Review of Neural Network Modeling of Shape Memory Alloys

Abstract

:1. Introduction

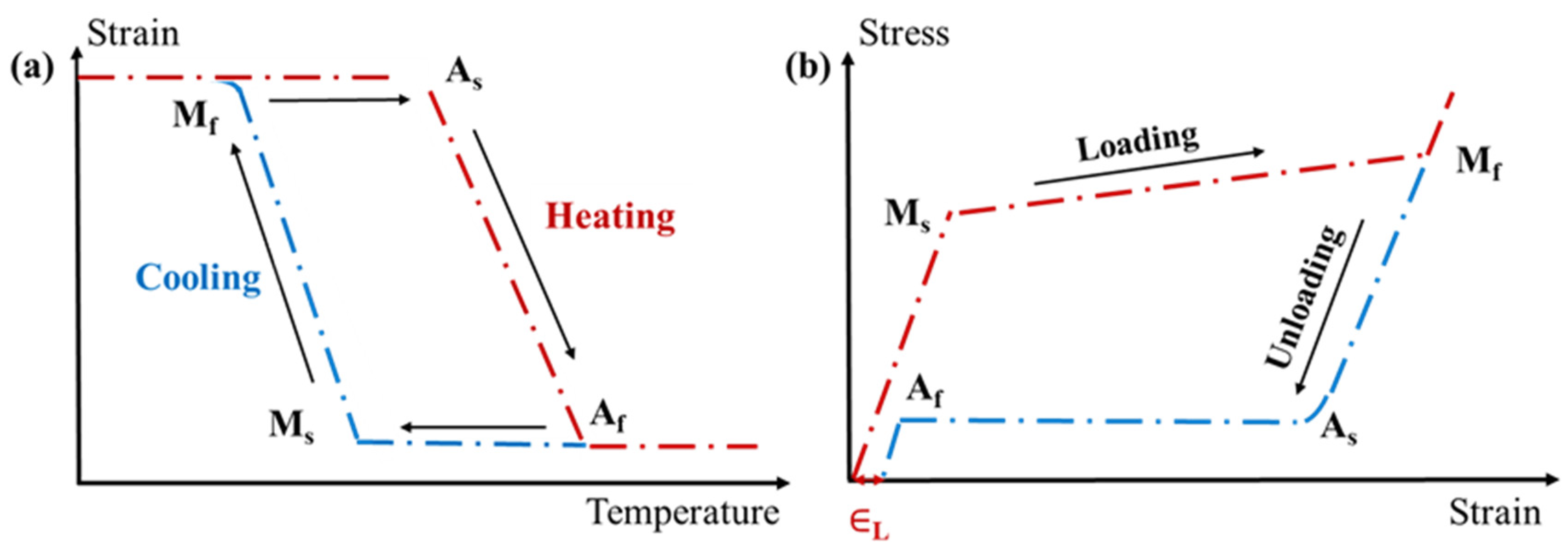

2. Description of the SMAs

3. Description of Artificial Neural Networks

4. SMA Forms and ANN Applications

4.1. Systems with a Wire for Linear Actuation

4.2. Systems with One Wire and One Spring for Linear Actuation

4.3. Magnetic SMA System

4.4. SMA Wire Systems for Rotatory Actuation

4.5. A Reinforced SMA Concrete Beam

4.6. Porous SMAs

4.7. SMA Bars and Rings as Self-Centering and Damping Device

4.8. SMA Self-Sensing Systems

5. Discussion

| NN | Definition | Domain |

|---|---|---|

| Full feedforward NN | It treats the information only in one direction “forward” from the input nodes, through the hidden nodes (if any) to the output nodes without cycles or loops in the network [114] | Clustering Regression |

| Long short term memory NN | It has feedback connectors. Its unit consists of a cell, an input gate, an output gate and a forget gate. The gate is a threshold help NN distinguishing between using the identity connections over the stacked layers. | Prediction Classifying |

| Multilayer ormal feed NN | It is a full feedforward NN, but with multicomputational layers (multihidden layer). | Clustering Regression |

| Nonlinear autoregressive exogenous NN (NARX) | It is a recurrent NN that has loop connections between the nodes. | Time Series |

| NN estimator | It is NN that is based on an estimator, which is a technique or method that calculates an accurate result that depends on actual observations. | Prediction Classification |

| General regression (GRNN) | It has a radial-basis function layer and a linear layer [115] | Regression Approximation Classification |

| Proportional- integral-differential NN (PIDNN) | It is a dynamic feedforward network, a combination of neural networks with the PID control concept. | Controlling |

| Takagi–Sugeno fuzzy neural network (TSFNN) | It is a fuzzy system model that needs fewer inputs without the capability of handling online data [116] | Clustering |

| Functional link artificial intelligent NN (FLANN) | It is a single-layer higher-order class of an ANN [117] | Pattern Recognition Classification |

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Aïssa, B.; Memon, N.K.; Ali, A.; Khraisheh, M.K. Recent Progress in the Growth and Applications of Graphene as a Smart Material: A Review. Front. Mater. 2015, 2, 58. [Google Scholar] [CrossRef]

- Cao, W.; Cudney, H.H.; Waser, R. Smart materials and structures. Proc. Natl. Acad. Sci. USA 1999, 96, 8330–8331. [Google Scholar] [CrossRef] [PubMed]

- Chaudhari, R.; Vora, J.J.; Patel, V.; López de Lacalle, L.N.; Parikh, D.M. Surface Analysis of Wire-Electrical-Discharge-Machining-Processed Shape-Memory Alloys. Materials 2020, 13, 530. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, Y.; Li, Y.; Chen, M.Z.Q.; Wei, Y. Bioinspired Robotic Fingers Based on Pneumatic Actuator and 3D Printing of Smart Material. Soft Robot. 2017, 4, 147–162. [Google Scholar] [CrossRef]

- Prokoshkin, S.; Brailovski, V.; Dubinskiy, S.; Zhukova, Y.; Sheremetyev, V.; Konopatsky, A.; Inaekyan, K. Manufacturing, Structure Control, and Functional Testing of Ti–Nb-Based SMA for Medical Application. Shape Mem. Superelast. 2016, 2, 130–144. [Google Scholar] [CrossRef]

- Isalgue, A.; Torra, V.; Lovey, F.; Terriault, P.; Carreras, G.; Soul, H.; Dieng, L. Experimental study of damping in civil engineering structures using smart materials (NiTi-SMA). Application to stayed cables for bridges. Int. Rev. Mech. Eng. 2010, 4, 601–611. [Google Scholar]

- Tzou, H.; Lee, H.-J.; Arnold, S.M. Smart Materials, Precision Sensors/Actuators, Smart Structures, and Structronic Systems. Mech. Adv. Mater. Struct. 2004, 11, 367–393. [Google Scholar] [CrossRef]

- Ma, N.; Song, G.; Lee, H.-J. Position control of shape memory alloy actuators with internal electrical resistance feedback using neural networks. Smart Mater. Struct. 2004, 13, 777–783. [Google Scholar] [CrossRef]

- Zhang, J.-J.; Yin, Y.-H.; Zhu, J.-Y. Electrical Resistivity-Based Study of Self-Sensing Properties for Shape Memory Alloy-Actuated Artificial Muscle. Sensors 2013, 13, 12958–12974. [Google Scholar] [CrossRef]

- Gómez-Espinosa, A.; Castro Sundin, R.; Loidi Eguren, I.; Cuan-Urquizo, E.; Treviño-Quintanilla, C.D. Neural Network Direct Control with Online Learning for Shape Memory Alloy Manipulators. Sensors 2019, 19, 2576. [Google Scholar] [CrossRef]

- Ölander, A. An Electrochemical Investigation of Solid Caduim-Gold Alloys. J. Am. Chem. Soc. 1932, 54, 3819–3833. [Google Scholar] [CrossRef]

- Zhang, X.P.; Liu, H.Y.; Yuan, B.; Zhang, Y.P. Superelasticity decay of porous NiTi shape memory alloys under cyclic strain-controlled fatigue conditions. Mater. Sci. Eng. A 2008, 481–482, 170–173. [Google Scholar] [CrossRef]

- Qader, İ.N.; Kök, M.; Dagdelen, F.; Aydoğdu, Y. A review of smart materials: Researches and applications. El-Cezeri J. Sci. Eng. 2019, 6, 755–788. [Google Scholar] [CrossRef]

- Alsoruji, G.; Muthuramalingam, T.; Moustafa, E.B.; Elsheikh, A. Investigation and TGRA based optimization of laser beam drilling process during machining of Nickel Inconel 718 alloy. J. Mater. Res. Technol. 2022, 18, 720–730. [Google Scholar] [CrossRef]

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Carrera, G.V.S.M.; Branco, L.C.; Aires-de-Sousa, J.; Afonso, C.A.M. Exploration of quantitative structure–property relationships (QSPR) for the design of new guanidinium ionic liquids. Tetrahedron 2008, 64, 2216–2224. [Google Scholar] [CrossRef]

- Xu, S.X.; Koko, T.S. Finite element analysis and design of actively controlled piezoelectric smart structures. Finite Elem. Anal. Des. 2004, 40, 241–262. [Google Scholar] [CrossRef]

- Manjaiah, M.; Narendranath, S.; Basavarajappa, S. Review on non-conventional machining of shape memory alloys. Trans. Nonferrous Met. Soc. China 2014, 24, 12–21. [Google Scholar] [CrossRef]

- Kaya, E.; Kaya, İ. A review on machining of NiTi shape memory alloys: The process and post process perspective. Int. J. Adv. Manuf. Technol. 2019, 100, 2045–2087. [Google Scholar] [CrossRef]

- Chaudhari, R.; Vora, J.J.; Mani Prabu, S.S.; Palani, I.A.; Patel, V.K.; Parikh, D.M.; de Lacalle, L.N.L. Multi-Response Optimization of WEDM Process Parameters for Machining of Superelastic Nitinol Shape-Memory Alloy Using a Heat-Transfer Search Algorithm. Mater. Basel Switz. 2019, 12, 1277. [Google Scholar] [CrossRef]

- Dick, S. Artificial Intelligence. Harv. Data Sci. Rev. 2019. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, T.; Ju, W.; Shi, S. Materials discovery and design using machine learning. J. Mater. 2017, 3, 159–177. [Google Scholar] [CrossRef]

- Mendizabal, A.; Márquez-Neila, P.; Cotin, S. Simulation of hyperelastic materials in real-time using deep learning. Med. Image Anal. 2020, 59, 101569. [Google Scholar] [CrossRef]

- Bogue, R. Smart materials: A review of capabilities and applications. Assem. Autom. 2014, 34, 16–22. [Google Scholar] [CrossRef]

- Bogue, R. Smart materials: A review of recent developments. Assem. Autom. 2012, 32, 3–7. [Google Scholar] [CrossRef]

- Guo, F.; Guo, Z. Inspired smart materials with external stimuli responsive wettability: A review. RSC Adv. 2016, 6, 36623–36641. [Google Scholar] [CrossRef]

- Owusu-Danquah, J.S.; Bseiso, A.; Allena, S. Artificial neural network models to predict the response of 55NiTi shape memory alloy under stress and thermal cycles. Neural Comput. Appl. 2022, 34, 3829–3842. [Google Scholar] [CrossRef]

- Goldberg, Y. Neural Network Methods for Natural Language Processing. Synth. Lect. Hum. Lang. Technol. 2017, 10, 1–309. [Google Scholar] [CrossRef]

- Das, S.; Pegu, H.; Sahu, K.K.; Nayak, A.K.; Ramakrishna, S.; Datta, D.; Swayamjyoti, S. Machine learning in materials modeling—Fundamentals and the opportunities in 2D materials. In Synthesis, Modeling, and Characterization of 2D Materials, and Their Heterostructures; Elsevier: Amsterdam, The Netherland, 2020; pp. 445–468. [Google Scholar] [CrossRef]

- Butler, K.T.; Davies, D.W.; Cartwright, H.; Isayev, O.; Walsh, A. Machine learning for molecular and materials science. Nature 2018, 559, 547–555. Available online: https://www.nature.com/articles/s41586-018-0337-2 (accessed on 6 April 2021). [CrossRef]

- Phillips, C.L.; Voth, G.A. Discovering crystals using shape matching and machine learning. Soft Matter 2013, 9, 8552–8568. [Google Scholar] [CrossRef]

- Majid, A.; Khan, A.; Choi, T.-S. Predicting lattice constant of complex cubic perovskites using computational intelligence. Comput. Mater. Sci. 2011, 50, 1879–1888. [Google Scholar] [CrossRef]

- Lorente, D.; Martínez-Martínez, F.; Rupérez, M.J.; Lago, M.A.; Martínez-Sober, M.; Escandell-Montero, P.; Martínez-Martínez, J.M.; Martínez-Sanchis, S.; Serrano-López, A.J.; Monserrat, C.; et al. A framework for modelling the biomechanical behaviour of the human liver during breathing in real time using machine learning. Expert Syst. Appl. 2017, 71, 342–357. [Google Scholar] [CrossRef]

- Zakerzadeh, M.R.; Salehi, H. Comparative Analysis of Some one-Dimensional SMA Constitutive Models for a Ni-Ti Wire for Shape Control Applications with Experimental Data. In Proceeding of the 20th International Conference on Adaptive Structures and Technologies, Hong Kong, China, 20–22 October 2009; pp. 1101–1113. [Google Scholar]

- Prajna, M.R.; Antony, P.J.; Jnanesh, N.A. Machine learning approach for flexural characterization of smart material. J. Phys. Conf. Ser. 2018, 1142, 012007. [Google Scholar] [CrossRef]

- Farber, E.; Zhu, J.-N.; Popovich, A.; Popovich, V. A review of NiTi shape memory alloy as a smart material produced by additive manufacturing. Mater. Today Proc. 2020, 30, 761–767. [Google Scholar] [CrossRef]

- Morgan, N.B. Medical shape memory alloy applications—The market and its products. Mater. Sci. Eng. A 2004, 378, 16–23. [Google Scholar] [CrossRef]

- Sreekumar, M.; Nagarajan, T.; Singaperumal, M.; Zoppi, M.; Molfino, R. Critical review of current trends in shape memory alloy actuators for intelligent robots. Ind. Robot Int. J. 2007, 34, 285–294. [Google Scholar] [CrossRef]

- Rodrigue, H.; Wang, W.; Han, M.-W.; Kim, T.J.Y.; Ahn, S.-H. An Overview of Shape Memory Alloy-Coupled Actuators and Robots. Soft Robot. 2017, 4, 3–15. [Google Scholar] [CrossRef]

- Song, G.; Ma, N.; Li, H.-N. Applications of shape memory alloys in civil structures. Eng. Struct. 2006, 28, 1266–1274. [Google Scholar] [CrossRef]

- Cladera, A.; Weber, B.; Leinenbach, C.; Czaderski, C.; Shahverdi, M.; Motavalli, M. Iron-based shape memory alloys for civil engineering structures: An overview. Constr. Build. Mater. 2014, 63, 281–293. [Google Scholar] [CrossRef]

- Hartl, D.J.; Lagoudas, D.C. Aerospace applications of shape memory alloys. J. Sagepub 2007, 221, 535–552. [Google Scholar] [CrossRef]

- Exarchos, D.A.; Dalla, P.T.; Tragazikis, I.K.; Dassios, K.G.; Zafeiropoulos, N.E.; Karabela, M.M.; De Crescenzo, C.; Karatza, D.; Musmarra, D.; Chianese, S.; et al. Development and Characterization of High Performance Shape Memory Alloy Coatings for Structural Aerospace Applications. Materials 2018, 11, 832. [Google Scholar] [CrossRef]

- Jani, J.M.; Leary, M.; Subic, A. Shape Memory Alloys in Automotive Applications. Appl. Mech. Mater. 2014, 663, 248–253. [Google Scholar] [CrossRef]

- Bellini, A.; Colli, M.; Dragoni, E. Mechatronic Design of a Shape Memory Alloy Actuator for Automotive Tumble Flaps: A Case Study. IEEE Trans. Ind. Electron. 2009, 56, 2644–2656. [Google Scholar] [CrossRef]

- Fang, C.; Zheng, Y.; Chen, J.; Yam, M.C.H.; Wang, W. Superelastic NiTi SMA cables: Thermal-mechanical behavior, hysteretic modelling and seismic application. Eng. Struct. 2019, 183, 533–549. [Google Scholar] [CrossRef]

- Chemisky, Y.; Duval, A.; Patoor, E.; Ben Zineb, T. Constitutive model for shape memory alloys including phase transformation, martensitic reorientation and twins accommodation. Mech. Mater. 2011, 43, 361–376. [Google Scholar] [CrossRef]

- Lovey, F.C.; Torra, V. Shape memory in Cu-based alloys: Phenomenological behavior at the mesoscale level and interaction of martensitic transformation with structural defects in Cu-Zn-Al. Prog. Mater. Sci. 1999, 44, 189–289. [Google Scholar] [CrossRef]

- Taillard, K.; Chirani, S.A.; Calloch, S.; Lexcellent, C. Equivalent transformation strain and its relation with martensite volume fraction for isotropic and anisotropic shape memory alloys. Mech. Mater. 2008, 40, 151–170. [Google Scholar] [CrossRef]

- Shape Memory Effect—An Overview|ScienceDirect Topics. Available online: https://www.sciencedirect.com/topics/chemistry/shape-memory-effect (accessed on 8 April 2021).

- Lexcellent, C.; Leclercq, S.; Gabry, B.; Bourbon, G. The two way shape memory effect of shape memory alloys: An experimental study and a phenomenological model. Int. J. Plast. 2000, 16, 1155–1168. [Google Scholar] [CrossRef]

- Barnes, C. Innovations: Shape Memory and Superelastic Alloys. 1999. Available online: https://www.copper.org/publications/newsletters/innovations/1999/07/shape.html (accessed on 21 April 2021).

- Wang, X.; Hu, G. Stress transfer for a SMA fiber pulled out from an elastic matrix and related bridging effect. Compos. Part Appl. Sci. Manuf. 2005, 36, 1142–1151. [Google Scholar] [CrossRef]

- Divringi, K.; Ozcan, C. Advanced Shape Memory Alloy Material Models for ANSYS. Ozen Eng. Inc. 2016, 94085, 408. [Google Scholar]

- Kirkpatrick, K.; Valasek, J. Reinforcement Learning for Characterizing Hysteresis Behavior of Shape Memory Alloys. J. Aerosp. Comput. Inf. Commun. 2009, 6, 227–238. [Google Scholar] [CrossRef]

- Rustighi, E.; Brennan, M.J.; Mace, B.R. Real-time control of a shape memory alloy adaptive tuned vibration absorber. Smart Mater. Struct. 2005, 14, 1184–1195. [Google Scholar] [CrossRef]

- Wang, S.-C. Artificial Neural Network. In Interdisciplinary Computing in Java Programming; Wang, S.-C., Ed.; The Springer International Series in Engineering and Computer Science: Boston, MA, USA, 2003; pp. 81–100. ISBN 978-1-4615-0377-4. [Google Scholar]

- Abraham, A. Artificial Neural Networks. In Handbook of Measuring System Design; American Cancer Society: Atlanta, GA, USA, 2005; ISBN 978-0-471-49739-4. [Google Scholar]

- Kohli, S.; Miglani, S.; Rapariya, R. Basics of artificial neural network. Int. J. Comput. Sci. Mob. Comput. 2014, 3, 745–751. [Google Scholar]

- Abdi, H. A neural network primer. J. Biol. Syst. 1994, 02, 247–281. [Google Scholar] [CrossRef]

- Hansen, L.K.; Salamon, P. Neural network ensembles. IEEE Trans. Pattern Anal. Mach. Intell. 1990, 12, 993–1001. [Google Scholar] [CrossRef]

- Du, K.-L. Clustering: A neural network approach. Neural Netw. 2010, 23, 89–107. [Google Scholar] [CrossRef]

- Ghahari, S.; Queiroz, C.; Labi, S.; McNeil, S. Cluster Forecasting of Corruption Using Nonlinear Autoregressive Models with Exogenous Variables (NARX)—An Artificial Neural Network Analysis. Sustainability 2021, 13, 11366. [Google Scholar] [CrossRef]

- Dorffner, G. Neural Networks for Time Series Processing. Neural Netw. World 1996, 6, 447–468. [Google Scholar]

- Minasny, B.; McBratney, A.B. The Neuro-m Method for Fitting Neural Network Parametric Pedotransfer Functions-Minasny. Soil Sci. Soc. Am. J. 2002, 66, 352–361. [Google Scholar] [CrossRef]

- Haykin, S. Neural Networks and Learning Machines, 3rd ed.; Pearson: London, UK, 2008. [Google Scholar]

- Albawi, S.; Mohammed, T.A.; Al-Zawi, S. Understanding of a convolutional neural network. In Proceedings of the 2017 International Conference on Engineering and Technology (ICET), Antalya, Turkey, 21–23 August 2017; pp. 1–6. [Google Scholar]

- Psaltis, D.; Sideris, A.; Yamamura, A.A. A multilayered neural network controller. IEEE Control Syst. Mag. 1988, 8, 17–21. [Google Scholar] [CrossRef]

- Xu, L.; Ren, J.S.; Liu, C.; Jia, J. Deep Convolutional Neural Network for Image Deconvolution. Adv. Neural Inf. Process. Syst. 2014, 1, 1790–1798. [Google Scholar]

- Yang, S.X.; Meng, M. Real-time Collision-free Path Planning of Robot Manipulators using Neural Network Approaches. Auton. Robot. 2000, 9, 27–39. [Google Scholar] [CrossRef]

- Cont, A.; Henry, C. Real-Time Gesture Mapping in pd Environment Using Neural Networks. In NIME; Hamamatsu: Shizuoka, Japan, 2004; pp. 39–42. Available online: https://www.researchgate.net/profile/Arshia_Cont/publication/228795048_Real-time_gesture_mapping_in_pd_environment_using_neural_networks/links/5406c5140cf2bba34c1e582b.pdf (accessed on 17 November 2020).

- Li, Z.; Xia, Y.; Su, C.; Deng, J.; Fu, J.; He, W. Missile Guidance Law Based on Robust Model Predictive Control Using Neural-Network Optimization. IEEE Trans. Neural Netw. Learn. Syst. 2015, 26, 1803–1809. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Wang, N.; Meng, X. Real-time forest fire detection with wireless sensor networks. In Proceedings of the 2005 International Conference on Wireless Communications, Networking and Mobile Computing, Wuhan, China, 23–26 September 2005; pp. 1214–1217. [Google Scholar]

- Mekaouche, A.; Chapelle, F.; Balandraud, X. A compliant mechanism with variable stiffness achieved by rotary actuators and shape-memory alloy. Meccanica 2018, 53, 2555–2571. [Google Scholar] [CrossRef]

- Yuan, H.; Chapelle, F.; Fauroux, J.-C.; Balandraud, X. Concept for a 3D-printed soft rotary actuator driven by a shape-memory alloy. Smart Mater. Struct. 2018, 27, 055005. [Google Scholar] [CrossRef]

- Yuan, H.; Fauroux, J.; Chapelle, F.; Balandraud, X. A review of rotary actuators based on shape memory alloys. J. Intell. Mater. Syst. Struct. 2017, 28, 1863–1885. [Google Scholar] [CrossRef]

- Geaorges, T.; Brailovski, V.; Terriault, P. Characterization and design of antagonistic shape memory alloy actuators-IOPscience. Smart Mater. Struct. 2012, 21, 035010. [Google Scholar] [CrossRef]

- Mohd Jani, J.; Leary, M.; Subic, A. Designing shape memory alloy linear actuators: A review-Jaronie Mohd Jani, Martin Leary, Aleksandar Subic, 2017. J. Intell. Mater. Syst. Struct. 2016, 28, 1699–1718. [Google Scholar] [CrossRef]

- Boufayed, R.; Chapelle, F.; Destrebecq, J.F.; Balandraud, X. Finite element analysis of a prestressed mechanism with multi-antagonistic and hysteretic SMA actuation. Meccanica 2020, 55, 1007–1024. [Google Scholar] [CrossRef]

- Asua, E.; Etxebarria, V.; García-Arribas, A. Neural network-based micropositioning control of smart shape memory alloy actuators. Eng. Appl. Artif. Intell. 2008, 21, 796–804. [Google Scholar] [CrossRef]

- MATLAB Tutorial, Levenberg-Marquardt (Trainlm): Backpropagation (Deep Learning Toolbox). Available online: https://fr.mathworks.com/help/deeplearning/ref/trainlm.html (accessed on 16 November 2020).

- Senthilkumar, P.; Umapathy, M. Use of load generated by a shape memory alloy for its position control with a neural network estimator. J. Vib. Control 2014, 20, 1707–1717. [Google Scholar] [CrossRef]

- Majumder, H.; Maity, K. Application of GRNN and multivariate hybrid approach to predict and optimize WEDM responses for Ni-Ti shape memory alloy. Appl. Soft Comput. 2018, 70, 665–679. [Google Scholar] [CrossRef]

- Hmede, R.; Chapelle, F.; Lapusta, Y. Modeling the butterfly behavior of SMA actuators using neural networks. Comptes Rendus Mécanique 2022, 350, 143–157. [Google Scholar] [CrossRef]

- Lee, H.J.; Lee, J.J. Evaluation of the characteristics of a shape memory alloy spring actuator. Smart Mater. Struct. 2000, 9, 817–823. [Google Scholar] [CrossRef]

- Wang, H.; Song, G. Innovative NARX recurrent neural network model for ultra-thin shape memory alloy wire. Neurocomputing 2014, 134, 289–295. [Google Scholar] [CrossRef]

- Song, G.; Chaudhry, V.; Batur, C. A Neural Network Inverse Model for a Shape Memory Alloy Wire Actuator. J. Intell. Mater. Syst. Struct. 2003, 14, 371–377. [Google Scholar] [CrossRef]

- Song, G.; Chaudhry, V.; Batur, C. Precision tracking control of shape memory alloy actuators using neural networks and a sliding-mode based robust controller. Smart Mater. Struct. 2003, 12, 223–231. [Google Scholar] [CrossRef]

- Tai, N.T.; Ahn, K.K. A hysteresis functional link artificial neural network for identification and model predictive control of SMA actuator. J. Process Control 2012, 22, 766–777. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, Y.; Wang, Y.; Zhou, M. Takagi–Sugeno Fuzzy Neural Network Hysteresis Modeling for Magnetic Shape Memory Alloy Actuator Based on Modified Bacteria Foraging Algorithm. Int. J. Fuzzy Syst. 2020, 22, 1314–1329. [Google Scholar] [CrossRef]

- Zhou, M.; Zhang, Q. Hysteresis Model of Magnetically Controlled Shape Memory Alloy Based on a PID Neural Network. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Nikdel, N.; Nikdel, P.; Badamchizadeh, M.A.; Hassanzadeh, I. Using Neural Network Model Predictive Control for Controlling Shape Memory Alloy-Based Manipulator. IEEE Trans. Ind. Electron. 2014, 61, 1394–1401. [Google Scholar] [CrossRef]

- Cao, Y.; Fan, Q.; Mahmoudi Azar, S.; Alyousef, R.; Yousif, S.T.; Wakil, K.; Jermsittiparsert, K.; Si Ho, L.; Alabduljabbar, H.; Alaskar, A. Computational parameter identification of strongest influence on the shear resistance of reinforced concrete beams by fiber reinforcement polymer. Structures 2020, 27, 118–127. [Google Scholar] [CrossRef]

- Hannen, J.C.; Crews, J.H.; Buckner, G.D. Indirect intelligent sliding mode control of a shape memory alloy actuated flexible beam using hysteretic recurrent neural networks. Smart Mater. Struct. 2012, 21, 085015. [Google Scholar] [CrossRef]

- Elbahy, Y.I.E.; Nehdi, M.N.; Youssef, M.A.Y. Artificial neural network model for deflection analysis of superelastic shape memory alloy reinforced concrete beams. Can. J. Civ. Eng. 2010, 37, 842–854. [Google Scholar] [CrossRef]

- Wisutmethangoon, S.; Denmud, N.; Sikong, L. Characteristics and compressive properties of porous NiTi alloy synthesized by SHS technique. Mater. Sci. Eng. A 2009, 515, 93–97. [Google Scholar] [CrossRef]

- Ratner, B.D.; Hoffman, A.S.; Schoen, F.J.; Lemons, J.E. Biomaterials Science: An Introduction to Materials in Medicine. San Diego Calif. 2004, 31, 58–60. [Google Scholar]

- Velmurugan, C.; Senthilkumar, V.; Dinesh, S.; Arul kirubakaran, D. Artificial neural network prediction of wire electrical discharge machining properties on sintered porous NiTi shape memory alloy. Mater. Today Proc. 2018, 5, 8382–8390. [Google Scholar] [CrossRef]

- Li, Q.; Yu, J.-Y.; Mu, B.-C.; Sun, X.-D. BP neural network prediction of the mechanical properties of porous NiTi shape memory alloy prepared by thermal explosion reaction. Mater. Sci. Eng. A 2006, 419, 214–217. [Google Scholar] [CrossRef]

- Choi, E.; Nguyen, H.D.; Jeon, J.-S.; Kang, J.-W. Self-centering and damping devices using SMA dual rings. Smart Mater. Struct. 2019, 28, 085005. [Google Scholar] [CrossRef]

- Qiu, C.; Fang, C.; Liang, D.; Du, X.; Yam, M.C. Behavior and application of self-centering dampers equipped with buckling-restrained SMA bars. Smart Mater. Struct. 2020, 29, 035009. [Google Scholar] [CrossRef]

- Torra, V. Damping in Civil Engineering Using SMA. The Fatigue Behavior and Stability of CuAlBe and NiTi Alloys. J. Mater. Eng. Perform. 2009, 18, 738–745. [Google Scholar] [CrossRef]

- Torra, V.; Isalgue, A.; Auguet, C.; Carreras, G.; Lovey, F.C.; Terriault, P.; Dieng, L. SMA in Mitigation of Extreme Loads in Civil Engineering: Damping Actions in Stayed Cables. Appl. Mech. Mater. 2011, 82, 539–544. [Google Scholar] [CrossRef]

- Wang, W.; Fang, C.; Liu, J. Large size superelastic SMA bars: Heat treatment strategy, mechanical property and seismic application. Smart Mater. Struct. 2016, 25, 075001. [Google Scholar] [CrossRef]

- Ozbulut, O.E.; Hurlebaus, S. Evaluation of the performance of a sliding-type base isolation system with a NiTi shape memory alloy device considering temperature effects. Eng. Struct. 2010, 32, 238–249. [Google Scholar] [CrossRef]

- Lu, Y.; Jiang, J.; Zhang, J.; Zhang, R.; Zhang, Q.; Zhou, Y.; Wang, L.; Yue, H. A dynamic stiffness improvement method for thin plate structures with laminated/embedded shape memory alloy actuators. Thin-Walled Struct. 2022, 175, 109286. [Google Scholar] [CrossRef]

- Furst, S.J.; Crews, J.H.; Seelecke, S. Stress, strain, and resistance behavior of two opposing shape memory alloy actuator wires for resistance-based self-sensing applications. J. Intell. Mater. Syst. Struct. 2013, 24, 1951–1968. [Google Scholar] [CrossRef]

- Narayanan, P.; Elahinia, M. Control of a shape memory alloy–actuated rotary manipulator using an artificial neural network–based self-sensing technique. J. Intell. Mater. Syst. Struct. 2016, 27, 1885–1894. [Google Scholar] [CrossRef]

- Formentini, M.; Lenci, S. An innovative building envelope (kinetic façade) with Shape Memory Alloys used as actuators and sensors. Autom. Constr. 2018, 85, 220–231. [Google Scholar] [CrossRef]

- Tung, A.T.; Park, B.-H.; Liang, D.H.; Niemeyer, G. Laser-machined shape memory alloy sensors for position feedback in active catheters. Sens. Actuators Phys. 2008, 147, 83–92. [Google Scholar] [CrossRef]

- Gurung, H.; Banerjee, A. Self-sensing SMA Actuator Using Extended Kalman Filter and Artificial Neural Network. Procedia Eng. 2016, 144, 629–634. [Google Scholar] [CrossRef]

- Bhargaw, H.N.; Singh, S.; Botre, B.A.; Akbar, S.A.; Hashmi, S.A.R.; Sinha, P. Deep Neural Network-Based Physics-Inspired Model of Self-Sensing Displacement Estimation for Antagonistic Shape Memory Alloy Actuator. IEEE Sens. J. 2022, 22, 3254–3262. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Abd Elaziz, M.; Vendan, A. Modeling ultrasonic welding of polymers using an optimized artificial intelligence model using a gradient-based optimizer. Weld. World 2022, 66, 27–44. [Google Scholar] [CrossRef]

- Feedforward Neural Networks 1. What Is a Feedforward Neural Network? Available online: https://www.fon.hum.uva.nl/praat/manual/Feedforward_neural_networks_1__What_is_a_feedforward_ne.html (accessed on 11 May 2021).

- Generalized Regression Neural Networks-MATLAB & Simulink. Available online: https://www.mathworks.com/help/deeplearning/ug/generalized-regression-neural-networks.html (accessed on 11 May 2021).

- Wang, D.; Quek, C.; Ng, G.S. MS-TSKfnn: Novel Takagi-Sugeno-Kang fuzzy neural network using ART like clustering. In Proceedings of the 2004 IEEE International Joint Conference on Neural Networks (IEEE Cat. No.04CH37541), Budapest, Hungary, 25–29 July 2004; pp. 2361–2366. [Google Scholar]

- Naik, B.; Nayak, J.; Behera, H.S.; Abraham, A. A self adaptive harmony search based functional link higher order ANN for non-linear data classification. Neurocomputing 2015, 179, 69–87. [Google Scholar] [CrossRef]

| Activation Function | Equation |

|---|---|

| Step function | , otherwise 1 |

| Linear function | |

| Rectified linear (ReLU) | |

| Hyperbolic tangent | |

| Radial basis function |

| Type of Property | Description |

|---|---|

| Mechanical property | Roughness [98] Maximum peak to valley height [83] Square roughness [83] Microhardness [83] Load measurements [103] Position [10] Moment of inertia [95] Reduction factor betta [95] Green density (D) [99] Compressive yield stress [99] Density [99] Elastic modulus [99] Speed [99] Time response in the hysteresis behavior [86] Shape recovery force [85] Seismic response [104] Frequency [106] Strain response [84] |

| Thermal property | Austenite-finish temperature [8] Temperature [96] Heating rate (V) [99] |

| Chemical Property | Reactant particle size [99] |

| Electrical property | Servo voltage [98] Pulse on time [98] Pulse off time [98] Current [98] Electrical resistance (ER) [8] |

| Dimensional Property | Length of the wire [99] Cross-sectional area [99] |

| Magnetic Property | [90] |

| SMA Form | Application Type | NN Type | Training Method |

|---|---|---|---|

| Wire | Position Actuator | NN multilayer | Levenberg–Marquardt (LM) algorithm [80] |

| NN Estimator | Parameter epochs: 3000 [80] | ||

| Magnetic Actuator | Takagi–Sugeno fuzzy | MBFA and GDA algorithms [90] | |

| Rotatory-Manipulator: actuator | NN direct control with online learning | BP algorithm [10] | |

| Rotatory Manipulator: self-sensor | Shallow NN | LM algorithm [108] | |

| Linear Actuator with a spring bias | Nonlinear-Autoregressive Exogenous NARX NN | Jordan–Elman and Jordan–Plus–Elman algorithm [86] | |

| Proportional–Integral–Differential GRPID NN | Backpropagation algorithm [91] | ||

| Functional Link Artificial Intelligent Neural Network | Particle-swarm optimization [89] | ||

| Self-sensing with a spring bias | Shallow ANN | Extended Kalman Filter [111] | |

| Antagonistic System: Actuator | LSTM | [84] | |

| Self-sensor | DNN | DNN has two LSTM layers [88] | |

| Conventional Machining | General Regression | ||

| Forwarded | |||

| Conventional Machining | Multilayer normal feed | VIKOR FUZZY [83] | |

| Porous | Medical | Multilayer normal feed Full feedforward | Batch Backpropagation [99] |

| Earthquake Civil Damping Self-centering | Feedforward Backpropagation FFBP | Incremental Backpropagation [98] | |

| Vibrational control | Quick Prop algorithm QP [98] Genetic algorithms GA [98] | ||

| Reinforced Concrete Beam | Aircrafts | BPNN | Backpropagation algorithm [95] |

| Ring and Bars | Civil Damping Self-centering | Neuro_Fuzzy Model | [105] |

| Plates | Aircrafts | BPNN | Genetic algorithm [106] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hmede, R.; Chapelle, F.; Lapusta, Y. Review of Neural Network Modeling of Shape Memory Alloys. Sensors 2022, 22, 5610. https://doi.org/10.3390/s22155610

Hmede R, Chapelle F, Lapusta Y. Review of Neural Network Modeling of Shape Memory Alloys. Sensors. 2022; 22(15):5610. https://doi.org/10.3390/s22155610

Chicago/Turabian StyleHmede, Rodayna, Frédéric Chapelle, and Yuri Lapusta. 2022. "Review of Neural Network Modeling of Shape Memory Alloys" Sensors 22, no. 15: 5610. https://doi.org/10.3390/s22155610