3.3. Definition of OSP Problem and Selected Methods

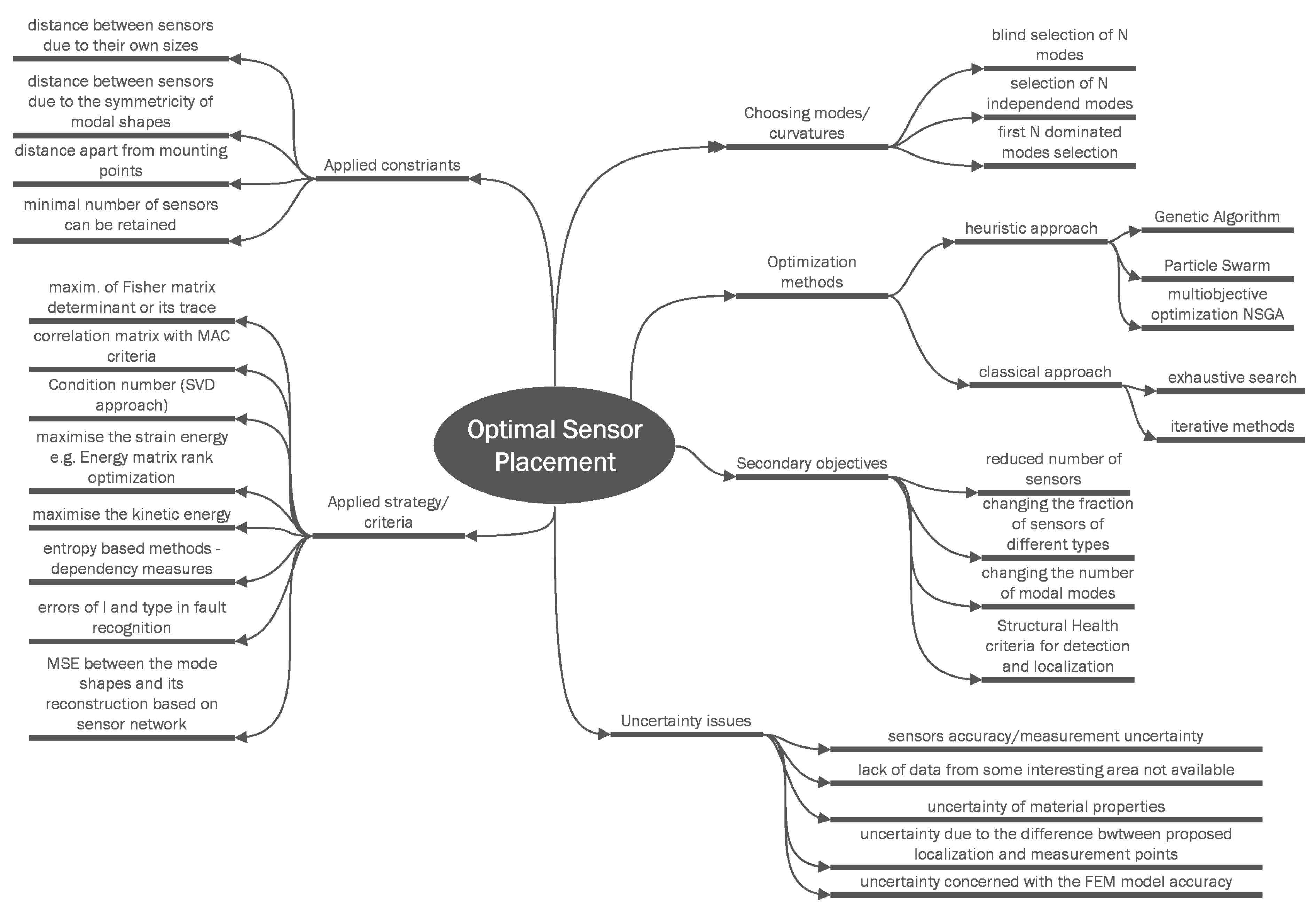

The data-driven structural health monitoring system is dependent on the data provided by the distributed sensors. The evaluation of the state of the composite plate, the detection of damage, and the information on its localization depend on the quality of the data recorded by the sensor network. The sensor network is considered to be a limited number of sensors distributed in a determined localization of the composite plate. The goal of the optimal sensor placement problem is to treat the number of sensors and its localization as design variables to obtain the optimal layout, taking into account the different issues presented in

Figure 1, such as applied strategies, constraints, etc.

In this study, the minimum number of sensors is considered to minimize the cost of sensor deployment. Another important factor from the point of view of further application of an SHM system is the added mass from sensor deployment, which, in the case of aircraft structures, has a significant impact, even if sensors are lightweight. The influence of deployed sensors on the take-off weight of an aircraft and further economic consequences are discussed in [

55]. In addition to that, the number of modes of composite plate is also of interest because sensors should deliver the most relevant dynamic information about the measured structure with limited data processing. As input data, the strains of the selected

ith-mode shape in X-direction

, and the Y-direction

are treated as independent input data set, where x and y are coordinates that localize the strains on the plate. Normally, the data take the form of a modal matrix, where the rows contain subsequent values of the strains for X, and then the localizations of Y and columns are related to subsequent shape modes. In the considered case, the columns that represent the modes are ordered according to the highest amplitude of the mode obtained from the experimental frequency response function, so the first column is connected with the highest energy modal shape.

In this study, the following optimal sensor placement methods and their variants are considered:

- (1)

Method A1. In this method, the input data contain absolute strain values at each grid point for the appropriate numerically calculated modes that are summed without normalization (each shape mode has a different weight).

- (2)

Method A2. Absolute strain values at each grid point for appropriate numerically calculated modes are normalized with respect to the largest value of the particular mode and then summed (all modes are equally weighted). In methods A1 and A2, the sum of the strain values for each grid point is sorted in a vector in descending order from the highest value. The algorithm searches for the next largest strain value and checks the eligibility for sensor placement taking into account the following constraints:

- a.

Distance from the edge of the plate or the edge of the clamp ≥ 5 mm due to the size of the strain sensors;

- b.

Distance between any two sensors > 127.5 mm (the mode shapes are symmetric and the summed absolute strain values are the same in four imaginary quadrants of the plate, so the idea is to place the sensors in different quadrants so that they are sensitive to all possible damage locations: .

- (3)

Method A3 is a modified version of an effective independence method proposed in [

56], which is still widely applied in many OSP issues [

24,

27,

36,

42]. This modification allows one to apply the constraint distance between any two sensors. The pseudocode of this method is as follows.

Stage I Remove any candidate sensor points that cannot be measured (e.g., areas under clamps, edges) from the set of possible candidate point localization.

Stage II Repeat until the required number of candidate points is obtained:

Create Fisher Information Matrix FIM for all available candidate points;

Create orthogonal projection matrix E;

Analyze the trace of the E matrix and find the index of the minimum value;

Store the history about the removed candidate points;

Remove the candidate point with the minimum value from the trace from the FIM matrix;

Create the set of candidate points.

Stage III Repeat until the constraint about the required distance between the candidate points in the set is not met:

Find the candidate points that break the distance constraint with other points;

Replace the previously selected candidate points into other candidate points using the points from the stored history of the previously removed points. For this purpose, use Last Input First Output history sequence queue.

Methods A1, A2, and A3 treat the input data strains and as independent. It results in two separate sensor networks for x-strain sensors and y-strain sensors. Because in some cases the information from strains in the X direction can be more informative than that from strains in Y direction or vice versa, these constraints have been loosen, and the next three variants of the above A1, A2, and A3 methods are also considered. Methods B1, B2, and B3 refer consequently to previous methods A1, A2, and A3, but the input data of the strains from the ith-mode shapes in X-direction and the Y-direction are treated commonly as one common data set. This results in a sensor network that could have a different fraction of sensors in the X and Y directions.

As already mentioned, the goal of the OSP is not only to determine the distribution of the sensor localization on the composite plate but also to determine the appropriate number of required sensor number and used mode shapes. To evaluate this, different metrics can be applied for this purpose. In the considered study, the following metrics have been applied [

24,

28,

38,

51]:

where

are indexes of modes,

refers to the triangular matrix,

is the number of modes, and

is a matrix of modal assurance criteria defined by:

where

are vectors of

i or

j modes with strain values of selected sensor networks.

According to the above definitions, contains the root means square of the off-diagonal elements of the triangular matrix. The improved quality of the sensor network is indicated by low off-diagonal terms.

This criterion can take the form of a relative criterion with the reference point related to the full modal matrix, which means that it can refer to all available candidate points and the maximum number of observable modes:

- (b)

Fisher matrix determinant:

where

is the modal matrix of the selected sensor network. This value decreases with the reduction in the number of candidate points, but algorithms based on this criterion usually try to maintain the highest possible value of this determinant for the finally reduced modal matrix for the obtained sensor network:

where

svd represents the singular value decomposition operation, and

and

represent the maximum and minimum singular values from the modal matrix of considered sensor network. The low value of the condition number indicates a better configuration of the sensor network.

The presented indices allow the performance of different sensor networks to be evaluated, although the high value of one index does not have to be confirmed by other indices: examples of which can be found in [

25,

51]. Because of this, the following aggregation function based on the Hamacher function [

57] has been proposed to support the selection of sensor network configuration:

where

is a t-norm and

is a t-conorm of the Hamacher function [

57], and

correspond, e.g., to RMS MAC and det(FIM), respectively.

is a parameter that defines how strictly t-norm and t-conorm are decreasing and increasing, respectively.

The aggregation functions require the use of normalized inputs of indices to range from zero to one. Finally, normalized det(FIM) has been applied, so the total distribution of the value of the metrics along the considered range of sensor number and mode number sum to one. Because the optimal values for RMS MAC and CN should be minimalized, the complements of normalized values, e.g., , were used as input values for the aggregation function.

Due to the symmetricity and associativity [

57] of the Hamacher function, the number of used metrics can be added to the evaluation of the performance of the candidate sensor networks. In the same manner, other t-norms and t-conorms family functions can be applied for this purpose.

3.4. Evaluation and Selection of Sensor Networks

Using the methods presented in

Section 3.3 different candidate sensors networks can be obtained. To select appropriate design variables of the sensor networks, the number of sensors and used modes was calculated. This resulted in 251 sensor networks candidates. For methods A1, A2, and A3, the number of sensors changed in a range of 1 to 5 and the number of modes changed from 2 to 7. For methods B1, B2, and B3 the number of modes was changed in the same range as for A type methods. The number of sensors for B1, B2, and B3 changed from 2 to 10, finally providing the opportunity to obtain the same total number of the sensors, as in the case of A1, A2, and A3 methods where the number of sensors in the

x and

y directions independently was limited to 5 (and totally to 10). Next, all candidate sensor obtained with different methods were evaluated using different metrics shown in

Section 3.3.

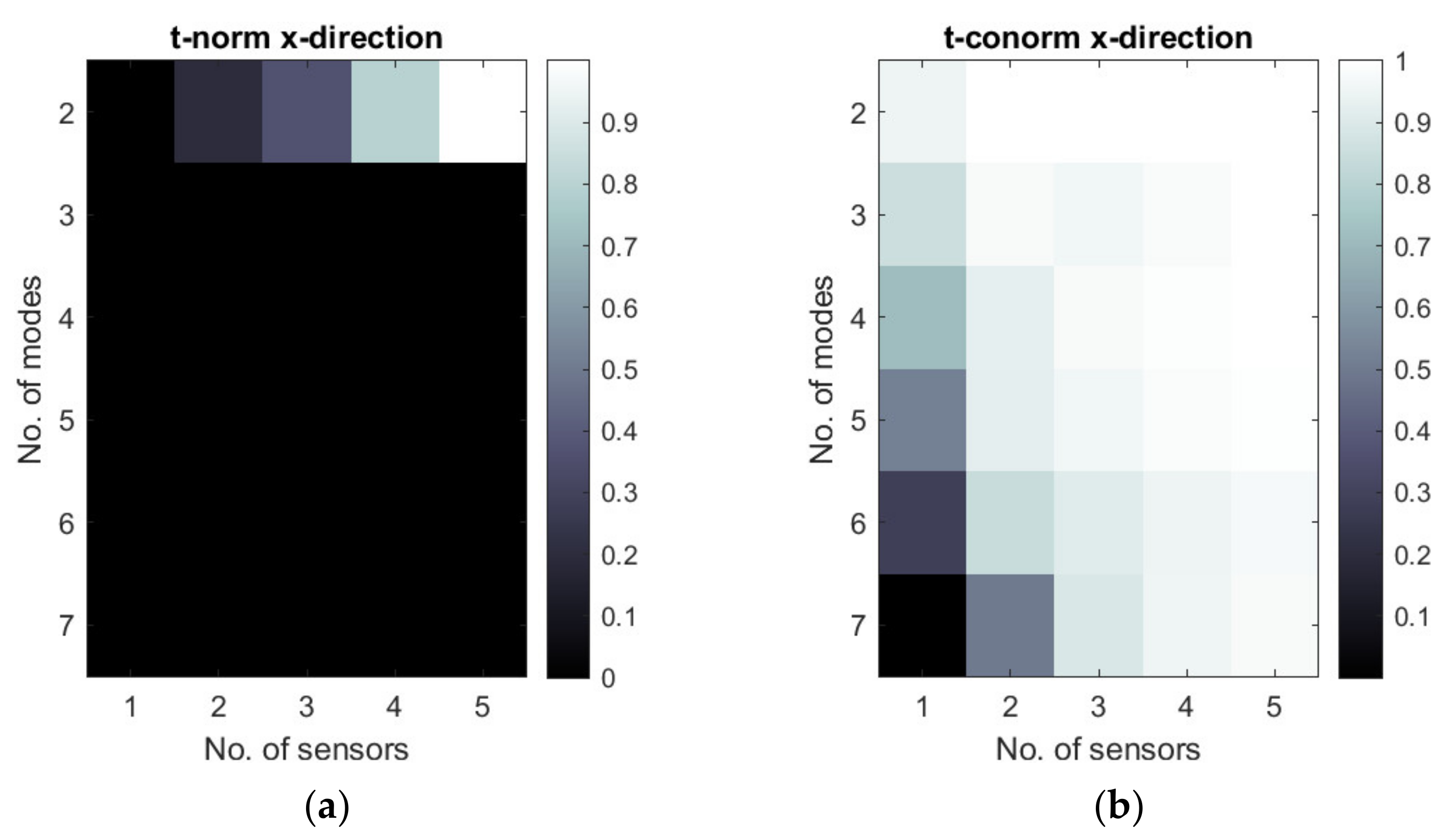

Figure 9 and

Figure 10 show selected distributions of different normalized metrics obtained for different methods.

Figure 11,

Figure 12 and

Figure 13 show the selected examples of the map of t-norms and t-conorms of the Hamacher aggregation function for different methods and with the application of different normalized metrics number. For example,

Figure 11 and

Figure 12 show that on the basis of the RMS MAC and Fisher determinant using t-conorms, the appropriate sensors network for the placement of y- sensors obtained using the A1 method can be obtained using 2 dominated modes and 2–5 sensors and also for 5 modes and 4 sensors. Similarly, appropriate sensor networks obtained for the A3 method in y-strain sensors in the sense of the proposed aggregation function can be obtained for 2 modes and 2–5 sensors, as well as for 3–4 modes and 5 sensors.

Figure 13 shows that, for method B3, the t-norm based on all 3 metrics can lead to a wider set of allowable sensor networks. The t-conorms presented in

Figure 11,

Figure 12 and

Figure 13 usually suggest solutions with a larger number of sensors, but they are very limited in the number of modes used.

The above presented Figures of maps of t-conorms and t-norms can be helpful in the selection of appropriate parameters of sensor networks for the SHM system. In the considered research study, mainly RMS MAC and Fisher Determinant were used as inputs for the t-norm and t-conorm functions. Next, the set of allowable (mainly for t-conorms) set of allowable sensor networks can be extended/reduced on the basis of Condition Number and associativity of aggregation functions if necessary. The allowable set of sensor networks obtained using the A1, A2, and A3 method is presented in

Table 3. This table presents the localization of the individual X and Y strain sensors in the localization together with information on the number of sensors used in the X (sX) and Y directions (sY), and the number of dominant modes (mX and mY) used to establish the considerer sensor network. Similarly, the sensor networks obtained using the B1, B2, and B3 methods are presented in

Table 4. In this table, the sensor networks SN#4, SN#5, and SN#6 were obtained using the B1, B2, and B3 method correspondingly. Columns nS and sM present the number of sensors used and the modes used for the considered sensor networks.

Since different metrics of sensors networks can lead to quite a different set of possible sensor networks, the use of the t-norm is not always the right choice, especially if the number of used metrics is large—this may lead to the empty set of solutions. The reason is that the t-norm has properties of the type of conjunctive function. In this case, the t-conorm can lead to a wider set of possible configurations of sensor networks in the sense of the number and modes.

Table 5 and

Table 6 present selected sensor networks obtained using different methods using t-conorms maps. Because t-conorms sensors networks usually also contain the sensor networks suggested by the t-norm, the choice from the set of possible solutions for the t-conorm was restricted to the cases with the minimum number of used sensors. The results of selected sensor networks are shown in

Table 5 for the A1, A2, and A3 methods, as well as in

Table 6 for the B1, B2, and B3 methods, adequately.

The selected sensor networks specific for the considered cases are visualized in

Figure 14,

Figure 15 and

Figure 16. They are only a graphical representation of the results shown in

Table 3,

Table 4,

Table 5 and

Table 6. The background of these figures shows the specific sum of the strains obtained for the number of modes in individual cases. In

Figure 14 and

Figure 16, sensor positions are shown separately to indicate that the sensor network comprises the composition of the optimal sensor network for the x-strain sensor and the y-strain sensors separately. In

Figure 15, the sensor network is presented on one map to distinguish that the optimal sensor algorithm has used x-strains and y-strains commonly (methods B1, B2, and B3). To distinguish the sensors direction of the used in this case, X and Y labels were used in

Figure 14.