Construction and Evaluation of an Optical Medium Voltage Transducer Module Aimed at a 132 kV Optical Voltage Sensor for WAMPAC Systems

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sensor Voltage Requirements

2.2. Fiber Bragg Gratings Technology

2.3. Medium Voltage Transducer

2.4. Sensor Construction

2.5. Capacitive Voltage Divider

3. Results

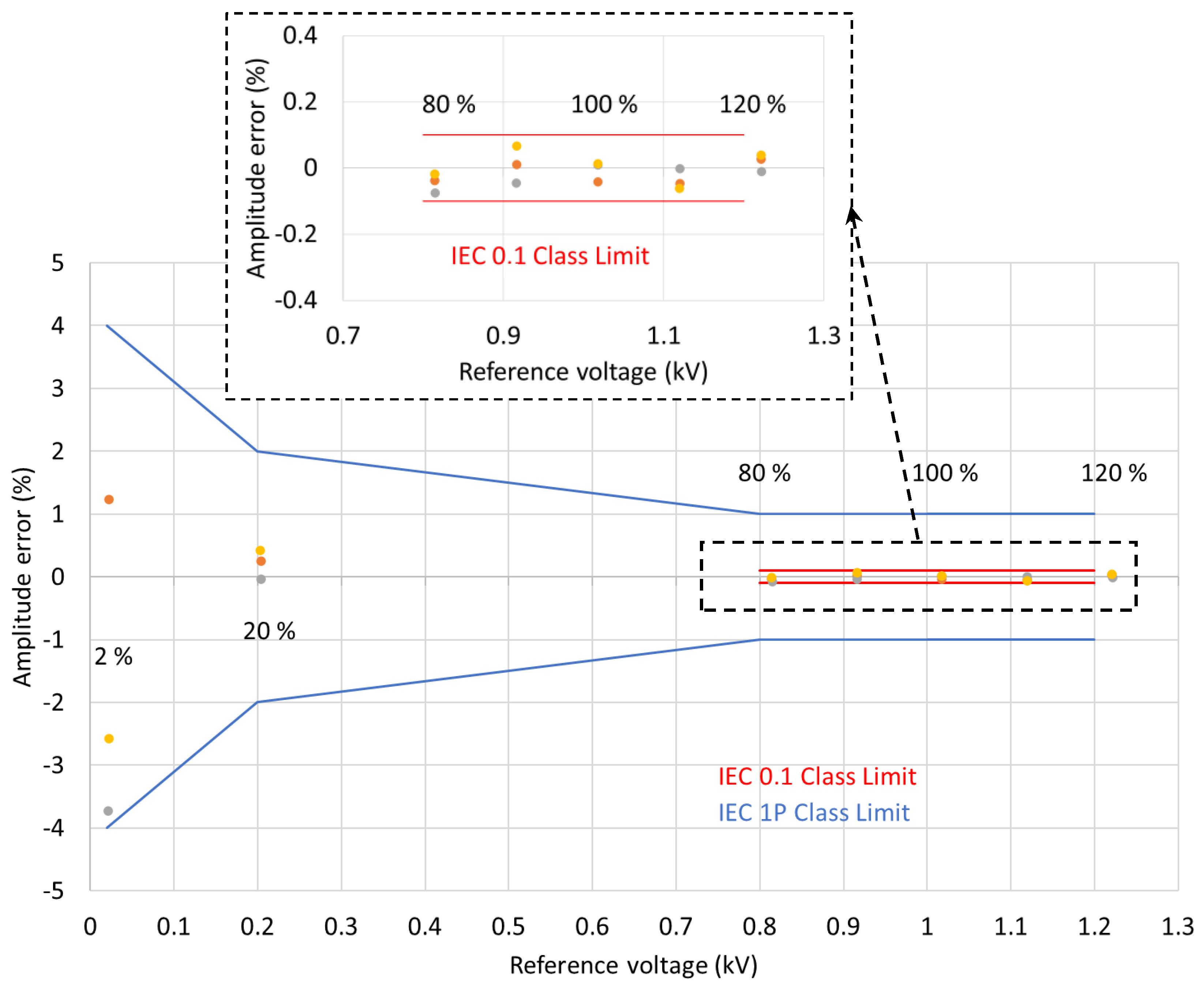

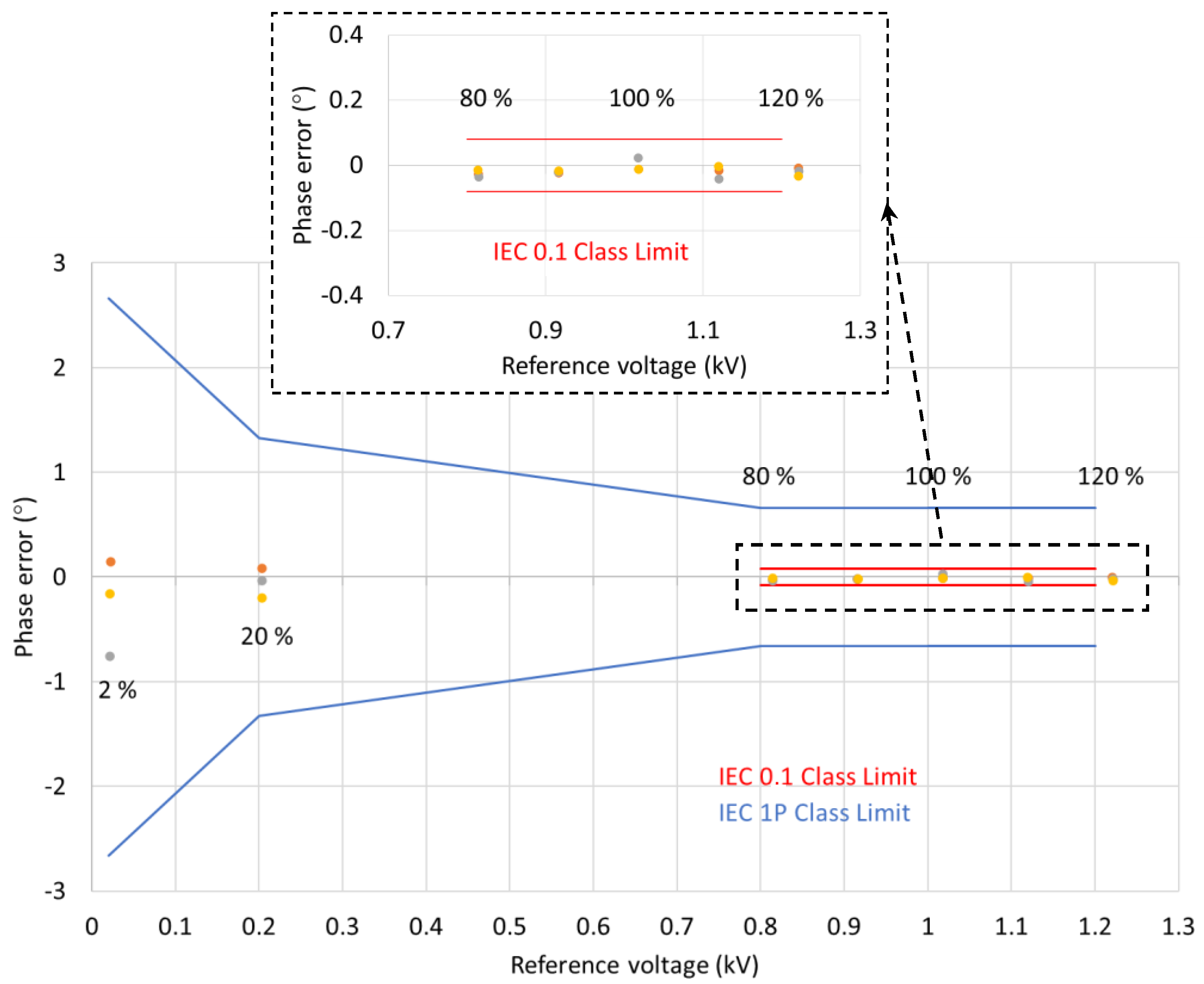

3.1. Accuracy Requirements

3.2. Experimental Setup

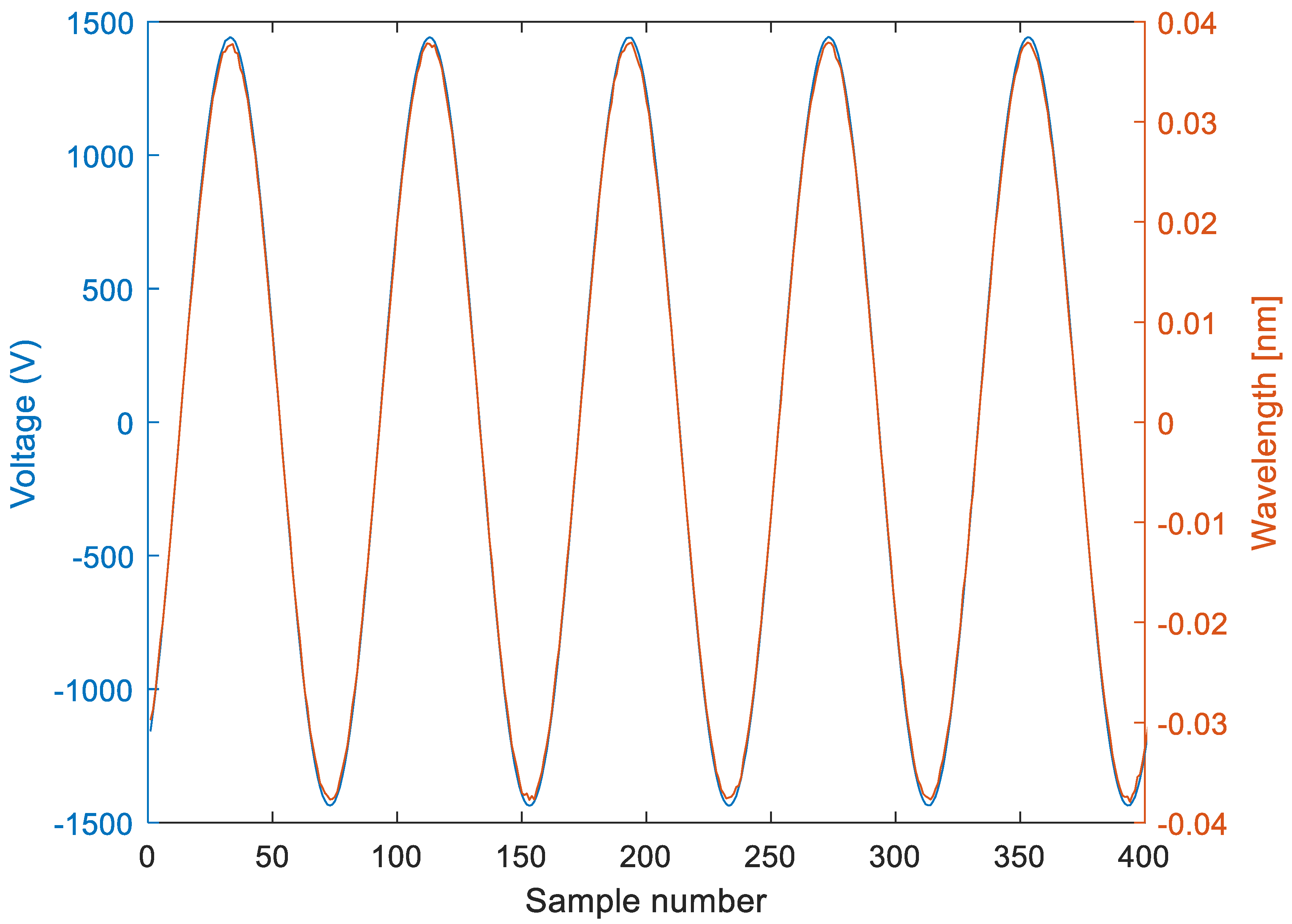

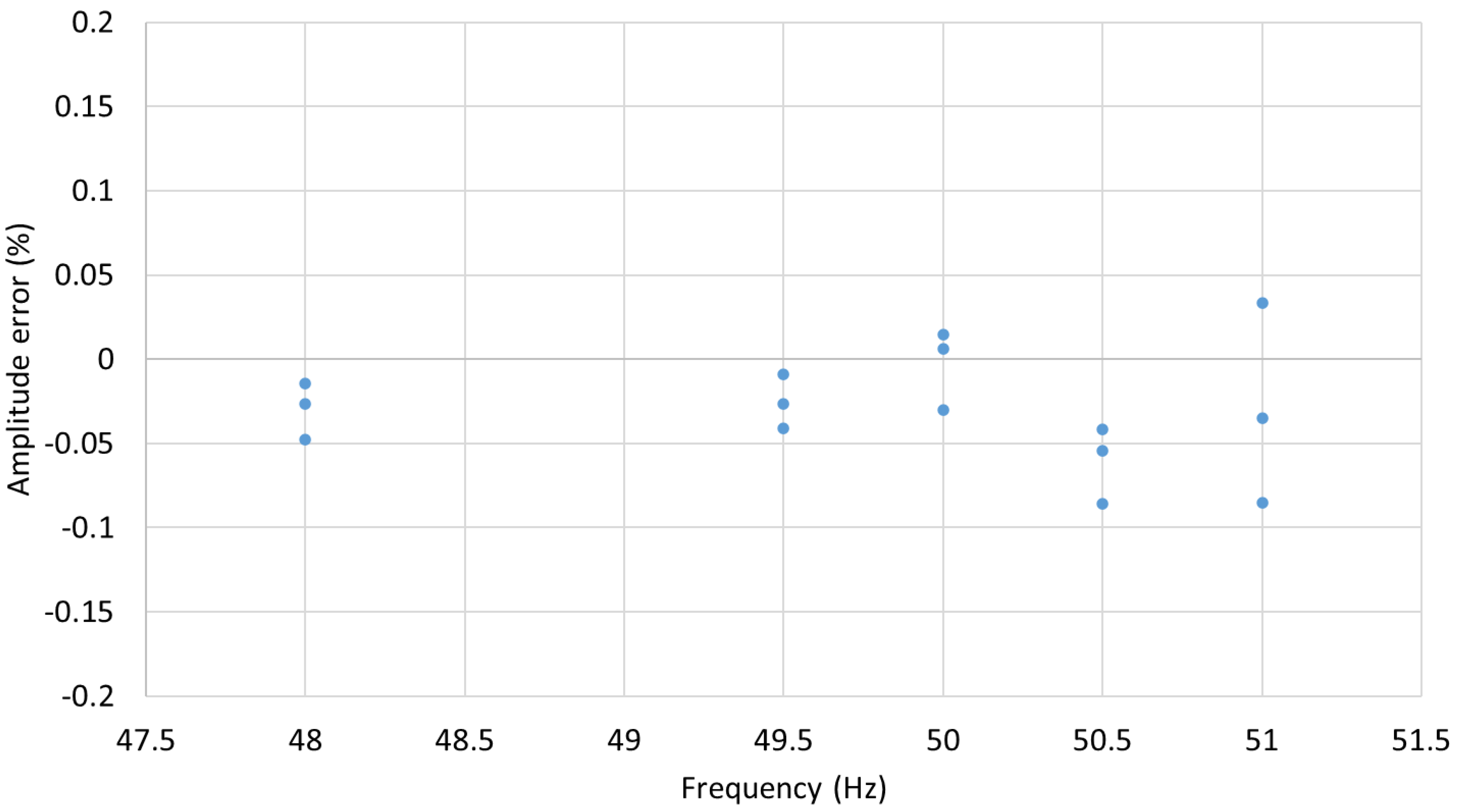

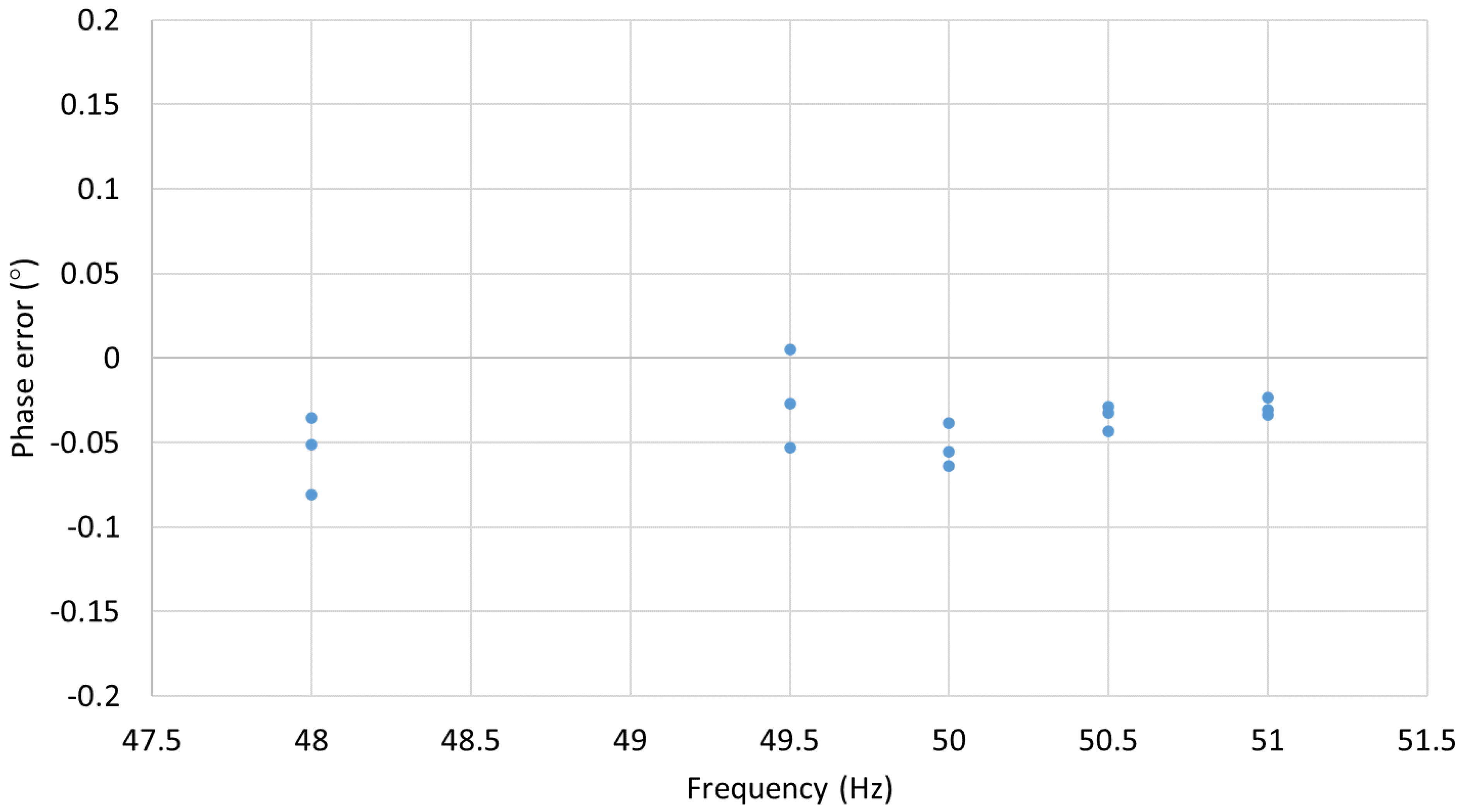

3.3. Sensor Characterization and Accuracy Testing

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- De Vita, A.; Tsiropoulos, I.; Capros, P. ASSET Study on Energy Outlook Analysis; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Hojabri, M.; Dersch, U.; Papaemmanouil, A.; Bosshart, P. A Comprehensive Survey on Phasor Measurement Unit Applications in Distribution Systems. Energies 2019, 12, 4552. [Google Scholar] [CrossRef] [Green Version]

- Oettinger, G.H. Roadmap 2050; European Commission: Brussels, Belgium, 2011. [Google Scholar]

- Lee, J.W.; Kim, W.K.; Han, J.; Jang, W.H.; Kim, C.H. Fault area estimation using traveling wave for wide area protection. J. Mod. Power Syst. Clean Energy 2016, 4, 478–486. [Google Scholar] [CrossRef] [Green Version]

- Terzija, V.; Valverde, G.; Cai, D.; Regulski, P.; Madani, V.; Fitch, J.; Skok, S.; Begovic, M.M.; Phadke, A. Wide-Area Monitoring, Protection, and Control of Future Electric Power Networks. Proc. IEEE 2011, 99, 80–93. [Google Scholar] [CrossRef]

- Phadke, A.G.; Wall, P.; Ding, L.; Terzija, V. Improving the performance of power system protection using wide area monitoring systems. J. Mod. Power Syst. Clean Energy 2016, 4, 319–331. [Google Scholar] [CrossRef] [Green Version]

- Zobaa, V. (Ed.) Wide Area Monitoring, Protection and Control Systems: The Enabler for Smarter Grids; Institution of Engineering and Technology: London, UK, 2016; ISBN 9781849198301. [Google Scholar]

- Wall, P.; Dattaray, P.; Jin, Z.; Mohapatra, P.; Yu, J.; Wilson, D.; Hay, K.; Clark, S.; Osborne, M.; Ashton, P.M.; et al. Deployment and demonstration of wide area monitoring system in power system of Great Britain. J. Mod. Power Syst. Clean Energy 2016, 4, 506–518. [Google Scholar] [CrossRef] [Green Version]

- Gan, C.K.; Silva, N.; Pudjianto, D.; Strbac, G.; Ferris, R.; Foster, I.; Aten, M. Evaluation of alternative distribution network design strategies. In Proceedings of the IET Conference Publications, Edinburgh, UK, 28–30 April 2009; IET: London, UK, 2009; p. 690. [Google Scholar]

- Fusiek, G.; Niewczas, P. Conceptual design and evaluation of an optical sensor for wide-area high-voltage metering and protection applications. In Proceedings of the I2MTC 2021—2021 IEEE International Instrumentation and Measurement Technology Conference, Virtual, 17–20 May 2021. in press. [Google Scholar]

- Wang, L. The Fault Causes of Overhead Lines in Distribution Network. MATEC Web Conf. 2016, 61, 02017. [Google Scholar] [CrossRef] [Green Version]

- Lehtonen, M. Fault rates of different types of medium voltage power lines in different environments. In Proceedings of the 2010 Electric Power Quality and Supply Reliability Conference, Kuressaare, Estonia, 16–18 June 2010; pp. 197–202. [Google Scholar] [CrossRef]

- Haes Alhelou, H.; Hamedani-Golshan, M.; Njenda, T.; Siano, P. A Survey on Power System Blackout and Cascading Events: Research Motivations and Challenges. Energies 2019, 12, 682. [Google Scholar] [CrossRef] [Green Version]

- Orr, P.; Fusiek, G.; Niewczas, P.; Booth, C.D.; Dysko, A.; Kawano, F.; Nishida, T.; Beaumont, P. Distributed Photonic Instrumentation for Power System Protection and Control. IEEE Trans. Instrum. Meas. 2015, 64, 19–26. [Google Scholar] [CrossRef] [Green Version]

- Nelson, J.; Fusiek, G.; Clayburn, L.; Niewczas, P.; Booth, C.; Orr, P.; Gordon, N. Development and testing of optically-interrogated current sensors. In Proceedings of the 2016 IEEE International Workshop on Applied Measurements for Power Systems (AMPS), Aachen, Germany, 28–30 September 2016; IEEE: Manhattan, NY, USA, 2016; pp. 1–5. [Google Scholar]

- Fusiek, G.; Nelson, J.; Niewczas, P.; Havunen, J.; Suomalainen, E.-P.; Hallstrom, J. Optical voltage sensor for MV networks. In Proceedings of the 2017 IEEE SENSORS, Glasgow, UK, 29 October–1 November 2017; IEEE: Manhattan, NY, USA, 2017; pp. 1–3. [Google Scholar]

- Fusiek, G.; Niewczas, P.; Gordon, N.; Orr, P.; Clarkson, P. 132 kV optical voltage sensor for wide area monitoring, protection and control applications. In Proceedings of the I2MTC 2020—2020 IEEE International Instrumentation and Measurement Technology Conference, Dubrovnik, Croatia, 25–28 May 2020. [Google Scholar]

- Fusiek, G.; Niewczas, P. Photonic Voltage Transducer with Lightning Impulse Protection for Distributed Monitoring of MV Networks. Sensors 2020, 20, 4830. [Google Scholar] [CrossRef] [PubMed]

- Promsawat, M.; Marungsri, B.; Promsawat, N.; Janphuang, P.; Luo, Z.; Pojprapai, S. Effects of temperature on aging degradation of soft and hard lead zirconate titanate ceramics. Ceram. Int. 2017, 43, 9709–9714. [Google Scholar] [CrossRef] [Green Version]

- Guillon, O.; Thiebaud, F.; Perreux, D. Tensile fracture of soft and hard PZT. Int. J. Fract. 2002, 117, 235–246. [Google Scholar] [CrossRef]

- Peddigari, M.; Kim, G.-Y.; Park, C.H.; Min, Y.; Kim, J.-W.; Ahn, C.-W.; Choi, J.-J.; Hahn, B.-D.; Choi, J.-H.; Park, D.-S.; et al. A Comparison Study of Fatigue Behavior of Hard and Soft Piezoelectric Single Crystal Macro-Fiber Composites for Vibration Energy Harvesting. Sensors 2019, 19, 2196. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- PI Physik Instrumente Ltd. Available online: http://www.piceramic.com/product-detail-page/p-882 (accessed on 18 November 2020).

- IEC 60044; Instrument Transformers—Part 7: Electronic Voltage Transformers. IEC: Geneva, Switzerland, 1999.

- IEC 61869; Instrument Transformers—Part 11: Additional Requirements for Low-Power Passive Voltage Transformers. IEC: Geneva, Switzerland, 2017.

- Rao, Y.-J. In-fibre Bragg grating sensors. Meas. Sci. Technol. 1997, 8, 355–375. [Google Scholar] [CrossRef]

- Fusiek, G.; Niewczas, P.; Judd, M.D. Towards the development of a downhole optical voltage sensor for monitoring electrical submersible pumps. Sens. Actuators A Phys. 2012, 184, 173–181. [Google Scholar] [CrossRef]

- IEC 60060; High-Voltage Test Techniques—Part 2: Measuring Systems. IEC: Geneva, Switzerland, 2011.

- Fusiek, G. Improved method of hysteresis compensation for a piezoelectric fiber optic voltage sensor. Opt. Eng. 2007, 46, 034401. [Google Scholar] [CrossRef]

- Perry, M.; Orr, P.; Niewczas, P.; Johnston, M. Nanoscale resolution interrogation scheme for simultaneous static and dynamic fiber bragg grating strain sensing. J. Light. Technol. 2012, 30, 3252–3258. [Google Scholar] [CrossRef] [Green Version]

| Property | Value |

|---|---|

| PZT material | PIC181 |

| Length (mm) | 20 |

| Diameter (mm) | 5 |

| Piezoelectric charge constant d33 (pm/V) | 265 |

| Resistance R (MΩ) | 200 |

| Capacitance CMVT (pF) | 10.4 |

| Series resonant frequency (kHz) | 80 |

| Full displacement time (µs) | 4.2 |

| Maximum permissible electric field strength of the material (kV/mm) | 2.5 |

| Maximum compressive stress (MPa) | 100 |

| Maximum tensile stress (MPa) | 10 |

| Nominal (rated) voltage (kV) | 1 |

| Accuracy Class | Voltage (Ratio) Error εu | Phase Error φe | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ±% | ±Minutes | ±Centiradians | |||||||||||||

| at Voltage (% of Rated) | at Voltage (% of Rated) | at Voltage (% of Rated) | |||||||||||||

| 2 | 20 | 80 | 100 | X 1) | 2 | 20 | 80 | 100 | X 1) | 2 | 20 | 80 | 100 | X 1) | |

| 0.1P | 0.5 | 0.2 | 0.1 | 0.1 | 0.1 | 20 | 10 | 5 | 5 | 5 | 0.6 | 0.3 | 0.15 | 0.15 | 0.15 |

| 0.2P | 1 | 0.4 | 0.2 | 0.2 | 0.2 | 40 | 20 | 10 | 10 | 10 | 1.2 | 0.6 | 0.3 | 0.3 | 0.3 |

| 0.5P | 2 | 1 | 0.5 | 0.5 | 0.5 | 80 | 40 | 20 | 20 | 20 | 2.4 | 1.2 | 0.6 | 0.6 | 0.6 |

| 1P | 4 | 2 | 1 | 1 | 1 | 160 | 80 | 40 | 40 | 40 | 4.8 | 2.4 | 1.2 | 1.2 | 1.2 |

| 3P | 6 | 3 | 3 | 3 | 3 | 240 | 120 | 120 | 120 | 120 | 7 | 3.5 | 3.5 | 3.5 | 3.5 |

| 6P | 12 | 6 | 6 | 6 | 6 | 480 | 240 | 240 | 240 | 240 | 14 | 7 | 7 | 7 | 7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fusiek, G.; Niewczas, P. Construction and Evaluation of an Optical Medium Voltage Transducer Module Aimed at a 132 kV Optical Voltage Sensor for WAMPAC Systems. Sensors 2022, 22, 5307. https://doi.org/10.3390/s22145307

Fusiek G, Niewczas P. Construction and Evaluation of an Optical Medium Voltage Transducer Module Aimed at a 132 kV Optical Voltage Sensor for WAMPAC Systems. Sensors. 2022; 22(14):5307. https://doi.org/10.3390/s22145307

Chicago/Turabian StyleFusiek, Grzegorz, and Pawel Niewczas. 2022. "Construction and Evaluation of an Optical Medium Voltage Transducer Module Aimed at a 132 kV Optical Voltage Sensor for WAMPAC Systems" Sensors 22, no. 14: 5307. https://doi.org/10.3390/s22145307

APA StyleFusiek, G., & Niewczas, P. (2022). Construction and Evaluation of an Optical Medium Voltage Transducer Module Aimed at a 132 kV Optical Voltage Sensor for WAMPAC Systems. Sensors, 22(14), 5307. https://doi.org/10.3390/s22145307