Substrateless Packaging for a D-Band MMIC Based on a Waveguide with a Glide-Symmetric EBG Hole Configuration

Abstract

:1. Introduction

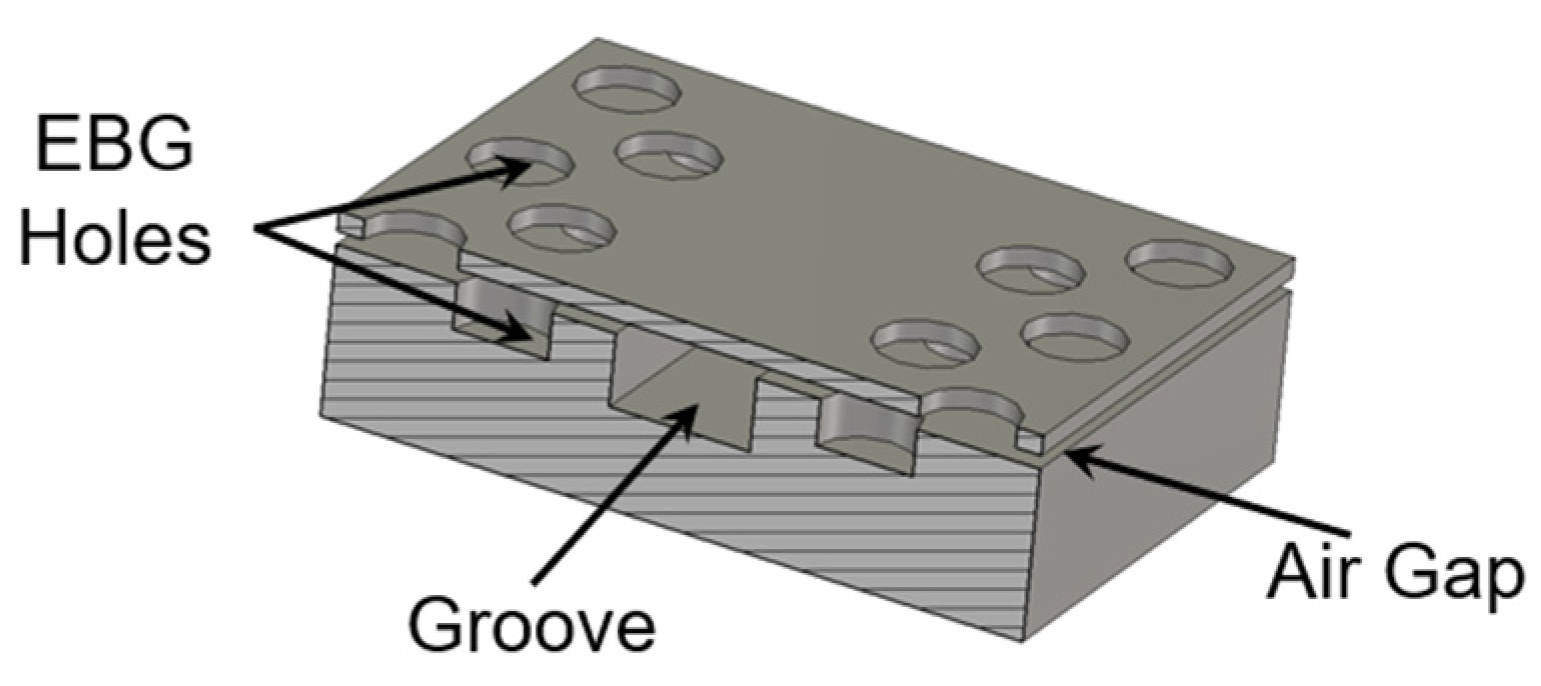

2. Design of the Waveguide Based on a Glide-Symmetric Holey Configuration

3. MMIC to GWG Transition Design

4. Mixer-Packaged Module Configuration and Design

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pfeiffer, U.R.; Jain, R.; Grzyb, J.; Malz, S.; Hillger, P.; Rodríguez-Vízquez, P. Current Status of Terahertz Integrated Circuits—From Components to Systems. In Proceedings of the 2018 IEEE BiCMOS and Compound Semiconductor Integrated Circuits and Technology Symposium (BCICTS), San Diego, CA, USA, 15–17 October 2018; pp. 1–7. [Google Scholar]

- Weimann, N. InP HBT Technology for THz Applications. In Proceedings of the 2020 IEEE International Symposium on Radio-Frequency Integration Technology (RFIT), Hiroshima, Japan, 2–4 September 2020; pp. 190–192. [Google Scholar]

- Schröter, M.; Rosenbaum, T.; Chevalier, P.; Heinemann, B.; Voinigescu, S.P.; Preisler, E.; Böck, J.; Mukherjee, A. SiGe HBT Technology: Future Trends and TCAD-Based Roadmap. Proc. IEEE 2017, 105, 1068–1086. [Google Scholar] [CrossRef]

- FCC Online Table of Frequency Allocations. Federal Communications Commission, Washington, DC, USA. 2018. Available online: https://transition.fcc.gov/oet/spectrum/table/fcctable.pdf (accessed on 1 July 2022).

- Li, Y.; Hansryd, J. Fixed Wireless Communication Links Beyond 100 GHZ. In Proceedings of the 2018 Asia-Pacific Microwave Conference (APMC), Kyoto, Japan, 6–9 November 2018; pp. 31–33. [Google Scholar]

- Campion, J.; Hassona, A.; He, Z.S.; Beuerle, B.; Gomez-Torrent, A.; Shah, U.; Vecc, S. Toward Industrial Exploitation of THz Frequencies: Integration of SiGe MMICs in Silicon-Micromachined Waveguide Systems. IEEE Trans. Terahertz Sci. Technol. 2019, 9, 624–636. [Google Scholar] [CrossRef]

- Lewis, S.M.; Nanni, E.A.; Temkin, R.J. Direct Machining of Low-Loss THz Waveguide Components with an RF Choke. IEEE Microw. Wirel. Compon. Lett. 2014, 24, 842–844. [Google Scholar] [CrossRef]

- Beuerle, B.; Campion, J.; Shah, U.; Oberhammer, J. A Very Low Loss 220–325 GHz Silicon Micromachined Waveguide Technology. IEEE Trans. Terahertz Sci. Technol. 2018, 8, 248–250. [Google Scholar] [CrossRef]

- Kildal, P. Gap Waveguides and PMC Packaging: Octave Bandwidth mm- and sub mm-Wave Applications of Soft & Hard Surfaces, EBGs and AMCs. In Proceedings of the 2013 Asia-Pacific Microwave Conference Proceedings (APMC), Seoul, Korea, 2 January 2013; pp. 34–36. [Google Scholar]

- Vosoogh, A.; Kildal, P.-S.; Vassilev, V. Wideband and high-gain corporate-fed gap waveguide slot array antenna with ETSI class II radiation pattern in V-band. IEEE Trans. Antennas Propag. 2016, 65, 1823–1831. [Google Scholar] [CrossRef]

- Rezaee, M.; Zaman, A.U. Groove Gap Waveguide Filter Based on Horizontally Polarized Resonators for V-Band Applications. IEEE Trans. Microw. Theory Tech. 2020, 68, 2601–2609. [Google Scholar] [CrossRef]

- Alfonso, E.; Zaman, A.U.; Pucci, E.; Kildal, P. Gap Waveguide Components for Millimetre-Wave Systems: Couplers, Filters, Antennas, MMIC Packaging. In Proceedings of the 2012 International Symposium on Antennas and Propagation (ISAP), Nagoys, Japan, 29 October 2012–2 November 2012; pp. 243–246. [Google Scholar]

- Shi, Y.; Feng, W.; Cao, B. W-Band Gap Waveguide Antenna Array: Passive/Active Component Gap Waveguide Transition Interface for System Integration. IEEE Antennas Propag. Mag. 2021, 63, 40–49. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, J.; Zhou, M.; Feng, W.; Cao, B.; Che, W. Miniaturized W-band Gap Waveguide Bandpass Filter Using the MEMS Technique for Both Waveguide and Surface Mounted Packaging. IEEE Trans. Circuits Syst. II Express Briefs 2019, 66, 938–942. [Google Scholar] [CrossRef]

- Vosoogh, A.; Sorkherizi, M.S.; Vassilev, V.; Zaman, A.U.; He, Z.S.; Yang, J.; Kishk, A.A.; Zirath, H. Compact Integrated Full-Duplex Gap Waveguide-Based Radio Front End for Multi-Gbit/s Point-to-Point Backhaul Links at E-Band. IEEE Trans. Microw. Theory Tech. 2019, 67, 3783–3797. [Google Scholar] [CrossRef]

- Ferrando-Rocher, M.; Herranz-Herruzo, J.I.; Valero-Nogueira, A.; Bernardo-Clemente, B. Performance Assessment of Gap-Waveguide Array Antennas: CNC Milling Versus Three-Dimensional Printing. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 2056–2060. [Google Scholar] [CrossRef] [Green Version]

- Palomares-Caballero, Á.; Alex-Amor, A.; Valenzuela-Valdés, J.; Padilla, P. Millimeter-Wave 3-D-Printed Antenna Array Based on Gap-Waveguide Technology and Split E-Plane Waveguide. IEEE Trans. Antennas Propag. 2021, 69, 164–172. [Google Scholar] [CrossRef]

- Rahiminejad, S.; Raza, H.; Zaman, A.U.; Haasl, S.; Enoksson, P.; Kildal, P. Micromachined Gap Waveguides for 100 GHz Applications. In Proceedings of the 2013 7th European Conference on Antennas and Propagation (EuCAP), Gothenburg, Sweden, 8–12 April 2013; pp. 1935–1938. [Google Scholar]

- Ebrahimpouri, M.; Quevedo-Teruel, O.; Rajo-Iglesias, E. Design Guidelines for Gap Waveguide Technology Based on Glide-Symmetric Holey Structures. IEEE Microw. Wirel. Compon. Lett. 2017, 27, 542–544. [Google Scholar] [CrossRef]

- Chen, Q.; Mesa, F.; Yin, X.; Quevedo-Teruel, O. Accurate Characterization and Design Guidelines of Glide-Symmetric Holey EBG. IEEE Trans. Microw. Theory Tech. 2020, 68, 4984–4994. [Google Scholar] [CrossRef]

- Vosoogh, H.; Zirath, Z.; He, S. Novel Air-Filled Waveguide Transmission Line Based on Multilayer Thin Metal Plates. IEEE Trans. Terahertz Sci. Technol. 2019, 9, 282–290. [Google Scholar] [CrossRef]

- Vosoogh, A.; Brazález, A.A.; Li, Y.; He, Z.S. A Compact Mass-producible E-band Bandpass Filter Based on Multi-layer Waveguide Technology. In Proceedings of the 2020 14th European Conference on Antennas and Propagation (EuCAP), Copenhagen, Denmark, 15–20 March 2020; pp. 1–5. [Google Scholar]

- Rajo-Iglesias, E.; Ebrahimpouri, M.; Quevedo-Teruel, O. Wideband Phase Shifter in Groove Gap Waveguide Technology Implemented with Glide-Symmetric Holey EBG. IEEE Microw. Wirel. Compon. Lett. 2018, 28, 476–478. [Google Scholar] [CrossRef]

- Monje-Real, A.; Fonseca, N.J.G.; Zetterstrom, O.; Pucci, E.; Quevedo-Teruel, O. Holey Glide-Symmetric Filters for 5G at Millimeter-Wave Frequencies. IEEE Microw. Wirel. Compon. Lett. 2020, 30, 31–34. [Google Scholar] [CrossRef]

- Chen, Q.; Zetterstrom, O.; Pucci, E.; Palomares-Caballero, A.; Padilla, P.; Quevedo-Teruel, O. Glide-Symmetric Holey Leaky-Wave Antenna with Low Dispersion for 60 GHz Point-to-Point Communications. IEEE Trans. Antennas Propag. 2020, 68, 1925–1936. [Google Scholar] [CrossRef]

- Samoska, L.A. An Overview of Solid-State Integrated Circuit Amplifiers in the Submillimeter-Wave and THz Regime. IEEE Trans. Terahertz Sci. Technol. 2011, 1, 9–24. [Google Scholar] [CrossRef]

- Hurm, V.; Weber, R.; Tessmann, A.; Massler, H.; Leuther, A.; Kuri, M.; Riessle, M.; Stulz, H.P.; Zink, M.; Schlechtweg, M.; et al. A 243 GHz LNA Module Based on mHEMT MMICs With Integrated Waveguide Transitions. IEEE Microw. Wirel. Compon. Lett. 2013, 23, 486–488. [Google Scholar] [CrossRef]

- Jameson, S.; Socher, E. A Wide-Band CMOS to Waveguide Transition at mm-Wave Frequencies with Wire-Bonds. IEEE Trans. Microw. Theory Tech. 2015, 63, 2741–2750. [Google Scholar] [CrossRef]

- Hou, D.; Xiong, Y.; Goh, W.; Hu, S.; Hong, W.; Madihian, M. 130-GHz On-Chip Meander Slot Antennas With Stacked Dielectric Resonators in Standard CMOS Technology. IEEE Trans. Antennas Propag. 2012, 60, 4102–4109. [Google Scholar] [CrossRef]

- Hou, Z.J.; Yang, Y.; Zhu, X.; Liao, S.; Man, S.K.; Xue, Q. A 320 GHz on-chip slot antenna array using CBCPW feeding network in 0.13-μm SiGe technology. In Proceedings of the 2017 IEEE MTT-S International Microwave Symposium (IMS), Honololu, HI, USA, 4–9 June 2017; pp. 843–846. [Google Scholar]

- Dong, Y.; Zhurbenko, V.; Hanberg, P.J.; Johansen, T.K. A D-Band Rectangular Waveguide-to-Coplanar Waveguide Transition Using Wire Bonding Probe. J. Infrared Millim. Terahertz Waves 2019, 40, 63–79. [Google Scholar] [CrossRef]

- Ahmadi, B.; Banai, A. Substrateless Amplifier Module Realized by Ridge Gap Waveguide Technology for Millimeter-Wave Applications. IEEE Trans. Microw. Theory Tech. 2016, 64, 3623–3630. [Google Scholar] [CrossRef]

- Gao, Z.; Tang, M.; Gao, P.; Yue, H.; Tang, Y. Design and Measurement of D-Band Bonding-Wire Interconnection on Quartz Glass Substrate. In Proceedings of the 2020 International Conference on Microwave and Millimeter Wave Technology (ICMMT), Shanghai, China, 20–23 September 2020; pp. 1–3. [Google Scholar]

- Hassona, A.; Vassilev, V.; Zaman, A.U.; Zirath, H. Packaging Technique of Highly Integrated Circuits Based on EBG Structure for +100 GHz Applications. In Proceedings of the 2020 14th European Conference on Antennas and Propagation (EuCAP), Copenhagen, Denmark, 15–20 March 2020; pp. 1–4. [Google Scholar]

- Hassona, A.; Vassilev, V.; Zaman, A.U.; Yan, Y.; An, S.; He, Z.S.; Habibpour, O.; Carpenter, S.; Bao, M.; Zirath, H. Nongalvanic Generic Packaging Solution Demonstrated in a Fully Integrated D-Band Receiver. IEEE Trans. Terahertz Sci. Technol. 2020, 10, 321–330. [Google Scholar] [CrossRef]

- Li, Y.; Hörberg, M.; Eriksson, K.; Campion, J.; Hassona, A.; Vecchiattini, S.; Dahl, T.; Lindman, R.; Bao, M.; He, Z.S.; et al. D-Band SiGe Transceiver Modules Based on Silicon-Micromachined Integration. In Proceedings of the 2019 IEEE Asia-Pacific Microwave Conference (APMC), Singapore, 10–13 December 2019; pp. 883–885. [Google Scholar]

- Hassona, A.; Vassilev, V.; He, Z.S.; Mariotti, C.; Dielacher, F.; Zirath, H. Silicon Taper Based D -Band Chip to Waveguide Interconnect for Millimeter-Wave Systems. IEEE Microw. Wirel. Compon. Lett. 2017, 27, 1092–1094. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Value (mm) | Parameter | Value (mm) |

|---|---|---|---|

| W1 | 0.373 | Wm | 0.035 |

| W2 | 0.1 | tm | 0.05 |

| L1 | 0.34 | Wpin | 0.4 |

| L2 | 0.15 | Lpin | 0.4 |

| Dw | 0.025 | Hpin | 0.5 |

| Hw | 0.03 | Hpin1 | 0.4 |

| D | 0.2 | p | 0.8 |

| Slot_W | 0.6 | Slot L | 1.3 |

| Parameter | Value (mm) | Parameter | Value (mm) |

|---|---|---|---|

| W1 | 0.5 | Wm | 0.035 |

| W2 | 0.18 | tm | 0.05 |

| L1 | 0.565 | Wpin | 0.5 |

| L2 | 0.15 | Lpin | 0.5 |

| Dw | 0.025 | Hpin | 0.9 |

| Hw | 0.03 | Hpin1 | 0.8 |

| D | 0.35 | p | 1 |

| Slot_W | 1.1 | Slot L | 2.9 |

| Parameter | Min | Typ | Max | Unit |

|---|---|---|---|---|

| RF frequency | 140 | 170 | GHz | |

| IF frequency | DC | 6 | GHz | |

| LO frequency | 70 | 85 | GHz | |

| LO input power | 15 | dBm | ||

| LO multiplication factor | 2 | |||

| Conversion loss | 12 | dB | ||

| P1dB | −5 | dBm | ||

| RF return loss | 10 | dB | ||

| IF return loss | 10 | dB | ||

| LO return loss | 10 | dB |

| No. | Process | Measured Topology | Bandwidth | Freq Band/GHz a | Insertion Loss/dB b | Return Loss/dB c |

|---|---|---|---|---|---|---|

| [6] | SiGe BiCMOS with heterogeneous integration | Transition + antenna | 16.95% | 135–160 | 4.2–5.5 | >5 |

| [33] | 127 μm-thick quartz with bonding-wire interconnect | Transition with single-ended ML | 16.4% | 144.7–170 | 2 | 10 |

| [36] | SiC chip with nongalvanic packaging | Transition with back-to-back ML | 23.7% | 125–137 147–170 | 0.7 | ~12 |

| [37] | eWLB with silicon taper interconnect | Transition with single-ended ML | 26% | 116–151 | 3.4 | 5 |

| This work | GaAs chip with substrateless packaging | Transition with single-ended mixer | 21.92% | 134–167 | 0.8 | >10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, W.; Vosoogh, A.; Wang, B.; He, Z.S. Substrateless Packaging for a D-Band MMIC Based on a Waveguide with a Glide-Symmetric EBG Hole Configuration. Sensors 2022, 22, 6696. https://doi.org/10.3390/s22176696

Yu W, Vosoogh A, Wang B, He ZS. Substrateless Packaging for a D-Band MMIC Based on a Waveguide with a Glide-Symmetric EBG Hole Configuration. Sensors. 2022; 22(17):6696. https://doi.org/10.3390/s22176696

Chicago/Turabian StyleYu, Weihua, Abbas Vosoogh, Bowu Wang, and Zhongxia Simon He. 2022. "Substrateless Packaging for a D-Band MMIC Based on a Waveguide with a Glide-Symmetric EBG Hole Configuration" Sensors 22, no. 17: 6696. https://doi.org/10.3390/s22176696