Non-Contact Shear Wave Generation and Detection Using High Frequency Air-Coupled Focused Transducer and Fiber Optic Based Sagnac Interferometer for Mechanical Characterization

Abstract

:1. Introduction

2. Fabrication of Focused Air-Coupled PZT Transducer

3. Pressure Characterization of Focused Air-Coupled PZT Transducer

3.1. Calibration of Hydrophone Needle in Air Measurement

3.2. Characterization of Focused Air-Coupled PZT Transducer

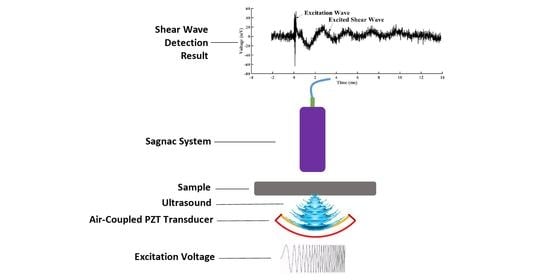

4. Shear Wave Detection Using Fiber Optic Sagnac Interferometer

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nightingale, K.; Soo, M.S.; Nightingale, R.; Trahey, G. Acoustic radiation force impulse imaging: In Vivo demonstration of clinical feasibility. Ultrasound Med. Biol. 2002, 28, 227–235. [Google Scholar] [CrossRef]

- Nguyen, T.-M.; Arnal, B.; Song, S.; Huang, Z.; Wang, R.K.; O’Donnell, M. Shear wave elastography using amplitude-modulated acoustic radiation force and phase-sensitive optical coherence tomography. J. Biomed. Opt. 2015, 20, 016001. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sarvazyan, A.P.; Rudenko, O.V.; Swanson, S.D.; Fowlkes, J.B.; Emelianov, S.Y. Shear wave elasticity imaging: A new ultrasonic technology of medical diagnostics. Ultrasound Med. Biol. 1998, 24, 1419–1435. [Google Scholar] [CrossRef]

- Hutchins, D.; Burrascano, P.; Davis, L.; Laureti, S.; Ricci, M. Coded waveforms for optimised air-coupled ultrasonic nondestructive evaluation. Ultrasonics 2014, 54, 1745–1759. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kažys, R.; Demčenko, A.; Žukauskas, E.; Mažeika, L. Air-coupled ultrasonic investigation of multi-layered composite materials. Ultrasonics 2006, 44, e819–e822. [Google Scholar] [CrossRef] [PubMed]

- Pallav, P.; Hutchins, D.A.; Gan, T. Air-coupled ultrasonic evaluation of food materials. Ultrasonics 2009, 49, 244–253. [Google Scholar] [CrossRef] [PubMed]

- Jayakumar, A.; Balachandran, A.; Mani, A.; Balasubramaniam, K. Falling film thickness measurement using air-coupled ultrasonic transducer. Exp. Therm. Fluid Sci. 2019, 109, 109906. [Google Scholar] [CrossRef]

- Ma, H.; Xiong, K.; Wu, J.; Ji, X.; Yang, S. Noncontact photoacoustic angiography with an air-coupled ultrasonic transducer for evaluation of burn injury. Appl. Phys. Lett. 2019, 114, 133701. [Google Scholar] [CrossRef]

- Li, C.; Song, S.; Guan, G.; Wang, R.K.; Huang, Z. Frequency dependence of laser ultrasonic SAW phase velocities measurements. Ultrasonics 2013, 53, 191–195. [Google Scholar] [CrossRef]

- Li, C.; Huang, Z.; Wang, R.K. Elastic properties of soft tissue-mimicking phantoms assessed by combined use of laser ultrasonics and low coherence interferometry. Opt. Express 2011, 19, 10153–10163. [Google Scholar] [CrossRef] [PubMed]

- Ambroziński, Ł.; Pelivanov, I.; Song, S.; Yoon, S.J.; Li, D.; Gao, L.; Shen, T.T.; Wang, R.K.; O’Donnell, M. Air-coupled acoustic radiation force for non-contact generation of broadband mechanical waves in soft media. Appl. Phys. Lett. 2016, 109, 043701. [Google Scholar] [CrossRef] [Green Version]

- Ambroziński, Ł.; Song, S.; Yoon, S.J.; Pelivanov, I.; Li, D.; Gao, L.; Shen, T.T.; Wang, R.K.; O’Donnell, M. Acoustic micro-tapping for non-contact 4D imaging of tissue elasticity. Sci. Rep. 2016, 6, 38967. [Google Scholar] [CrossRef] [Green Version]

- Kupnik, M.; Ho, M.-C.; Vaithilingam, S.; Khuri-Yakub, B.T. CMUTs for air coupled ultrasound with improved bandwidth. In Proceedings of the 2011 IEEE International Ultrasonics Symposium, Orlando, FL, USA, 18–21 October 2011; pp. 592–595. [Google Scholar]

- Zhang, H.; Liang, D.; Rui, X.; Wang, Z. Noncontact damage topography reconstruction by wavenumber domain analysis based on air-coupled ultrasound and full-field laser vibrometer. Sensors 2021, 21, 609. [Google Scholar] [CrossRef] [PubMed]

- Boccaccio, M.; Rachiglia, P.; Malfense Fierro, G.P.; Pio Pucillo, G.; Meo, M. Deep-subwavelength-optimized holey-structured metamaterial lens for nonlinear air-coupled ultrasonic imaging. Sensors 2021, 21, 1170. [Google Scholar] [CrossRef]

- Wandowski, T.; Mindykowski, D.; Kudela, P.; Radzienski, M. Analysis of air-coupled transducer-based elastic waves generation in cfrp plates. Sensors 2021, 21, 7134. [Google Scholar] [CrossRef]

- Razani, M.; Mariampillai, A.; Sun, C.; Luk, T.W.; Yang, V.X.; Kolios, M.C. Feasibility of optical coherence elastography measurements of shear wave propagation in homogeneous tissue equivalent phantoms. Biomed. Opt. Express 2012, 3, 972–980. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Song, S.; Huang, Z.; Nguyen, T.-M.; Wong, E.Y.; Arnal, B.; O’Donnell, M.; Wang, R.K. Shear modulus imaging by direct visualization of propagating shear waves with phase-sensitive optical coherence tomography. J. Biomed. Opt. 2013, 18, 121509. [Google Scholar] [CrossRef]

- Wang, S.; Larin, K.V. Shear wave imaging optical coherence tomography (SWI-OCT) for ocular tissue biomechanics. Opt. Lett. 2014, 39, 41–44. [Google Scholar] [CrossRef] [Green Version]

- Álvarez-Arenas, T.G. Acoustic impedance matching of piezoelectric transducers to the air. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2004, 51, 624–633. [Google Scholar] [CrossRef]

- Kinsler, L.E.; Frey, A.R.; Coppens, A.B.; Sanders, J.V. Fundamentals of Acoustics; John Wiley & Sons: Hoboken, NJ, USA, 2000. [Google Scholar]

- Pelivanov, I.; Buma, T.; Xia, J.; Wei, C.-W.; O’Donnell, M. A new fiber-optic non-contact compact laser-ultrasound scanner for fast non-destructive testing and evaluation of aircraft composites. J. Appl. Phys. 2014, 115, 113105. [Google Scholar] [CrossRef] [Green Version]

- Pelivanov, I.; Buma, T.; Xia, J.; Wei, C.-W.; O’Donnell, M. NDT of fiber-reinforced composites with a new fiber-optic pump–probe laser-ultrasound system. Photoacoustics 2014, 2, 63–74. [Google Scholar] [CrossRef] [Green Version]

- Newhouse, V.L.; Cathignol, D.; Chapelon, J. Introduction to ultrasonic pseudo-random code systems. Prog. Med. Imaging 1988, 215–226. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, G.; Xia, J. Non-Contact Shear Wave Generation and Detection Using High Frequency Air-Coupled Focused Transducer and Fiber Optic Based Sagnac Interferometer for Mechanical Characterization. Sensors 2022, 22, 5824. https://doi.org/10.3390/s22155824

Chen G, Xia J. Non-Contact Shear Wave Generation and Detection Using High Frequency Air-Coupled Focused Transducer and Fiber Optic Based Sagnac Interferometer for Mechanical Characterization. Sensors. 2022; 22(15):5824. https://doi.org/10.3390/s22155824

Chicago/Turabian StyleChen, Gui, and Jinjun Xia. 2022. "Non-Contact Shear Wave Generation and Detection Using High Frequency Air-Coupled Focused Transducer and Fiber Optic Based Sagnac Interferometer for Mechanical Characterization" Sensors 22, no. 15: 5824. https://doi.org/10.3390/s22155824

APA StyleChen, G., & Xia, J. (2022). Non-Contact Shear Wave Generation and Detection Using High Frequency Air-Coupled Focused Transducer and Fiber Optic Based Sagnac Interferometer for Mechanical Characterization. Sensors, 22(15), 5824. https://doi.org/10.3390/s22155824