Research and Application of Multi-Mode Joint Monitoring System for Shaft Wall Deformation

Abstract

:1. Introduction

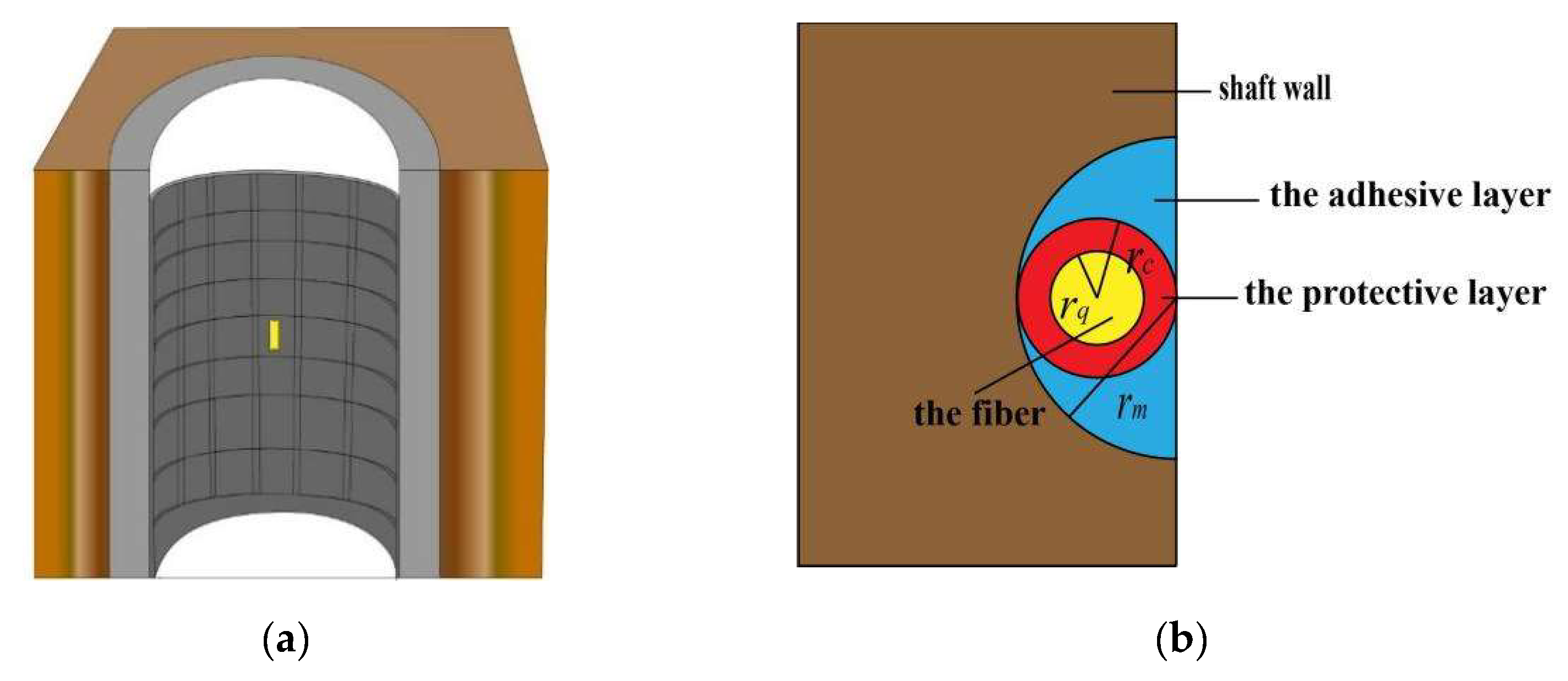

2. Analysis of Shaft Wall Damage Mechanism and Force Characteristics

2.1. Project Profile

2.2. Mechanisms of Shaft Wall Damage

2.3. Analysis of Shaft Wall Force Characteristics

- (1)

- Horizontal lateral pressure

- (2)

- Self-gravity load

- (3)

- Vertical additional stress

- (1)

- The outer wall of the shaft wall is buried in a deep soil layer, and the temperature remains basically constant. The inner wall of the shaft wall is connected to the outside, thus causing a temperature difference between the inside and outside. At this time, an additional vertical stress will be generated at the outer edge of the shaft wall.

- (2)

- When the internal temperature of the shaft wall changes greatly, the borehole wall will deform in the radial and vertical directions due to the principle of thermal expansion and contraction. In the radial direction, the interaction force is generated due to the blocking of the surrounding deep soil layer. In the vertical direction, the expansion and contraction of the borehole wall cause the interaction between the borehole wall and the soil layer to generate negative friction.

3. Strain-Sensing Transmission Mechanism of FBG on Shaft Wall Surface

Analysis of Shaft Wall Force Characteristics

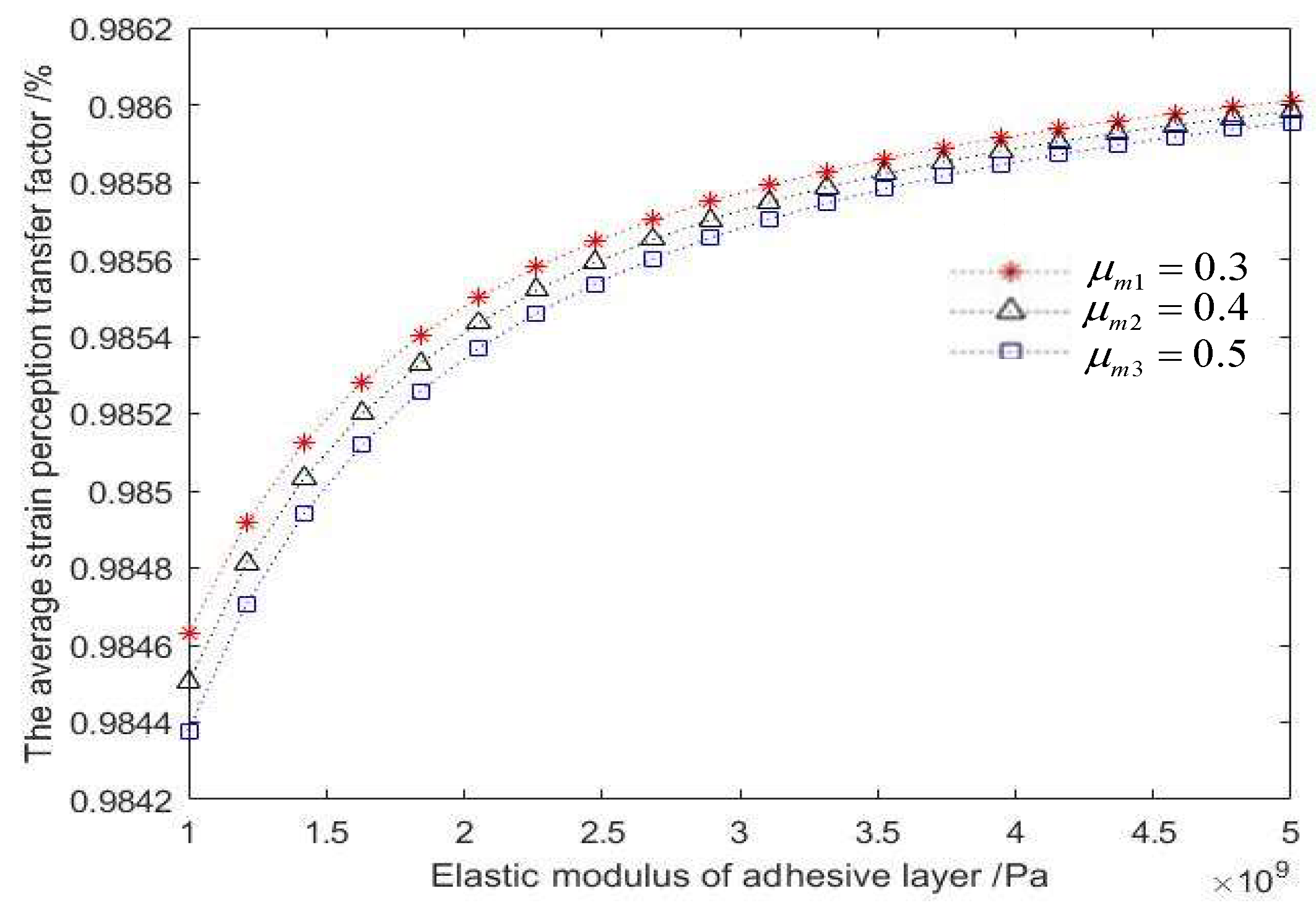

4. Analysis of Strain-Sensing Transmission Factors between Shaft Wall and the FBG

5. Field Industrial Test

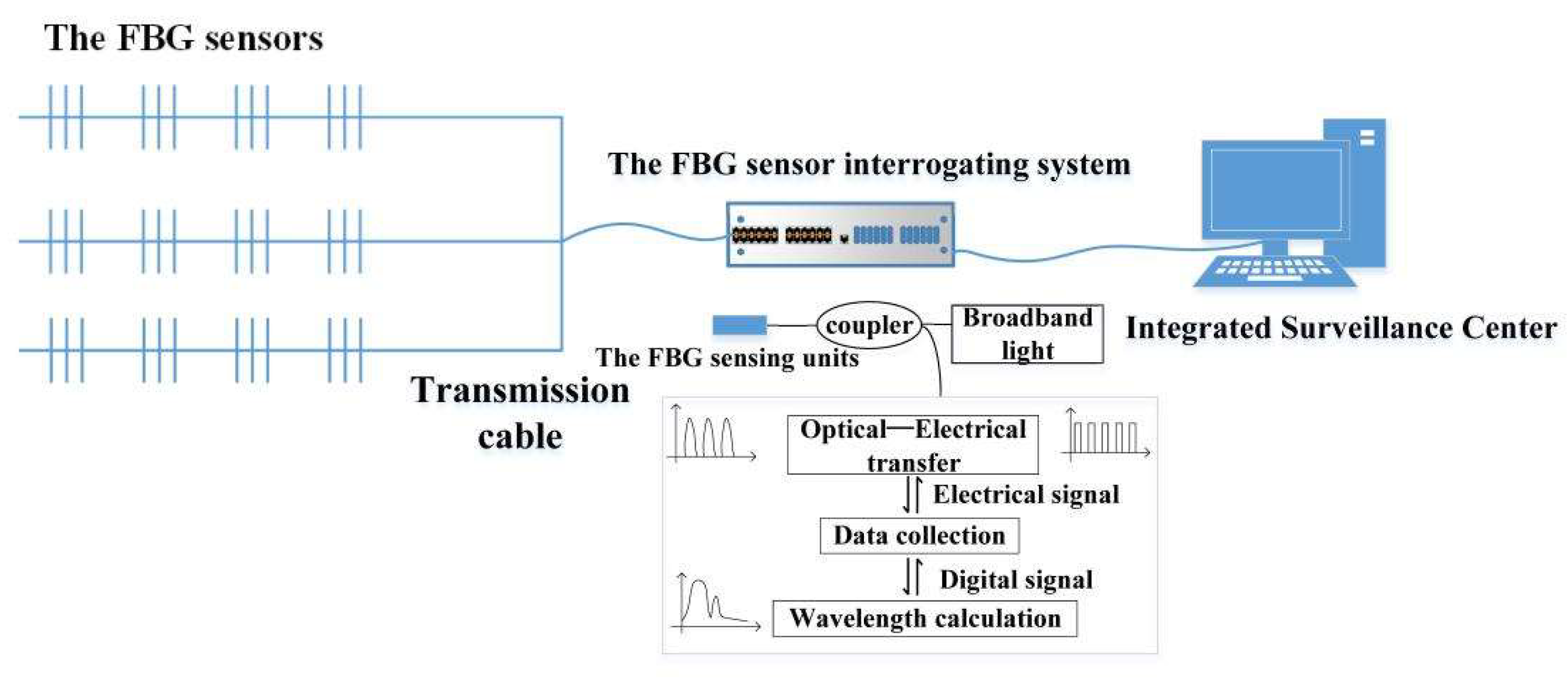

5.1. Shaft Wall Monitoring System

5.1.1. Monitoring System Principle

5.1.2. Monitoring Methods

5.1.3. Sensors Arrangement

- (1)

- Vibrating-string sensors arrangement

- (2)

- FBG sensors arrangement

5.1.4. The FBG Sensing Demodulation System

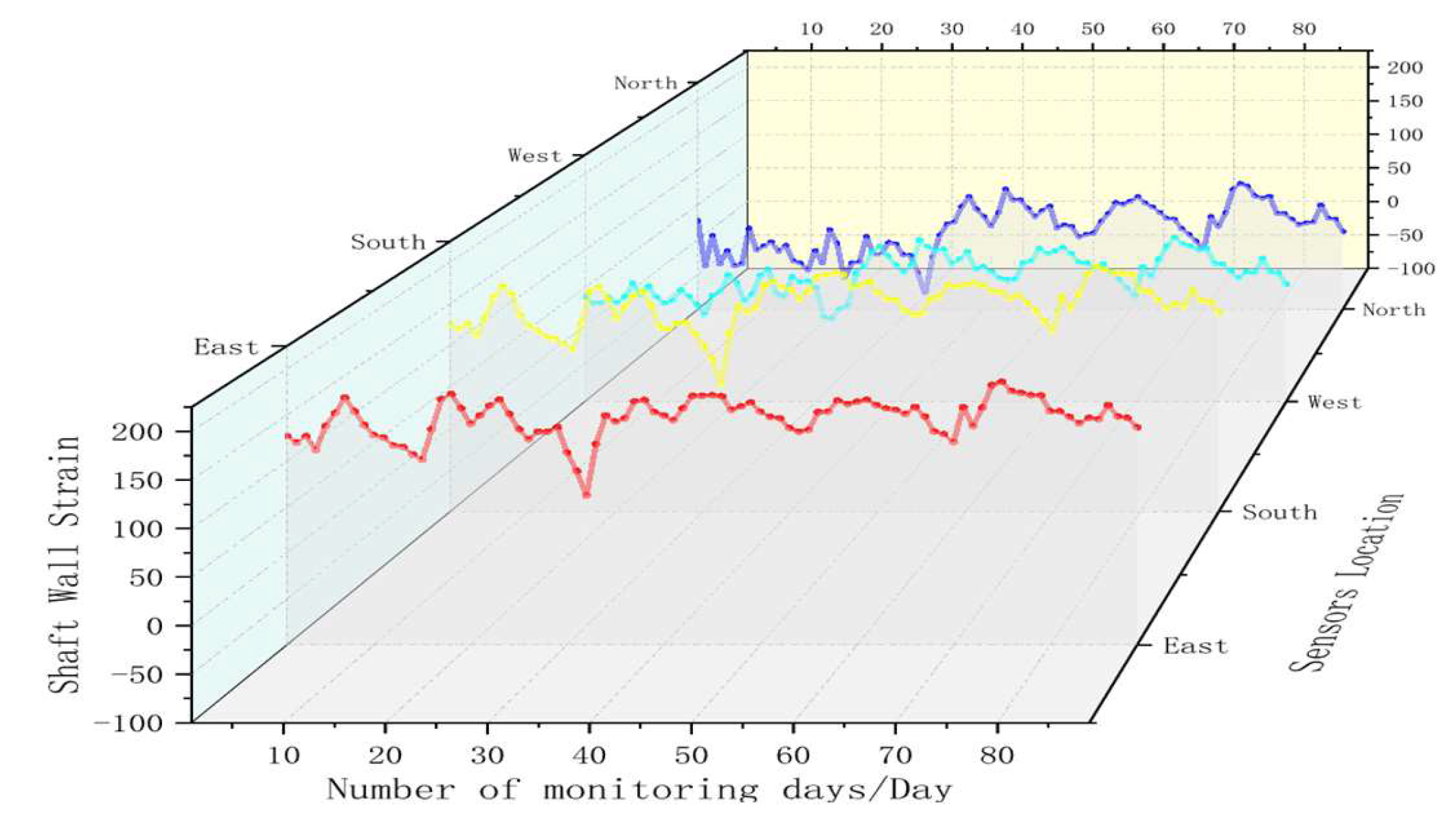

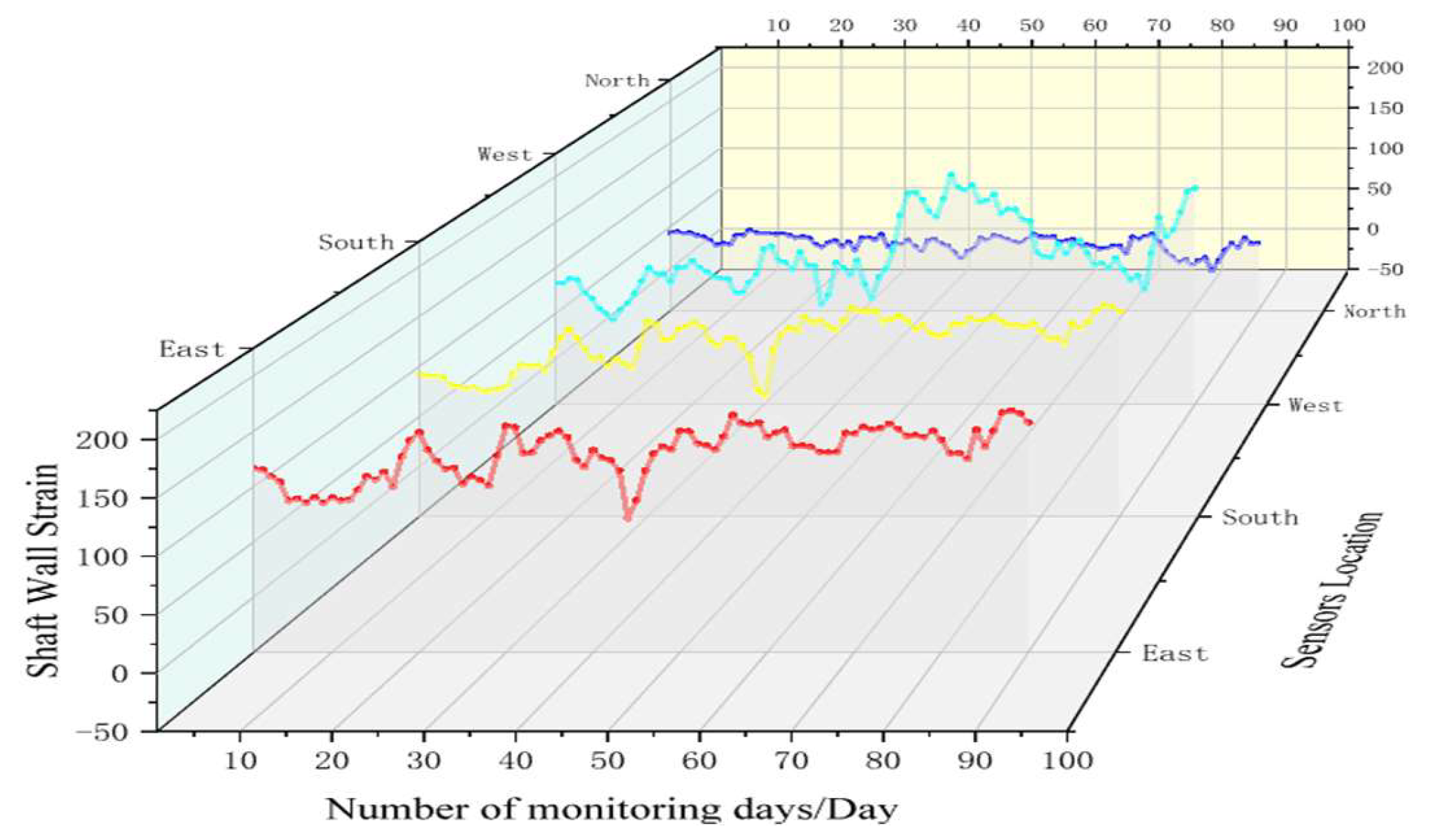

5.2. Analysis of Monitoring Data

6. Conclusions

- (1)

- In this paper, the strain transfer structure model of a shaft wall FBG is established with surface-mounted FBG sensing as the research object. The relational expression of strain transfer between the FBG and the borehole wall is derived, and the optimal average strain-sensing transfer rate is obtained.

- (2)

- Through the analysis of the strain transfer equation and the numerical simulation with MATLAB, the factors that affect the average strain perception transfer rate between the borehole wall and the FBG include the FBG adhesion length, the radius of the protective layer, the elasticity modulus of the adhesive layer and so on. Among them, the radius of the protective layer has the most obvious effect on the average strain transfer perception factor, followed by the length of the FBG, while the elasticity modulus of the adhesive layer has the least effect on the strain transfer effect. In summary of the above analysis and combined with the actual construction technology and conditions, the physical parameters of the above influencing factors are taken as the optimal values to achieve the best strain transfer effect.

- (3)

- In the field industrial test, a shaft wall’s deformation monitoring system based on combining the new FBG sensing monitoring with the traditional vibrating wire sensing was arranged in the auxiliary shaft of the coal mine. By selecting the vibrating wire sensing and FBG sensing monitoring data of adjacent horizontal horizons for analysis, it was found that the strain value measured by the FBG sensor and the theoretical strain value calculated at the corresponding horizontal conform to the deduced relational formula. This shows that the shaft wall deformation system achieved the expected monitoring effect and can realize long-term real-time and reliable monitoring. In the future, more subsystems can be added to this monitoring system, such as the variation of groundwater level, the amount of ground subsidence, and the deformation of the tank can be used as a reference to predict the borehole wall deformation. This will provide more abundant and comprehensive data support for early warning of shaft wall deformation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, W. Current status and development direction of intelligent mining technology for deep coal resources. Coal Sci. Technol. 2021, 49, 139–145. [Google Scholar]

- Wang, G. Speeding up intelligent construction of coal mine and promoting high-quality development of coal industry. China Coal 2021, 47, 2–10. [Google Scholar]

- Liu, F.; Guo, L.; Zhao, L. Research on coal safety range and green low-carbon technology path under the dual-carbon background. J. China Coal Soc. 2022, 47, 1–15. [Google Scholar] [CrossRef]

- Qian, Q. Energy geostructure engineering: promote carbon peak and neutrality, empower green cities. J. Shenzhen Univ. Sci. Eng. 2022, 39, 1–2. [Google Scholar] [CrossRef]

- Gao, M.; Zhang, J.; Feng, Z. Discussion on shaft wall failure mechanism in Linhuan mining area. Mine Constr. Technol. 1999, 22–25. [Google Scholar] [CrossRef]

- Peng, L.; Song, Z. Application of GPS Technique in Observation of Mining Coal Subsidence. Coal 2010, 19, 15–18. [Google Scholar]

- Moschas, F.; Stiros, S. Measurement of the dynamic displacements and of the modal frequencies of a short-span pedestrian bridge using GPS and an accelerometer. Eng. Struct. 2011, 33, 10–17. [Google Scholar]

- Jiang, C.; Wang, L.; Yu, X.; Lv, W.; Yang, X. A New Method of Monitoring 3D Mining-Included Deformation in Mountains Areas Based on Single-Track InSAR. Ksce J. Civ. Eng. 2022, 26, 2392. [Google Scholar] [CrossRef]

- Monserrat, O.; Crosetto, M. Deformation measurement using terrestrial laser scanning data and least squares 3D surface matching. ISPRS J. Photogramm. Remote Sens. 2008, 63, 142–154. [Google Scholar] [CrossRef]

- Luan, Y.; Luan, Y.; Sun, Q.; Wang, Y.; Zhang, C. Development of precision shaft deformation measurement system for mine shaft. Mine Constr. Technol. 2000, 21, 21–23. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, H. Error analysis of shaft deformation monitoring by steel wire reference line method. Mine Surv. 2001, 8–9. [Google Scholar] [CrossRef]

- Chen, M.; Du, Z.; Zhang, T.; Li, J. Research on Deformation Monitoring of Mine Shaft Based on Laser Datum. J. Geomat. 2022, 47, 73–76. [Google Scholar]

- Wang, P.; Zhang, N.; Kan, J.; Xie, Z.; Wei, Q.; Yao, W. Fiber Bragg Grating Monitoring of Full-Bolt Axial Force of the Bolt in the Deep Strong Mining Roadway. Sensors 2020, 20, 4242. [Google Scholar] [CrossRef] [PubMed]

- Ma, G.; Mao, N.; Li, Y. The Reusable Load Cell with Protection Applied for Online Monitoring of Overhead Transmission Lines Based on Fiber Bragg Grating. Sensors 2016, 16, 922. [Google Scholar] [CrossRef]

- Liang, M.; Fang, X.; Song, Y.; Li, S.; Chen, N.; Zhang, F. Research on Three-Dimensional Stress Monitoring Method of Surrounding Rock Based on FBG Sensing Technology. Sensors 2022, 22, 2624. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Chen, Z.; Xu, L.; Chen, J. A study of multi-layer automatic monitoring and its application in deep shaft. Rock Soil Mech. 2003, 384–387+391. [Google Scholar] [CrossRef]

- Liang, M.; Fang, X.; Chen, N.; Ma, M.; Li, X. Strain sensing mechanism of surface bonded fiber Bragg grating bolt and its application. J. China Univ. Min. Technol. 2018, 47, 1243–1251. [Google Scholar]

- Zhang, D.D.; Chai, J.; Li, Y.; Sun, Y.Y.; Liu, X.; Zhang, G. Strain transfer function of embedded Fiber Bragg Grating sensors for unconsolidated layer settlement. Chin. J. Rock Mech. Eng. 2015, 34 (Suppl. S1), 3289–3297. [Google Scholar]

- Zhu, J. Application Study of Fiber Optic Method Wellbore Deformation Monitoring System. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, 2019. [Google Scholar]

- Cui, G. On deep soil mechanics, a basic theory for determining the external load of underground structures in deep topsoil. J. China Coal Soc. 1999, 24, 123–126. [Google Scholar]

- Jing, L.; He, J.; Zhang, H. Problem in Structure Design of Shaft Lining in Depth Soil and Countermeasure. China Min. Mag. 2007, 16, 66–68. [Google Scholar]

- Huang, J.; Yang, W. Study on variation of vertical additional force on shaft lining by simulation tests. Chin. J. Rock Mech. Eng. 2006, 28, 1024–1028. [Google Scholar]

- Yao, Z. An experimental study on steel fiber reinforced high forced high strength concrete shaft lining in deep alluvium. Chin. J. Rock Mech. Eng. 2005, 24, 1253–1258. [Google Scholar] [CrossRef]

- Wang, J.; Luo, N.; Bai, Z. On the relation between interlayer glide caused by Coal Extraction and the shaft rupture occurring in coal mines in Huang Huai Area. Chin. J. Rock Mech. Eng. 2003, 22, 1072–1077. [Google Scholar]

- Yao, Z.; Xue, W.; Chen, H.; Ju, X.B.; Qin, Y. Research and application of composite shaft with inner steel plate and high strength reinforced concrete in frozen wellbore. J. Min. Saf. Eng. 2018, 35, 663–669. [Google Scholar]

| Physical Parameters | Numerical Value | Unit |

|---|---|---|

| Length of optical fiber paste 2 L | 100 | mm |

| Radius of protective layer | 10 | mm |

| Elastic modulus of protective layer | 4 × 109 | Pa |

| Radius of adhesive layer | 20 | mm |

| Elastic modulus of adhesive layer | 5 × 109 | Pa |

| Poisson’s ratio of adhesive layer | 0.35 | — |

| Number | Monitoring Horizontal Depth/m | Geotechnical Properties | Layer Thickness | Sensor Type | Number of Sensors |

|---|---|---|---|---|---|

| 1 | 325 m | Fine medium sand | 28.2 m | Vibrating-string sensor | 8 |

| 2 | 396 m | Fine sand | 18.4 m | FBG sensor | 10 |

| 3 | 473 m | medium sand | 7.6 m | Vibrating-string sensor | 8 |

| 4 | 579 m | Fine sand | 5. 86 m | FBG sensor | 10 |

| 5 | 581 m | Fine sand | 5.73 m | Vibrating-string sensor | 8 |

| 6 | 640 m | siltstone | 3.62 m | FBG sensor | 10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, X.; Zhang, F.; Shi, Z.; Liang, M.; Song, Y. Research and Application of Multi-Mode Joint Monitoring System for Shaft Wall Deformation. Sensors 2022, 22, 6551. https://doi.org/10.3390/s22176551

Fang X, Zhang F, Shi Z, Liang M, Song Y. Research and Application of Multi-Mode Joint Monitoring System for Shaft Wall Deformation. Sensors. 2022; 22(17):6551. https://doi.org/10.3390/s22176551

Chicago/Turabian StyleFang, Xinqiu, Fan Zhang, Zongshen Shi, Minfu Liang, and Yang Song. 2022. "Research and Application of Multi-Mode Joint Monitoring System for Shaft Wall Deformation" Sensors 22, no. 17: 6551. https://doi.org/10.3390/s22176551

APA StyleFang, X., Zhang, F., Shi, Z., Liang, M., & Song, Y. (2022). Research and Application of Multi-Mode Joint Monitoring System for Shaft Wall Deformation. Sensors, 22(17), 6551. https://doi.org/10.3390/s22176551