for High-G MEMS Accelerometer Based on RBF NN Improved Method. Appl. Sci. 2019, 9, 695. [Google Scholar] [CrossRef]

- He, J.; Xie, J.; He, X.; Du, L.; Zhou, W. Analytical study and compensation for temperature drifts of a bulk silicon MEMS capacitive accelerometer. Sens. Actuators A Phys. 2016, 239, 174–184. [Google Scholar] [CrossRef]

- Briffa, A.; Gatt, E.; Micallef, J.; Grech, I.; Casha, O.; Darmanin, J.M. Area minimization of a three-axis separate mass capacitive accelerometer using the ThELMA process. In Proceedings of the Eurocon 2013, Zagreb, Croatia, 1–4 July 2013; pp. 2094–2099. [Google Scholar]

- Wei, R.; Tao, Z.; Hai-yun, Z.; Lei-gang, W.; Yong-jie, Z.; Meng-kai, L.; Hui-feng, L.; Jing-wei, S. A research on calibration of low-precision MEMS inertial sensors. In Proceedings of the 2013 25th Chinese Control and Decision Conference (CCDC), Guiyang, China, 25–27 May 2013; pp. 3243–3247. [Google Scholar]

- Frosio, I.; Pedersini, F.; Borghese, N.A. Autocalibration of triaxial MEMS accelerometers with automatic sensor model selection. IEEE Sens. J. 2012, 12, 2100–2108. [Google Scholar] [CrossRef]

- Sipos, M.; Paces, P.; Rohac, J.; Novacek, P. Analyses of triaxial accelerometer calibration algorithms. IEEE Sens. J. 2011, 12, 1157–1165. [Google Scholar] [CrossRef]

- Qian, J.; Fang, B.; Yang, W.; Luan, X.; Nan, H. Accurate tilt sensing with linear model. IEEE Sens. J. 2011, 11, 2301–2309. [Google Scholar] [CrossRef]

- Fisher, C.J. Using an Accelerometer for Inclination Sensing. AN-1057, Application Note, Analog Devices. 2010. Available online: https://www.analog.com/en/app-notes/an-1057.html# (accessed on 3 March 2021).

- Łuczak, S. Guidelines for tilt measurements realized by MEMS accelerometers. Int. J. Precis. Eng. Manuf. 2014, 15, 489–496. [Google Scholar] [CrossRef]

- Liu, G.; Yang, F.; Bao, X.; Jiang, T. Robust optimization of a MEMS accelerometer considering temperature variations. Sensors 2015, 15, 6342–6359. [Google Scholar] [CrossRef] [PubMed]

- Dai, G.; Li, M.; He, X.; Du, L.; Shao, B.; Su, W. Thermal drift analysis using a multiphysics model of bulk silicon MEMS capacitive accelerometer. Sens. Actuators A Phys. 2011, 172, 369–378. [Google Scholar] [CrossRef]

- Li, H.; Zhai, Y.; Tao, Z.; Gui, Y.; Tan, X. Thermal drift investigation of an SOI-based MEMS capacitive sensor with an asymmetric structure. Sensors 2019, 19, 3522. [Google Scholar] [CrossRef]

- Pieniazek, J.; Ciecinski, P. Thermal hysteresis in inertial sensors. In Proceedings of the 2020 IEEE 7th International Workshop on Metrology for AeroSpace (MetroAeroSpace), Pisa, Italy, 22–24 June 2020; pp. 54–59. [Google Scholar]

| Parameter | Typical Value |

|---|---|

| Resolution | 16 bits |

| Sensitivity | 0.06 mg |

| Output data rate | 3.125 Hz to 1.6 kHz |

| Sensitivity change vs temperature () | 0.01%/°C |

| Typical zero-g level offset accuracy | ±40 mg |

| Zero-g level change vs. temperature () | ±0.5 mg/°C |

| Acceleration noise density (Data Rate = 100 Hz) | 150 μg/ |

| Register | Value (HEX) | Details |

|---|---|---|

| CTRL_REG4 (20 h) | 17 | ODR: 3.125 Hz. All axes active |

| CTRL_REG5 (24 h) | C0 | Antialiasing: 50 Hz. FS: ±2 g. No self-test. 4-wire SPI |

| X | Y | Z | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Time | Avg. | Worst | C.U. | Avg. | Worst | C.U. | Avg. | Worst | C.U. |

| 0–1 h | 1.24 | 3.43 | 2.31 | 1.68 | 2.21 | 4.79 | 1.18 | 2.75 | 3.58 |

| 1–3 h | 0.39 | 1.15 | 0.35 | 0.42 | 0.89 | 0.83 | 0.46 | 1.13 | 0.63 |

| 3–5 h | 0.20 | 0.55 | 0.06 | 0.23 | 0.48 | 0.12 | 0.28 | 0.81 | 0.12 |

| 5–10 h | 0.24 | 0.34 | 0.01 | 0.16 | 0.33 | 0.10 | 0.40 | 0.58 | 0.24 |

| 10–20 h | 0.10 | 0.25 | 0.07 | 0.13 | 0.21 | 0.02 | 0.16 | 0.33 | 0.10 |

| X | Y | Z | ||||

|---|---|---|---|---|---|---|

| DUT | Standard | Max | Standard | Max | Standard | Max |

| Deviation | Deviation | Deviation | Deviation | Deviation | Deviation | |

| 1 | 0.221 | 1.704 | 0.201 | 1.305 | 0.297 | 2.031 |

| 2 | 0.227 | 1.619 | 0.196 | 1.357 | 0.245 | 1.802 |

| 3 | 0.193 | 1.333 | 0.170 | 1.245 | 0.242 | 1.736 |

| 4 | 0.232 | 1.699 | 0.187 | 1.292 | 0.247 | 1.859 |

| 5 | 0.176 | 1.240 | 0.160 | 0.980 | 0.267 | 1.592 |

| Control | 0.224 | 1.678 | 0.216 | 1.445 | 0.261 | 1.699 |

| TDB (mg/°C) | TDSF (ppm/°C) | |||||

|---|---|---|---|---|---|---|

| DUT | X | Y | Z | X | Y | Z |

| 1 | 1.26 | 0.76 | −1.32 | −118 | −44 | −34 |

| 2 | 0.09 | 0.31 | 0.12 | −42 | −103 | −188 |

| 3 | 0.3 | −0.22 | −0.3 | −107 | −188 | −104 |

| 4 | −0.44 | 0.19 | −0.61 | −128 | −277 | −60 |

| 5 | 0.39 | −0.08 | −0.72 | −398 | −65 | −169 |

| Control | −1.18 | −0.21 | −0.81 | −134 | −46 | −226 |

| X | Y | Z | |||||||

|---|---|---|---|---|---|---|---|---|---|

| DUT | Uncomp. | Comp. | Impr. | Uncomp. | Comp. | Impr. | Uncomp. | Comp. | Impr. |

| 1 | 4.66 | 0.77 | 83.48% | 2.99 | 1.91 | 36.12% | 4.49 | 0.63 | 85.97% |

| 2 | 0.92 | 1.04 | −13.04% | 1.56 | 0.34 | 78.21% | 0.72 | 0.77 | −6.94% |

| 3 | 2.49 | 1.26 | 49.40% | 2.08 | 1.51 | 27.40% | 2.52 | 1.28 | 49.21% |

| 4 | 1.54 | 0.44 | 71.43% | 1.78 | 1.61 | 9.55% | 2.38 | 1.08 | 54.62% |

| 5 | 2.28 | 0.63 | 73.68% | 0.84 | 0.77 | 8.33% | 3.47 | 1.95 | 39.77% |

| Control | 5.51 | 0.69 | 87.48% | 1.96 | 1.88 | 4.08% | 3.21 | 0.68 | 78.82% |

| Avg. | 2.90 | 0.80 | 72.41% | 1.87 | 1.34 | 28.46% | 2.80 | 1.09 | 61.11% |

| X | Y | Z | |||||||

|---|---|---|---|---|---|---|---|---|---|

| DUT | Uncomp. | Comp. | Impr. | Uncomp. | Comp. | Impr. | Uncomp. | Comp. | Impr. |

| 1 | 17.63 | 4.63 | 73.74% | 18.51 | 13.81 | 25.39% | 18.44 | 4.26 | 76.90% |

| 2 | 5.41 | 6.31 | −16.64% | 6.08 | 1.92 | 68.42% | 4.07 | 3.78 | 7.13% |

| 3 | 11.07 | 6.26 | 43.45% | 11.28 | 8.41 | 25.44% | 11.21 | 6.25 | 44.25% |

| 4 | 7.12 | 3.41 | 52.11% | 11.10 | 10.66 | 3.96% | 10.19 | 4.77 | 53.19% |

| 5 | 9.44 | 3.48 | 63.14% | 4.96 | 4.68 | 5.65% | 13.27 | 7.47 | 43.71% |

| Control | 23.74 | 4.45 | 81.26% | 10.79 | 10.39 | 3.71% | 13.06 | 3.47 | 73.43% |

| Avg. | 12.40 | 4.76 | 61.64% | 10.45 | 8.31 | 20.49% | 11.71 | 5.00 | 57.29% |

| X | Y | Z | |||||||

|---|---|---|---|---|---|---|---|---|---|

| DUT | Uncomp. | Comp. | Impr. | Uncomp. | Comp. | Impr. | Uncomp. | Comp. | Impr. |

| 1 | 1.636 | 0.896 | 45.2% | 1.220 | 0.760 | 37.7% | −1.572 | −0.804 | 48.9% |

| 2 | −0.088 | −0.112 | −27.3% | 0.344 | 0.176 | 48.8% | −0.044 | −0.008 | 81.8% |

| 3 | 0.280 | 0.100 | 64.3% | −0.628 | −0.520 | 17.2% | −0.244 | 0.020 | 91.8% |

| 4 | −0.364 | −0.108 | 70.3% | 0.136 | 0.024 | 82.4% | −1.344 | −0.956 | 28.9% |

| 5 | 0.652 | 0.420 | 35.6% | −0.536 | −0.476 | 11.2% | −0.724 | −0.132 | 81.8% |

| Control | −0.716 | 0.052 | 92.7% | −1.268 | −1.116 | 12.0% | −1.040 | −0.636 | 38.8% |

| Avg. | 0.623 | 0.281 | 54.8% | 0.689 | 0.512 | 25.7% | 0.828 | 0.426 | 48.6% |

| Pitch | Roll | |||||

|---|---|---|---|---|---|---|

| DUT | Uncomp. | Comp. | Impr. | Uncomp. | Comp. | Impr. |

| 1 | 0.268 | 0.040 | 85.0% | 0.164 | 0.091 | 42.2% |

| 2 | 0.026 | 0.036 | −36.9% | 0.084 | 0.016 | 80.0% |

| 3 | 0.119 | 0.058 | 50.7% | 0.111 | 0.071 | 35.6% |

| 4 | 0.085 | 0.019 | 77.6% | 0.081 | 0.067 | 17.1% |

| 5 | 0.104 | 0.027 | 73.7% | 0.035 | 0.023 | 33.3% |

| Control | 0.302 | 0.036 | 88.1% | 0.076 | 0.085 | −11.8% |

| Pitch | Roll | |||||

|---|---|---|---|---|---|---|

| DUT | Uncomp. | Comp. | Impr. | Uncomp. | Comp. | Impr. |

| 1 | 0.953 | 0.194 | 79.5% | 0.824 | 0.529 | 35.7% |

| 2 | 0.142 | 0.173 | −21.9% | 0.304 | 0.085 | 72.0% |

| 3 | 0.507 | 0.274 | 45.9% | 0.539 | 0.356 | 33.9% |

| 4 | 0.330 | 0.110 | 66.6% | 0.393 | 0.351 | 10.6% |

| 5 | 0.405 | 0.140 | 65.4% | 0.158 | 0.129 | 18.1% |

| Control | 1.213 | 0.177 | 85.4% | 0.381 | 0.465 | −22.0% |

| MCU | Proposed Method | Second Order Surface | Third Order Curve |

|---|---|---|---|

| ATmega328P | 65.6 μs | 117.6 μs | 63.7 μs |

| ATSAMD21G18A | 27.7 μs | 49.1 μs | 34.1 μs |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martínez, J.; Asiain, D.; Beltrán, J.R. Lightweight Thermal Compensation Technique for MEMS Capacitive Accelerometer Oriented to Quasi-Static Measurements. Sensors 2021, 21, 3117. https://doi.org/10.3390/s21093117

Martínez J, Asiain D, Beltrán JR. Lightweight Thermal Compensation Technique for MEMS Capacitive Accelerometer Oriented to Quasi-Static Measurements. Sensors. 2021; 21(9):3117. https://doi.org/10.3390/s21093117

Chicago/Turabian StyleMartínez, Javier, David Asiain, and José Ramón Beltrán. 2021. "Lightweight Thermal Compensation Technique for MEMS Capacitive Accelerometer Oriented to Quasi-Static Measurements" Sensors 21, no. 9: 3117. https://doi.org/10.3390/s21093117

APA StyleMartínez, J., Asiain, D., & Beltrán, J. R. (2021). Lightweight Thermal Compensation Technique for MEMS Capacitive Accelerometer Oriented to Quasi-Static Measurements. Sensors, 21(9), 3117. https://doi.org/10.3390/s21093117