A Design of Electromagnetic Velocity Sensor with High Sensitivity Based on Dual-Magnet Structure

Abstract

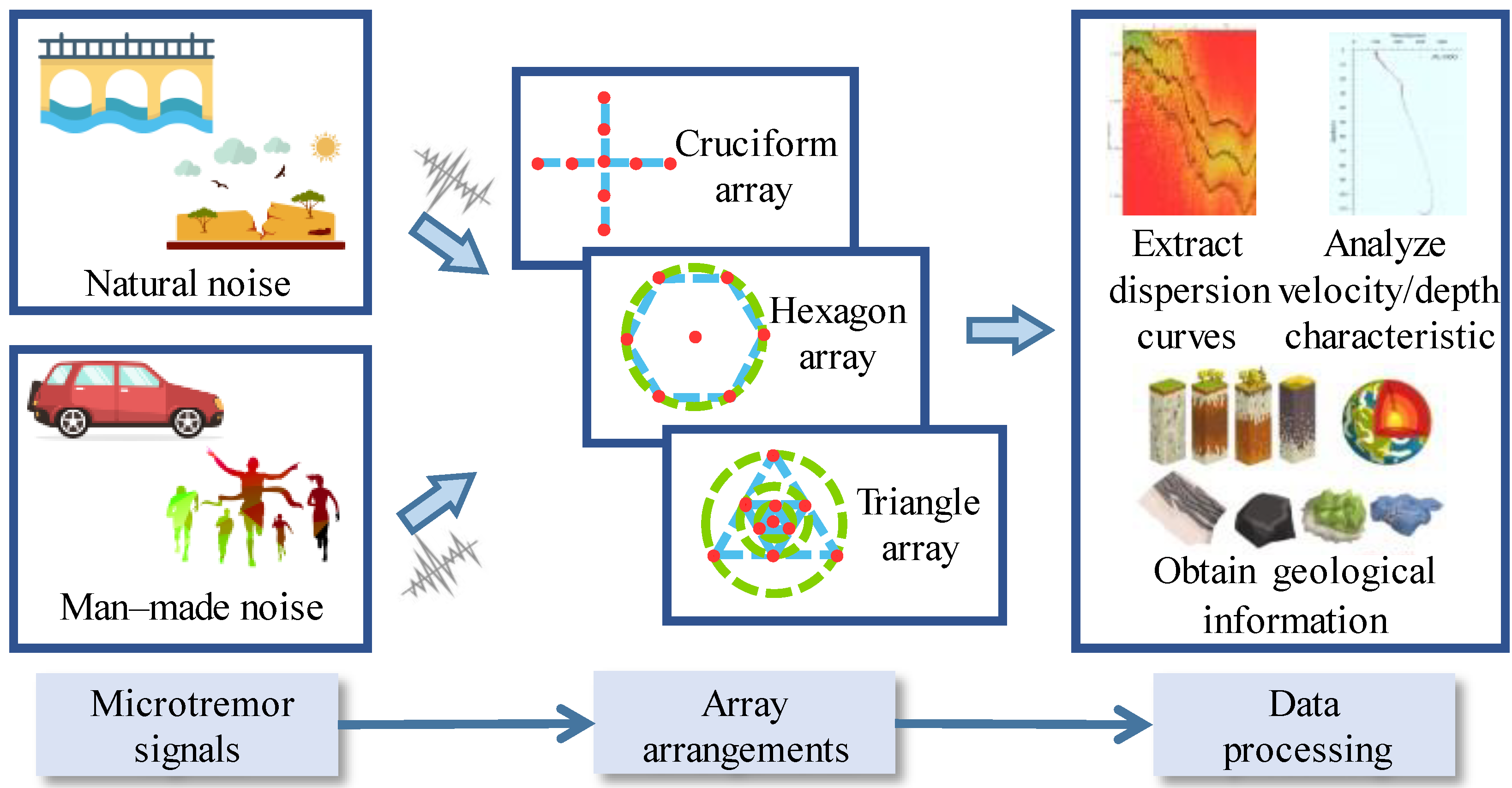

:1. Introduction

2. Analytical Model and Influencing Factors

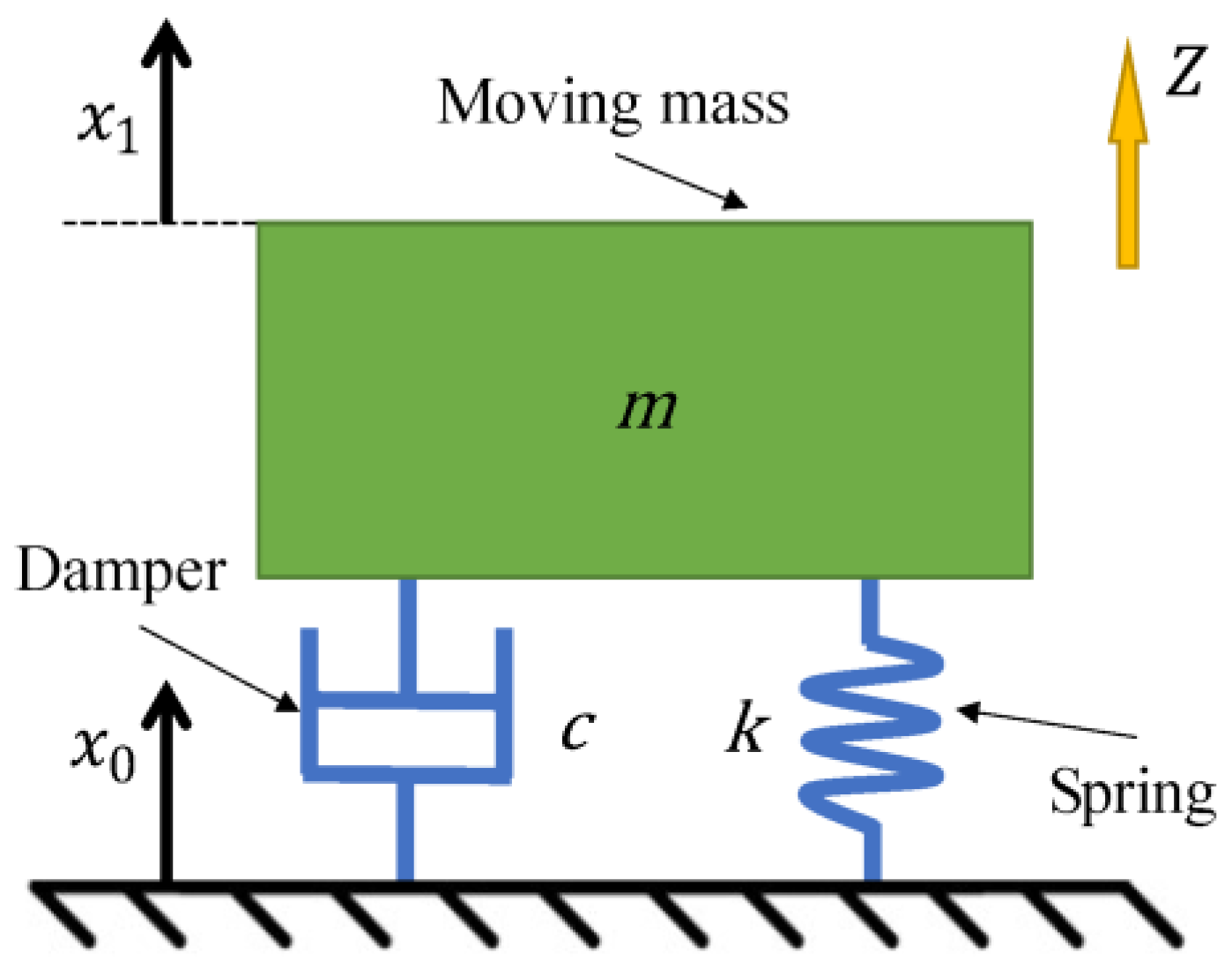

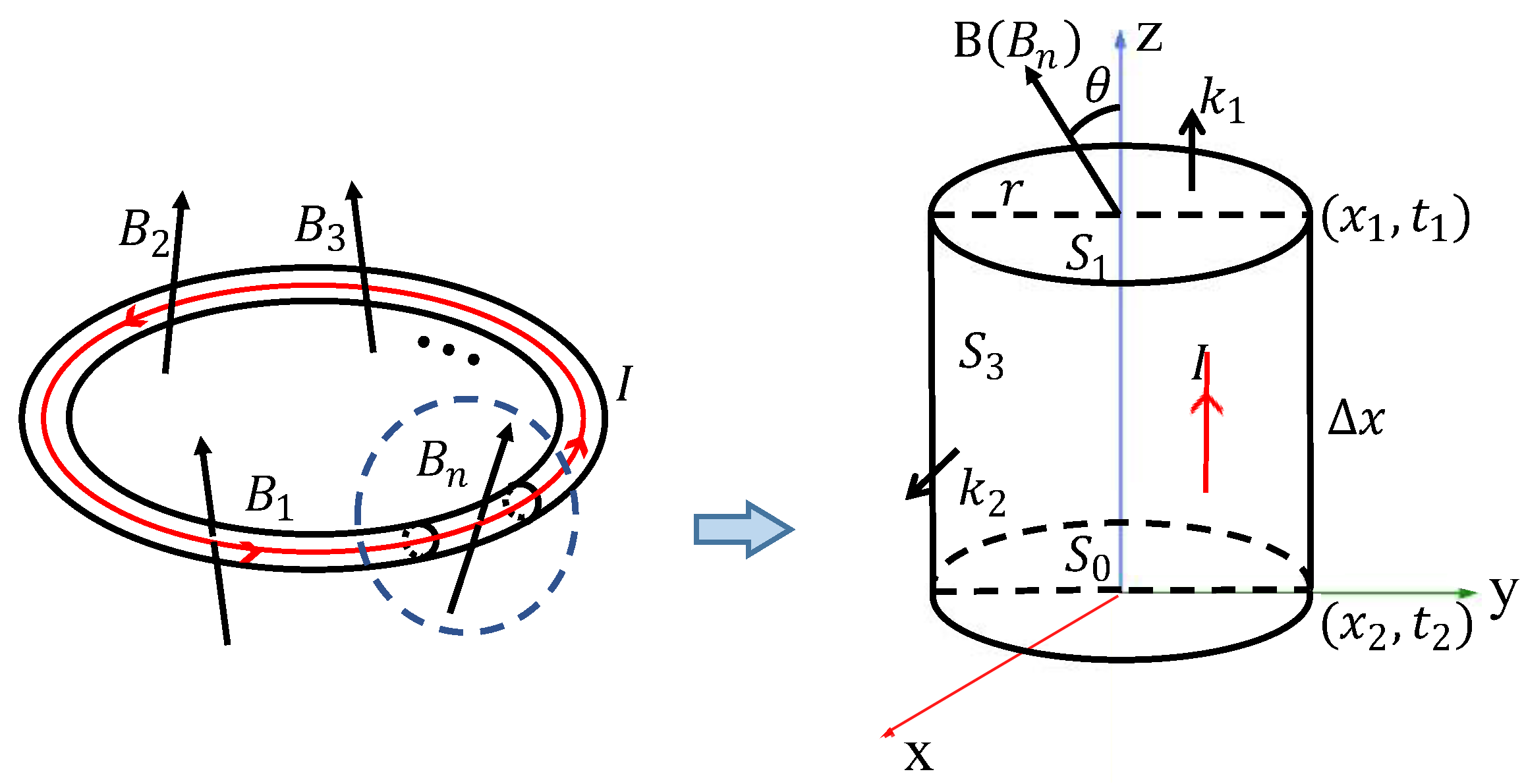

2.1. Principle of Electromagnetic Velocity Sensor

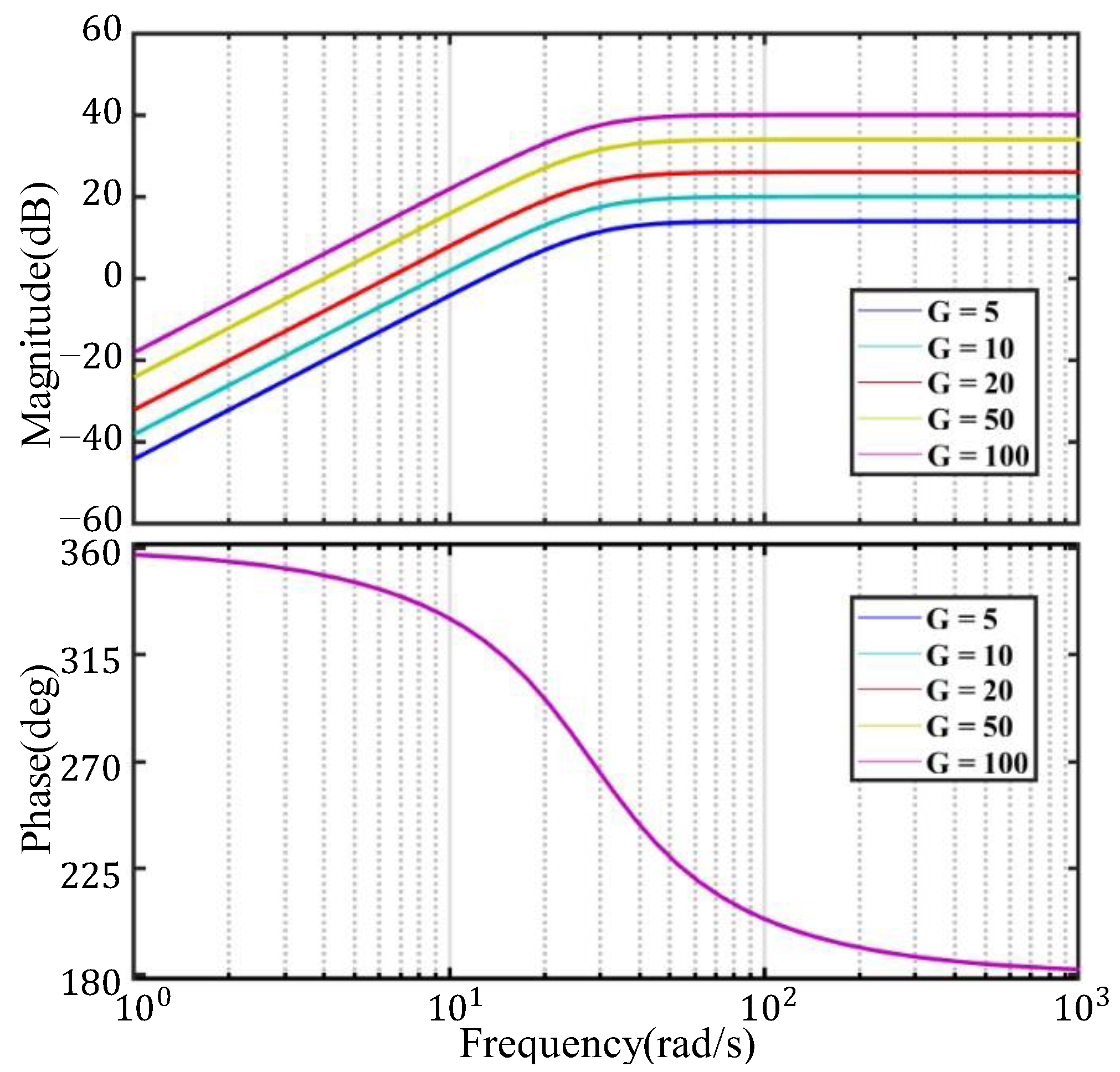

2.2. Effect of Sensitivity on Output Signal

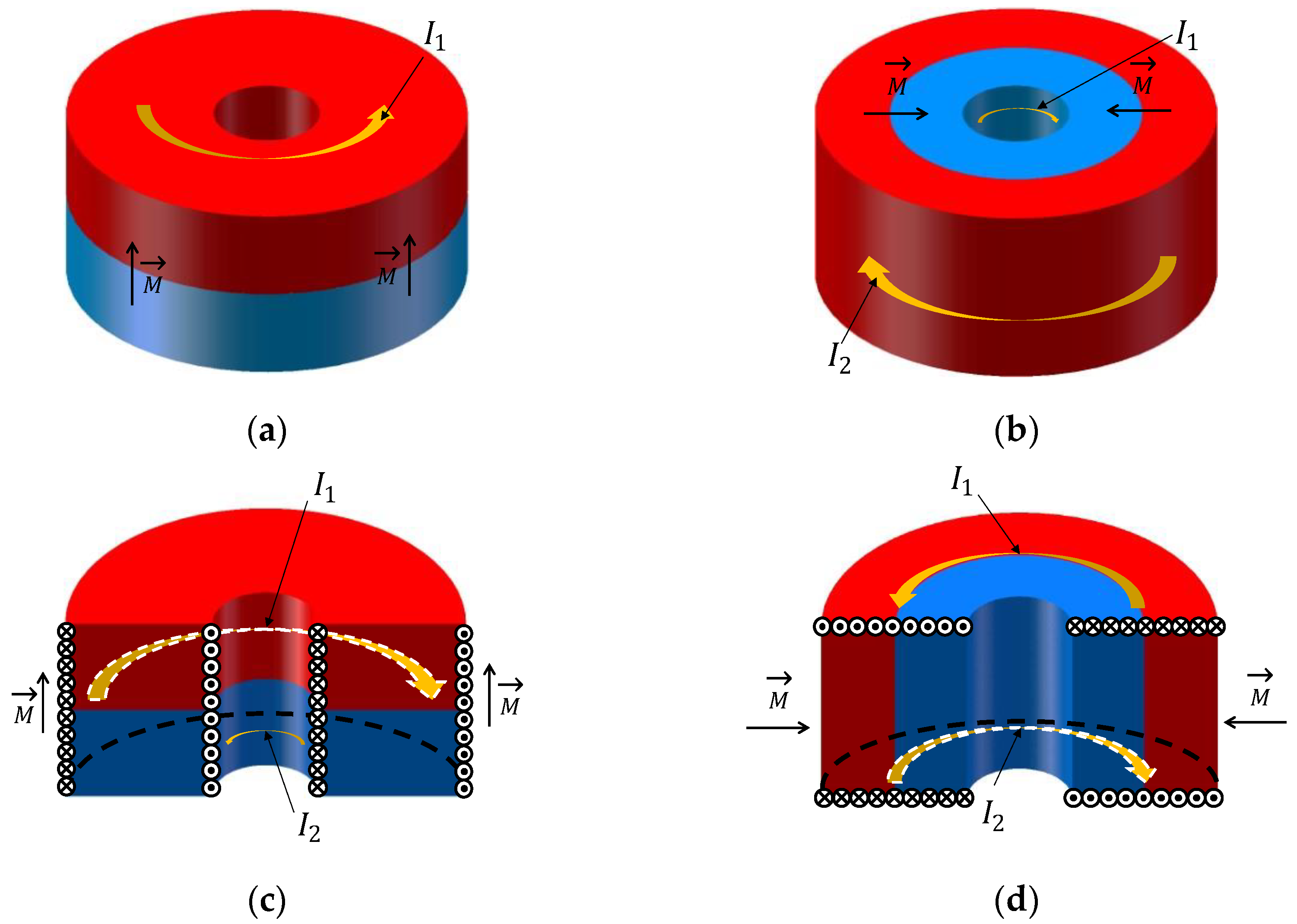

2.3. Effect of Magnetic Field Direction on Sensitivity

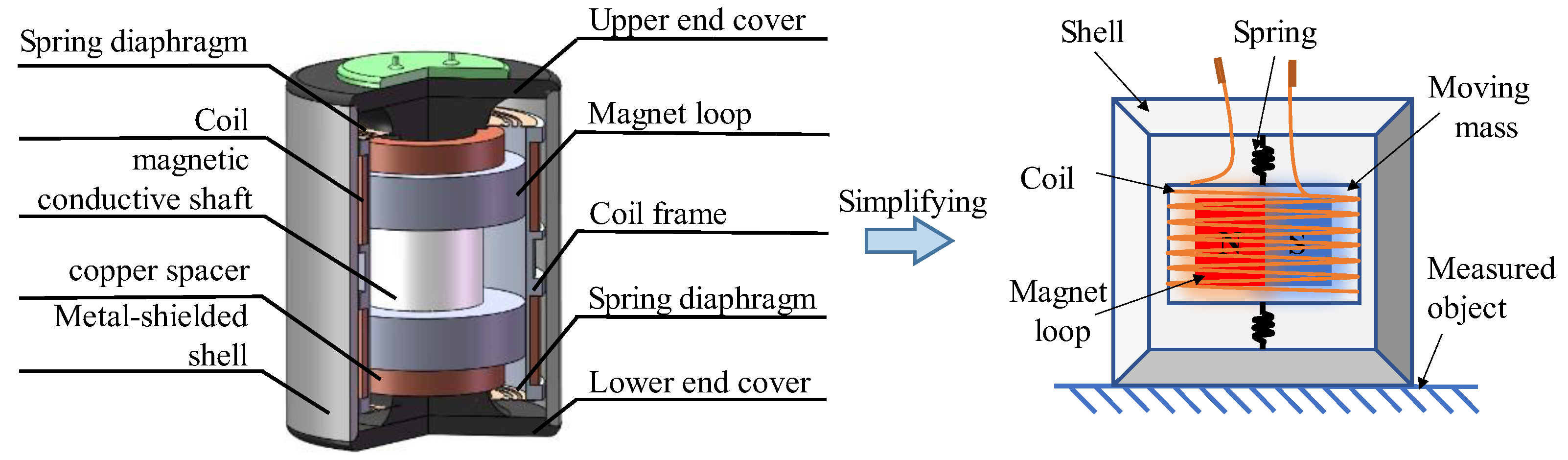

3. Structure Design and Numerical Simulation

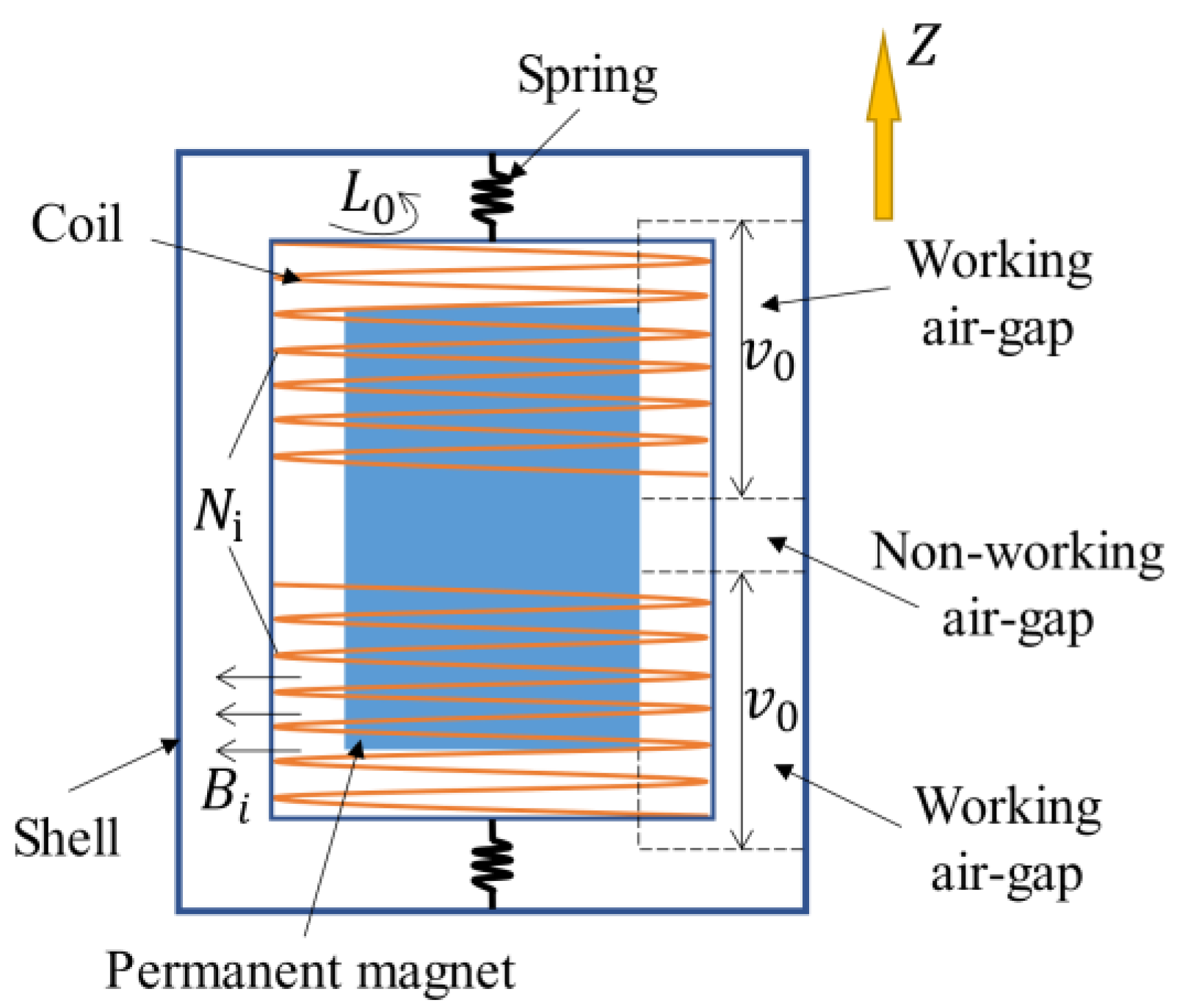

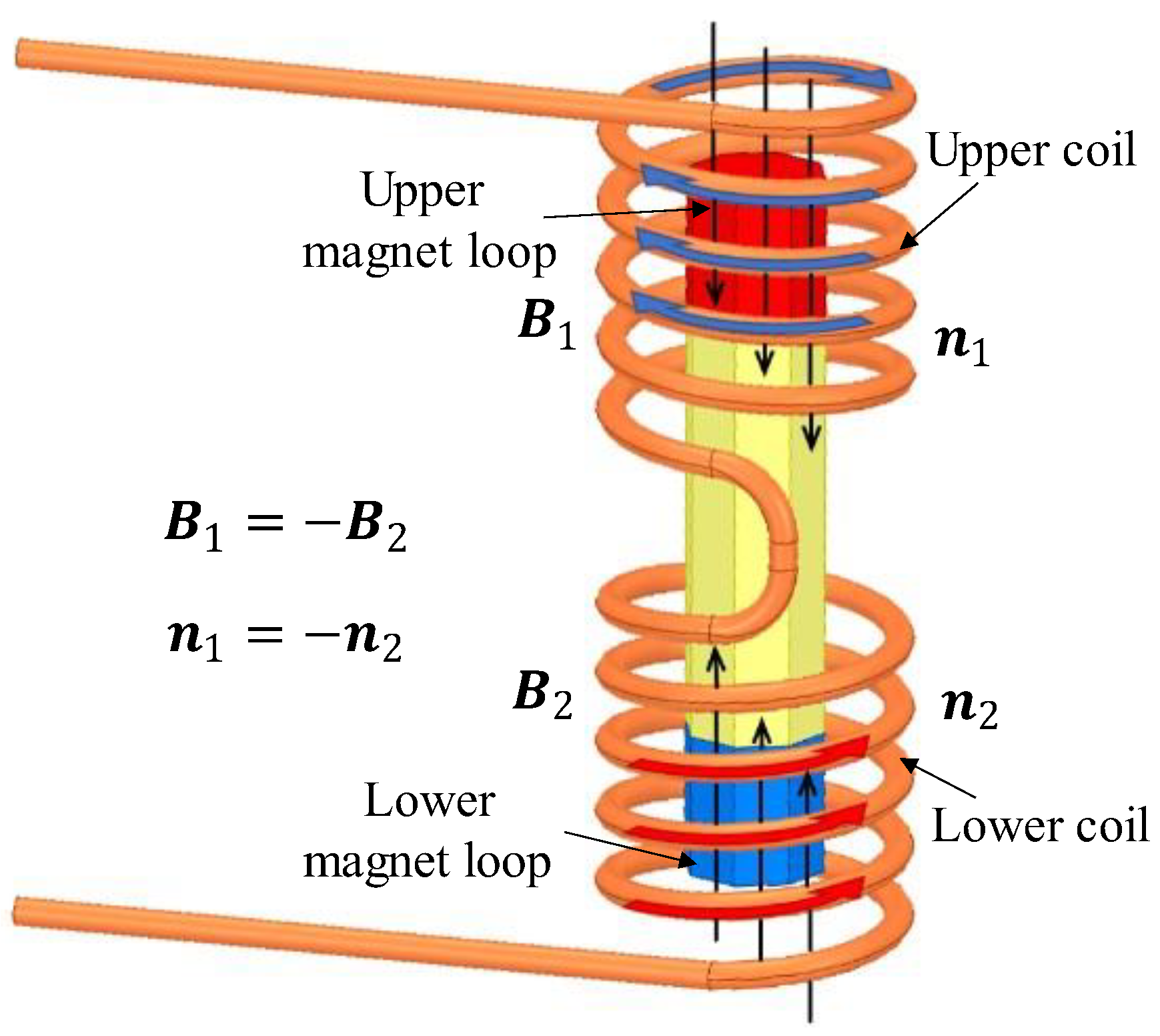

3.1. Mathematical Model of Dual-Magnet Velocity Sensor

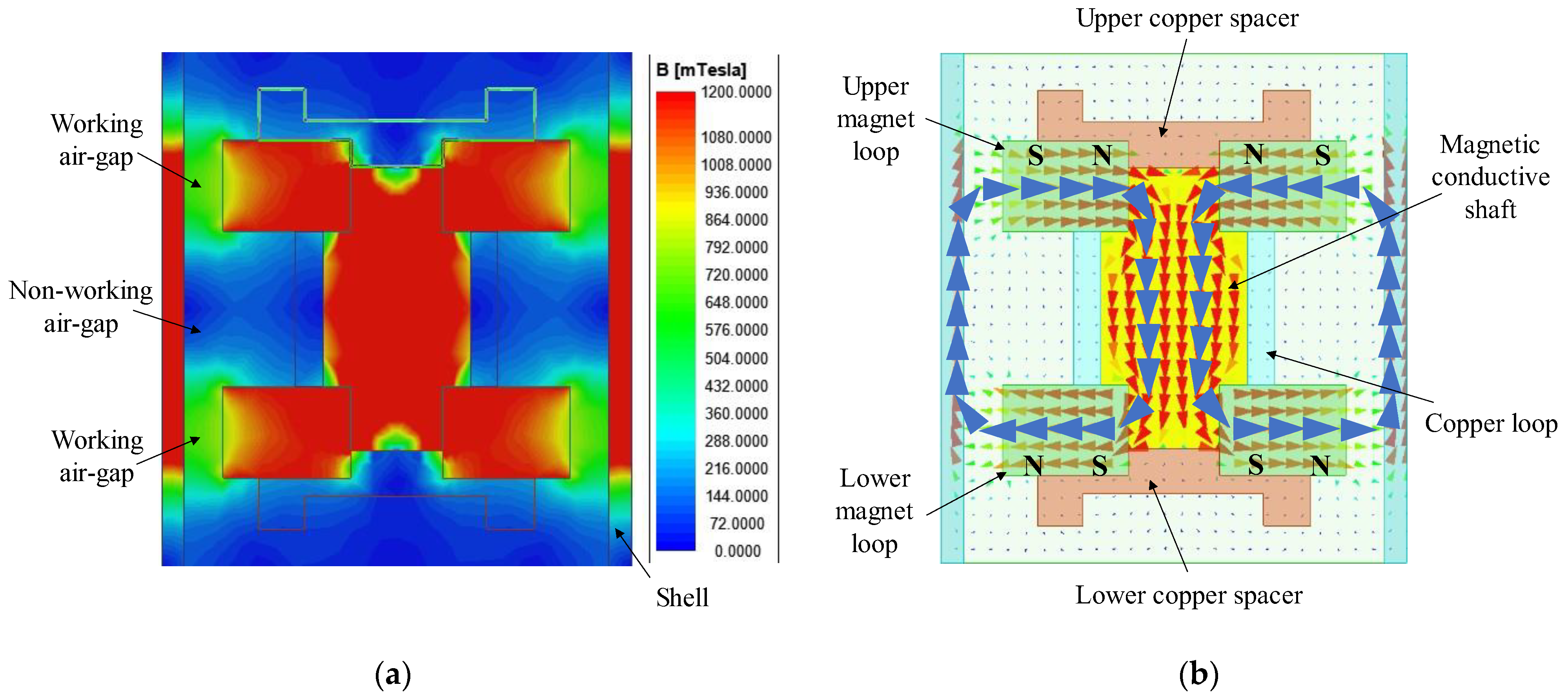

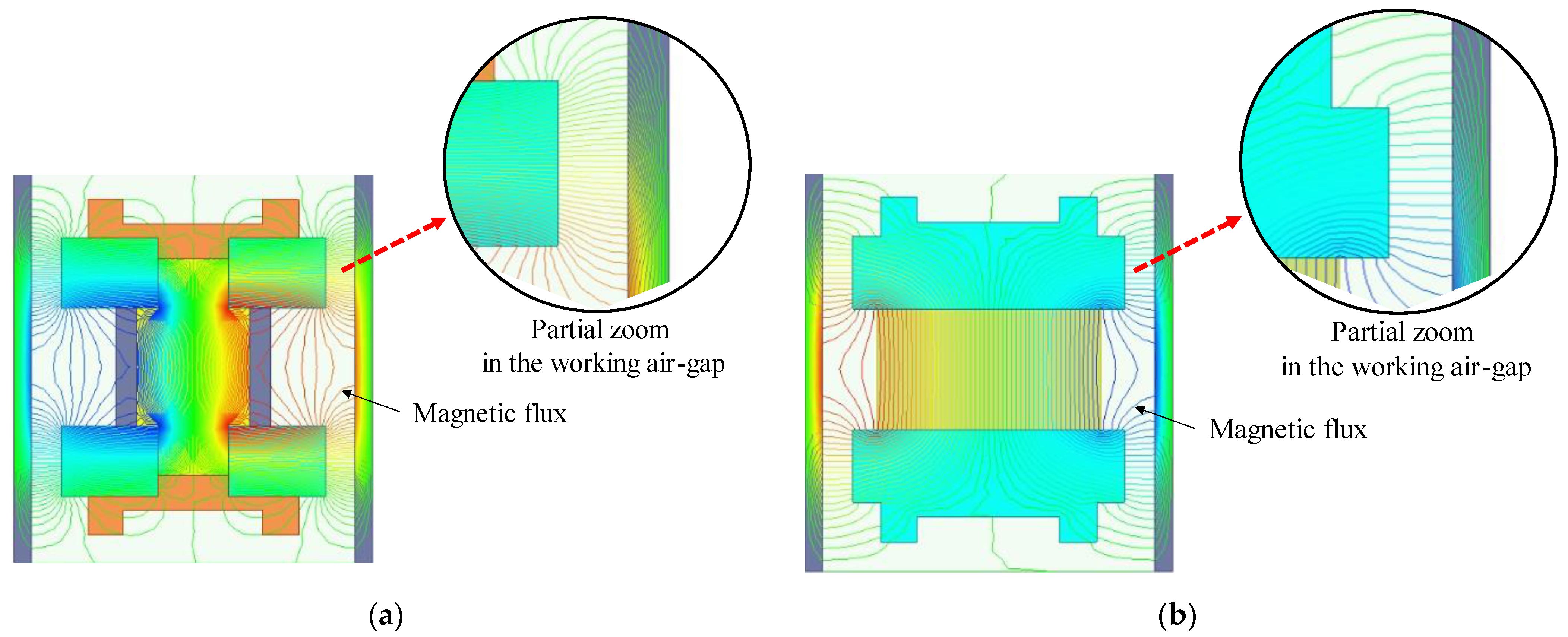

3.2. Magnetic Field Structure of Dual-Magnet Velocity Sensor

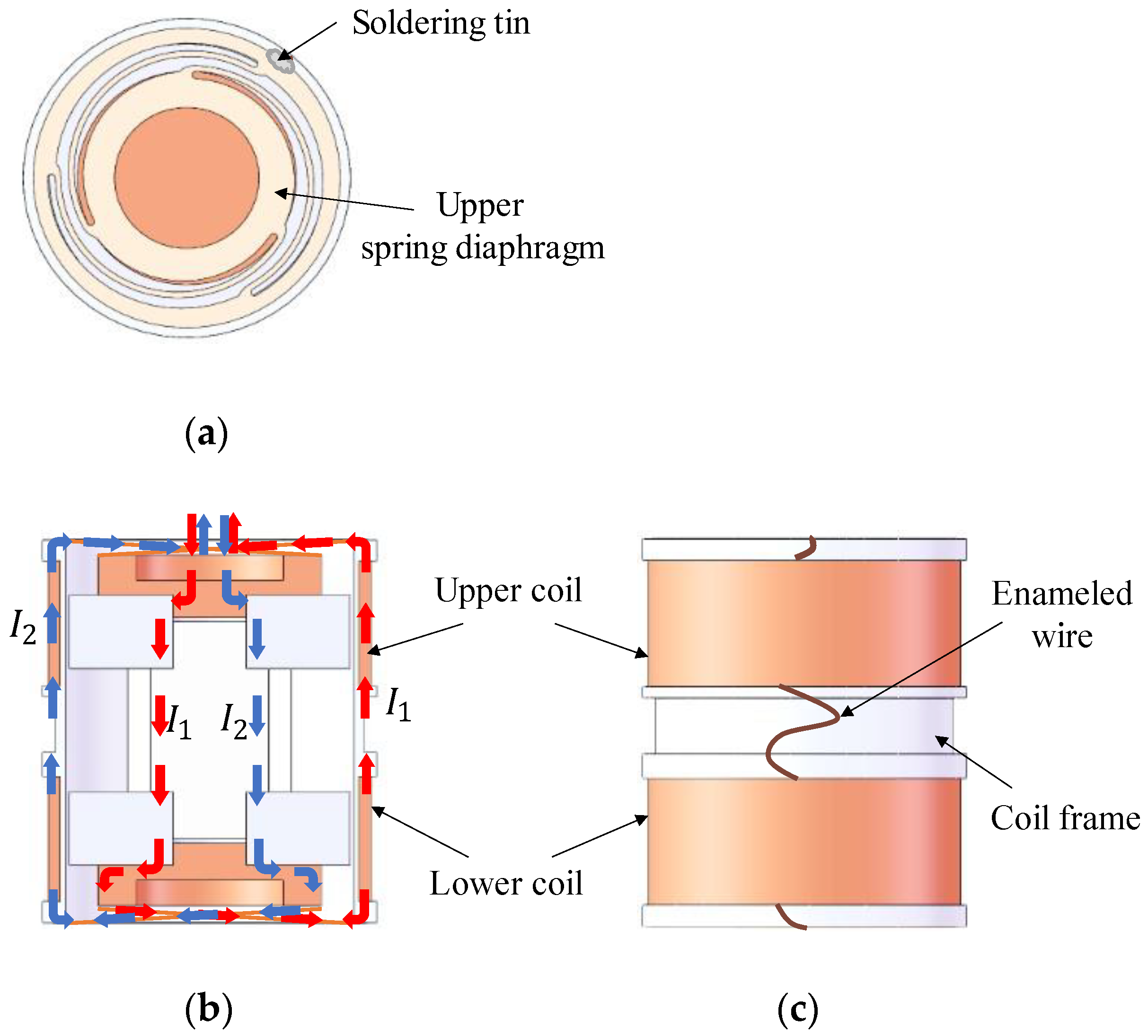

3.3. Circuit Structure of Dual-Magnet Velocity Sensor

- It can be explained by Ampere’s right-hand screw rule that, when the direction of the magnetic field and winding coils in the upper and lower working air-gaps are both opposite, the inductive electric potentials produced, respectively, by the two sets will be in the same direction. Therefore, the total inductive voltage will become promoted.

- According to Maxwell’s equations, when the coil moves relative to the magnetic field at a changing speed, the induced current will change consequently, which, in return, excites an extra magnetic field in space. This will influence the stability of the magnetic field generated by the magnet loops. By designing two sets of coils with the same number of turns and opposite winding directions, they can cancel each other out by exciting magnetic fields of the same magnitude but opposite directions in space, improving the system’s anti-interference capability.

4. Experimental Comparison and Analysis

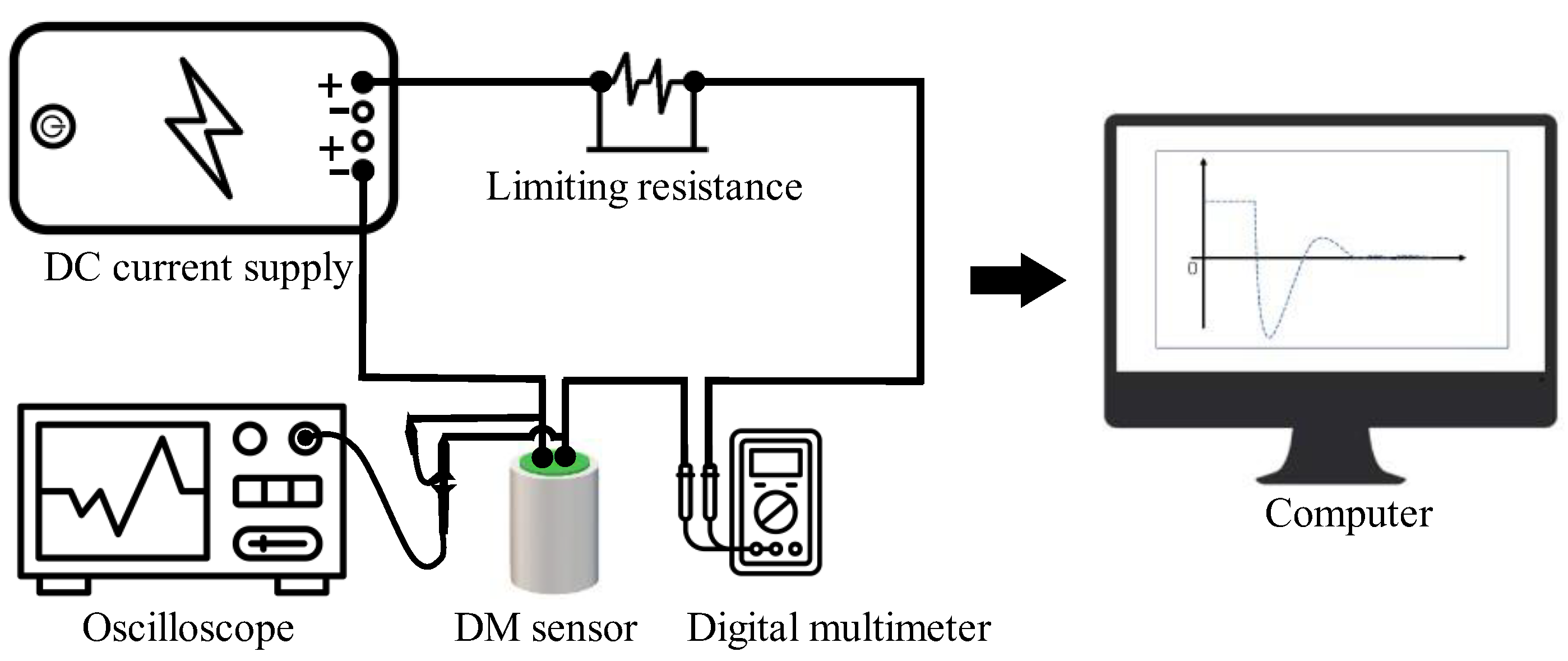

4.1. Measurement of Magnetic Field Intensity

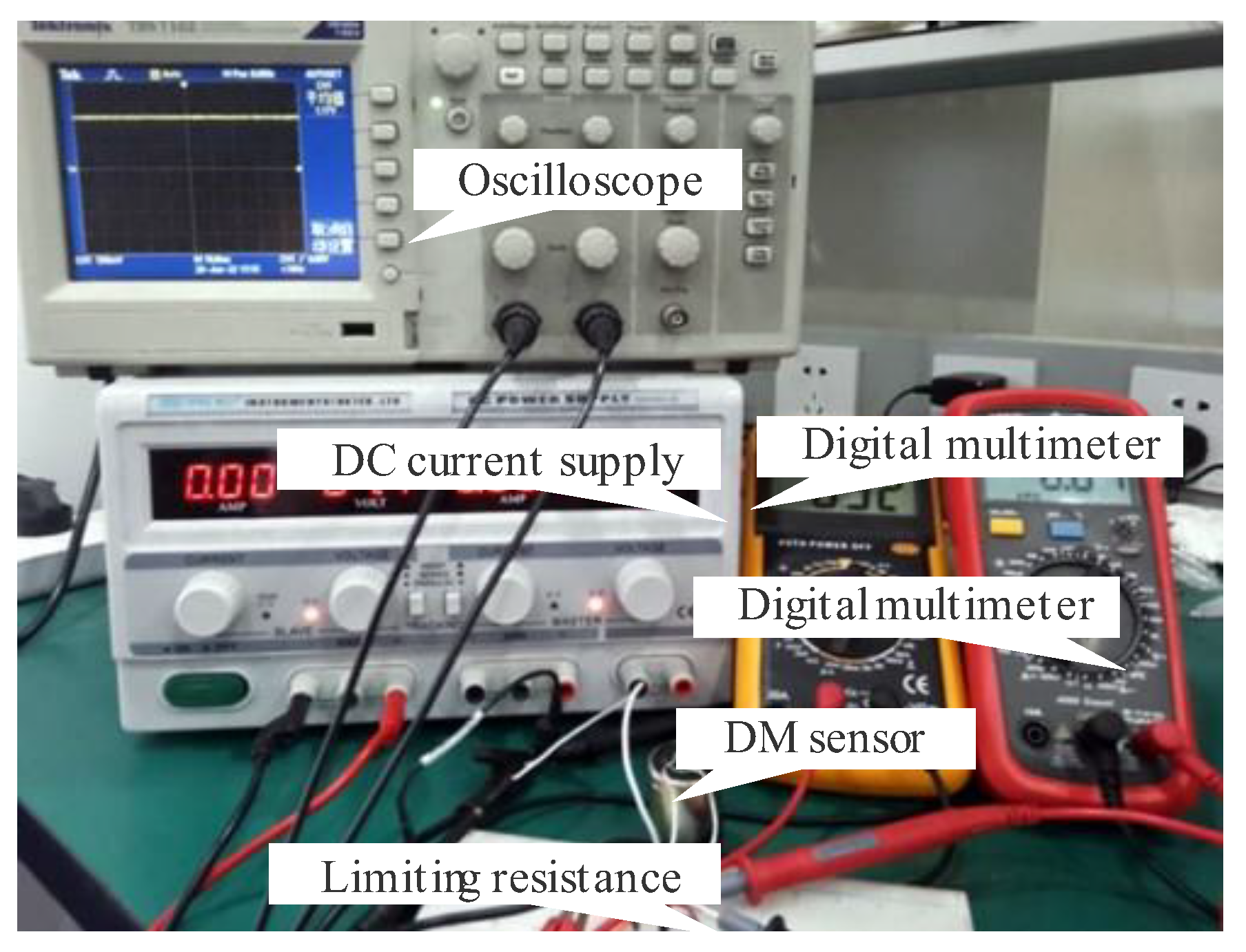

4.1.1. Experimental Methods

4.1.2. Experimental Results

4.2. Measurement of Sensitivity

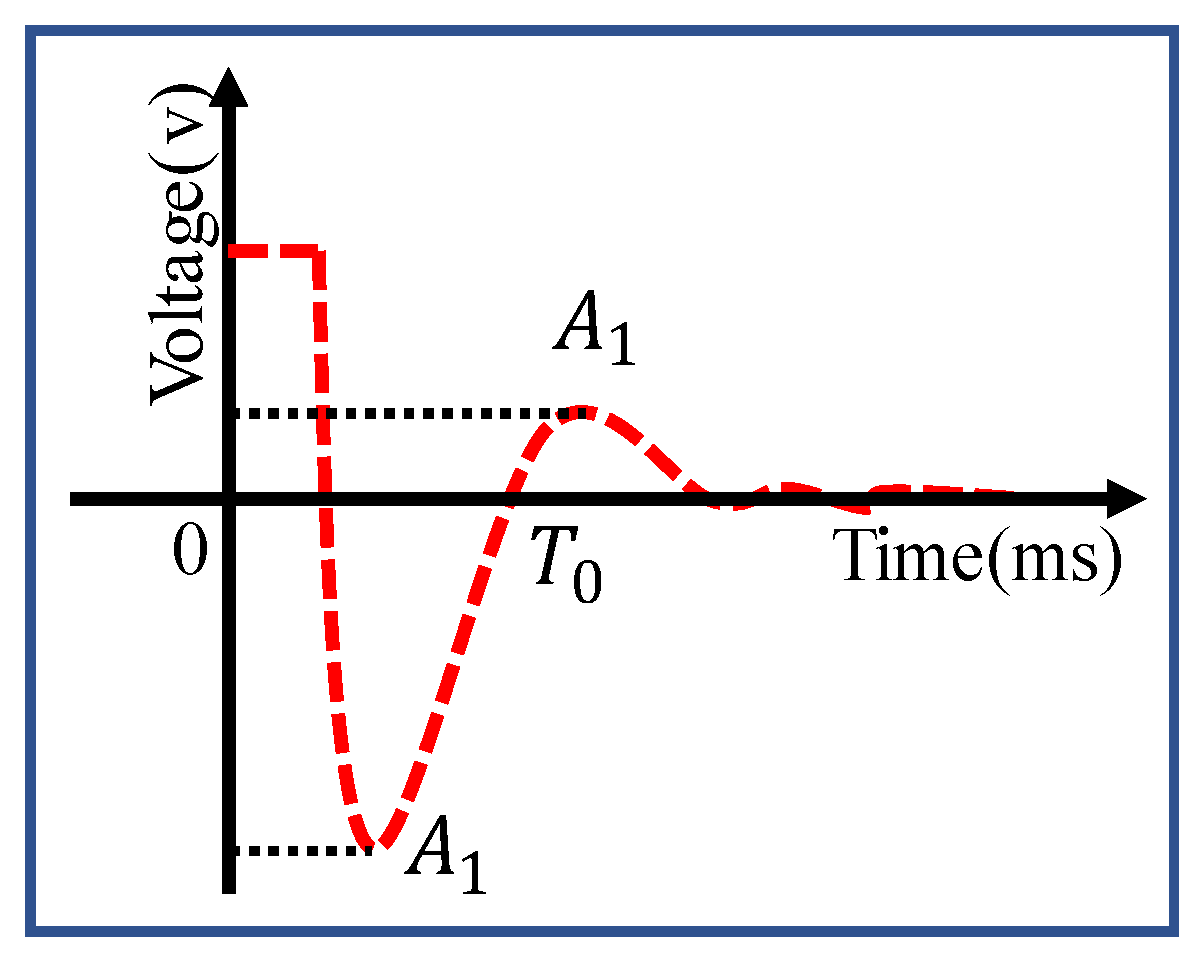

4.2.1. Measuring Principle

4.2.2. Results of Test

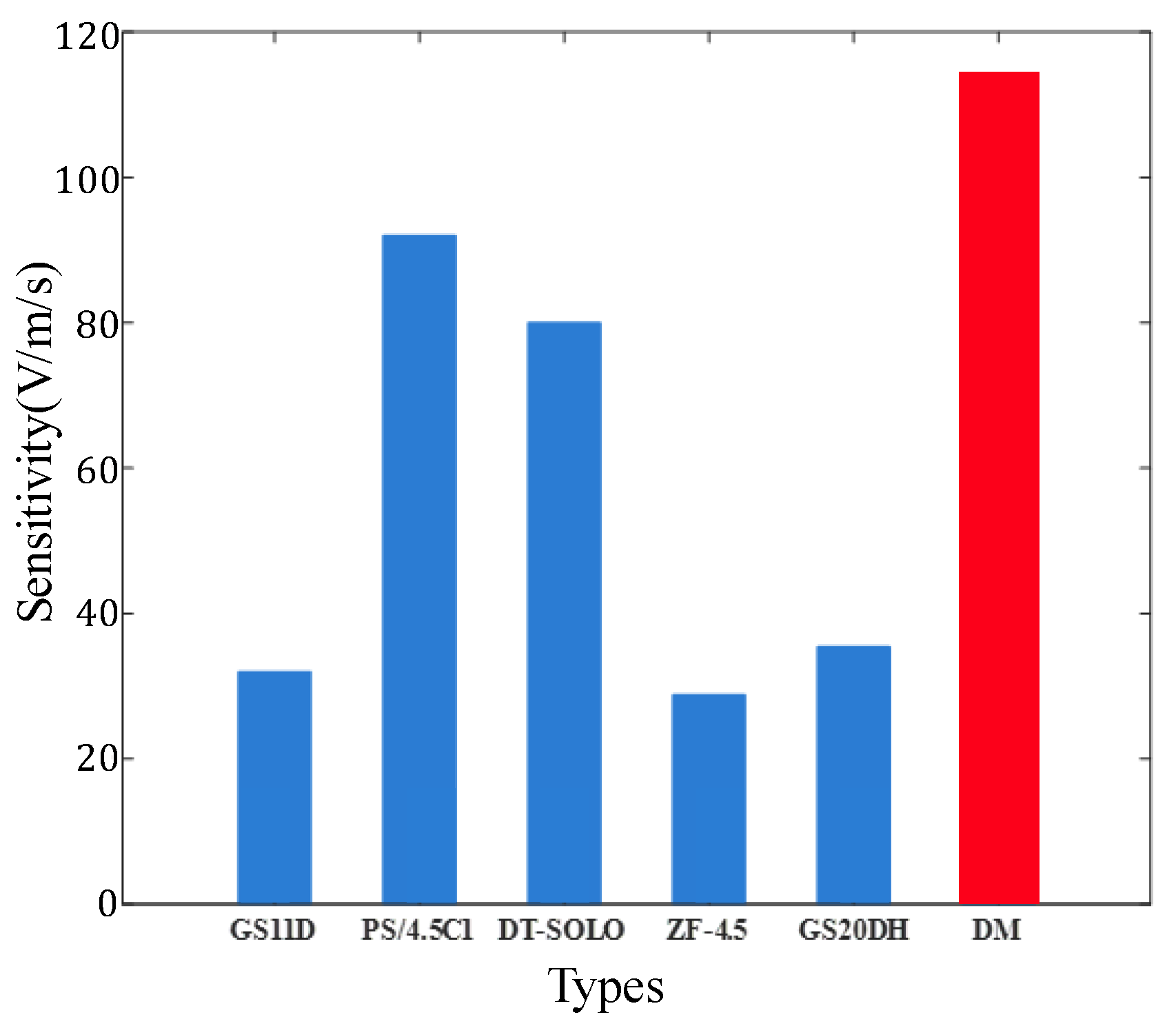

4.3. Comparison with Existing Velocity Sensors

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Baoqing, T.; Zhifeng, D.; Liming, Y.; Yifan, F.; Bo, Z. Microtremor Survey Method: A New Approach for Geothermal Exploration. Front. Earth Sci. 2022, 10, 817411. [Google Scholar] [CrossRef]

- Tian, R.; Wang, L.; Zhou, X.; Xu, H.; Lin, J.; Zhang, L. An Integrated Energy-Efficient Wireless Sensor Node for the Microtremor Survey Method. Sensors 2019, 19, 544. [Google Scholar] [CrossRef]

- Hakimitoroghi, N.; Raut, R.; Mirshafiei, M.; Bagchi, A. Compensation Techniques for Geophone Response Used as Vibration Sensor in Seismic Applications. In Proceedings of the 2017 Eleventh International Conference on Sensing Technology (ICST), Sydney, NSW, Australia, 4–6 December 2017; pp. 1–5. [Google Scholar]

- Tan, Z.; Chen, Y.; Liu, Y. Finite Element Model Updating Technique Oriented to the Bearing Capacity Improvement of Bridges. In Proceedings of the Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2019, Denver, CO, USA, 4–7 March 2019; Volume 10970. [Google Scholar]

- Zhao, B.-M.; Chen, J. Experimental Study on the Estimation of Seismic Ground Characteristic by Micro-Tremors. In Proceedings of the 2016 7th International Symposium on Rockburst and Seismicity in Mines (RASIM7), Dalian, China, 21–23 August 2009; pp. 95–100. [Google Scholar]

- Gao, W.; Gao, W.; Hu, R.; Xu, P.; Xia, J. Microtremor Survey and Stability Analysis of a Soil-Rock Mixture Landslide: A Case Study in Baidian Town, China. Landslides 2018, 15, 1951–1961. [Google Scholar] [CrossRef]

- Louie, J.N.; Pancha, A.; Kissane, B. Guidelines and Pitfalls of Refraction Microtremor Surveys. J. Seism. 2021, 26, 1–16. [Google Scholar] [CrossRef]

- Hammond, J.O.S.; England, R.; Rawlinson, N.; Curtis, A.; Sigloch, K.; Harmon, N.; Baptie, B. The Future of Passive Seismic Acquisition. Astron. Geophys. 2019, 60, 2.37–2.42. [Google Scholar] [CrossRef]

- Roberts, J.C.; Asten, M.W. Resolving a Velocity Inversion at the Geotechnical Scale Using the Microtremor (Passive Seismic) Survey Method. Explor. Geophys. 2004, 35, 14–18. [Google Scholar] [CrossRef]

- Kuo, C.-H.; Chen, C.-T.; Lin, C.-M.; Wen, K.-L.; Huang, J.-Y.; Chang, S.-C. S-Wave Velocity Structure and Site Effect Parameters Derived from Microtremor Arrays in the Western Plain of Taiwan. J. Asian Earth Sci. 2016, 128, 27–41. [Google Scholar] [CrossRef]

- Asten, M.W.; Hayashi, K. Application of the Spatial Auto-Correlation Method for Shear-Wave Velocity Studies Using Ambient Noise. Surv. Geophys. 2018, 39, 633–659. [Google Scholar] [CrossRef]

- Zhang, H.L.; Pankow, K. High-Resolution Bayesian Spatial Autocorrelation (SPAC) Quasi-3-D Vs Model of Utah FORGE Site with a Dense Geophone Array. Geophys. J. Int. 2021, 225, 1605–1615. [Google Scholar] [CrossRef]

- Tsai, V.C.; Moschetti, M.P. An Explicit Relationship between Time-Domain Noise Correlation and Spatial Autocorrelation (SPAC) Results. Geophys. J. Int. 2010, 182, 454–460. [Google Scholar] [CrossRef] [Green Version]

- Schmitt, R.M. Stability and Accuracy of Discrete-Time High Pass Filters with Application to Geophone Deconvolution. Master’s Thesis, Duke University, Durham, NC, USA, 2022. [Google Scholar]

- Wei, J. Comparing the MEMS Accelerometer and the Analog Geophone. Lead. Edge 2013, 32, 1206–1210. [Google Scholar] [CrossRef]

- Li, H.; Wang, R.; Cao, S.; Chen, Y.; Tian, N.; Chen, X. Weak Signal Detection Using Multiscale Morphology in Microseismic Monitoring. J. Appl. Geophys. 2016, 133, 39–49. [Google Scholar] [CrossRef]

- Li, H.; Wang, R.; Cao, S.; Chen, Y.; Huang, W. A Method for Low-Frequency Noise Suppression Based on Mathematical Morphology in Microseismic Monitoring. Geophysics 2016, 81, V159–V167. [Google Scholar] [CrossRef]

- Eisner, L.; Gei, D.; Hallo, M.; Oprsal, I.; Ali, M.Y. The Peak Frequency of Direct Waves for Microseismic Events. Geophysics 2013, 78, A45–A49. [Google Scholar] [CrossRef]

- Hong, L.; Wang, W.; Yao, Z.; Han, Z.; Li, Y.; Gao, Q.; Meng, J. Development Situation and Prospects of Seismometer. In Proceedings of the 2016 16th International Symposium on Communications and Information Technologies (ISCIT), Qingdao, China, 26–28 September 2016; pp. 410–413. [Google Scholar]

- Luka, M.P.; Loh, S.L.; Ching, D.L.C. Mathematical Modeling of Geophone Magnetic Ring for Sensitivity Studies. Malays. J. Fundam. Appl. Sci. 2017, 13, 351–353. [Google Scholar] [CrossRef]

- Ching, D.L.C. Mathematical Model of Vector Potential and Magnetic Surface Density of Geophone SM-24. J. Phys. Conf. Ser. 2018, 1123, 012038. [Google Scholar] [CrossRef]

- Anastasia, F.; Dmitry, Z.; Egor, E. A Simple and Cheap Method of Met Geophones and Seismic Accelerometers Temperature Sensitivity Stabilization in a Wide Temperature Band. Int. Multidiscip. Sci. GeoConf. SGEM 2020, 20, 411–418. [Google Scholar]

- Ding, J.; Wang, Y.; Wang, M.; Sun, Y.; Peng, Y.; Luo, J.; Pu, H. An Active Geophone with an Adjustable Electromagnetic Negative Stiffness for Low-Frequency Vibration Measurement. Mech. Syst. Signal Process. 2022, 178, 109207. [Google Scholar] [CrossRef]

- Xiaoyong, F.; Jiemei, M. Improvements for Seismometers Testing on Shake Table. In Proceedings of the 2019 14th IEEE International Conference on Electronic Measurement & Instruments (ICEMI), Changsha, China, 1–3 November 2019; pp. 868–872. [Google Scholar]

- Hong, L.; Wang, W.; Yao, Z.; Gao, Q.; Han, Z. Improving the Magnetic Field Homogeneity by Varying Magnetic Field Structure in a Geophone. Rev. Sci. Instrum. 2018, 89, 015008. [Google Scholar] [CrossRef]

- Fang, B. Reasearch of the Performance Improvement of Coil-Moving Geophone. Master’s Thesis, Jilin University, Jilin, China, 2009. [Google Scholar]

- Seo, K.S.; Lee, K.H.; Park, I.H. Characteristics of Electric and Magnetic Circuit Parameters in Thread-Type Magnetic Core System. IEEE Trans. Appl. Supercond. 2016, 26, 1–4. [Google Scholar] [CrossRef]

- Huang, X.; Sun, J.; Hua, H.; Zhang, Z. The Isolation Performance of Vibration Systems with General Velocity-Displacement-Dependent Nonlinear Damping under Base Excitation: Numerical and Experimental Study. Nonlinear Dyn. 2016, 85, 777–796. [Google Scholar] [CrossRef]

- Chen, Y.; Wen, H.; Jin, D. Design and Experiment of a Noncontact Electromagnetic Vibration Isolator with Controllable Stiffness. Acta Astronaut. 2020, 168, 130–137. [Google Scholar] [CrossRef]

- Baldauf, M.; Fidler, P.; Keutel, T.; Kanoun, O. Method for Application Specific Electrodynamic Harvester Design. In Proceedings of the Eighth International Multi-Conference on Systems, Signals & Devices, Sousse, Tunisia, 22–25 March 2011; pp. 1–2. [Google Scholar]

- DeMetz, F.C. Sensitivity Requirements for Fiber Optic Pressure and Velocity Sensors. In Proceedings of the Sixth Pacific Northwest Fiber Optic Sensor Workshop, Troutdale, OR, USA, 14–15 May 2003; Udd, E., Kreger, S.T., Bush, J., Eds.; SPIE: Bellingham, WA, USA, 2003; Volume 5278, pp. 32–41. [Google Scholar]

- Su, W. Development of a Geophone Tester Based on the Step-Release-Method. Master’s Thesis, Jilin University, Jilin, China, 2016. [Google Scholar]

- Redzic, D.V. Maxwell’s Inductions from Faraday’s Induction Law. Eur. J. Phys. 2018, 39, 025205. [Google Scholar] [CrossRef]

- Ceraolo, M.; Poli, D. The Fundamental Laws of Electromagnetism. In Fundamentals of Electric Power Engineering: From Electromagnetics to Power Systems; IEEE: Piscataway, NJ, USA, 2014; pp. 19–42. [Google Scholar]

- Tang, D.; Liang, Z.; Chen, H. A Novel Geophone with High Accuracy. J. Vib. Shock 2008, 27, 162–165. [Google Scholar]

- Li, S.; Yang, X. Research on the Character and System of Magnetic Annulus Style Geophone. J. Tianjin Univ. Sci. Technol. 2004, 19, 46–48. [Google Scholar]

- Zhao, B.; Shi, W.; Sun, D.; Tan, J. Compensation Network for Temperature Dependency and Bandwidth Expanding of Magnetoelectric Velocity Sensor Based on Phase Prediction Compensator. IEEE Sens. J. 2021, 21, 1704–1714. [Google Scholar] [CrossRef]

- Liu, Y.; Sellmyer, D.J.; Shindo, D. Handbook of Advanced Magnetic Materials: Vol 1. Nanostructural Effects. Vol 2. Characterization and Simulation. Vol 3. Fabrication and Processing. Vol 4. Properties and Applications; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Pashley, R.M.; Rzechowicz, M.; Pashley, L.R.; Francis, M.J. De-Gassed Water Is a Better Cleaning Agent. J. Phys. Chem. B 2005, 109, 1231–1238. [Google Scholar] [CrossRef]

- Deng, Y.; Peng, Z. Algorithm Improvement for Geophone Calibration with High Damping Ratio. In Proceedings of the 8th International Conference on Structural Dynamics, Eurodyn 2011, Leuven, Belgium, 4–6 July 2011; DeRoeck, G., Degrande, G., Lombaert, G., Muller, G., Eds.; European Assoc Structural Dynamics: Munich, Germany, 2011; pp. 2077–2082. [Google Scholar]

- Rodgers, P.W.; Martin, A.J.; Robertson, M.C.; Hsu, M.M.; Harris, D.B. Signal-Coil Calibration of Electromagnetic Seismometers. Bull. Seismol. Soc. Am. 1995, 85, 845–850. [Google Scholar] [CrossRef]

- Li, J.; Wang, L.; Zhao, B.; Zhao, G.; Wang, J.; Zhang, Z.; Chen, J.; Wang, S. Parameter Identification of Inertial Velocity Sensor for Low-Frequency Vibration Measurement. In Proceedings of the Tenth International Symposium on Precision Engineering Measurements and Instrumentation, Kunming, China, 8–10 August 2018; Tan, J., Lin, J., Eds.; SPIE: Bellingham, WA, USA, 2019; Volume 11053, p. 110533A. [Google Scholar]

- Mou, X.; Zhu, K.; Zhou, X.; Yu, Y. Design of Micro-Tremor Prospector Instrument Based on Local Wireless Synchronization. Digit. Manuf. Sci. 2022, 20, 87–92. [Google Scholar]

- Vitale, G.; Greco, L.; D’Alessandro, A.; Scudero, S. Bandwidth Extension of a 4.5 Hz Geophone for Seismic Monitoring Purpose. In Proceedings of the 2018 IEEE International Conference on Environmental Engineering (EE), Milan, Italy, 12–14 March 2018; pp. 1–5. [Google Scholar]

| Parts | Materials |

|---|---|

| Magnet loops | NdFe52 |

| Magnetic conductive shaft | Industrial pure iron |

| Copper spacers | Pure copper |

| Spring diaphragm | QBe2.0 |

| Coil frame | Aluminum alloy |

| Copper loop | Pure copper |

| End covers | Rubber |

| Metal-shielded shell | Stainless steel |

| Parameters | GS11D [42] | PS/4.5C1 [43] | DT-SOLO5 [36] | ZF-4.5 [44] | DM4.5 |

|---|---|---|---|---|---|

| Natural frequency | 4.5 ± 1.7% Hz | 4.5 ± 10% Hz | 5 ± 7.5% Hz | 4.5 ± 10% Hz | 4.5 ± 10% Hz |

| Sensitivity | 32 V/m/s | 92 V/m/s | 80 V/m/s | 28.8 V/m/s | 114 V/m/s |

| Moving mass | 23.6 g | 11.3 g | 22.7 g | 11.1 g | 11.3 g |

| Open circuit damping | 0.34 ± 10% | 0.76 ± 10% | 0.6 ± 7.5% | 0.56 ± 8% | 0.76 ± 10% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, X.; Ruan, Y.; Mou, X.; Yuan, Y.; He, Y. A Design of Electromagnetic Velocity Sensor with High Sensitivity Based on Dual-Magnet Structure. Sensors 2022, 22, 6925. https://doi.org/10.3390/s22186925

Zhou X, Ruan Y, Mou X, Yuan Y, He Y. A Design of Electromagnetic Velocity Sensor with High Sensitivity Based on Dual-Magnet Structure. Sensors. 2022; 22(18):6925. https://doi.org/10.3390/s22186925

Chicago/Turabian StyleZhou, Xiao, Yangfan Ruan, Xingang Mou, Yuhao Yuan, and Yi He. 2022. "A Design of Electromagnetic Velocity Sensor with High Sensitivity Based on Dual-Magnet Structure" Sensors 22, no. 18: 6925. https://doi.org/10.3390/s22186925