Comparative Analysis of Multilayer Lead Oxide-Based X-ray Detector Prototypes

Abstract

:1. Introduction

2. Materials and Methods

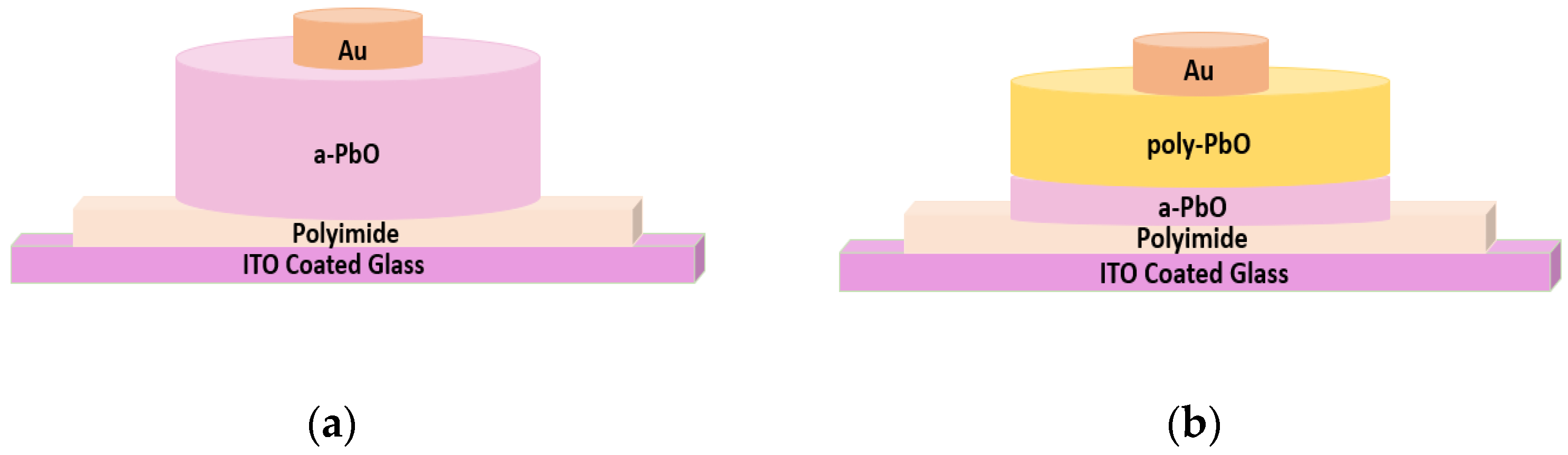

2.1. Preparation of Detectors

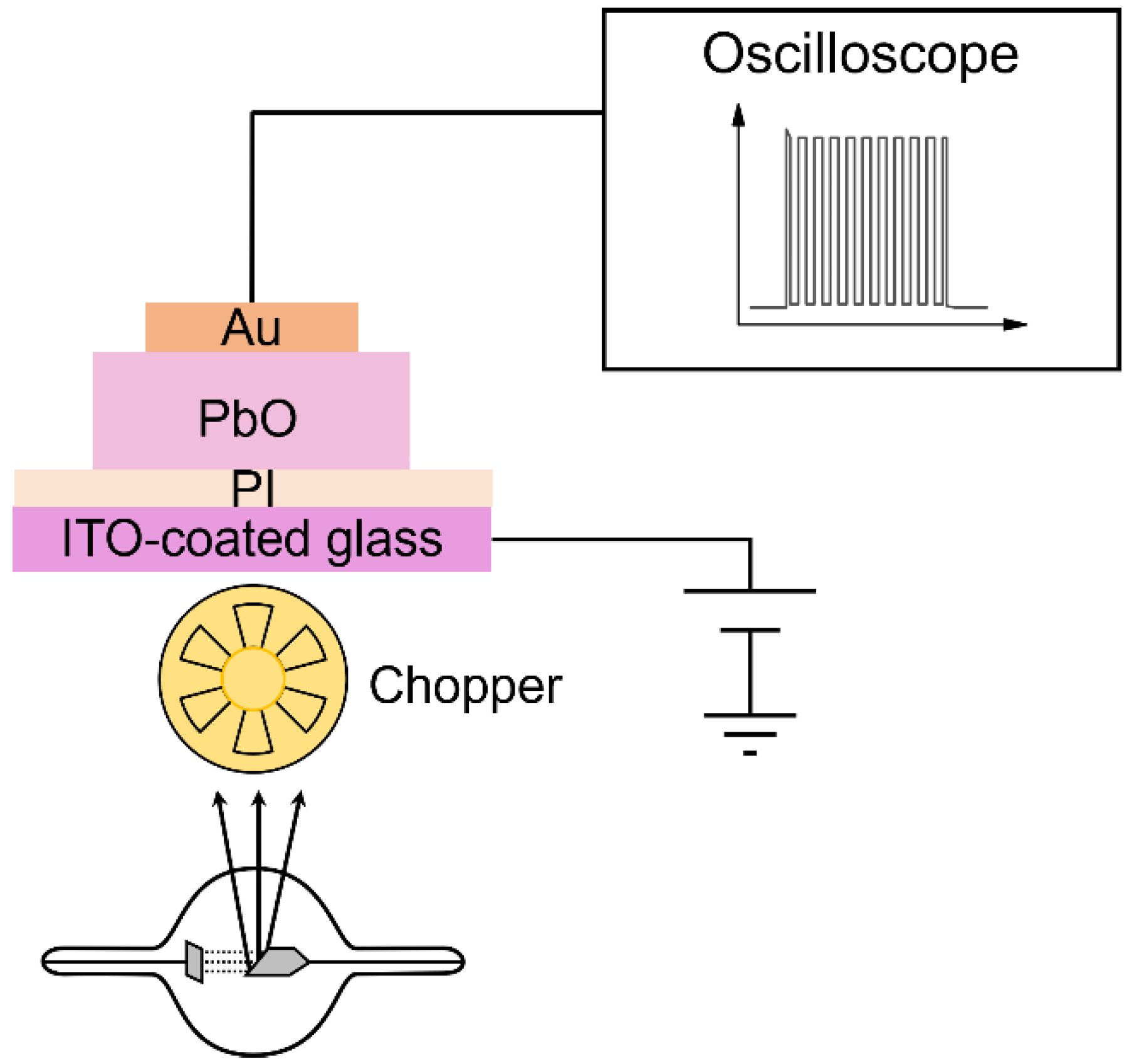

2.2. Detector Characterization

2.2.1. X-ray Sensitivity

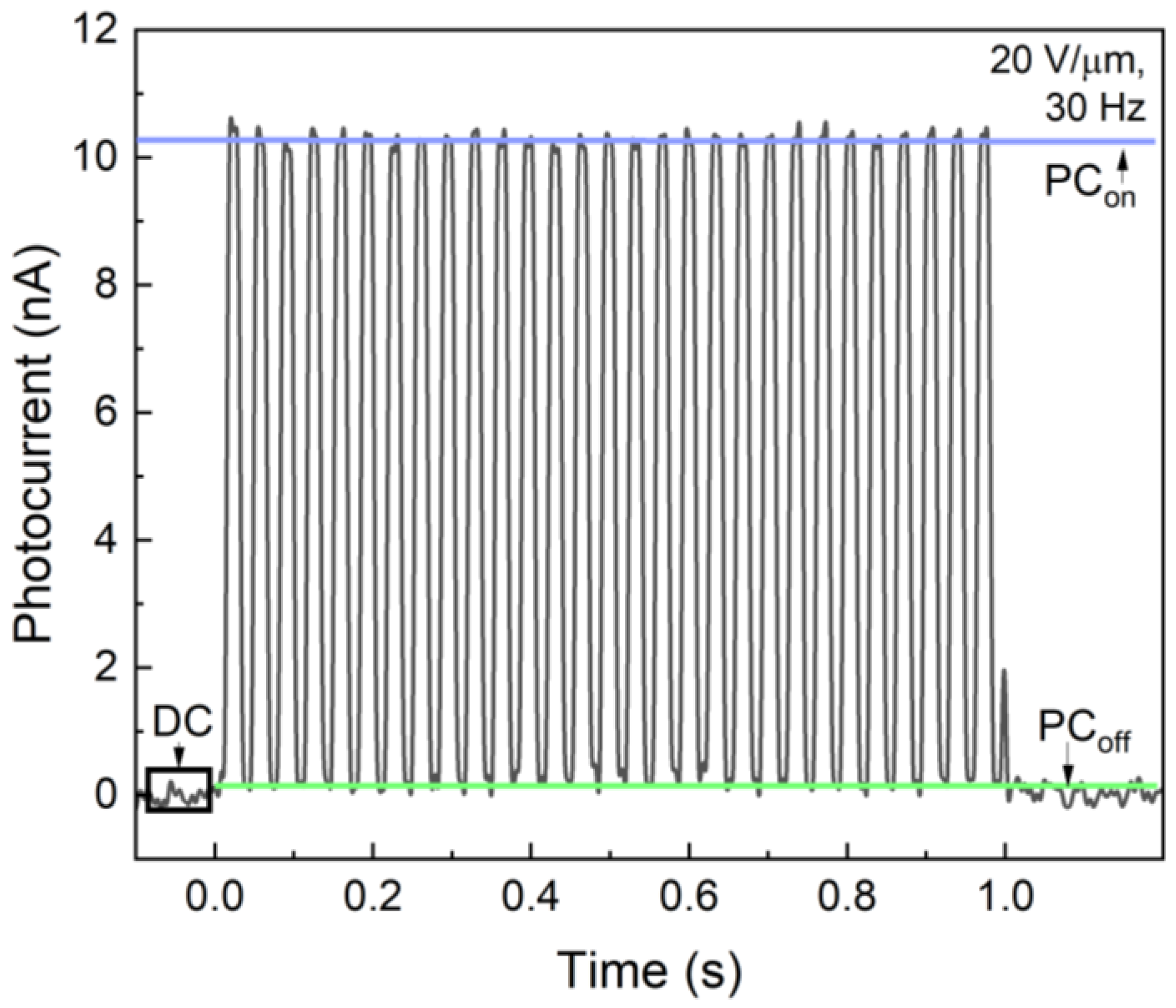

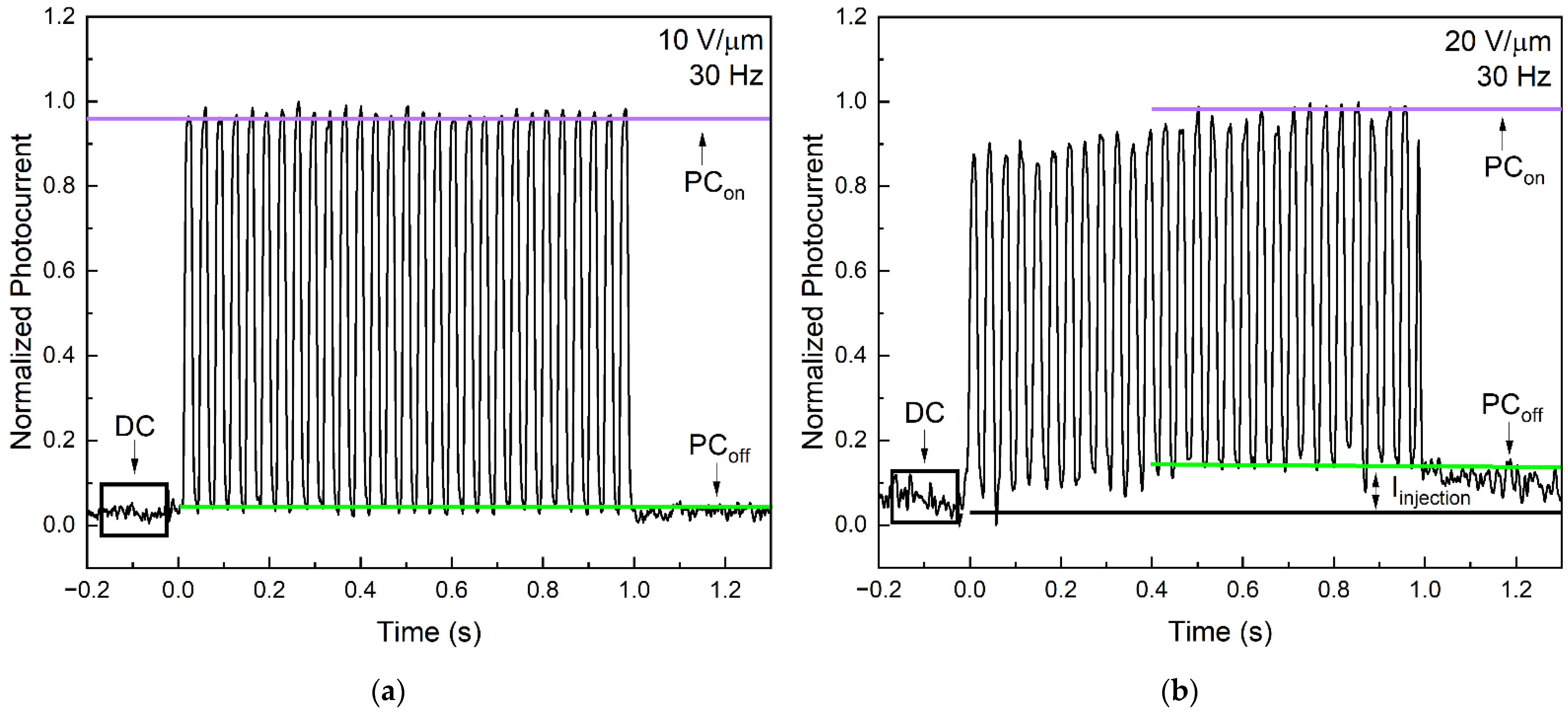

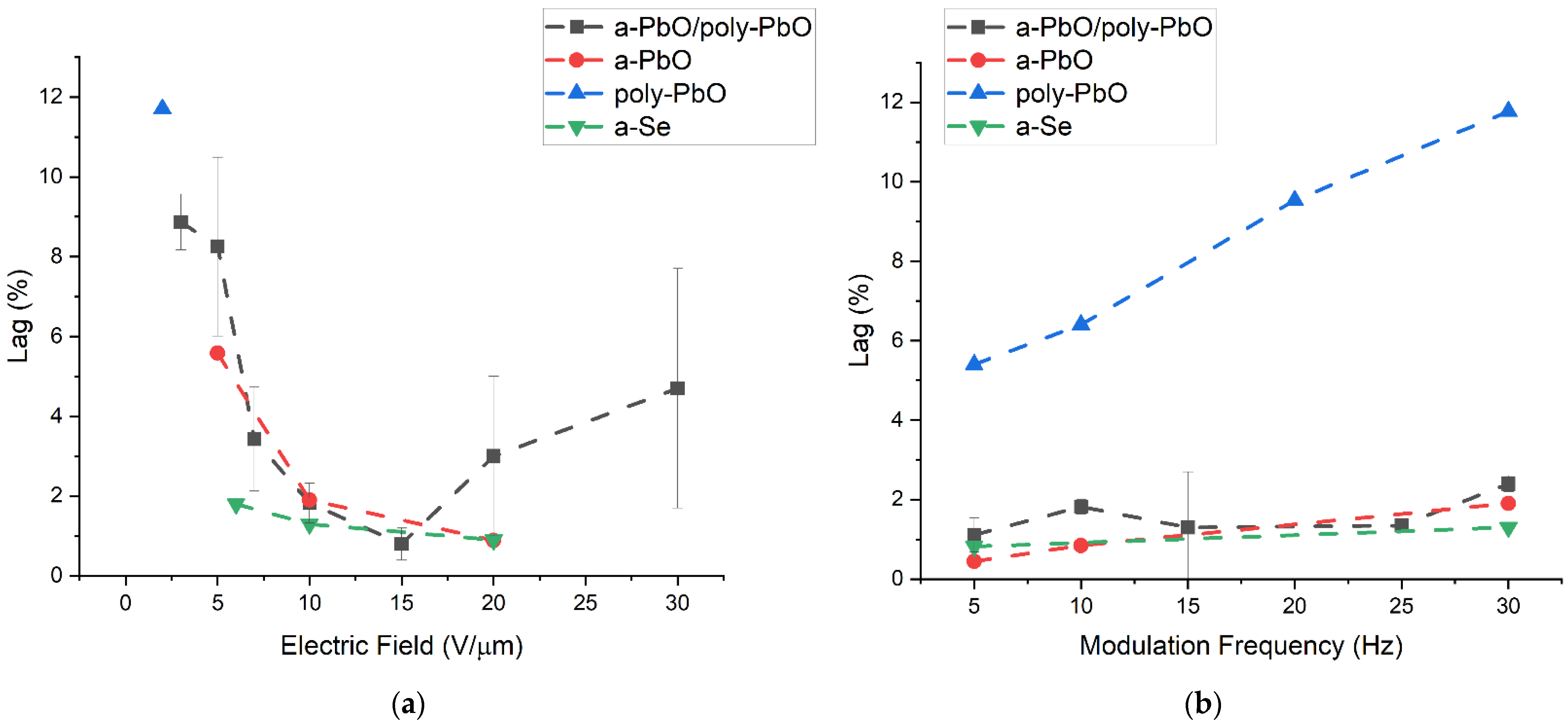

2.2.2. Temporal Response

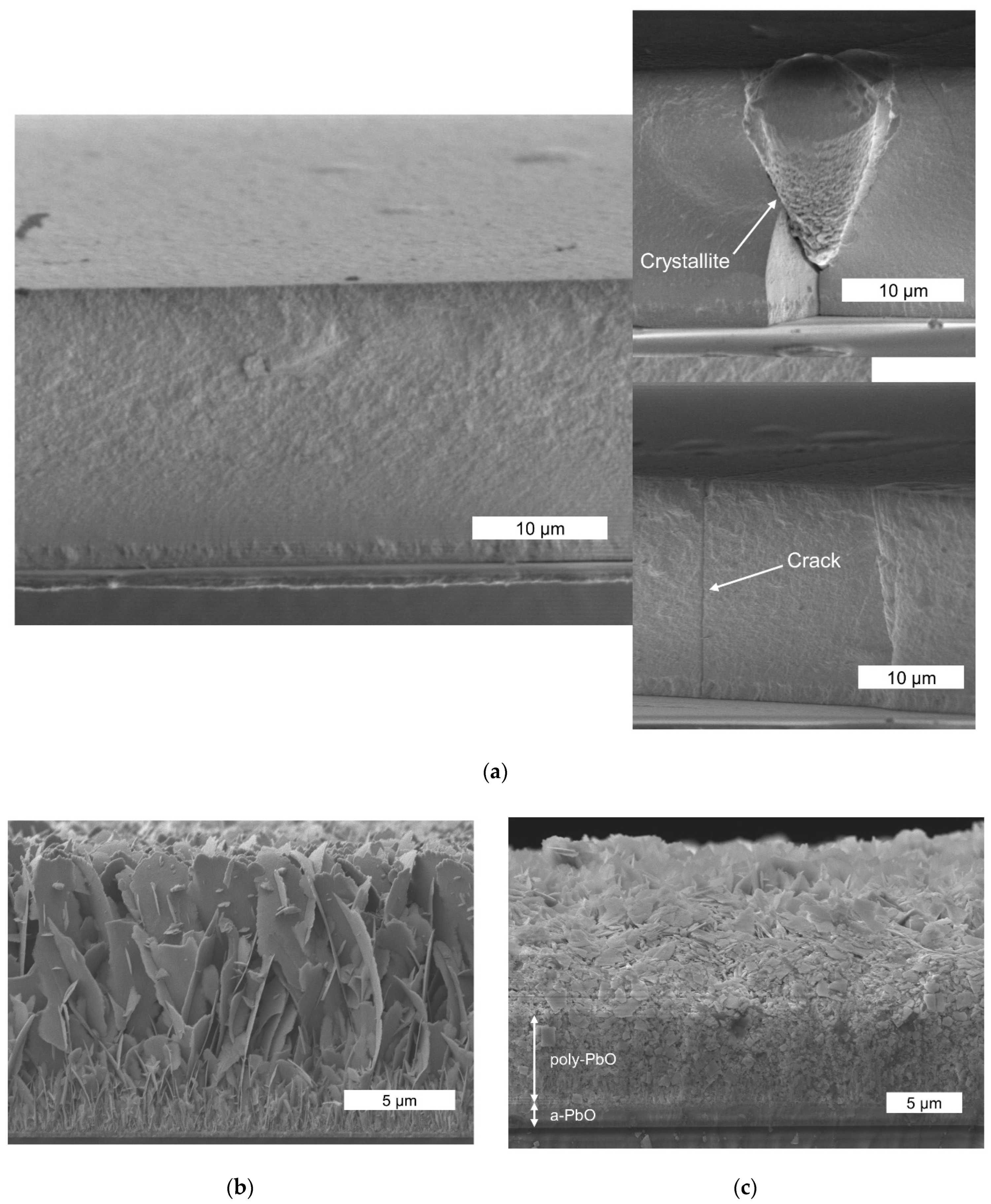

2.2.3. Morphological Analysis

3. Results

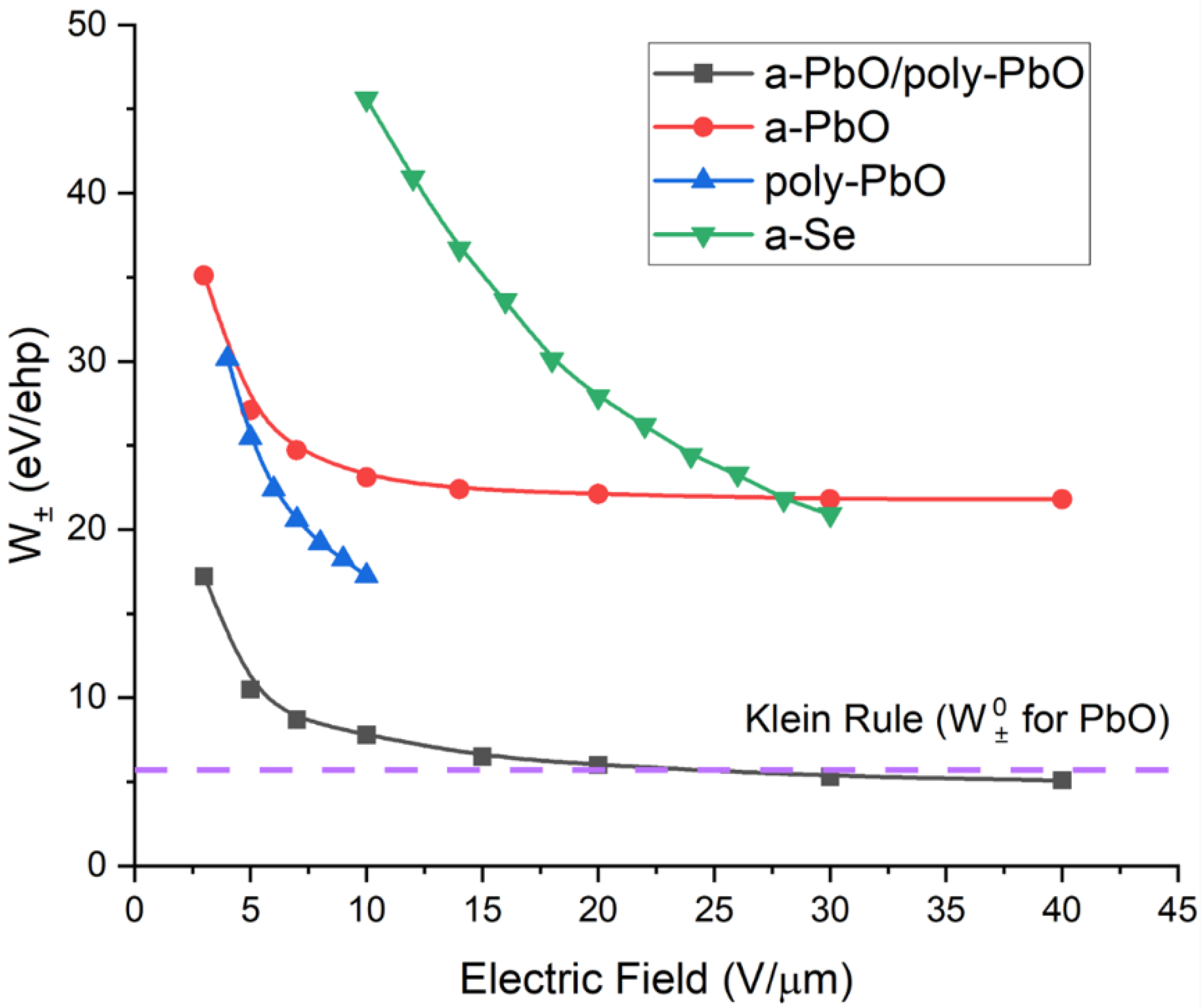

3.1. X-ray Sensitivity

3.2. Temporal Response

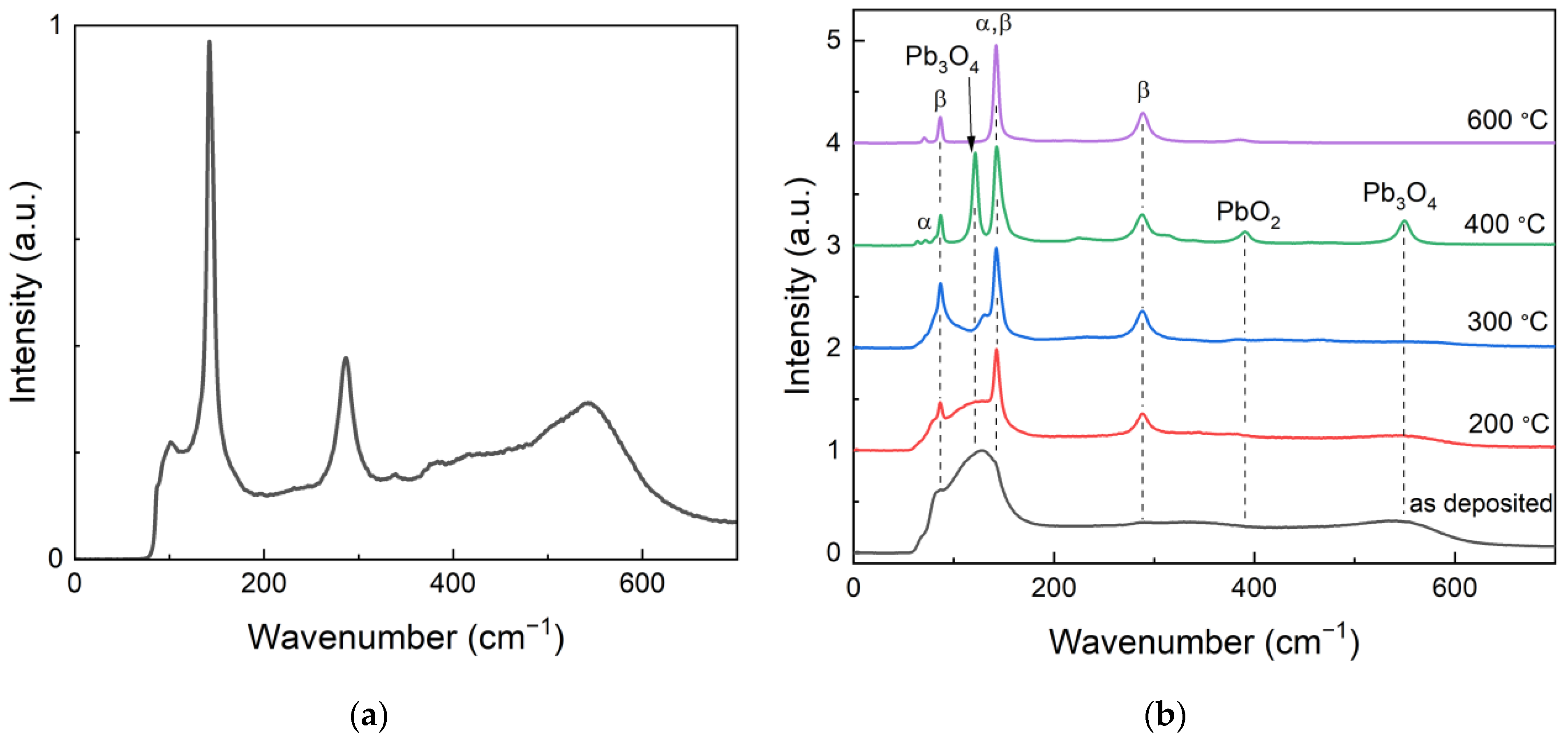

3.3. Morphological Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kasap, S.O.; Frey, J.B.; Belev, G.; Tousignant, O.; Mani, H.; Greenspan, J.; Laperriere, L.; Bubon, O.; Reznik, A.; DeCrescenzo, G.; et al. Amorphous and Polycrystalline Photoconductors for Direct Conversion Flat Panel X-Ray Image Sensors. Sensors 2011, 11, 5112–5157. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kasap, S.O. Doped and Stabilized Amorphous Selenium Single and Multilayer Photoconductive Layers for X-Ray Imaging Detector Applications. In Photoconductivity and Photoconductive Materials; Wiley: Hoboken, NJ, USA, 2022; pp. 715–779. [Google Scholar] [CrossRef]

- Kasap, S.O.; Frey, J.B.; Belev, G.; Tousignant, O.; Mani, H.; Laperriere, L.; Reznik, A.; Rowlands, J.A. Amorphous Selenium and Its Alloys from Early Xeroradiography to High Resolution X-Ray Image Detectors and Ultrasensitive Imaging Tubes. Phys. Status Solidi 2009, 246, 1794–1805. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, H.; Yang, D.; Wangyang, P.; Gao, X.; Gou, Z.; Zhu, X. Electrical Properties of X-Ray Detector Based on Bismuth Tri-Iodide Single Crystal with Electrode Configuration Considering. Mater. Res. Express 2019, 6, 55902. [Google Scholar] [CrossRef]

- Condeles, J.F.; Mulato, M. Polycrystalline Lead Iodide Films Produced by Solution Evaporation and Tested in the Mammography X-Ray Energy Range. J. Phys. Chem. Solids 2016, 89, 39–44. [Google Scholar] [CrossRef]

- Sun, H.; Zhao, B.; Zhu, X.; Zhu, S.; Yang, D.; Wangyang, P.; Gao, X. Laser-Induced Surface Recrystallization of Polycrystalline PbI 2 Thick Films for X-Ray Detector Application. Appl. Surf. Sci. 2018, 427, 1146–1151. [Google Scholar] [CrossRef]

- Street, R.A.; Ready, S.E.; van Schuylenbergh, K.; Ho, J.; Boyce, J.B.; Nylen, P.; Shah, K.; Melekhov, L.; Hermon, H. Comparison of PbI2 and HgI2 for Direct Detection Active Matrix X-Ray Image Sensors. J. Appl. Phys. 2002, 91, 3345–3355. [Google Scholar] [CrossRef]

- Antonuk, L.E.; El-Mohri, Y.; Zhao, Q.; Jiang, H. Exploration of Strategies for Implementation of Screen-Printed Mercuric Iodide Converters in Direct Detection AMFPIs for Digital Breast Tomosynthesis. In SPIE Medical Imaging, Proceedings of the Medical Imaging 2017: Physics of Medical Imaging, Orlando, FL, USA, 10 March 2017; Flohr, T.G., Lo, J.Y., Gilat Schmidt, T., Eds.; SPIE: Bellingham, WA, USA; Volume 10132, p. 101320A.

- Lee, D.; Lee, K.; Seo, J. High Signal-to-Noise Ratio HgI2 X-Ray Detector Assisted with Ultraviolet Radiation. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2019, 941, 162364. [Google Scholar] [CrossRef]

- Zhou, L.; Huang, Z.; Zhao, X.; He, Y.; Chen, L.; Xu, M.; Zhao, K.; Zhang, S.; Ouyang, X. A High-Resistivity ZnO Film-Based Photoconductive X-Ray Detector. IEEE Photonics Technol. Lett. 2019, 31, 365–368. [Google Scholar] [CrossRef]

- Lee, S.; Kim, J.S.; Ko, K.R.; Lee, G.H.; Lee, D.J.; Kim, D.W.; Kim, J.E.; Kim, H.K.; Kim, D.W.; Im, S. Direct Thermal Growth of Large Scale Cl-Doped CdTe Film for Low Voltage High Resolution X-Ray Image Sensor. Sci. Rep. 2018, 8, 14810. [Google Scholar] [CrossRef]

- Znamenshchykov, Y.V.; Kosyak, V.V.; Kononov, O.K.; Shpetnyi, I.O.; Grebinaha, V.I.; Fochuk, P.M.; Opanasyuk, A.S. Electrical, Structural and Optical Properties of Cd1-Zn Te Thick Polycrystalline Films. Vacuum 2018, 149, 270–278. [Google Scholar] [CrossRef]

- Simon, M.; Ford, R.A.; Franklin, A.R.; Grabowski, S.P.; Menser, B.; Much, G.; Nascetti, A.; Overdick, M.; Powell, M.J.; Wiechert, D.U. Analysis of Lead Oxide (PbO) Layers for Direct Conversion X-Ray Detection. IEEE Trans. Nucl. Sci. 2005, 52, 2035–2040. [Google Scholar] [CrossRef]

- Rowlands, J.A. Material Change for X-Ray Detectors. Nature 2017, 550, 47–48. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ghosh, J.; Sellin, P.J.; Giri, P.K. Recent Advances in Lead-Free Double Perovskites for x-Ray and Photodetection. Nanotechnology 2022, 33, 312001. [Google Scholar] [CrossRef] [PubMed]

- Jana, A.; Cho, S.; Patil, S.A.; Meena, A.; Jo, Y.; Sree, V.G.; Park, Y.; Kim, H.; Im, H.; Taylor, R.A. Perovskite: Scintillators, Direct Detectors, and X-Ray Imagers. Mater. Today 2022, 55, 110–136. [Google Scholar] [CrossRef]

- Simon, M.; Ford, R.A.; Franklin, A.R.; Grabowski, S.P.; Menser, B.; Much, G.; Nascetti, A.; Overdick, M.; Powell, M.J.; Wiechert, D.U. PbO as Direct Conversion X-Ray Detector Material. In Medical Imaging 2004: Physics of Medical Imaging; Yaffe, M.J., Flynn, M.J., Eds.; SPIE: Bellingham, WA, USA, 2004; Volume 5368, p. 188. [Google Scholar]

- Semeniuk, O.; Grynko, O.; Decrescenzo, G.; Juska, G.; Wang, K.; Reznik, A. Characterization of Polycrystalline Lead Oxide for Application in Direct Conversion X-Ray Detectors. Sci. Rep. 2017, 7, 8659. [Google Scholar] [CrossRef] [PubMed]

- Berger, M.L.; Hubbell, J.H.; Seltzer, S.M.; Chang, J.; Coursey, J.S.; Sukumar, R.; Zucker, D.S.; Olsen, K. NIST Standard Reference Database 8 (XGAM); NIST Physical Measurement Laboratory: Gaithersburg, MD, USA, 2009. [Google Scholar]

- Semeniuk, O.; Reznik, A.; Sukhovatkin, V. Amorphous Lead Oxide Based Energy Detection Devices and Methods of Manufacture Thereof. U.S. Patent No 10,163,970, 25 December 2018. [Google Scholar]

- Semeniuk, O.; Grynko, O.; Juska, G.; Reznik, A. Amorphous Lead Oxide (a-PbO): Suppression of Signal Lag via Engineering of the Layer Structure. Sci. Rep. 2017, 7, 13272. [Google Scholar] [CrossRef] [PubMed]

- Grynko, O.; Thibault, T.; Pineau, E.; Reznik, A. Engineering of a Blocking Layer Structure for Low-Lag Operation of the a-PbO-Based X-Ray Detector. IEEE Trans. Electron Devices 2021, 68, 2335–2341. [Google Scholar] [CrossRef]

- Grynko, O.; Thibault, T.; Pineau, E.; Reznik, A. The X-Ray Sensitivity of an Amorphous Lead Oxide Photoconductor. Sensors 2021, 21, 7321. [Google Scholar] [CrossRef] [PubMed]

- Grynko, O.; Reznik, A. Progress in Lead Oxide X-Ray Photoconductive Layers. In Photoconductivity and Photoconductive Materials; Wiley: Hoboken, NJ, USA, 2022; pp. 643–688. [Google Scholar] [CrossRef]

- Semeniuk, O.; Csik, A.; Kökényesi, S.; Reznik, A. Ion-Assisted Deposition of Amorphous PbO Layers. J. Mater. Sci. 2017, 52, 7937–7946. [Google Scholar] [CrossRef] [Green Version]

- Rougeot, H.M.; Jean, A.; Mani, H.; Shukri, Z.A. B1 Indirect X-Ray Image Detector for Radiology. US Patent US 6,982,425, 3 January 2006. [Google Scholar]

- Polischuk, B.T.; Jean, A. Multilayer Plate for X-Ray Imaging and Method of Producing Same. U.S. Patent No. 5,880,472, 9 March 1999. [Google Scholar]

- Sadasivam, K.P.C. X-Ray Dose Dependence of Dark Current in Amorphous Selenium-Alloy X-Ray Photoconductors. PhD Thesis, University of Saskatchewan, Saskatoon, SK, Canada, 2019. [Google Scholar]

- Brauers, A.; Conrads, N.; Frings, G.; Schiebel, U.; Powell, M.J.; Glasse, C. Charge Collection in a Se photoconductor on a Thin Film Transistor Array during X-Ray Imaging. MRS Proc. 1997, 467, 919. [Google Scholar] [CrossRef]

- Imai, S. B2 Radiation Image Detector. US Patent US 7,834,324, 6 November 2010. [Google Scholar]

- Frey, J.B.; Belev, G.; Tousignant, O.; Mani, H.; Kasap, S.O. Dark Current in Multilayer Stabilized Amorphous Selenium X-ray Photoconductors. Phys. Status Solidi 2009, 6, S251–S254. [Google Scholar] [CrossRef]

- Irisawa, K.; Noda, K.; Hayashi, K.; Yamane, K.; Miyake, K. A1 Raditation Detector. US Patent US 2009/0294705, 24 May 2011. [Google Scholar]

- Belev, G.; Kasap, S.O. Reduction of the Dark Current in Stabilized A-Se Based X-Ray Detectors. J. Non-Cryst. Solids 2006, 352, 1616–1620. [Google Scholar] [CrossRef]

- Abbaszadeh, S.; Scott, C.C.; Bubon, O.; Reznik, A.; Karim, K.S. Enhanced Detection Efficiency of Direct Conversion X-Ray Detector Using Polyimide as Hole-Blocking Layer. Sci. Rep. 2013, 3, 3360. [Google Scholar] [CrossRef] [Green Version]

- Grynko, O.; Thibault, T.; Pineau, E.; Juska, G.; Reznik, A. Bila±±yer Lead Oxide X-Ray Photoconductor for Lag-Free Operation. Sci. Rep. 2020, 10, 20117. [Google Scholar] [CrossRef]

- Thibault, T.; Grynko, O.; Pineau, E.; Reznik, A. Dark Current Modeling for a Polyimide–Amorphous Lead Oxide-Based Direct Conversion X-Ray Detector. Sensors 2022, 22, 5829. [Google Scholar] [CrossRef]

- Hubbell, J.H.; Seltzer, S.M. Tables of X-Ray Mass Attenuation Coefficients and Mass Energy-Absorption Coefficients from 1 KeV to 20 MeV for Elements Z = 1 to 92 and 48 Additional Substances of Dosimetric Interest; Technical Report; National Institution of Standards and Technology-PL: Gaithersburg, MD, USA, 2004. [Google Scholar]

- Tucker, D.M.; Barnes, G.T.; Chakraborty, D.P. Semiempirical Model for Generating Tungsten Target X-Ray Spectra. Med. Phys. 1991, 18, 211–218. [Google Scholar] [CrossRef] [PubMed]

- Klein, C.A. Bandgap Dependence and Related Features of Radiation Ionization Energies in Semiconductors. J. Appl. Phys. 1968, 39, 2029–2038. [Google Scholar] [CrossRef]

- Zhao, B.; Zhao, W. Temporal Performance of Amorphous Selenium Mammography Detectors. Med. Phys. 2004, 32, 128–136. [Google Scholar] [CrossRef]

- Erdman, N.; Bell, D.C.; Reichelt, R. Scanning Electron Microscopy. In Springer Handbook of Microscopy; Springer: Cham, Switzerland, 2019; pp. 229–318. [Google Scholar] [CrossRef] [Green Version]

- Blevis, I.M.; Hunt, D.C.; Rowlands, J.A. Measurement of X-Ray Photogeneration in Amorphous Selenium. J. Appl. Phys. 1999, 85, 7958–7963. [Google Scholar] [CrossRef]

- Kabir, Z. X-Ray Photoconductivity and Typical Large-Area X-Ray Photoconductors. In Photoconductivity and Photoconductive Materials; Wiley: Hoboken, NJ, USA, 2022; pp. 613–641. [Google Scholar] [CrossRef]

- Qamar, A.; Leblanc, K.; Semeniuk, O.; Reznik, A.; Lin, J.; Pan, Y.; Moewes, A. X-Ray Spectroscopic Study of Amorphous and Polycrystalline PbO Films, α-PbO, and β-PbO for Direct Conversion Imaging. Sci. Rep. 2017, 7, 13159. [Google Scholar] [CrossRef]

- Bubon, O.; Jandieri, K.; Baranovskii, S.D.; Kasap, S.O.; Reznik, A. Columnar Recombination for X-Ray Generated Electron-Holes in Amorphous Selenium and Its Significance in a-Se X-Ray Detectors. J. Appl. Phys. 2016, 119, 124511. [Google Scholar] [CrossRef]

- Kasap, S.O.; Haugen, C.; Nesdoly, M.; Rowlands, J.A. Properties of A-Se for Use in Flat Panel X-Ray Image Detectors. J. Non-Cryst. Solids 2000, 266–269, 1163–1167. [Google Scholar] [CrossRef]

- Que, W.; Rowlands, J.A. X-Ray Photogeneration in Amorphous Selenium: Geminate versus Columnar Recombination. Phys. Rev. B 1995, 51, 10500–10507. [Google Scholar] [CrossRef]

- Abbaszadeh, S.; Allec, N.; Ghanbarzadeh, S.; Shafique, U.; Karim, K.S. Investigation of Hole-Blocking Contacts for High-Conversion-Gain Amorphous Selenium Detectors for X-Ray Imaging. IEEE Trans. Electron Devices 2012, 59, 2383–2389. [Google Scholar] [CrossRef]

- Camlica, A.; Kabir, M.Z.; Liang, J.; Levine, P.M.; Lee, D.L.; Karim, K.S. Use of Pulse-Height Spectroscopy to Characterize the Hole Conduction Mechanism of a Polyimide Blocking Layer Used in Amorphous-Selenium Radiation Detectors. IEEE Trans. Electron Devices 2020, 67, 633–639. [Google Scholar] [CrossRef]

- Huang, T.C.; Lim, G.; Parmigiani, F.; Kay, E. Effect of Ion Bombardment during Deposition on the X-ray Microstructure of Thin Silver Films. J. Vac. Sci. Technol. A Vac. Surf. Film. 1985, 3, 2161–2166. [Google Scholar] [CrossRef]

- Sain, T.; Singh, C.K.; Ilango, S.; Mathews, T. Crystallization Kinetics and Role of Stress in Al Induced Layer Exchange Crystallization Process of Amorphous SiGe Thin Film on Glass. J. Appl. Phys. 2019, 126, 125303. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, W.; Cao, K.; Li, Y.; Zha, G.; Tan, T. Cracking Mechanism of CdZnTe Polycrystalline Film Deposited on TFT Circuit Board at High Temperature by Close-Spaced Sublimation Method. Mater. Sci. Semicond. Processing 2021, 131, 105821. [Google Scholar] [CrossRef]

- Bubon, O.; DeCrescenzo, G.; Rowlands, J.A.; Reznik, A. Amorphous Selenium (a-Se) Avalanche Photosensor with Metal Electrodes. J. Non-Cryst. Solids 2012, 358, 2431–2433. [Google Scholar] [CrossRef]

- Miller, J.W.; Chesaux, M.; Deligiannis, D.; Mascher, P.; Bradley, J.D.B. Low-Loss GeO2thin Films Deposited by Ion-Assisted Alternating Current Reactive Sputtering for Waveguide Applications. Thin Solid Film. 2020, 709, 138165. [Google Scholar] [CrossRef]

- Wang, K.; Abbaszadeh, S.; Karim, K.S.; Rowlands, J.A.; Reznik, A. Reactive Ion-Assisted Deposition of Cerium Oxide Hole-Blocking Contact for Leakage-Current Suppression in an Amorphous Selenium Multilayer Structure. IEEE Sens. J. 2015, 15, 3871–3876. [Google Scholar] [CrossRef]

| Spin Coating Parameters | Hot Plate Curing | ||||

|---|---|---|---|---|---|

| Step 1 | Step 2 | Step 3 | Final Temperature, °C | 350 | |

| Duration of Step, s | 5 | 30 | 7 | Duration of Curing, min | 30 |

| Speed, rpm | 500 | 6000 | 0 | Rate of Change in Temperature, °C/min | 4 |

| Acceleration, rpm/s | 550 | 990 | −1100 | Nitrogen Flow, sL/min | 2 |

| Deposition Parameters | ||

|---|---|---|

| Conventional Thermal Deposition (poly-PbO) | Ion-Assisted Thermal Deposition (a-PbO) | |

| Base Pressure, Pa | 5 × 10−5 | 5 × 10−5 |

| Process Pressure, Pa | 2 × 10−1 | 6 × 10−2 |

| Furnace Temperature, °C | 1000 | 1000 |

| Substrate Temperature, °C | 100 | 100 |

| Deposition Rate, µm/min | 1 | 0.22 |

| Ion Energy, eV | 50 | |

| Ion Flux, mA/cm2 | 0.2 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pineau, E.; Grynko, O.; Thibault, T.; Alexandrov, A.; Csík, A.; Kökényesi, S.; Reznik, A. Comparative Analysis of Multilayer Lead Oxide-Based X-ray Detector Prototypes. Sensors 2022, 22, 5998. https://doi.org/10.3390/s22165998

Pineau E, Grynko O, Thibault T, Alexandrov A, Csík A, Kökényesi S, Reznik A. Comparative Analysis of Multilayer Lead Oxide-Based X-ray Detector Prototypes. Sensors. 2022; 22(16):5998. https://doi.org/10.3390/s22165998

Chicago/Turabian StylePineau, Emma, Oleksandr Grynko, Tristen Thibault, Alexander Alexandrov, Attila Csík, Sándor Kökényesi, and Alla Reznik. 2022. "Comparative Analysis of Multilayer Lead Oxide-Based X-ray Detector Prototypes" Sensors 22, no. 16: 5998. https://doi.org/10.3390/s22165998