Sustainable Earthquake Resilience with the Versatile Shape Memory Alloy (SMA)-Based Superelasticity-Assisted Slider

Abstract

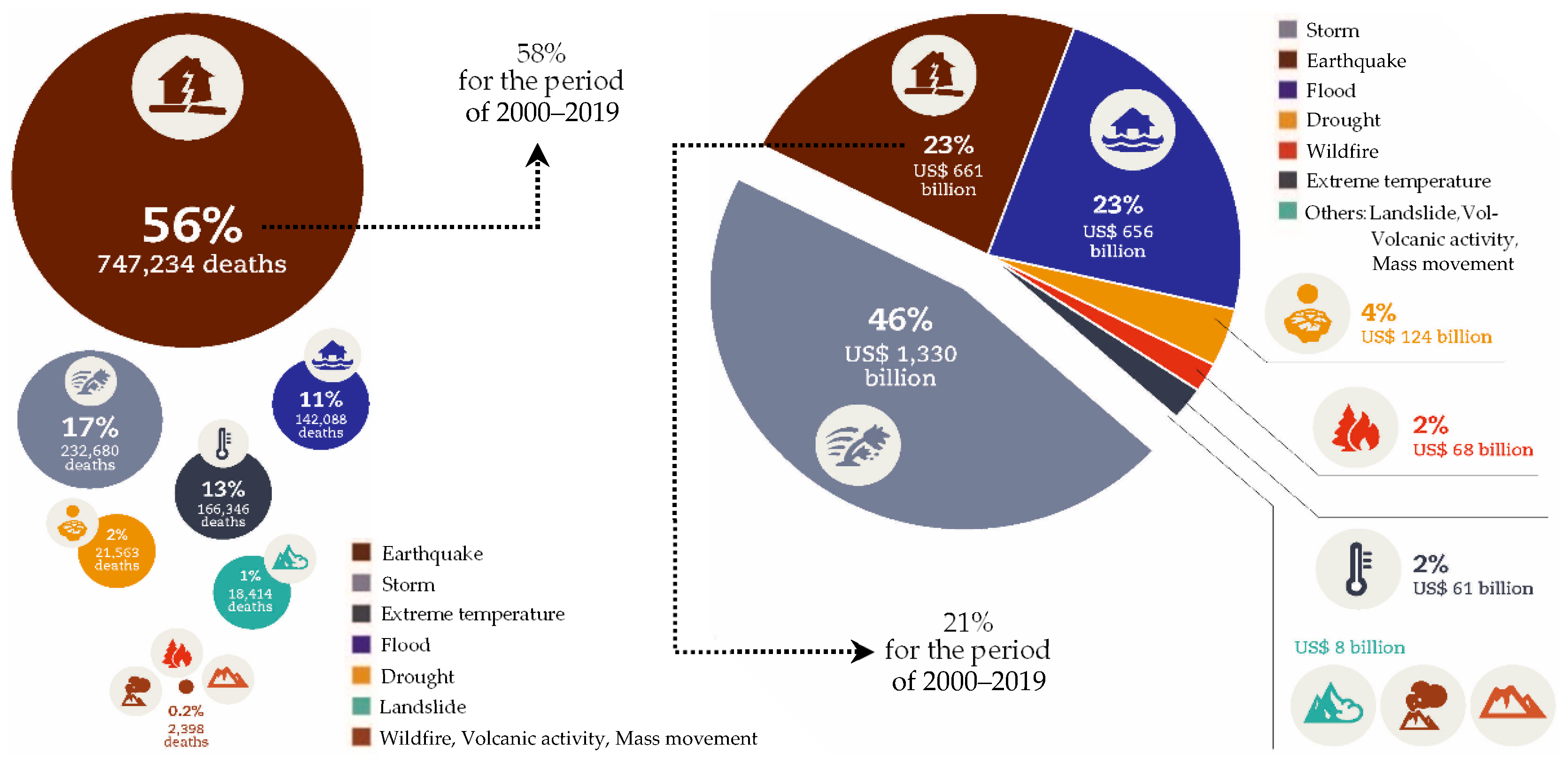

:1. Introduction

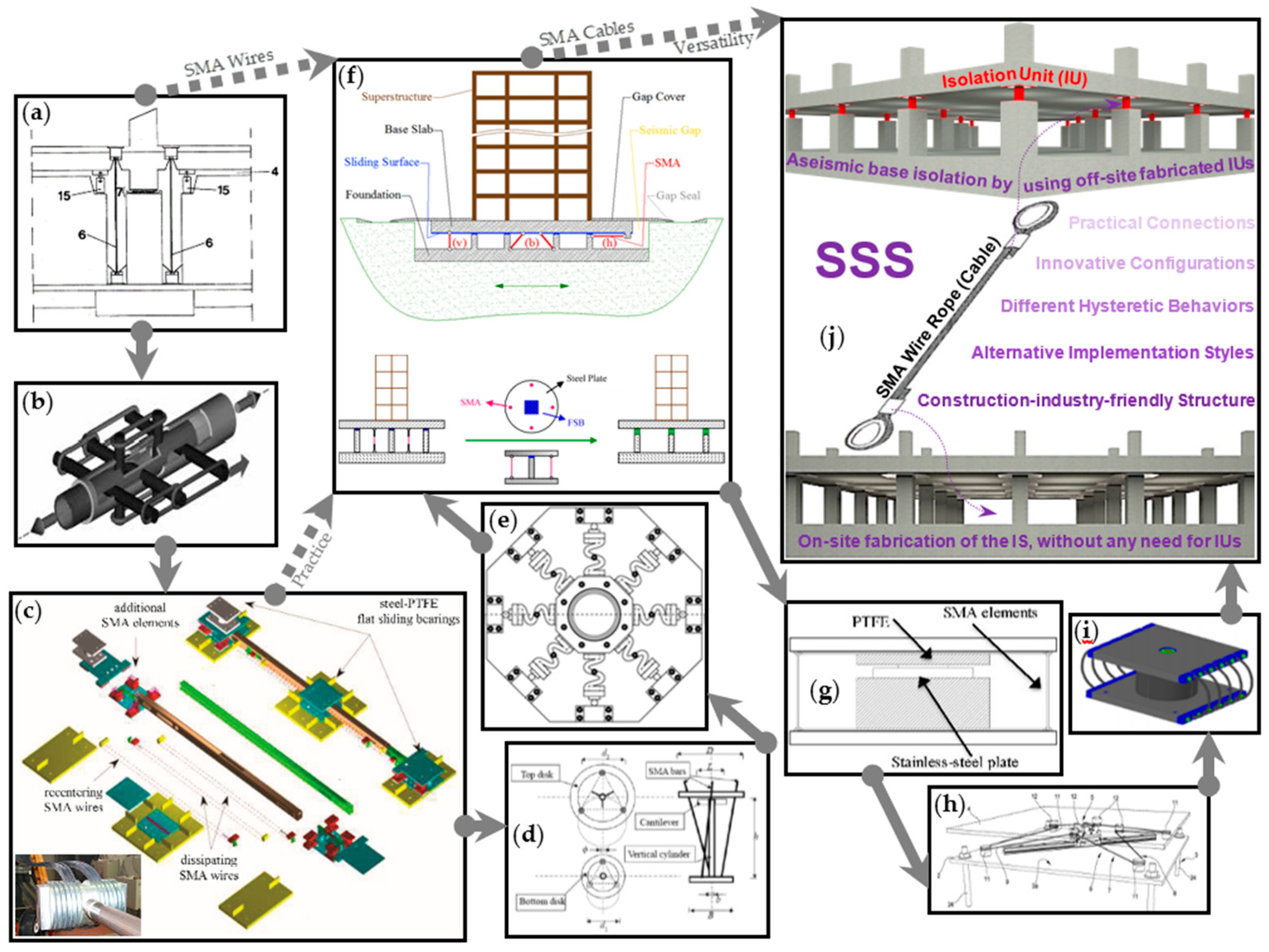

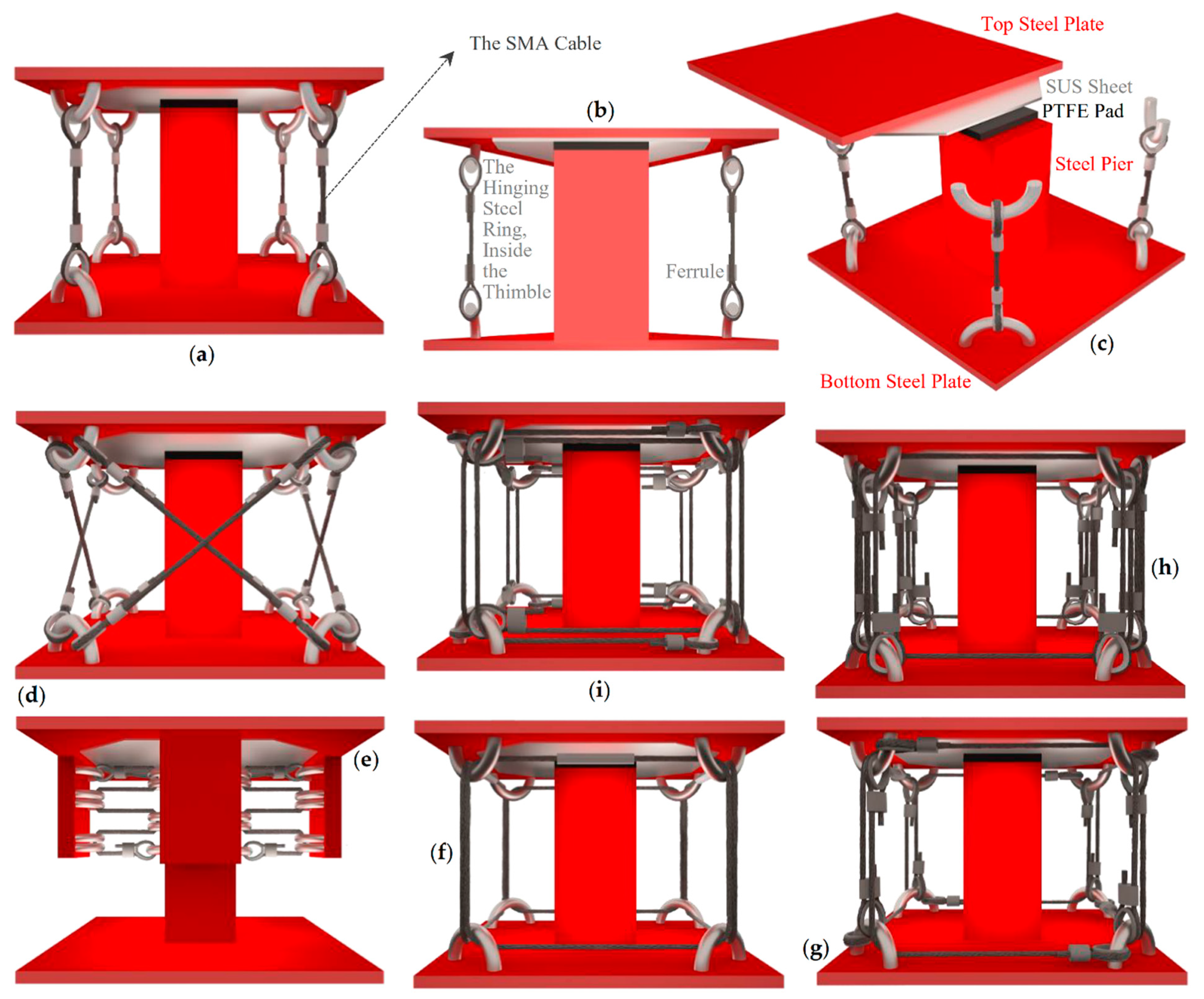

2. The Versatility of SSS

- (i)

- practical combination of the advantageous sliding and superelasticity by utilizing the cables of austenitic SMAs through the application of the connecting devices that are mainly composed of thimbles and ferrules (and additionally allow for some useful operations such as prestressing and replacing the cables);

- (ii)

- alternative novel and conventional configurations that provide this IS with the capability to adapt itself with various technical requirements of different projects, ranging from AI of a heavy large-scale structure such as a building to AI of a light-weight, small-scale structure such as an art object;

- (iii)

- various hysteretic behaviors that can be obtained by the alternative configurations and their geometric variants to make the different performance objectives (e.g., higher isolation capability with the relaxation chair or cleaver type hysteresis and higher restoring capability with the pure flag-shaped hysteresis) achievable [69];

- (iv)

- modularity that makes the system highly attractive in the practice of structural engineering and facilitates widespread AI;

- (v)

- possibility for using different cross-section layouts of the cables depending on the levels of the forces (e.g., 1 × 3 for a light-weight, small-scale art object and 7 × 7 or maybe 7 × 7 × 7 for a heavy large-scale building);

- (vi)

- possibility for working with any cross-section diameter of the SMA wires within the cables;

- (vii)

- possibility for using different SMA materials or alloy compounds (e.g., the well-known NiTi-based alloys [14,36], the alternative cheaper and easy-to-fabricate Cu-based alloys [94,95,96,97,98], or the low-price Fe-based alloys [99,100,101,102,103,104] that are going to reduce the cost and increase the affordability of the SMA-based structural and earthquake engineering due to the improving metallurgical technologies);

- (viii)

- possibility for using different sliding materials [105,106] and interfaces (e.g., the mostly used SUS-PTFE interface consisting of a mirror-polished stainless-steel plate on a polytetrafluoroethylene pad that can possibly include dimpled recesses for the purpose of lubrication [107], the SUS-PET interface that provides a relatively modern alternative for SUS-PTFE to be used in climatic regions [108] by replacing PTFE with self-lubricating thermoplastics blend of polyethyleneterephtalate (PET), the recently proposed [109] economic interfaces composed of different types of polyethylene, such as high-density polyethylene or ultrahigh molecular weight polyethylene sliding on galvanized steel);

- (ix)

- alternative implementation styles (the IU-less traditional style of implementation, in addition to the IU-based industrialized style of implementation);

- (x)

- capability to provide enhanced vertical isolation effect [74] through the utilization of some mechanisms or added elements of traditional or advanced materials (e.g., steel or SMA coil springs [110], super high damping rubber pads [111], viscous or steel dampers [112], telescoping piers [113], metallic or nonmetallic 3d/4d-printed metamaterial or periodic material pads [114], biomimetic architected elements [115], or combinations thereof).

- (xi)

- the passive control framework;

- (xii)

- capability to monitor the health of the IS based on the self-diagnostic properties of the utilized SMA cables;

- (xiii)

- capability to rehabilitate the IS by replacing its elements in cases of overloading;

- (xiv)

- uplift resistance provided by the SMA component of the system;

- (xv)

- fail-safe robustness provided by the sliding basis of the system;

- (xvi)

- resistance to aging due to the superiority of SMAs also in this regard.

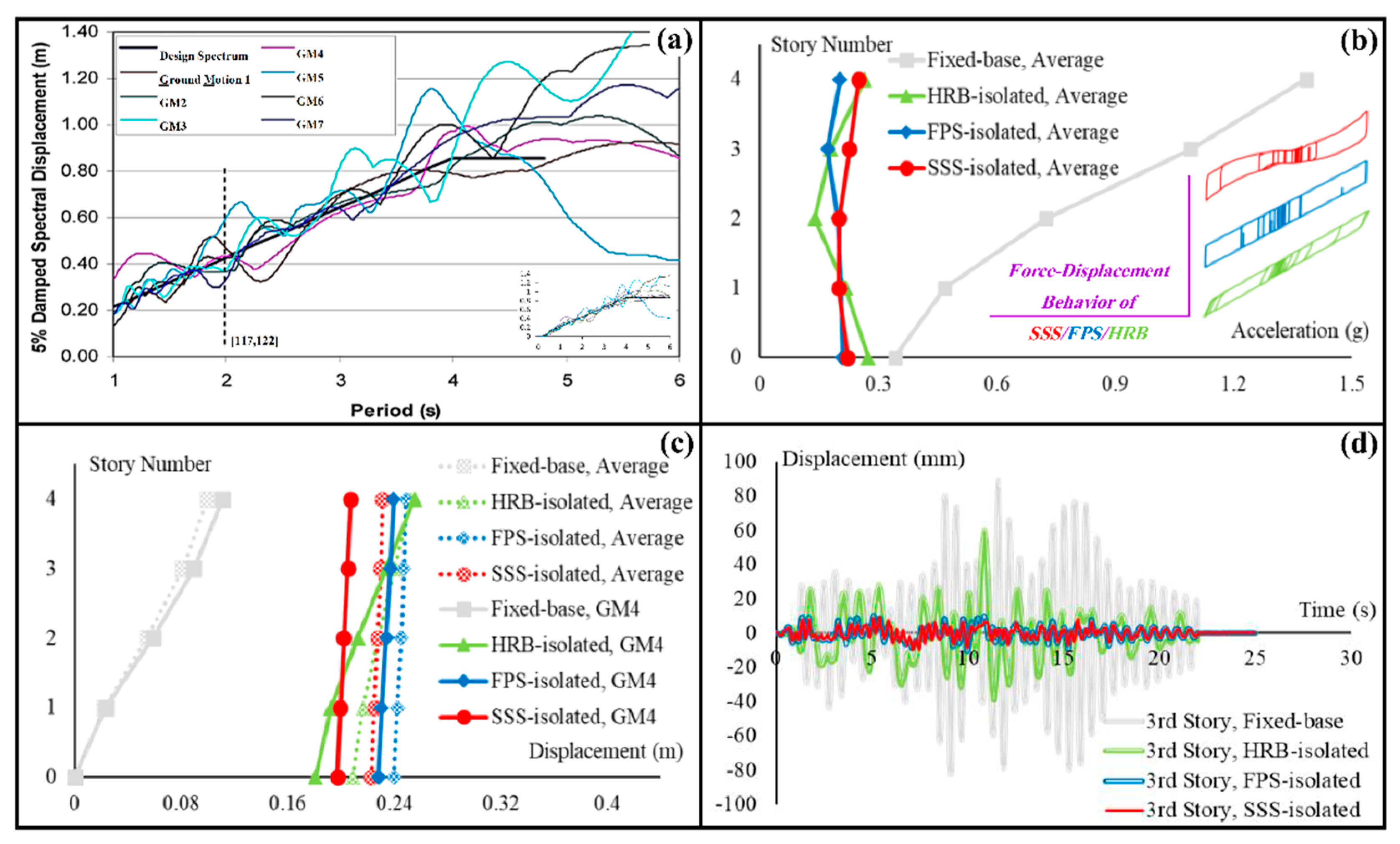

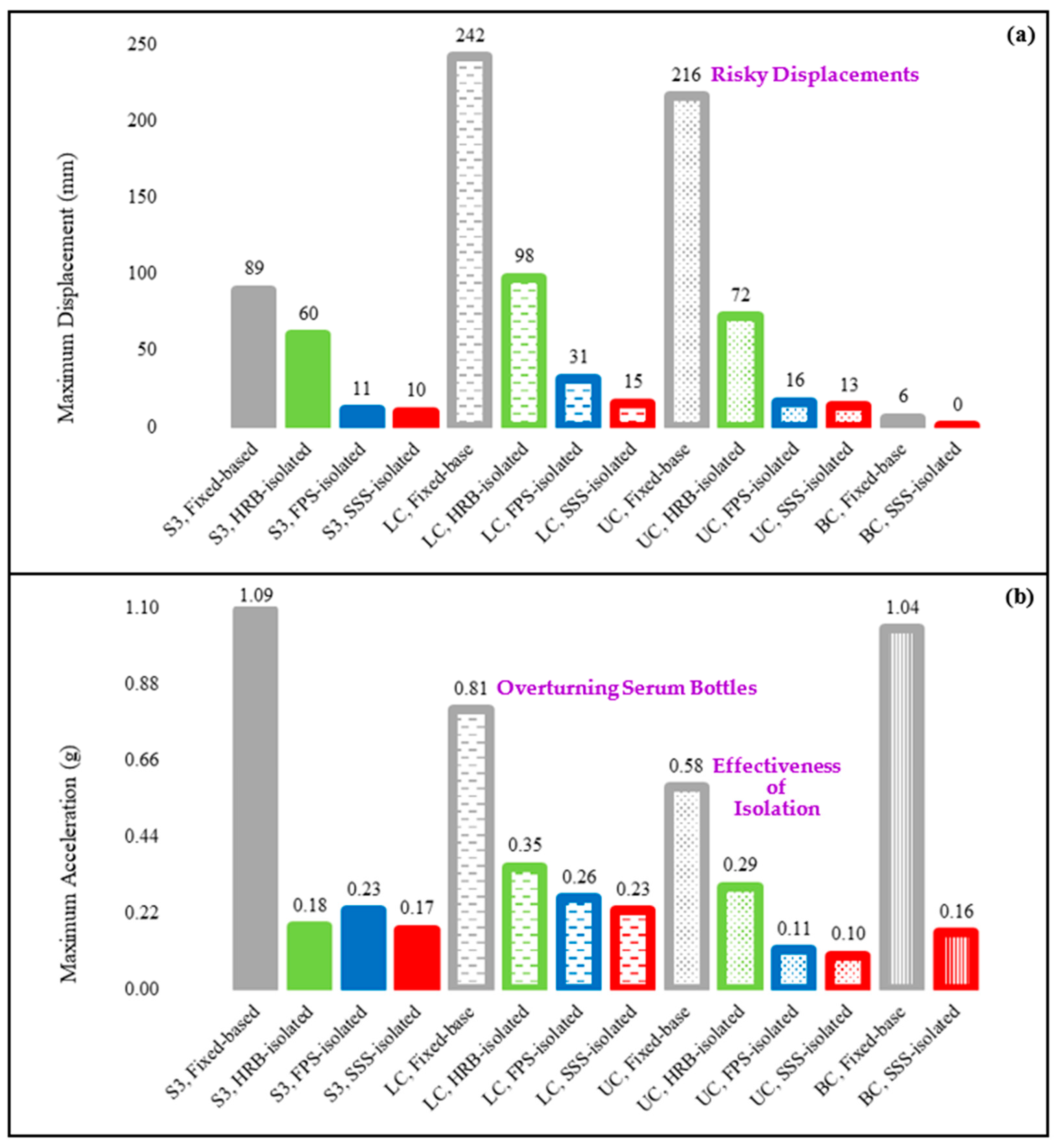

3. Shaking Table Studies

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Freddi, F.; Galasso, C.; Cremen, G.; Dall’Asta, A.; Di Sarno, L.; Giaralis, A.; Gutiérrez-Urzúa, F.; Málaga-Chuquitaype, C.; Mitoulis, S.A.; Petrone, C.; et al. Innovations in earthquake risk reduction for resilience: Recent advances and challenges. Int. J. Disast. Risk Re. 2021, 60, 102267. [Google Scholar] [CrossRef]

- Sadiq Amin, M.; Ahn, H. Earthquake disaster avoidance learning system using deep learning. Cogn. Syst. Res. 2020, 66, 221–235. [Google Scholar] [CrossRef]

- United Nations Office for Disarmament Affairs (UNODA). Human Cost of Disasters, PDF ed.; UN-iLibrary, UNODA, United Nations: New York, NY, USA, 2020; pp. 1–29. [Google Scholar] [CrossRef]

- Wallemacq, P.; House, R.; McClean, D. Economic Losses, Poverty and Disasters 1998–2017; United Nations Office for Disaster Risk Reduction (UNDRR)/Center for Research on the Epidemiology of Disasters (CRED): Geneva, Switzerland; Brussels, Belgium, 2018; pp. 1–31. Available online: https://www.cred.be/unisdr-and-cred-report-economic-losses-poverty-disasters-1998-2017 (accessed on 10 September 2022).

- Pietra, D.; Pampanin, S.; Mayes, R.L.; Wetzel, N.G.; Feng, D. Design of base-isolated buildings: An overview of international codes. Bull. N. Z. Soc. Earthq. Eng. 2015, 48, 118–135. [Google Scholar]

- McAllister, T.P.; Walker, R.F., Jr.; Baker, A. Assessment of Resilience in Codes, Standards, Regulations, and Best Practices for Buildings and Infrastructure Systems; Technical Note 2209; National Institute of Standards and Technology (NIST): Gaithersburg, MD, USA, 2022. [Google Scholar] [CrossRef]

- Cirak Karakas, C.; Palanci, M.; Senel, S.M. Fragility based evaluation of different code based assessment approaches for the performance estimation of existing buildings. Bull. Earthq. Eng. 2022, 20, 1685–1716. [Google Scholar] [CrossRef]

- Carofilis Gallo, W.W.; Clemett, N.; Gabbianelli, G.; O’Reilly, G.; Monteiro, R. Seismic resilience assessment in optimally integrated retrofitting of existing school buildings in Italy. Buildings 2022, 12, 845. [Google Scholar] [CrossRef]

- Takagi, J.; Wada, A. Recent earthquakes and the need for a new philosophy for earthquake-resistant design. Soil Dyn. Earthq. Eng. 2019, 119, 499–507. [Google Scholar] [CrossRef]

- Martelli, A.; Clemente, P.; De Stefano, A.; Forni, M.; Salvatori, A. Recent development and application of seismic isolation and energy dissipation and conditions for their correct use (Chapter 14). In Perspectives on European Earthquake Engineering and Seismology; Ansal, A., Ed.; Springer: Cham, Switzerland, 2014; Volume 1, pp. 449–488. [Google Scholar] [CrossRef]

- Japan Society of Seismic Isolation (JSSI). Available online: https://jssi.or.jp/english/aboutus/doc/SI_data_2020.pdf (accessed on 22 April 2022).

- Italian National Agency for New Technologies, Energy and Sustainable Economic Development (ENEA). Available online: https://www.enea.it/en/news-enea/news/earthquakes-italy-leading-country-for-applications-of-anti-seismic-systems-but-critical-situations-still-affect-safety-of-building-stock (accessed on 22 April 2022).

- Van Humbeeck, J. Non-medical applications of shape memory alloys. Mater. Sci. and Eng. A-Struct. 1999, 273–275, 134–148. [Google Scholar] [CrossRef]

- Dolce, M.; Cardone, D. Mechanical behavior of shape memory alloys for seismic applications: Part 2—Austenite NiTi wires subjected to tension. Int. J. Mech. Sci. 2001, 43, 2657–2677. [Google Scholar] [CrossRef]

- Desroches, R.; Smith, B. Shape memory alloys in seismic resistant design and retrofit: A critical review of their potential and limitations. J. Earthq. Eng. 2004, 8, 415–429. [Google Scholar] [CrossRef]

- Noori, M.; Narjabadifam, P. Innovative civil engineering applications of smart materials for smart sustainable urbanization. J. Civil Eng. Urban. 2019, 9, 24–35. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Qiu, C.; Zhao, X. Seismic Behavior of Superelastic Shape Memory Alloy Spring in Base Isolation System of Multi-Story Steel Frame. Materials 2019, 12, 997. [Google Scholar] [CrossRef] [PubMed]

- Song, G.; Ma, N.; Li, H.N. Applications of shape memory alloys in civil structures. Eng. Struct. 2006, 28, 1266–1274. [Google Scholar] [CrossRef]

- Motavalli, M.; Czaderski, C.; Bergamini, A.; Janke, L. Shape memory alloys for civil engineering structures—On the way from vision to reality. ACEE 2009, 2, 81–94. [Google Scholar]

- Hedayati Dezfuli, F.; Shahria Alam, M. Shape memory alloy wire-based smart natural rubber bearing. Smart Mater. Struct. 2013, 22, 045013. [Google Scholar] [CrossRef]

- Alvandi, S.; Ghassemieh, M. Application of shape memory alloys in seismic isolation: A review. Civil Eng. Infrastruct. J. 2014, 47, 153–171. [Google Scholar] [CrossRef]

- Sherif, M.M.; Ozbulut, O.E. Tensile and superelastic fatigue characterization of NiTi shape memory cables. Smart Mater. Struct. 2018, 27, 015007. [Google Scholar] [CrossRef]

- Feng, Q.; Kong, Q.; Jiang, J.; Liang, Y.; Song, G. Detection of Interfacial Debonding in a Rubber–Steel-Layered Structure Using Active Sensing Enabled by Embedded Piezoceramic Transducers. Sensors 2017, 17, 2001. [Google Scholar] [CrossRef]

- Falborski, T.; Jankowski, R. Advanced Hysteretic Model of a Prototype Seismic Isolation System Made of Polymeric Bearings. Appl. Sci. 2018, 8, 400. [Google Scholar] [CrossRef]

- Nakamura, Y.; Okada, K. Review on seismic isolation and response control methods of buildings in Japan. Geoenviron. Disasters 2019, 6, 7. [Google Scholar] [CrossRef]

- Narjabadifam, P.; Tiong, P.L.Y.; Mousavi-Alanjagh, R. Effects of inherent structural characteristics on seismic performances of aseismically base-isolated buildings. Iran J. Sci. Technol. Trans. Civ. Eng. 2020, 44, 1385–1401. [Google Scholar] [CrossRef]

- Anajafi, H.; Poursadr, K.; Roohi, M.; Santini-Bell, E. Effectiveness of seismic isolation for long-period structures subject to far-field and near-field excitations. Front. Built Environ. 2020, 6, 24. [Google Scholar] [CrossRef]

- Higashino, M.; Hamaguchi, H.; Minewaki, S.; Aizawa, S. Basic characteristics and durability of low-friction sliding bearings for base isolation. Earthq. Eng. Eng. Seismol. 2003, 4, 95–105. [Google Scholar]

- Panchal, V.; Jangid, R. Seismic response of structures with variable friction pendulum system. J. Earthq. Eng. 2009, 13, 193–216. [Google Scholar] [CrossRef]

- Fallah, N.; Zamiri, G. Multi-objective optimal design of sliding base isolation using genetic algorithm. Sci. Iran. 2013, 20, 87–96. [Google Scholar] [CrossRef]

- Massa, L.; Marenda, I. Sliding bearing for supporting civil or structural engineering works. U.S. Patent No. 10273680B2, 30 April 2019. [Google Scholar]

- Constantinou, M.; Mokha, A.; Reinhorn, A. Teflon bearings in base isolation (II- Modeling). J. Struct. Eng. 1990, 116, 455–474. [Google Scholar] [CrossRef]

- Calafell, R.L.; Roschke, P.N.; De la Llera, J.C. Optimized friction pendulum and precast-prestressed pile to base-isolate a Chilean masonry house. Bull. Earthq. Eng. 2010, 8, 1019–1036. [Google Scholar] [CrossRef]

- Calvi, G.M.; Calvi, P.M.; Moratti, M. Seismic isolation of buildings using devices based on sliding between surfaces with variable friction coefficient. Innov. Infrastruct. Solut. 2017, 2, 39. [Google Scholar] [CrossRef]

- Wilde, K.; Gardoni, P.; Fujino, Y. Base isolation system with shape memory alloy device for elevated highway bridges. Eng. Struct. 2000, 22, 222–229. [Google Scholar] [CrossRef]

- Saadat, S.; Salichs, J.; Noori, M.; Hou, Z.; Davoodi, H.; Bar-on, I.; Suzuki, Y.; Masuda, A. An overview of vibration and seismic applications of NiTi shape memory alloy. Smart Mater. Struct. 2002, 11, 218–229. [Google Scholar] [CrossRef]

- Desroches, R.; McCormick, J.; Delemont, M. Cyclic properties of superelastic shape memory alloy wires and bars. J. Struct. Eng. 2004, 130, 38–46. [Google Scholar] [CrossRef]

- Asgarian, B.; Salari, N.; Saadati, B. Application of intelligent passive devices based on shape memory alloys in seismic control of structures. Structures 2016, 5, 161–169. [Google Scholar] [CrossRef]

- Narjabadifam, P.; Watandust, A.S. Latest trends on the application of shape memory alloy cables (wire ropes) in structural earthquake engineering. Int. J. Adv. Eng. Res. Appl. 2018, 4, 9–21. [Google Scholar]

- Choi, E.; Nguyen, H.D.; Jeon, J.S.; Kang, J.W. Self-centering and damping devices using SMA dual rings. Smart Mater. Struct. 2019, 8, 085005. [Google Scholar] [CrossRef]

- Casciati, S. SMA-based devices: Insight across recent proposals toward civil engineering applications. Smart Struct. Syst. 2019, 24, 111–125. [Google Scholar] [CrossRef]

- Logiadis, I.; Logiadis, E.; Logiadis, G. Antiseismic Connector of Limited Vibration for Seismic Isolation of an Structure. U.S. Patent No. 5669189, 23 September 1997. [Google Scholar]

- Hayward, V.; Grant, D. Deformable Structural Arrangement. U.S. Patent No. 5727391, 17 March 1998. [Google Scholar]

- Krumme, R.; Hodgson, D.E. Hysteretic Damping Apparati and Methods. U.S. Patent No. 5842312, 1 December 1998. [Google Scholar]

- Dolce, M.; Cardone, D.; Marnetto, R. Implementation and testing of passive control devices based on shape memory alloys. Earthq. Eng. Struct. Dyn. 2000, 29, 945–968. [Google Scholar] [CrossRef]

- Davoodi, H.; Just, F.A.; Saffar, A.; Noori, M. Building system using shape memory alloy elements. U.S. Patent No. 6170202, 9 January 2001. [Google Scholar]

- Khan, M.M.; Lagoudas, D. Modeling of shape memory alloy pseudoelastic spring elements using Preisach model for passive vibration isolation. In Proceedings of the SPIE’s 9th Annual International Symposium on Smart Structures and Materials, San Diego, CA, USA, 17–21 March 2002. [Google Scholar]

- Cardone, D.; De Canio, G.; Dolce, M.; Marnetto, R.; Moroni, C.; Nicoletti, M.; Nigro, D.; Pizzari, A.; Ponzo, F.C.; Renzi, E.; et al. Comparison of different passive control techniques through shaking table tests. In Proceedings of the 8th World Seminar on Seismic Isolation, Energy Dissipation and Active Vibration Control of Structures, Yerevan, Armenia, 6–10 October 2003. [Google Scholar]

- Casciati, F.; Faravelli, L.; Hamdaoui, K. Performance of a base isolator with shape memory alloy bars. Earthq. Eng. Eng. Vib. 2007, 6, 401–408. [Google Scholar] [CrossRef]

- Attanasi, G.; Auricchio, F.; Crosti, C.; Fenves, G.L. An innovative isolation bearing with shape memory alloys. In Proceedings of the 14th World Conference on Earthquake Engineering, Beijing, China, 12–17 October 2008. [Google Scholar]

- Attanasi, G.; Auricchio, F.; Fenves, G.L. Feasibility assessment of an innovative isolation bearing system with shape memory alloys. J. Earthq. Eng. 2009, 13 (Suppl. 1), 18–39. [Google Scholar] [CrossRef]

- Cardone, D.; Palermo, G.; Narjabadifam, P. Smart restorable sliding base isolation system for the aseismic control of structures. In Proceedings of the 11th World Conference on Seismic Isolation, Energy Dissipation and Active Vibration Control of Structures, Guangzhou, China, 17–20 November 2009. [Google Scholar]

- Jalali, A.; Cardone, D.; Narjabadifam, P. Smart restorable sliding base isolation system. Bull. Earthq. Eng. 2011, 9, 657–673. [Google Scholar] [CrossRef]

- Cardone, D.; Narjabadifam, P.; Nigro, D. Shaking table tests of the Smart Restorable Sliding Base Isolation System (SRSBIS). J. Earthq. Eng. 2011, 15, 1157–1177. [Google Scholar] [CrossRef]

- Fanucchi, J.P.; Bystricky, P. Shape memory alloy composite material shock and vibration device. U.S. Patent No. 8053068, 8 November 2011. [Google Scholar]

- Tremblay, R.; Christopoulos, C. Self-centering energy dissipative brace apparatus with tensioning elements. U.S. Patent No. 8250818, 28 August 2012. [Google Scholar]

- Khodaverdian, A.; Ghorbani-Tanha, K.; Rahimian, M. An innovative base isolation system with Ni–Ti alloy and its application in seismic vibration control of Izadkhast Bridge. J. Intell. Mat. Syst. Str. 2012, 23, 897–908. [Google Scholar] [CrossRef]

- Ozbulut, O.E.; Silwal, B. Performance of isolated buildings with superelastic-friction base isolators under high seismic hazards. In Proceedings of the Structures Congress, Boston, MA, USA, 3–5 April 2014. [Google Scholar]

- Colato, G.P.; Castellano, M.G. Isolation device for absorbing seismic waves suffered by a reference surface. European Patent No. 2942543, 11 November 2015. [Google Scholar]

- Fang, C.; Yam, M.C.H.; Lam, A.C.C.; Zhang, Y. Feasibility study of shape memory alloy ring spring systems for self-centring seismic resisting devices. Smart Mater. Struct. 2015, 24, 075024. [Google Scholar] [CrossRef]

- Ozbulut, O.E.; Silwal, B. Performance assessment of buildings isolated with S-FBI system under near-fault earthquakes. Smart Struct. Syst. 2016, 17, 709–724. [Google Scholar] [CrossRef]

- Saiidi, M. Deconstructable support column structures. U.S. Patent 9677274, 13 June 2017. [Google Scholar]

- Zheng, Y.; Dong, Y. Comparative seismic performance of conventional and resilient bridges with SMA-cable-based frictional sliding bearings. In Proceedings of the 2017 World Congress on Advances in Structural Engineering and Mechanics (ASEM17), Seoul, Korea, 28 August–1 September 2017. [Google Scholar]

- Wang, B.; Zhu, S. Superelastic SMA U-shaped dampers with self-centering functions. Smart Mater. Struct. 2018, 27, 055003. [Google Scholar] [CrossRef]

- Lacarbonara, W.; Carboni, B. Multi-performance hysteretic rheological device. U.S. Patent No. 20180245655, 30 August 2018. [Google Scholar]

- Zheng, W.Z.; Wang, H.; Li, J.; Shen, H.J. Performance evaluation of bridges isolated with SMA-based friction pendulum system at low temperatures. Soil Dyn. Earthq. Eng. 2019, 125, 105734. [Google Scholar] [CrossRef]

- Zhang, Z.-X.; Ping, Y.; He, X. Self-centering shape memory alloy-viscoelastic hybrid braces for seismic resilience. Materials 2022, 15, 2349. [Google Scholar] [CrossRef] [PubMed]

- Eguchi, K. Seismic isolation using shape memory alloy heavy-duty spring, and shape memory alloy heavy-duty spring for seismic isolation. Japanese Patent No. 2007332757, 27 December 2007. [Google Scholar]

- Sawaguchi, T.; Sawaguchi, T.; Kikuchi, K.; Ogawa, S.; Kajiwara, T.; Ogawa, A.; Higashino, M.K. Damping material using iron-based shape memory alloy, damping device using this material, and method of using iron alloy-based damping material. Japanese Patent No. 4709555, 22 June 2011. [Google Scholar]

- Shi, Z.H.; Dou, X.; Tianzhen, J.L. Rope type self-reset shape memory alloy seismic isolation and seismic reduction support. Chinese Patent No. 103867625, 8 February 2017. [Google Scholar]

- Pan, B. Shape memory alloy friction combined vibration isolator. Chinese Patent No. 104805926, 24 May 2017. [Google Scholar]

- Narjabadifam, P. Shape memory alloy (SMA)-based Superelasticity-assisted Slider (SSS). In Proceedings of the 7th International Conference on Seismology and Earthquake Engineering, Tehran, Iran, 18–21 May 2015. [Google Scholar]

- Narjabadifam, P.; Noori, M.; Cardone, D.; Eradat, R.; Kiani, M. Shape memory alloy (SMA)-based Superelasticity-assisted Slider (SSS): An engineering solution for practical aseismic isolation with advanced materials. Smart Struct. Syst. 2020, 26, 89–102. [Google Scholar] [CrossRef]

- Noori, M.; Narjabadifam, P. Earthquake protection systems, methods and apparatus using shape memory alloy (SMA)-based superelasticity-assisted slider (SSS). U.S. Patent No. 11313145, 26 April 2022. [Google Scholar]

- Wilde, K.; Gardoni, P.; Fujino, Y. Seismic response of base-isolated structures with shape memory alloy damping devices. In Proceedings of the SPIE’s Smart Structures and Materials ’97, San Diego, CA, USA, 3–6 March 1997. [Google Scholar]

- Shinozuka, M.; Chaudhuri, S.R.; Mishra, S.K. Shape-Memory-Alloy supplemented Lead Rubber Bearing (SMA-LRB) for seismic isolation. Probabilist. Eng. Mech. 2015, 41, 34–45. [Google Scholar] [CrossRef]

- Tsai, C.S. Energy absorber. U.S. Patent No. 2017/0204603, 20 July 2017. [Google Scholar]

- Hedayati Dezfuli, F.; Shahria Alam, M. Smart lead rubber bearings equipped with ferrous shape memory alloy wires for seismically isolating highway bridges. J. Earthq. Eng. 2018, 22, 1042–1067. [Google Scholar] [CrossRef]

- Collins, M.J. Wire rope isolator with crimp bar and method for making same. U.S. Patent No. 5549285, 27 August 1996. [Google Scholar]

- Demetriades, G.F.; Constantinou, M.C.; Reinhorn, A.M. Study of Wire Rope Systems for Seismic Protection of Equipment in Building; Research Report No. NCEER-92-0012; National Center for Earthquake Engineering Research (NCEER), State University of New York at Buffalo: Buffalo, NY, USA, 1992. [Google Scholar]

- Dang, X.Z.; Yang, H.L.; Yuan, W.C.; Song, D.Q. Experimental investigation on composite seismic isolation system. Adv. Mat. Res. 2013, 74, 146–149. [Google Scholar] [CrossRef]

- Ruan, S.; Zemanek, T. Seismic isolation assembly. U.S. Patent No. 9809975, 12 May 2016. [Google Scholar]

- Spizzuoko, M. Study of wire rope devices for improving the re-centering capability of base isolated buildings. Struct. Control Health Monit. 2017, 24, e1928. [Google Scholar] [CrossRef]

- Graesser, E.J.; Cozzarelli, F.A. Shape-memory alloys as new materials for aseismic isolation. J. Eng. Mech. 1991, 117, 2590–2608. [Google Scholar] [CrossRef]

- Beltran, J.F.; Cruz, C.; Herrera, R.; Moroni, R. Shape memory alloy CuAlBe strands subjected to cyclic axial loads. Eng. Struct. 2011, 33, 2910–2918. [Google Scholar] [CrossRef]

- Reedlunn, B.; Daly, S.; Shaw, J. Superelastic shape memory alloy cables: Part I—Isothermal tension experiments. Int. J. Solids Struct. 2013, 50, 3009–3026. [Google Scholar] [CrossRef]

- Mercuri, V. Shape memory alloys strands: Conventional 3D FEM modeling and simplified models. Ph.D. Dissertation, University of Pavia, Pavia, Italy, 2014. [Google Scholar]

- Carboni, B.; Lacarbonara, W.; Auricchio, F. Hysteresis of multiconfiguration assemblies of Nitinol and steel strands: Experiments and phenomenological identification. J. Eng. Mech. 2015, 141, 04014135. [Google Scholar] [CrossRef]

- Kitamura, K. Mechanical property of Ti–Ni superelastic wire ropes. Trans. Mat. Res. Soc. Japan. 2016, 41, 355–358. [Google Scholar] [CrossRef]

- Ozbulut, O.E.; Daghash, S.; Sherif, M.M. Shape memory alloy cables for structural applications. J. Mater. Civ. Eng. 2016, 28, 04015176. [Google Scholar] [CrossRef]

- Biggs, D.B. Thermo-mechanical behavior and shakedown of shape memory alloy cable structure. Ph.D. Dissertation, University of Michigan, MI, USA, 2017. [Google Scholar]

- Fang, C.; Zheng, Y.; Chen, J.; Yam, M.C.H.; Wang, W. Superelastic NiTi SMA cables: Thermal-mechanical behavior, hysteretic modelling and seismic application. Eng. Struct. 2019, 183, 533–549. [Google Scholar] [CrossRef]

- Vahidi, S.; Arghavani, J.; Choi, E.; Ostadrahimi, A. Mechanical response of single and double-helix SMA wire ropes. Mech. Adv. Mater. Struct. 2021. [Google Scholar] [CrossRef]

- Casciati, F.; Van der Ejik, C. Variability in mechanical properties and microstructure characterization of CuAlBe shape memory alloys for vibration mitigation. Smart Struct. Syst. 2008, 4, 103–121. [Google Scholar] [CrossRef]

- Yuan, B.; Zheng, P.; Gao, Y.; Zhu, M.; Dunand, D.C. Effect of directional solidification and porosity upon the superelasticity of Cu-Al-Ni shape-memory alloys. Mater. Des. 2015, 80, 28–35. [Google Scholar] [CrossRef]

- Niedbalski, S.; Durán, A.; Walczak, M.; Ramos-Grez, J.A. Laser-Assisted Synthesis of Cu-Al-Ni Shape Memory Alloys: Effect of Inert Gas Pressure and Ni Content. Materials 2019, 12, 794. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ćorić, D.; Žmak, I. Influence of Ausforming Treatment on Super Elasticity of Cu-Zn-Al Shape Memory Alloy for Seismic Energy Dissipaters. Buildings 2021, 11, 22. [Google Scholar] [CrossRef]

- Mazzer, E.M.; da Silva, M.R.; Gargarella, P. Revisiting Cu-based shape memory alloys: Recent developments and new perspectives. J. Mater. Res. 2022, 37, 162–182. [Google Scholar] [CrossRef]

- Cladera, A.; Weber, B.; Leinenbach, C.; Czaderski, C.; Shahverdi, M.; Motavalli, M. Iron-based shape memory alloys for civil engineering structures: An overview. J. Constr. Build. Mater. 2014, 63, 281–293. [Google Scholar] [CrossRef]

- Wen, Y.H.; Peng, H.B.; Raabe, D.; Gutierrez-Urrutia, I.; Chen, J.; Du, Y.Y. Large recovery strain in Fe-Mn-Si based shape memory steels obtained by engineering annealing twin boundaries. Nat. Commun. 2014, 5, 4964. [Google Scholar] [CrossRef] [PubMed]

- Sakon, T. Novel research for development of shape memory alloys. Metals 2018, 8, 125. [Google Scholar] [CrossRef]

- Zhang, Z.-X.; Zhang, J.; Wu, H.; Ji, Y.; Kumar, D.D. Iron-Based Shape Memory Alloys in Construction: Research, Applications and Opportunities. Materials 2022, 15, 1723. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Y.; Dong, K.; Zhang, Z. Research Progress of Fe-Based Superelastic Alloys. Crystals 2022, 12, 602. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Okotete, E.A. Reconciling viability and cost-effective shape memory alloy options—A review of copper and iron based shape memory metallic systems. Eng. Sci. Technol. Int. J. 2016, 19, 1582–1592. [Google Scholar] [CrossRef]

- Fenz, D.M. Frictional Properties of Non-Metallic Materials for Use in Sliding Bearings: An Experimental Study; Student Research Accomplishments 2001-2002(19) 113-118; Multidisciplinary Center for Earthquake Engineering Research (MCEER), State University of New York at Buffalo: Buffalo, NY, USA, 2002. [Google Scholar]

- Constantinou, M.C.; Withaker, A.S.; Kalpakidis, Y.; Fenz, D.M.; Warn, G.P. Performance of Seismic Isolation Hardware under Service and Seismic Loading; Technical Report No. MCEER-07-0012; Multidisciplinary Center for Earthquake Engineering Research (MCEER), State University of New York at Buffalo: Buffalo, NY, USA, 2007. [Google Scholar]

- Dolce, M.; Cardone, D.; Croatto, F. Frictional behavior of steel-PTFE interfaces for seismic isolation. Bull. Earthq. Eng. 2005, 3, 75–99. [Google Scholar] [CrossRef]

- Quaglini, V.; Dubini, P.; Poggi, C. Experimental assessment of sliding materials for seismic isolation systems. Bull. Earthq. Eng. 2012, 10, 717–740. [Google Scholar] [CrossRef]

- Messina, A.; Miranda, E. Frictional behavior of low-cost steel-polymer interfaces for seismic isolation. J. Struct. Eng. 2022, 148, 04021239. [Google Scholar] [CrossRef]

- Zhou, Z.; Wong, J.; Mahin, S. Potentiality of using vertical and three-dimensional isolation systems in nuclear structures. Nucl. Eng. Technol. 2016, 48, 1237–1251. [Google Scholar] [CrossRef]

- Pourmasoud, M.M.; Lim, J.B.P.; Hajirasouliha, I.; McCrum, D. Multi-directional base isolation system for coupled horizontal and vertical seismic excitations. J. Earthq. Eng. 2020, 26, 1145–1170. [Google Scholar] [CrossRef]

- Lee, D.; Constantinou, M.C. Combined horizontal–vertical seismic isolation system for high-voltage–power transformers: Development, testing and validation. Bull. Earthq. Eng. 2018, 16, 4273–4296. [Google Scholar] [CrossRef]

- Kammula, V.; Erochko, J.; Kwon, O.-S.; Christopoulos, C. Application of hybrid-simulation to fragility assessment of the telescoping self-centering energy dissipative bracing system. Earthq. Eng. Struct. Dyn. 2014, 43, 811–830. [Google Scholar] [CrossRef]

- Al Rifaie, M.; Abdulhadi, H.; Mian, A. Advances in mechanical metamaterials for vibration isolation: A review. Adv. Mech. Eng. 2022, 14, 1–20. [Google Scholar] [CrossRef]

- Fraternali, F.; Singh, N.; Amendola, A.; Benzoni, G.; Milton, G.W. A biomimetic sliding–stretching approach to seismic isolation. Nonlinear Dyn. 2021, 106, 3147–3159. [Google Scholar] [CrossRef]

- CSI (Computers and Structures Inc.). SAP2000 v23 Analysis Reference Manual; Computers and Structures Inc.: Berkeley, CA, USA, 2021. [Google Scholar]

- Smerzini, C.; Paolucci, F. A Database with Selected Input Motions for Displacement-Based Assessment and Design; Research Project DPC-RELUIS 2010-2013, Italian Network of Seismic Engineering Laboratories—Rete dei Laboratori Universitari di Ingegneria Sismica (ReLUIS); Department of Structural Engineering, Politecnico di Milano: Milan, Italy, 2013. [Google Scholar]

- Haselton, C.B.; Whittaker, A.S.; Hortacsu, A.; Bray, J.; Grant, D.N. Selecting and scaling earthquake ground motions for performing response-history analyses. In Proceedings of the 15th World Conference on Earthquake Engineering, Lisbon, Portugal, 24–28 September 2012. [Google Scholar]

- Pant, D.R.; Maharjan, M. On selection and scaling of ground motions for analysis of seismically isolated structures. Earthq. Eng. Eng. Vib. 2007, 6, 401–408. [Google Scholar] [CrossRef]

- Macedo, L.; Castro, J.M. SelEQ: An advanced ground motion record selection and scaling framework. Advances in Engineering Software 2017, 114, 32–47. [Google Scholar] [CrossRef]

- Manfredi, V.; Masi, A.; Özcebe, A.G.; Paolucci, R.; Smerzini, C. Selection and spectral matching of recorded ground motions for seismic fragility analyses. Bull. Earthq. Eng. 2022, 20, 4961–4987. [Google Scholar] [CrossRef]

- Sorace, S.; Terenzi, G. Analysis, design, and construction of a base-isolated multiple building structure. Adv. Civ. Eng. 2014, 2014, 585429. [Google Scholar] [CrossRef]

- Katsanos, E.I.; Sextos, A.G.; Manolis, G.D. Selection of earthquake ground motion records: A state-of-the-art review from a structural engineering perspective. Soil Dyn. Earthq. Eng. 2010, 30, 157–169. [Google Scholar] [CrossRef]

- Papazafeiropoulos, G.; Georgioudakis, M.; Papadrakakis, M. Selecting and scaling of energy-compatible ground motion records. Front. Built Environ. 2019, 5, 140. [Google Scholar] [CrossRef]

- Vukobratović, V.; Ruggieri, S. Jerk in Earthquake Engineering: State-of-the-Art. Buildings 2022, 12, 1123. [Google Scholar] [CrossRef]

- Cao, S.; Ozbulut, O.E.; Shi, F.; Deng, J. An SMA cable-based negative stiffness seismic isolator: Development, experimental characterization, and numerical modeling. J. Intell. Mat. Syst. Str. 2022, 33, 1819–1833. [Google Scholar] [CrossRef]

- Li, S.; Hedayati Dezfuli, F.; Shahria Alam, M.; Wang, J. Design, manufacturing, and performance evaluation of a novel smart roller bearing equipped with shape memory alloy wires. Smart Mater. Struct. 2022, 31, 025032. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Narjabadifam, P.; Noori, M.; Taciroglu, E.; Zhang, J.; Khoshnevis, B.; Cardone, D.; Basu, D.; Wang, T.; Elghandour, E.; Noroozinejad Farsangi, E.; et al. Sustainable Earthquake Resilience with the Versatile Shape Memory Alloy (SMA)-Based Superelasticity-Assisted Slider. Sensors 2022, 22, 6876. https://doi.org/10.3390/s22186876

Narjabadifam P, Noori M, Taciroglu E, Zhang J, Khoshnevis B, Cardone D, Basu D, Wang T, Elghandour E, Noroozinejad Farsangi E, et al. Sustainable Earthquake Resilience with the Versatile Shape Memory Alloy (SMA)-Based Superelasticity-Assisted Slider. Sensors. 2022; 22(18):6876. https://doi.org/10.3390/s22186876

Chicago/Turabian StyleNarjabadifam, Peyman, Mohammad Noori, Ertugrul Taciroglu, Jian Zhang, Behrokh Khoshnevis, Donatello Cardone, Dipanjan Basu, Tao Wang, Eltahry Elghandour, Ehsan Noroozinejad Farsangi, and et al. 2022. "Sustainable Earthquake Resilience with the Versatile Shape Memory Alloy (SMA)-Based Superelasticity-Assisted Slider" Sensors 22, no. 18: 6876. https://doi.org/10.3390/s22186876