1. Introduction

Electromagnetic induction is routinely used in eddy current testing as a non-destructive technique for flaw detection and material characterisation [

1,

2,

3,

4]. This technique offers the advantage of non-contact scanning without causing damage to the sample under test. Such measurements have various applications, for example, in the detection, localisation, and characterisation of metallic objects in the defence, aerospace, and quality control industries [

5,

6,

7,

8,

9]. Flaw detection through the use of eddy current induction has already shown potential in a number of industries, including aerospace, transport, and power supply [

10]. Applications within aerospace and related industries include surface and subsurface crack detection and subsurface corrosion detection [

11]. Additional applications include weld inspection, tube inspection, and material verification. Current technology typically uses frequencies on the order of kHz to MHz, which confer the potential to detect cracks ∼0.1 mm or less in depth [

1,

10]. The method is based on detecting and characterising electrically conductive objects using an active excitation, wherein an oscillating primary magnetic field

created by a coil induces eddy currents in the object. The eddy currents then create a secondary magnetic field,

, which can be measured by a sensitive magnetometer such as a fluxgate magnetometer. This technique can be used to detect a wide range of objects, as it is sensitive to both the electrical conductivity

and the magnetic permeability

of the object, where

is the vacuum permeability and

is the relative permeability. It has been shown that measuring both the amplitude and phase of the magnetic field can be used to reconstruct the eddy currents. This principle finds applications in various areas, such as in the monitoring of fuel cells [

12,

13].

A major challenge when detecting a metallic object is discriminating the object, such as an unexploded ordnance (UXO), from the noisy environment it is in [

14]. It takes time and resources to identify the object, especially due to false signals from other metal objects and cultural features such as metal buildings, pipelines, and oil well casings. By measuring the secondary magnetic field of an electrically conductive object which is placed in a low frequency primary magnetic field, distinct spectral characteristics such as electrical conductivity, magnetic permeability, object geometry, and size can be obtained [

15,

16,

17].

In this work, we have built a tabletop setup with coils and a commercial fluxgate magnetometer. With this setup, we carried out a systematic study in which a number of metallic objects were detected at different positions and with different excitation frequencies. From the frequency dependence of the measured induced magnetic field, we extracted values for the electrical conductivity and magnetic permeability of the objects by fitting experimental data to analytical formulae. In order to validate our experimental results, we built a range of different COMSOL models and made comparisons between the experimental results and numerical simulations. The results are in good agreement with the numerical simulations performed in COMSOL.

The rest of this work is organised as follows: first, we describe the experimental setup, and methods, and different configurations in which the metallic objects were placed, including on-axis eddy current measurements for (a) varying the frequency of the primary oscillating magnetic field and (b) varying the position of the object along the z-axis relative to the excitation coil and magnetometer. We then present off-axis measurements, in which the primary coil and magnetometer are fixed in position while the object is moved off-axis (i.e., along the y-axis at a fixed z-position). We present results for solid and hollow cylinders made of aluminium and steel.

2. Setup and Methods

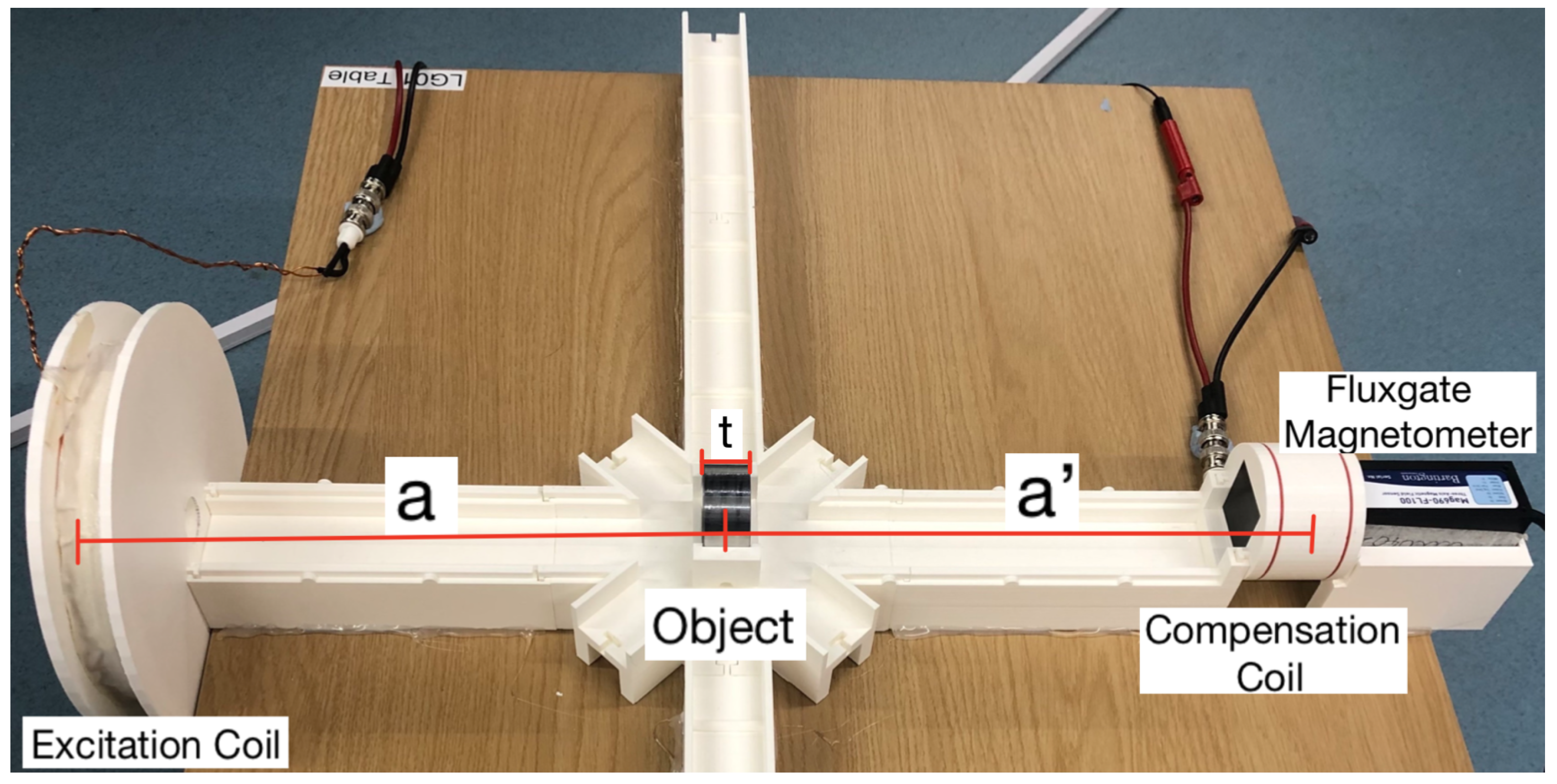

Our tabletop setup for detecting and characterising metallic samples is shown in

Figure 1. The setup is 3D printed, which allows the components to be placed with high precision. The experiments were controlled with an sbRIO-9627 field-programmable gate array (FPGA) programmed in LabVIEW. The FPGA can output sinusoidal signals, record data, perform lock-in amplification, apply real-time feedback, and analyse data. Magnetic fields are detected with a Bartington MAG690 fluxgate magnetometer, which has a scale factor of 100 mV/

T and a bandwidth of ≈1 kHz. The fluxgate magnetometer measures all three components of the magnetic field, although for simplicity only the

z-component was recorded. In our experiments, the data were obtained with the magnetic field oscillating at a particular frequency

. The resulting oscillating signal,

, can be decomposed into the in-phase

I and out-of-phase

Q components. These components are detected with a lock-in amplifier implemented via the FPGA.

Two coils, an excitation coil and a compensation coil, are used for generating magnetic fields. The excitation coil produces a primary field oscillating at a particular frequency ranging between 10–1000 Hz. The reference phase of the lock-in amplifier was adjusted such that the primary field was detected in the in-phase component I only. A compensation coil with a one-turn Helmholtz configuration and a radius of 3 cm was used, placed around the magnetometer’s detection point. We placed a 6 power resistor in series with the compensation coil. This creates an additional magnetic field , the ‘compensation field’, at the same frequency as the primary field, cancelling the primary magnetic field at the position of the magnetometer such that the total magnetic field in the absence of an object.

The excitation coil has an 8 cm radius, 60 windings, and is positioned such that the centre of the coil is 48.4 cm away from the detection point of the magnetometer. We used a relatively thick wire with a diameter of 1 mm, which leads to a small resistance and negligible heating in our excitation coil. Furthermore, a 10 power resistor was placed in series. In order to produce a magnetic field, a sinusoidal voltage of ≈7.2 V (peak to peak) is sent to the excitation coil and the phase is adjusted such that the signal is in the in-phase component of the lock-in output. The applied voltage generates a current of A in the excitation coil corresponding to a magnetic dipole moment of Am (pointing in the z-direction). The magnetic field produced is T at the position of the magnetometer. To compensate for this field, a V (peak to peak) oscillating voltage is applied to the compensation coil. This generates a current of A in the compensation coil corresponding to a magnetic dipole moment of Am.

When a conductive object is placed between the compensation coil and the excitation coil, eddy currents are induced in the object, producing a secondary magnetic field (or an ‘induced field’)

oscillating at the same frequency as the primary field. Note that the eddy currents are mainly generated by the primary field, as the compensation field is small (compared to the primary field) at the position of the object. The amplitude of the secondary field is therefore proportional to the amplitude of the primary field

. Due to the applied compensation field, the magnetometer directly measures the secondary field as the total oscillating field

at the magnetometer’s position. Applying a compensation field in order to measure the secondary field directly can be convenient; when using an optically pumped magnetometer for detecting the magnetic field, the signal-to-noise ratio of the measurement can improve by several orders of magnitude [

18,

19,

20]. However, we note that the stability and noise in our measurements with the fluxgate magnetometer was independent of whether the compensation field was applied or not (see

Appendix B).

We detected and characterised four different samples (see

Figure 2). The samples were solid/hollow cylinders with radii of 2 cm and width 2 cm. The hollow cylinders had a thickness of 4 mm. The cylinders were made of either 6061 T6 aluminium or 440c steel; 6061 T6 aluminium has an electrical conductivity of

MS/m, is non-magnetic, and has a relative magnetic permeability of

, while 440c steel has an unknown relative permeability. While the electrical conductivity is unknown, it can be determined experimentally [

21]. We chose to study aluminium and steel samples in order to highlight the differences between non-magnetic and magnetically permeable materials. Other metals, such as brass, copper, and ferrite, can be studied and differentiated using electromagnetic induction [

22].

Using our tabletop setup, we measured how the secondary field depends on the frequency of the primary field and on the distance from the excitation coil to the sample, and hence from the sample to the fluxgate. For on-axis measurements, the object was placed directly between the excitation coil and the magnetometer. In order to study how variations in the frequency affect the induced eddy currents, the sample was placed 22.4 cm away from the front of the excitation coil and the frequency was varied between 10 Hz and 1 kHz. When varying the distance of the object, a constant frequency of 500 Hz was used. The conductive objects were placed at approximately 5 cm intervals, beginning at 5 cm from the front of the excitation coil to 39.5 cm away. The off-axis measurements were carried out with the samples approximately half-way between the two coils, that is, 22.4 cm away from the front of the excitation coil. The conductive objects were placed from 0 cm to 34 cm off-axis, then the induced magnetic field was measured.

3. Numerical Simulations

Eddy current simulations were performed in COMSOL Multiphysics 5.6 using the AC/DC module. The Magnetic Fields interface was used to compute the magnetic field and induced current distributions in and around the coils and conductors. The default settings in COMSOL were used for this interface. The experimental setup was built as a 3D model (

Figure 3). The model consisted of a circular coil placed above a metallic object. To reduce complexity, an imaginary single-turn coil was chosen for the primary magnetic field. The coil and the object were placed in the finite sphere air domain, the size of which was ten times bigger than the size of the object. As seen in

Figure 3, the model includes the infinite element domain, which is one-tenth of the overall dimension of the model. The functionality of the infinite domain means that the governing equations behave similarly to nature and achieve a non-reflecting boundary condition. The finite element mesh was used to subdivide the CAD model into smaller domains, where a set of equations can be solved. As these elements are made as small as possible (i.e., the mesh is refined), the solution approaches the true solution. We performed subsequent mesh refinements until no appreciable changes occurred in the simulated curves; these results are shown in

Appendix A.

Figure 3b shows that the finite element mesh consists of three-dimensional tetrahedral solid elements and five layers of infinite element meshes, which have been added to the spherical domain. All of the simulations were performed on a workstation using a 3.60 GHz Intel(R) Xeon processor with 128 GB RAM.

Each simulation was run twice, first with the object present (matching the properties of those used experimentally) and then again without the object present. Instead of removing the object from the simulation, its properties (most notably its electrical conductivity and magnetic permeability) were changed to match that of the host medium (air). When using this technique, the mesh was preserved in both cases, eliminating the influence of the mesh on the results. The difference between these two simulation outputs is the magnetic field induced in the object.

Figure 4 shows the directions of the primary and secondary magnetic fields when an object is placed on-axis and off-axis, respectively. When the object is placed on-axis, the primary and secondary magnetic fields only have a

z-component at the magnetometer position. When the object is placed off-axis in the

y-

z-plane, the secondary field generally has both

y- and

z-components. In the following section, we present experimentally measured values for the

z-component of the secondary field and compare them to the values from the numerical simulations.

4. Results and Discussion

Figure 5 shows examples of experimentally recorded time traces when conductive objects were placed into the setup for ∼10 s and then taken back out for ∼5 s. Three repeats of this measurement were taken. The time traces show the demodulated fluxgate magnetometer signals

I and

Q for an excitation frequency of 500 Hz when aluminium and steel cylinders, respectively, were placed into the setup. Using these time traces, the in-phase

and out-of-phase

components of the secondary magnetic field can be found by subtracting the signals with and without the object. The standard deviation (SD) of

and

was ∼0.03 mV in all time traces for both the aluminium and steel samples. We found that the in-phase component for aluminium (

Figure 5a) has a signal-to-noise ratio (SNR) of ∼17, while the out-of-phase component has an SNR of ∼7. Similarly, we can see that for steel (

Figure 5b) the SNR is ∼24 for the in-phase component of the field and ∼4 for the out-of-phase component. The values for

and

can then be used to calculate the magnitude of the secondary field relative to the primary magnetic field

measured at the magnetometer position as well as the phase

of the secondary magnetic field with respect to the primary magnetic field. In oder to account for the bandwidth of the magnetometer, the primary field was recorded at every frequency. Time traces were taken for a range of frequencies between 10 Hz and 1 kHz; the results are shown in

Figure 6.

4.1. Varying Frequency

Figure 6 shows the detected secondary magnetic field for solid aluminium (

Figure 6a,c,e) and steel (

Figure 6b,d,f) cylinders as functions of the excitation frequency,

f. The figure shows the in-phase

and out-of phase

components of the secondary field normalised to the amplitude of the primary field (

Figure 6a,b), the normalised amplitude of the secondary field (

Figure 6c,d), and the phase

of the secondary field relative to the primary field (

Figure 6c,d).

For the aluminium sample, the out-of-phase component

is linear up to around 50 Hz and dominates (i.e., is larger than

) up to 150 Hz (see

Figure 6a). The overall magnetic field ratio saturates at ∼350 Hz (see

Figure 6c) due to the skin effect. The skin effect becomes important when the skin depth

becomes comparable to or smaller than the thickness

t of the object, corresponding to frequencies

Hz when using

t = 2 cm,

and

= 24.6 MS/m for our aluminium sample. For a non-magnetic sample, such as our aluminium sample, the phase

at low frequencies, when the signal is mainly in the out-of-phase component, and approaches

at higher frequencies, when the in-phase component dominates (see

Figure 6e). This is due to the secondary field being in the opposite direction to the primary field at high frequencies. The conductivity of our aluminium sample can be extracted from the gradient

at low frequencies. This is achieved by comparing the experimentally determined gradient to an analytical formula valid for a non-magnetic conductive cylinder. Detailed calculations based on [

23] are presented in

Appendix C. Using the gradient of the magnetic field ratio up to 20 Hz we determined the conductivity to be

MS/m, which is in agreement with the expected value of 24.6 MS/m for 6061 T6 aluminium.

Figure 6a,c,e show the results of the numerical simulations carried out in COMSOL, which agree very well with these experimental results.

For our steel sample, the largest signal is seen at low frequencies, as shown in

Figure 6b. This is because steel is magnetically permeable. The secondary field is produced in the same direction as the primary field due to steel being ferromagnetic. As the in-phase component dominates at all frequencies, as expected the phase of the signal is small

(

Figure 6f) and the magnetic field ratio (

Figure 6d) is very similar to that of the in-phase component. While the overall detected magnetic field decreases slightly with frequency, its signal remains a large one. It can be seen that at higher frequencies the out of-phase component increases as the in-phase component decreases.

The exact value of the magnetic permeability of the 440c steel samples we used was not known to us in advance. In [

21], their 440c steel samples were found to have a value of

16–17. However, no other studies could be found in which the magnetic permeability of 440c steel has been calculated, and thus it is unknown how much this value changes between samples. For low permeabilities, a small change in permeability can cause a large change in the detected signal [

21,

24]. As

, the change in the signal is much smaller. Hence, in order for a simulation comparison to be performed, the conductivity and permeability first need to be determined experimentally. To determine these values, we fitted our experimental results to analytical formulae from [

21]. As those formulae are valid for a sphere in a uniform field, and our experimental objects were cylinder and were not in a uniform RF field, we included a scale factor in the fit function (see

Appendix C.2). For our 440c steel sample, a permeability of

and conductivity of

MS/m were obtained from the fit (see

Figure A4); these values were then used in the simulations. The simulation results for the magnetic field ratio agree within ∼5% with the experimental data for these parameters, with both following the same trends. Hence, these values were used throughout the simulations.

The obtained results for the solid aluminium and steel cylinders are shown side-by-side in

Figure 6. As can be seen, the samples can easily be differentiated by varying the excitation frequency. In particular, at low frequencies the phase of the secondary magnetic field is close to

for steel (which is magnetic), while the phase is close to

for aluminium (which is non-magnetic). We performed measurements with hollow aluminium and steel cylinders as well;

Figure 7 shows a comparison of the magnetic field ratio

as a function of frequency for the solid and hollow cylinders (see

Figure 2). We found that the secondary field from the hollow cylinders was close to that of the solid cylinders, which is due to the objects having similar dimensions.

4.2. Varying Distance

In this subsection, we present our on-axis measurements when the objects were placed directly in between the excitation coil and the fluxgate magnetometer. The excitation coil was placed at 0 cm. The conductive objects were then placed at intervals between 5 cm and 39.5 cm away from the excitation coil. The measurements were taken at 500 Hz. This frequency was chosen based on

Figure 7, as there is a large signal for both aluminium and steel. For both aluminium and steel objects, the magnetic field ratio is smallest when the object is halfway between the excitation coil and fluxgate magnetometer and largest when the object is placed near either the excitation coil or the magnetometer (see

Figure 8). By comparing

Figure 8a,b, it can be seen that the signal is larger for steel than aluminium, as is the case when the frequency is varied. The sample can be detected at all positions.

Figure 8 shows the results of numerical simulations, again showing good agreement between experiment and simulation.

4.3. Off-Axis Measurements

Here, we present our results when detecting objects placed off-axis. The object was placed at

cm (on-axis) to

cm off-axis. As both the aluminium and steel cylinders are moved off-axis, the in-phase and out-of-phase components become smaller and change their signs, as shown in

Figure 9. For aluminium, the signals change their sign when the object is around 16 cm off-axis. Similarly, for steel the signal changes its sign when the object is around 12 cm off-axis. These results were validated by COMSOL simulations. The reason for the change in sign is due to the orientation of the induced dipole (see

Figure 4). In the experiment, only the

z-component of the magnetic field was recorded; however, the secondary magnetic field generally has both

y- and

z-components when the object is placed off-axis. In order to study how the vector components of the detected secondary magnetic field change as the object is moved off the axis, we carried out COMSOL simulations in which the object was swept along the

y-axis (see

Figure 10). For the analysis of solid aluminium and steel cylinders,

and

were obtained in addition to

. The signal was measured at an excitation frequency of 500 Hz in order to match the experimental conditions. We found that the

z-component of the secondary magnetic field is maximal when the object is on-axis (at

), and that the

y-component reaches a maximum at around 5 cm to 10 cm for both aluminum and steel samples. The

x-component of the field is zero, as the induced dipole is in the

y–

z-plane.

5. Conclusions

In conclusion, we have detected and characterised non-magnetic (aluminium) and magnetic (steel) samples by inducing eddy currents in them and detecting the secondary magnetic field with a fluxgate magnetometer. We have shown that the samples can be differentiated by varying the frequency of the primary magnetic field. Their electrical conductivity and magnetic permeability were determined by fitting the experimentally measured secondary field to analytical formulae. Overall, our experimental results are in good agreement with numerical simulations carried out in COMSOL. Using a 3D printed setup was critical for achieving good agreement, as it enabled us to place samples at well-defined positions in a reproducible way. By varying the position of the sample with respect to the excitation coil and magnetometer, we were able to demonstrate the possibility of locating metallic objects based on the

x-,

y-, and

z-components of the secondary magnetic field. Our experimental setup (primary coil, object, fluxgate magnetometer, and compensation coil) was placed horizontally on a table. However, by measuring all components of the magnetic field, our apparatus is able to detect objects placed below the table as well. If the same setup were modified to be used outdoors, it would thus be able to detect and characterise underground objects. Localisation of a magnetic dipole can be carried out using a small array of vector fluxgate magnetometers [

25]. Using a primary field and detecting the induced secondary magnetic field has advantages in that both magnetic and non-magnetic objects can be detected. Our measurements were carried out in unshielded conditions using lock-in detection at particular discrete frequencies between 10 Hz and 1000 Hz. This method is not sensitive to the Earth’s background magnetic field (around 0.5 Gauss in our laboratory) as long as it is within the range of the magnetometer (which in this case was

Gauss, although the same magnetometer is available with a

Gauss range). This method can potentially be application to the detection of unexploded ordnance. For outdoor measurements, our setup could be mounted on a moving platform on land, or alternatively on an underwater glider [

17] or an airborne drone [

26,

27]. Technical difficulties may arise due to additional noise from a moving platform. Additionally, for detection of objects at larger distances the magnetic dipole moment of the primary coil should be increased. The localisation and characterisation of samples could be further explored with the help of machine learning [

28]. It is worth noting that, although we used a fluxgate magnetometer to detect eddy currents in this study, other types of sensors can be used, including optically pumped magnetometers [

29,

30,

31,

32,

33] and magnetoresistive sensors [

34,

35]. Using a highly sensitive optically pumped magnetometer instead of a fluxgate magnetometer could potentially extend the detection range [

20].