Test Structure Design for Defect Detection during Active Thermal Cycling

Abstract

:1. Introduction

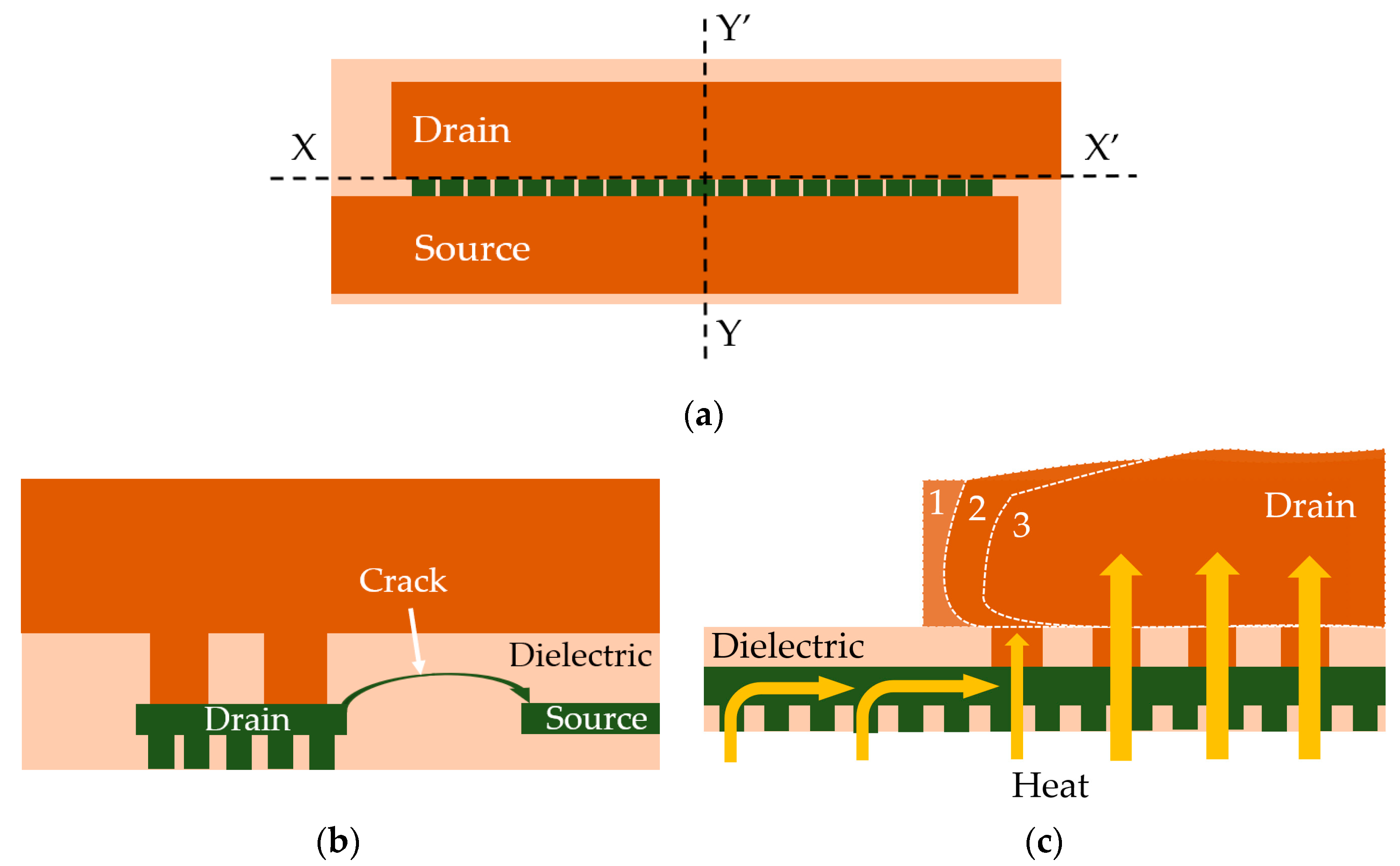

1.1. IMD Cracking Failure Mode

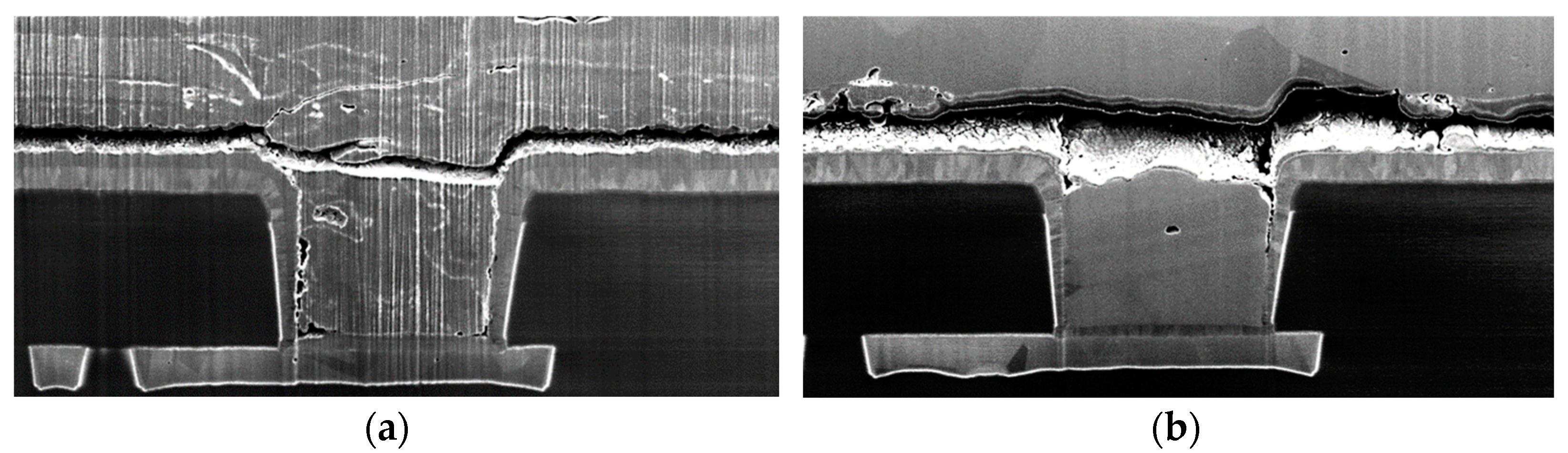

1.2. Power Metal Delamination/Disruption

1.3. Objective of the Current Work

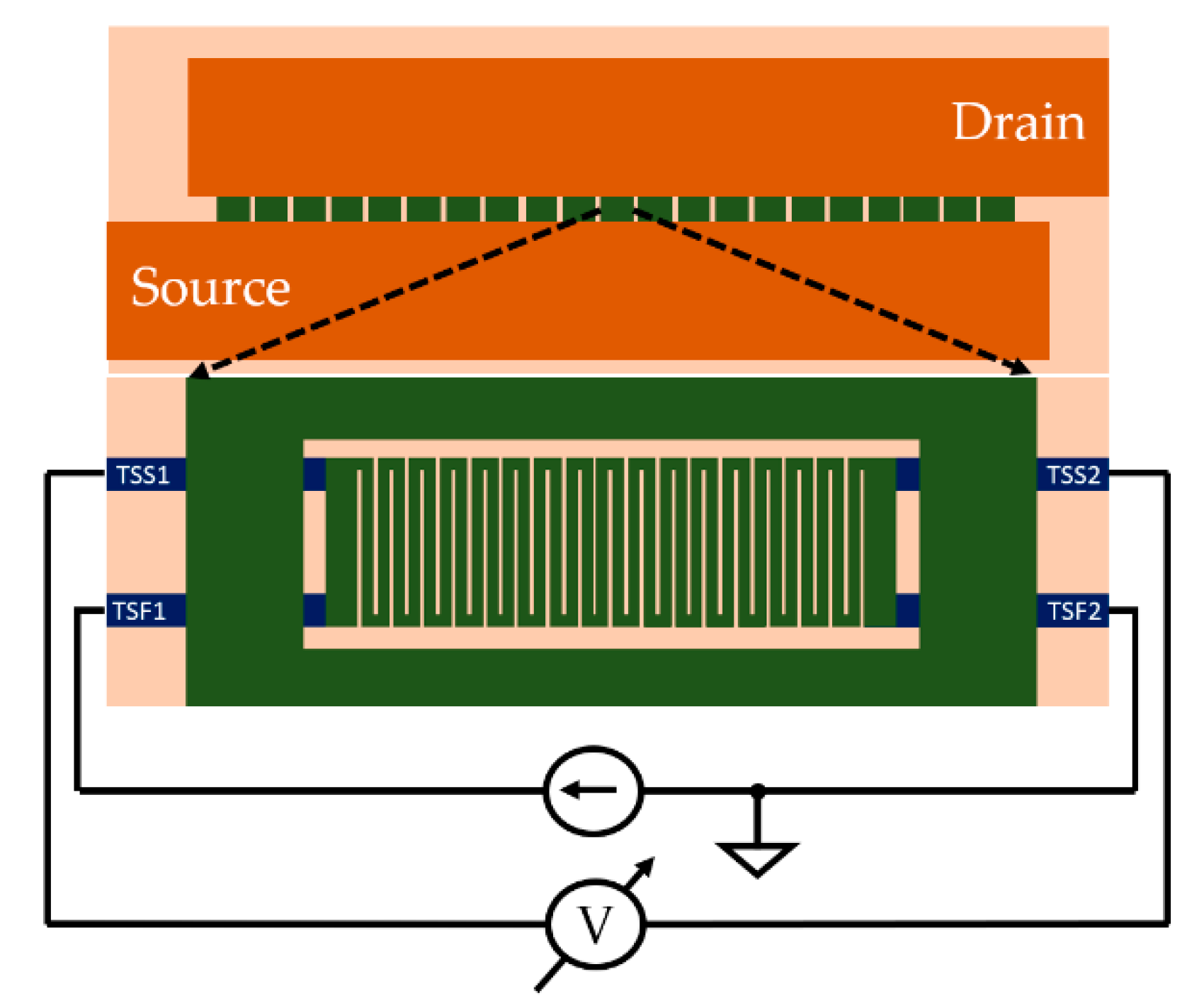

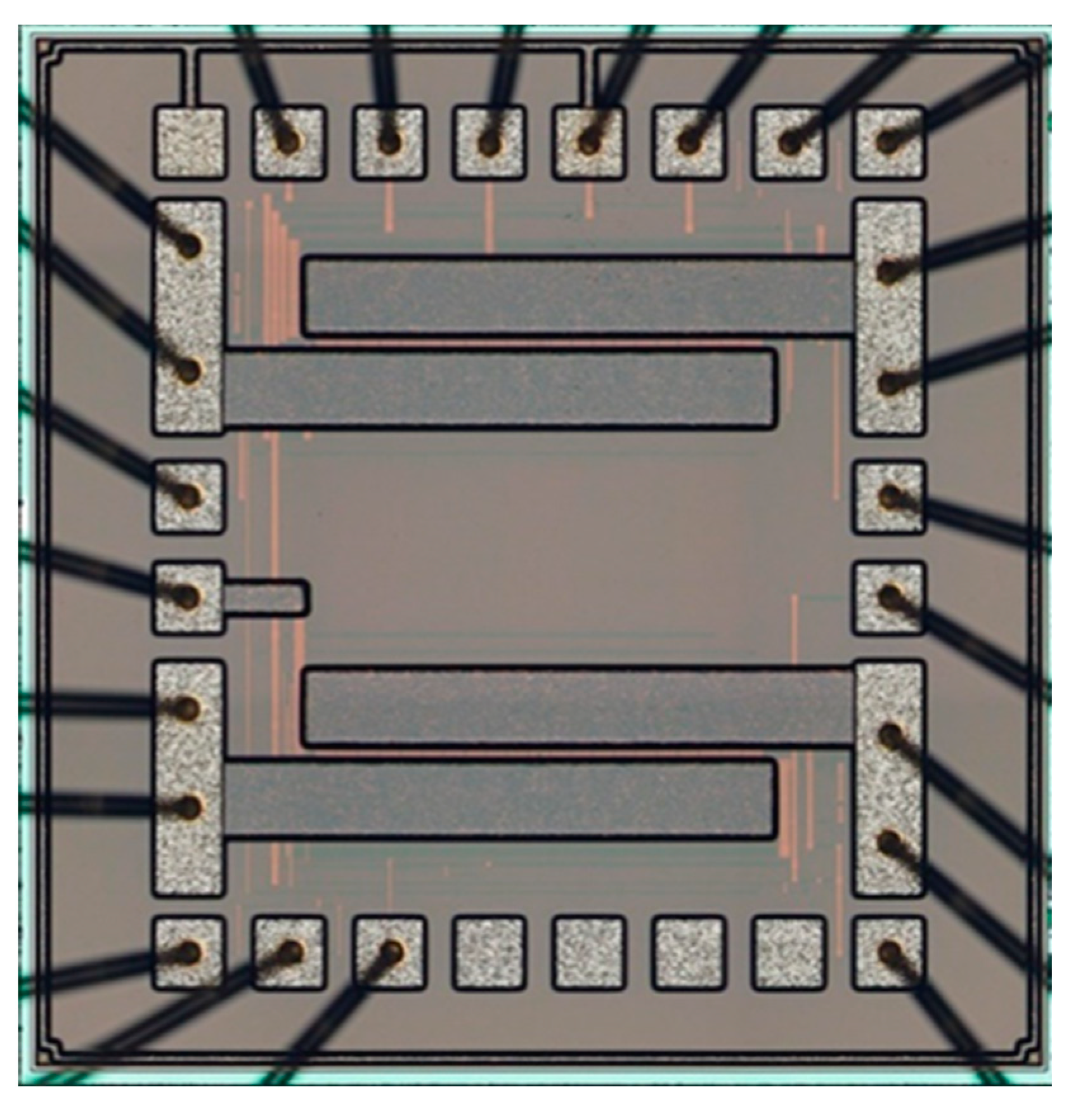

2. The Test Chip

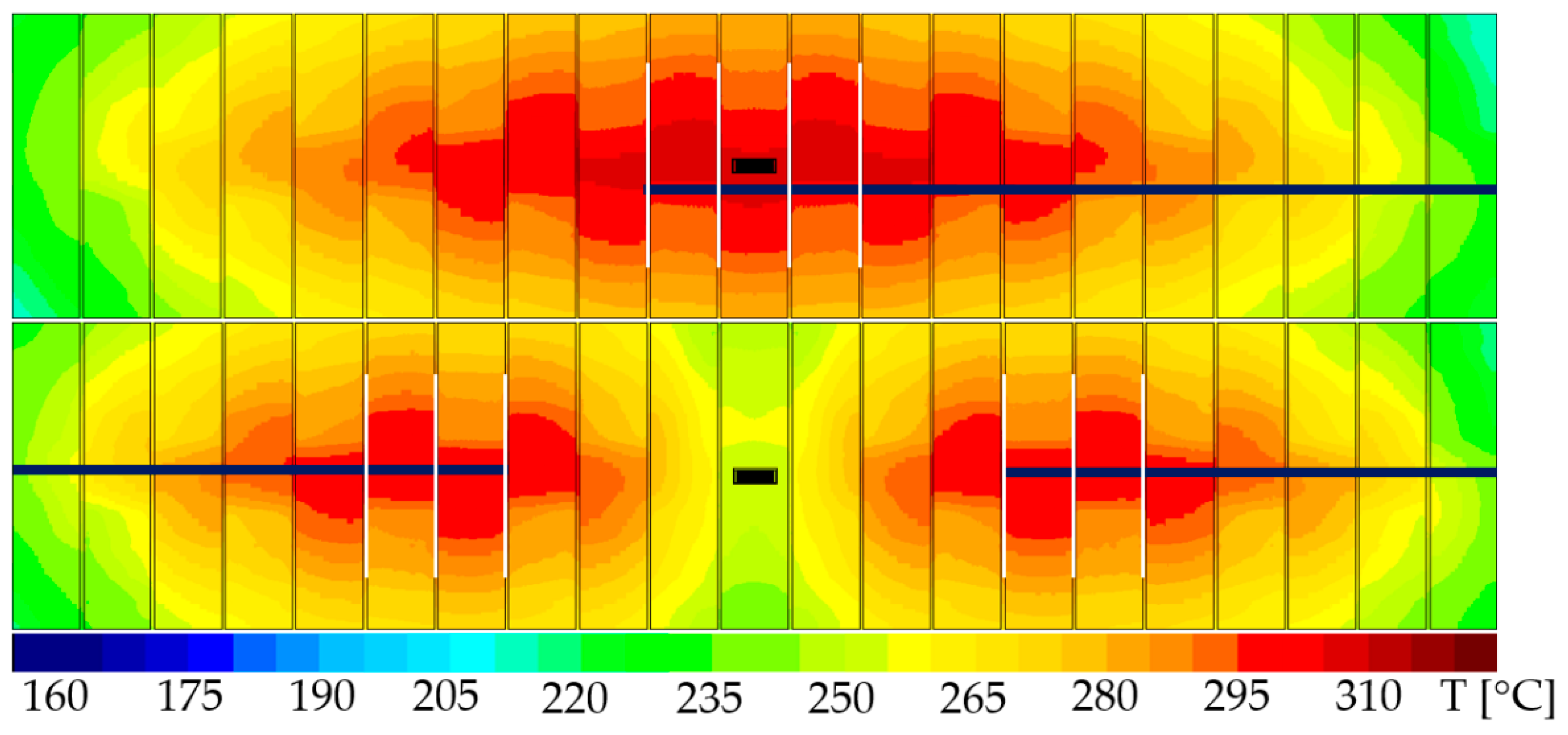

2.1. The DMOS Transistor

- 100%AA (100% of the active area operational);

- 90%AA (90% of the active area operational, 10% of DMOS deactivated in the center);

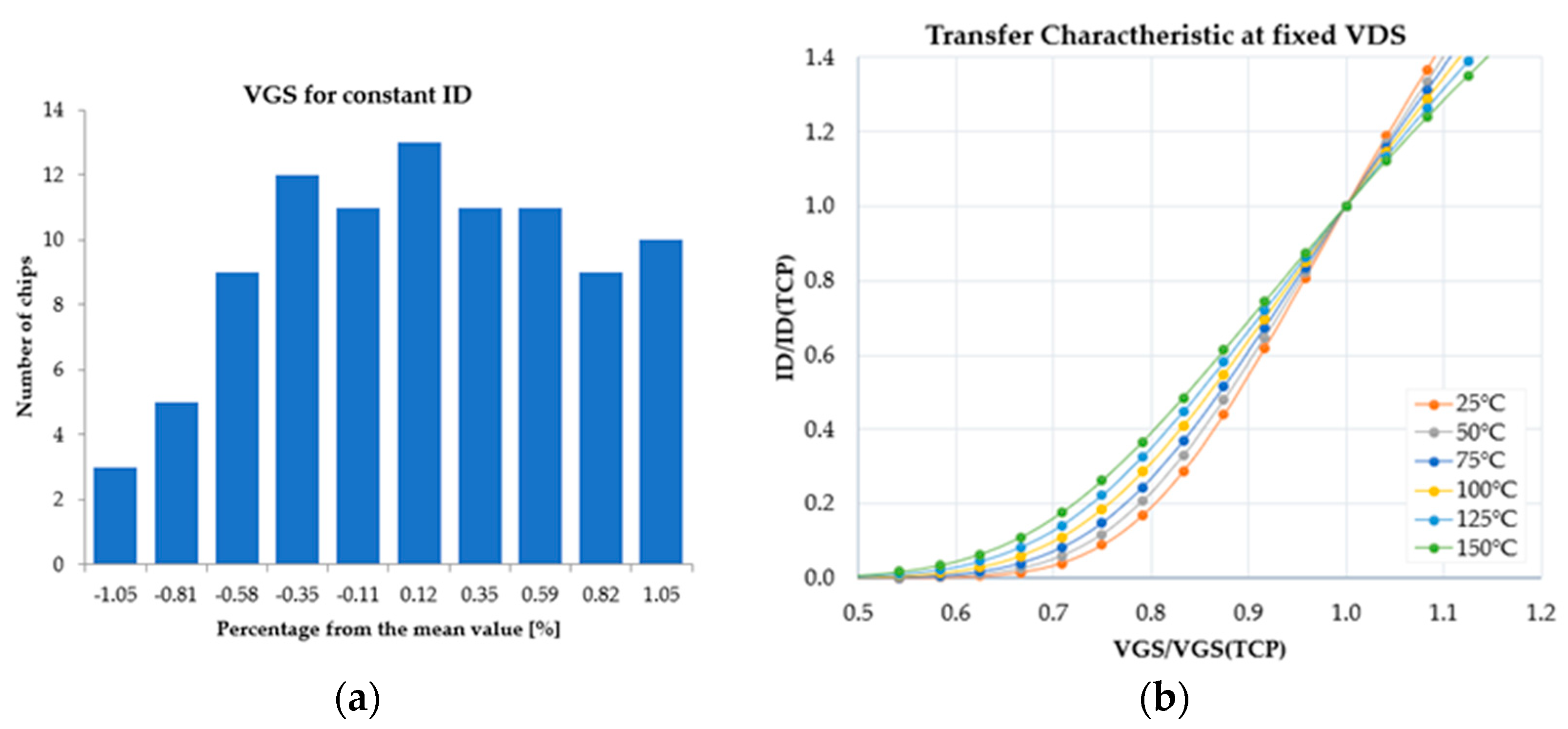

2.2. The Temperature Sensor

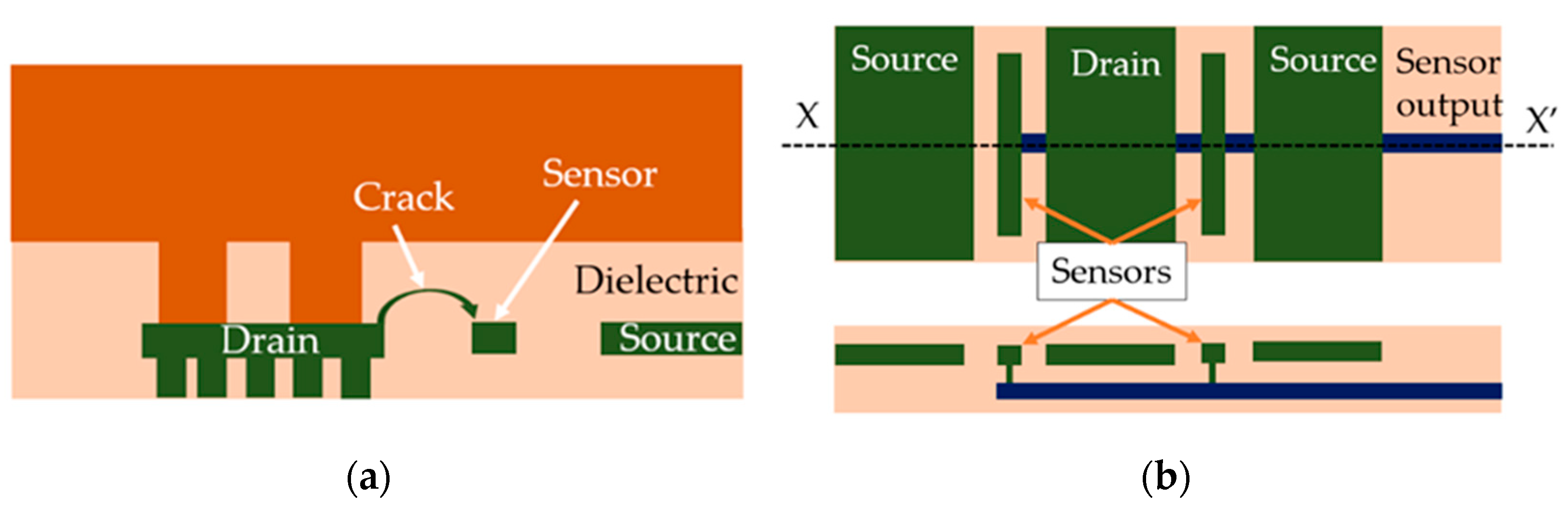

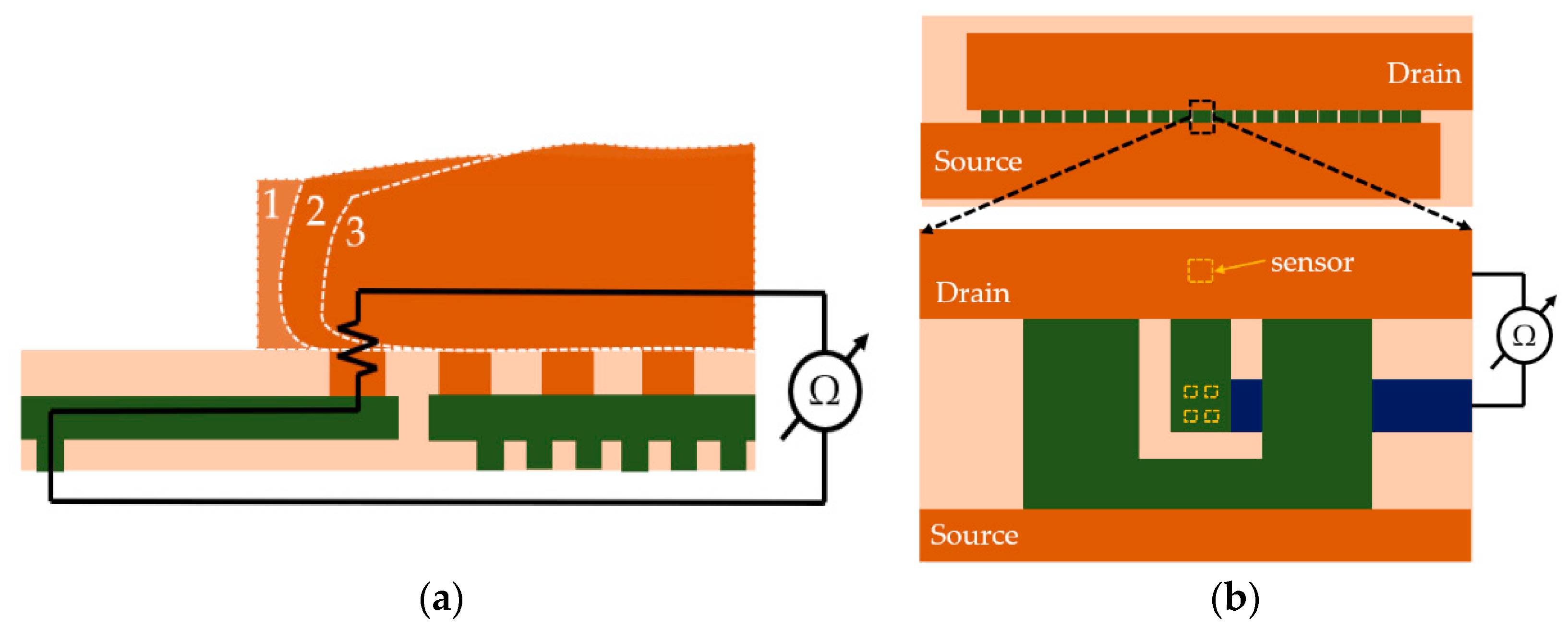

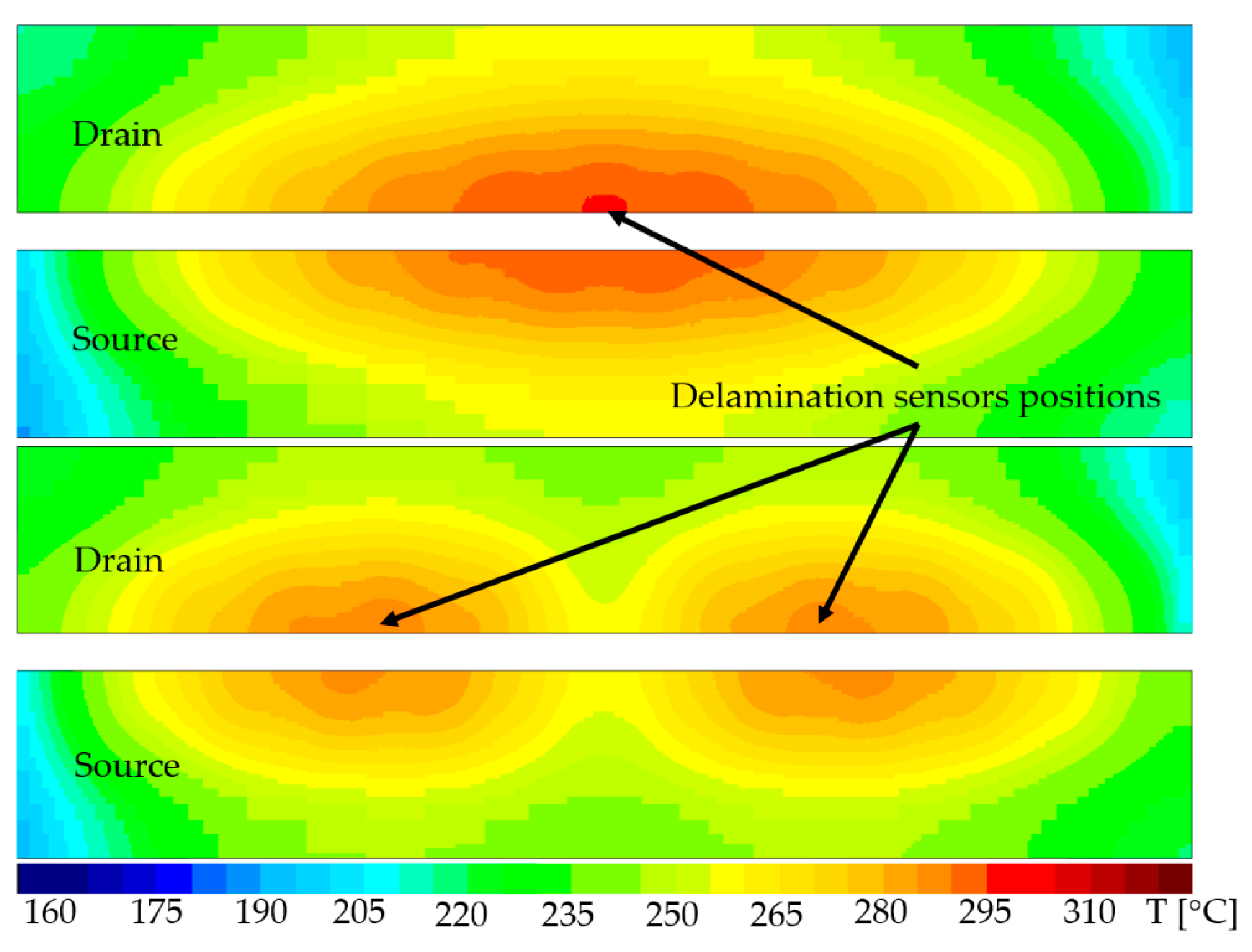

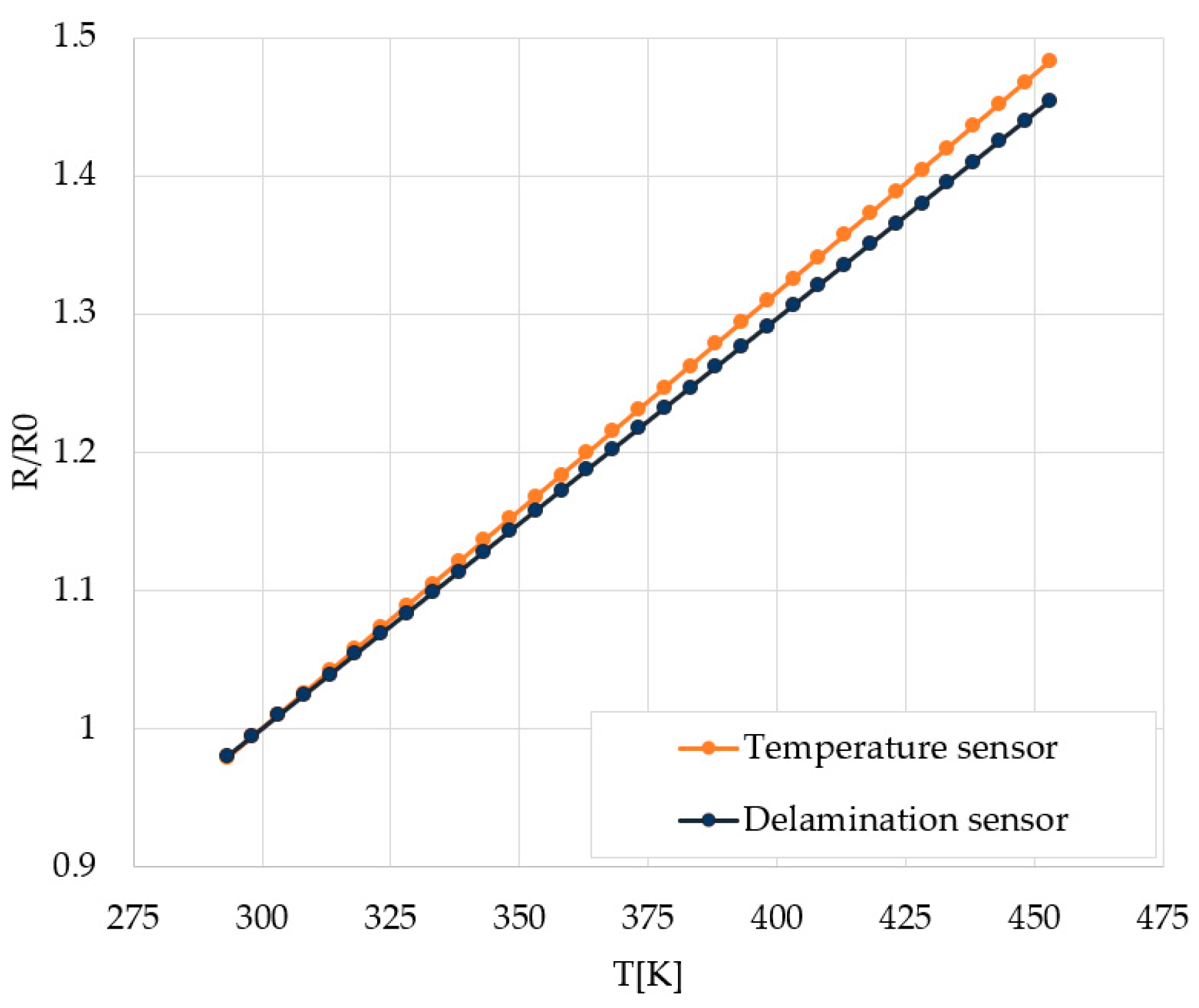

2.3. The Mechanical Sensors

2.4. Test Chip Overview

3. Testing Procedure

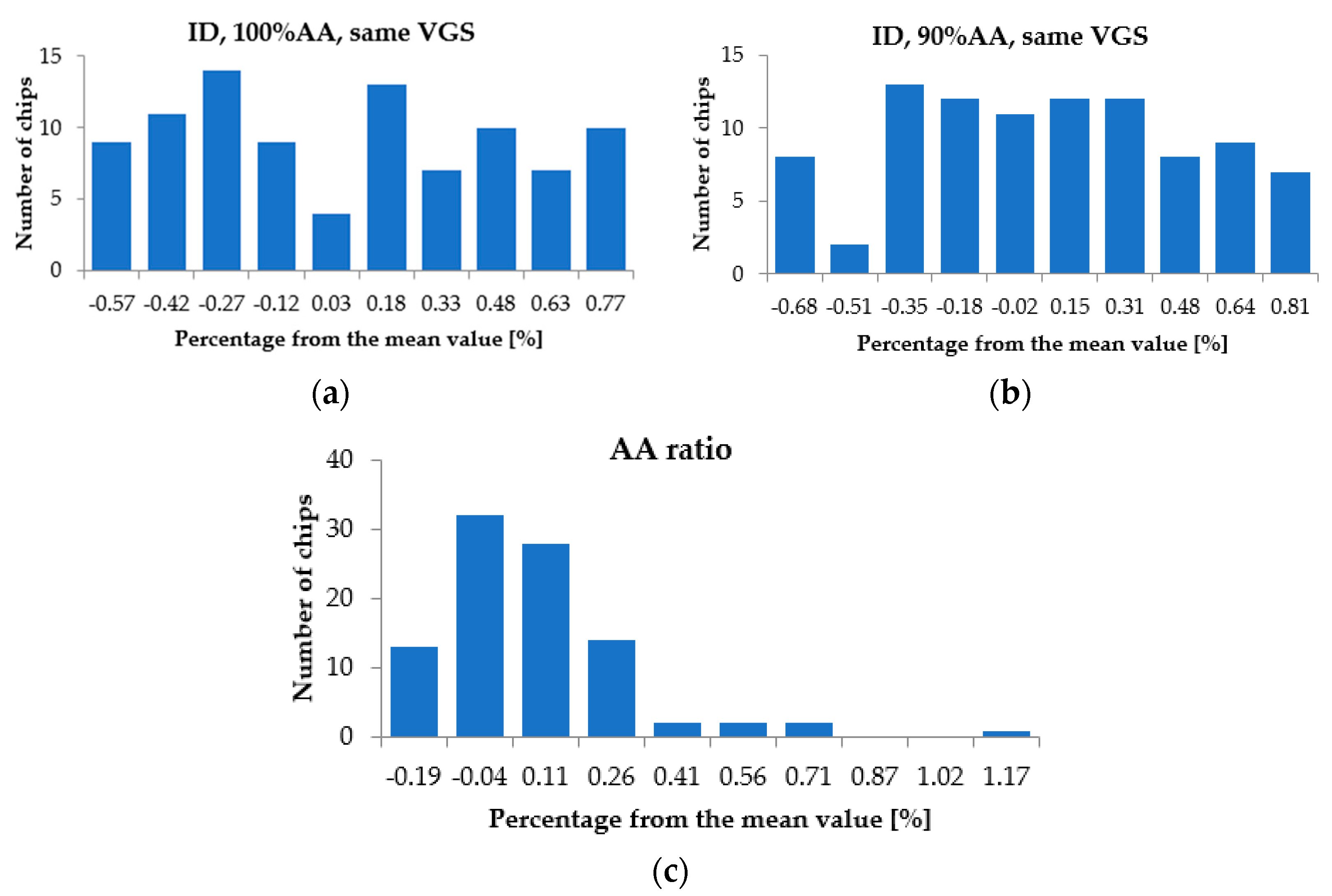

3.1. Preliminary Measurements

3.2. The Power Cycling Procedure

4. Experimental Results

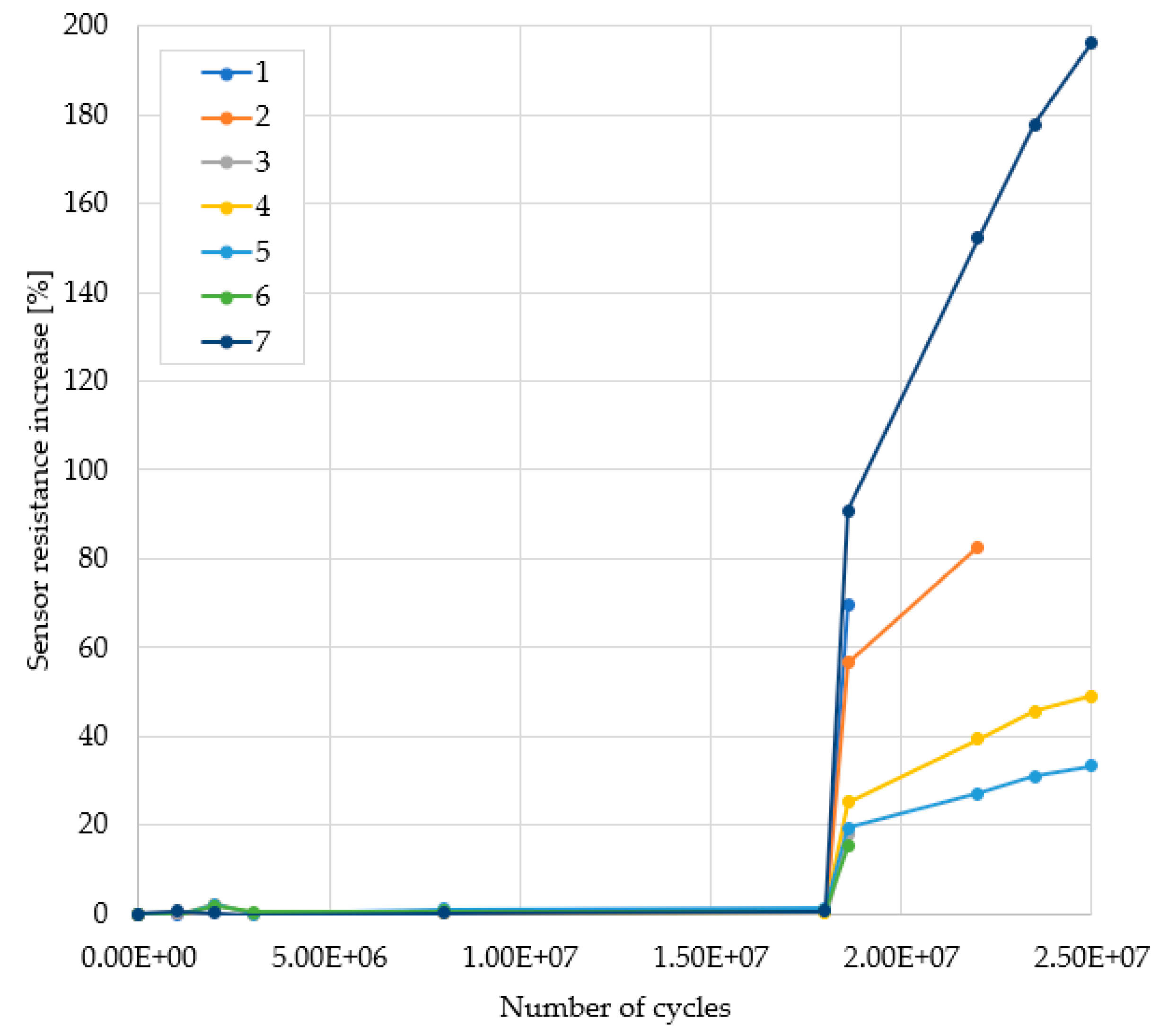

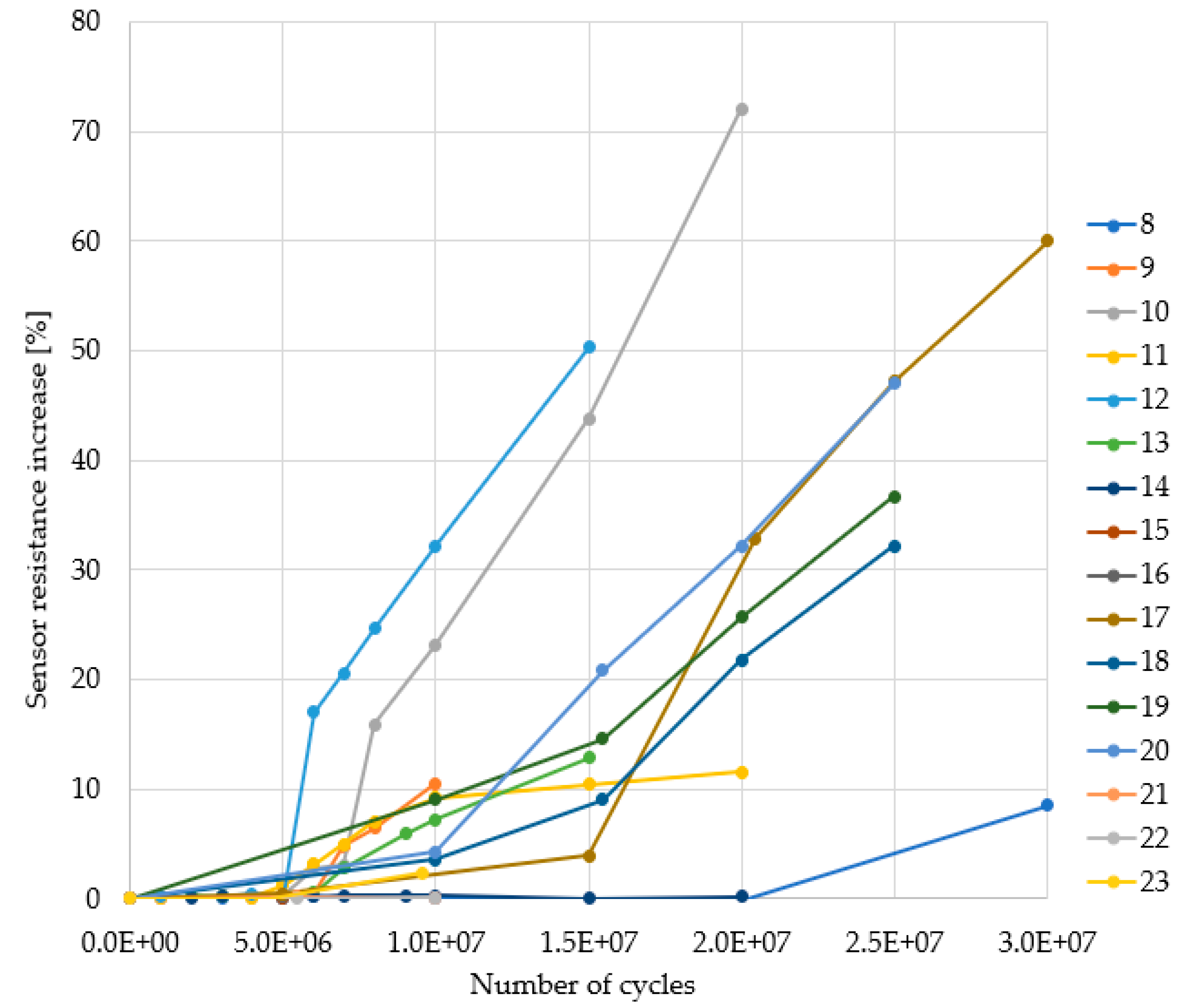

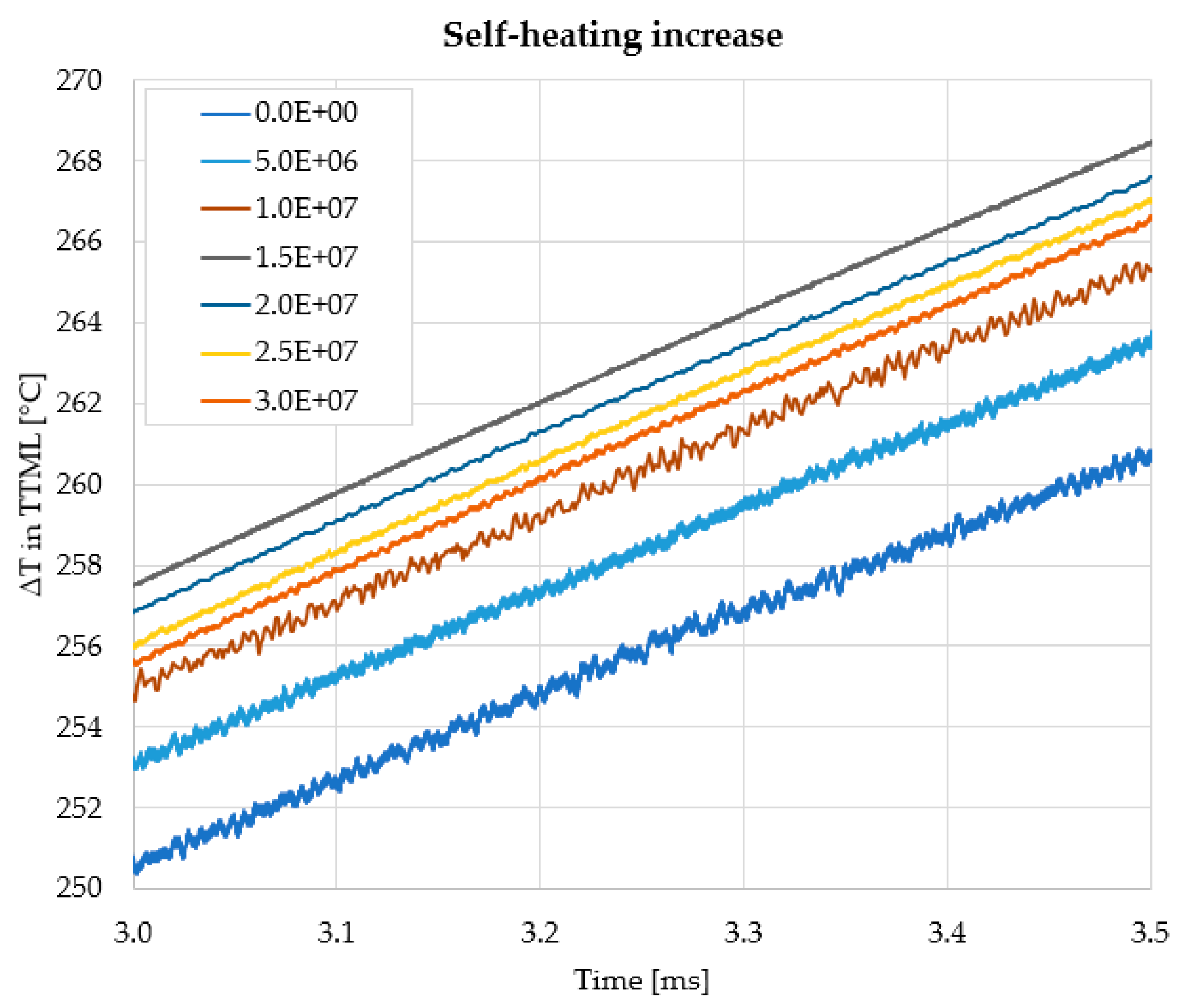

4.1. Delamination Sensor Resistance Variation and Self-Heating Increase

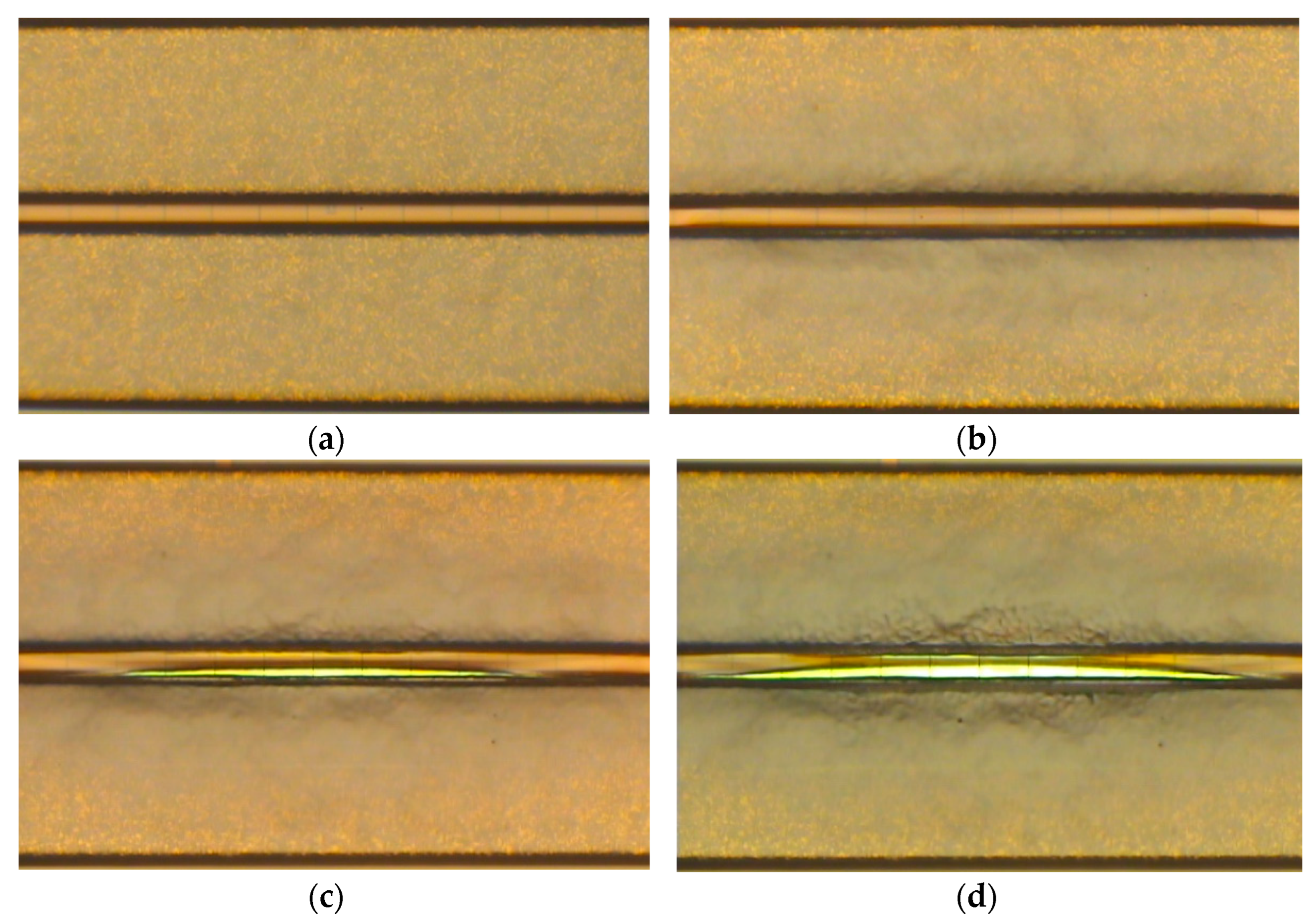

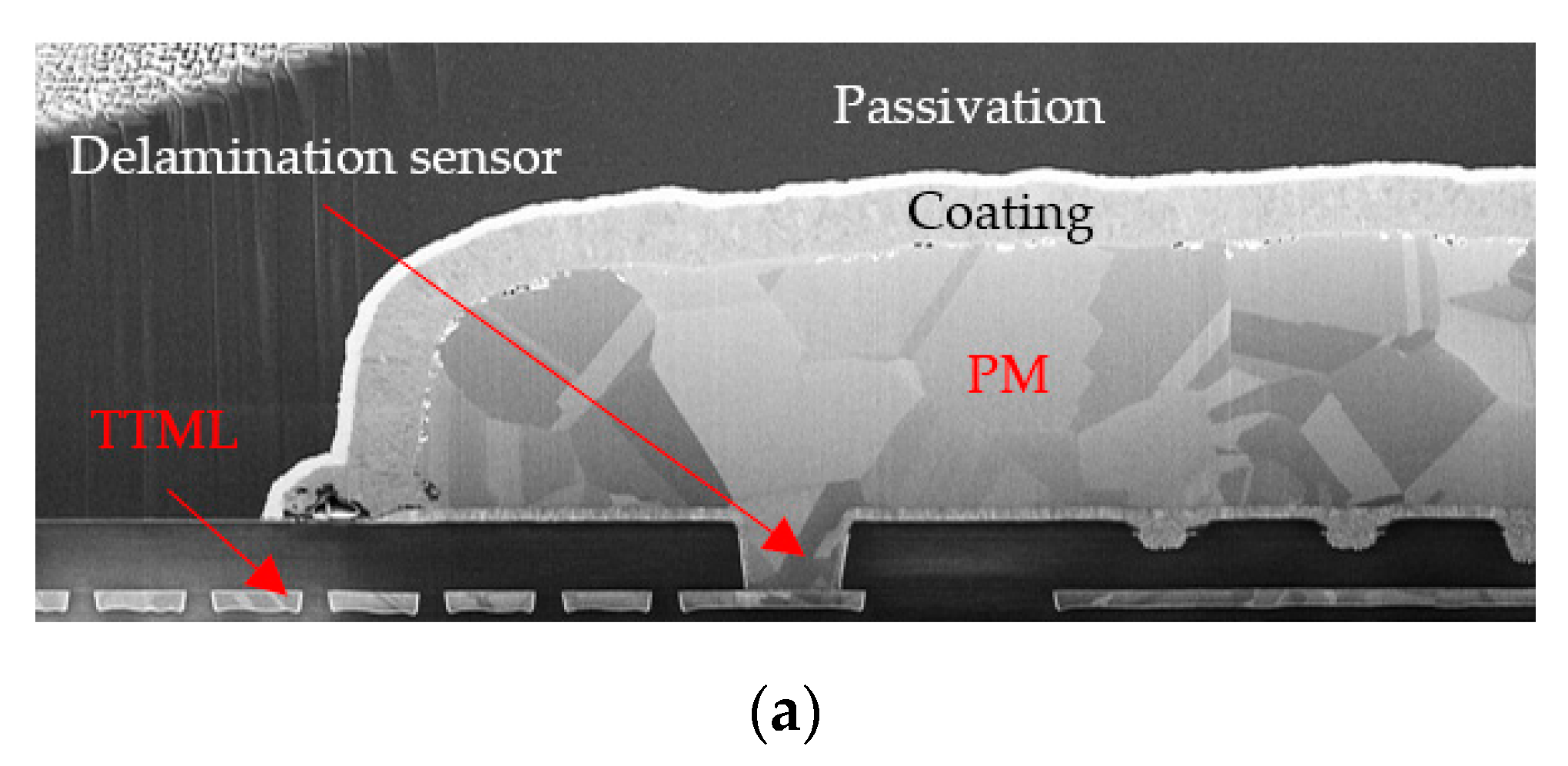

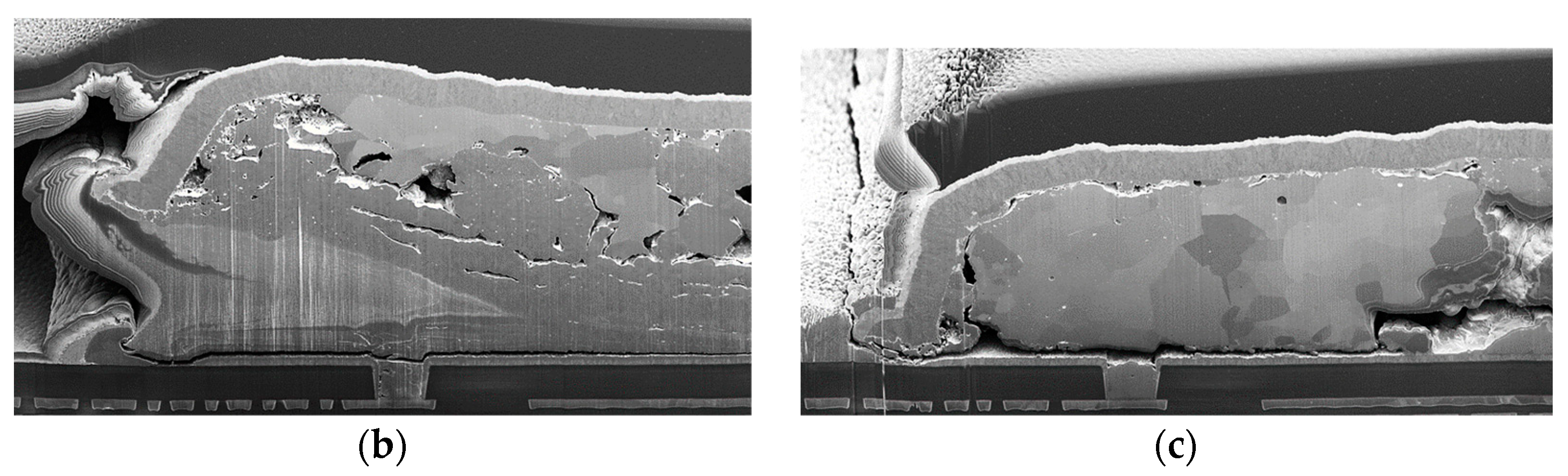

4.2. Failure Analysis Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Contiero, C.; Andreini, A.; Galbiati, P. Roadmap Differentiation and Emerging Trends in BCD Technology. In Proceedings of the 32nd European Solid-State Device Research Conference, Firenze, Italy, 24–26 September 2002; pp. 275–282. [Google Scholar] [CrossRef]

- Rudolf, R.; Wagner, C.; O’Riain, L.; Gebhardt, K.-H.; Kuhn-Heinrich, B.; von Ehrenwall, B.; von Ehrenwall, A.; Strasser, M.; Stecher, M.; Glaser, U.; et al. Automotive 130 nm smart-power-technology including embedded flash functionality. In Proceedings of the 2011 IEEE 23rd Internation Symposium on Power Semiconductor Devices and ICs, San Diego, CA, USA, 23–26 May 2011; pp. 20–23. [Google Scholar] [CrossRef]

- Pfost, M.; Costachescu, D.; Mayerhofer, A.; Stecher, M.; Bychikhin, S.; Pogany, D.; Gornik, E. Accurate Temperature Measurements of DMOS Power Transistors up to Thermal Runaway by Small Embedded Sensors. IEEE Trans. Semicond. Manuf. 2012, 25, 294–302. [Google Scholar] [CrossRef]

- Boianceanu, C.; Simon, D.; Blanaru, R.; Costachescu, D.; Pfost, M. High temperature on-wafer measurement structure for DMOS characterization. In Proceedings of the 2011 IEEE ICMTS International Conference on Microelectronic Test Structures, Amsterdam, The Netherlands, 4–7 April 2011; pp. 170–175. [Google Scholar] [CrossRef]

- Consoli, A.; Gennaro, F.; Testa, A.; Consentino, G.; Frisina, F.; Letor, R.; Magri, A. Thermal instability of low voltage power-MOSFETs. IEEE Trans. Power Electron. 2000, 15, 575–581. [Google Scholar] [CrossRef]

- Breglio, G.; Frisina, F.; Magri, A.; Spirito, P. Electro-thermal instability in low voltage power MOS: Experimental characterization. In Proceedings of the 11th International Symposium on Power Semiconductor Devices and ICs. ISPSD’99 Proceedings (Cat. No.99CH36312), Toronto, ON, Canada, 26–28 May 1999; pp. 233–236. [Google Scholar] [CrossRef]

- Dibra, D.; Stecher, M.; Decker, S.; Lindemann, A.; Lutz, J.; Kadow, C. On the Origin of Thermal Runaway in a Trench Power MOSFET. IEEE Trans. Electron Devices 2011, 58, 3477–3484. [Google Scholar] [CrossRef]

- Smorodin, T.; Wilde, J.; Alpern, P.; Stecher, M. A Temperature-Gradient-Induced Failure Mechanism in Metallization Under Fast Thermal Cycling. IEEE Trans. Device Mater. Reliab. 2008, 8, 590–599. [Google Scholar] [CrossRef]

- Smorodin, T.; Wilde, J.; Alpern, P.; Stecher, M. Investigation and Improvement of Fast Temperature-Cycle Reliability for DMOS-Related Conductor Path Design. In Proceedings of the 2007 IEEE International Reliability Physics Symposium Proceedings, 45th Annual, Phoenix, AZ, USA, 15–19 April 2007; pp. 486–491. [Google Scholar] [CrossRef]

- Simon, D.; Boianceanu, C.; De Mey, G.; Topa, V.; Spitzer, A. Reliability Analysis for Power Devices which Undergo Fast Thermal Cycling. IEEE Trans. Device Mater. Reliab. 2016, 16, 336–344. [Google Scholar] [CrossRef]

- Martineau, D.; Levade, C.; Legros, M.; Dupuy, P.; Mazeaud, T. Universal mechanisms of Al metallization ageing in power MOSFET devices. Microelectron. Reliab. 2014, 54, 2432–2439. [Google Scholar] [CrossRef]

- Nelhiebel, M.; Illing, R.; Detzel, T.H.; Wöhlert, S.; Auer, B.; Lanzerstorfer, S.; Rogalli, M.; Robl, W.; Decker, S.; Fugger, J.; et al. Effective and reliable heat management for power devices exposed to cyclic short overload pulses. Microelectron. Reliab. 2013, 53, 1745–1749. [Google Scholar] [CrossRef]

- Pfost, M.; Boianceanu, C.; Lascau, I.; Simon, D.; Sosin, S. Influence of the On-Chip Metallization on Self-Heating in Integrated Power Technologies. IEEE Trans. Semicond. Manuf. 2014, 27, 169–177. [Google Scholar] [CrossRef]

- Sun, X.J.; Wang, C.C.; Zhang, J.; Liu, G.; Zhang, G.J.; Ding, X.D.; Zhang, G.P.; Sun, J. Thickness dependent fatigue life at microcrack nucleation for metal thin films on flexible substrates. J. Phys. D Appl. Phys. 2008, 41, 195404. [Google Scholar] [CrossRef]

- Durand, C.; Klingler, M.; Bigerelle, M.; Coutellier, D. Solder fatigue failures in a new designed power module under Power Cycling. Microelectron. Reliab. 2016, 66, 122–133. [Google Scholar] [CrossRef]

- Chowdhury, A.; Guenin, B.; Woo, C.; Kim, S.; Lee, S. The effect of die attach layer delamination on the thermal performance of plastic packages. In Proceedings of the 1998 48th Electronic Components and Technology Conference (Cat. No.98CH36206), Seattle, WA, USA, 25–28 May 1998. [Google Scholar] [CrossRef]

- Mercado, L.L.; Wieser, H.; Hauck, T. Mold delamination and die fracture analysis of mechatronic packages. In Proceedings of the 2001 51st Electronic Components and Technology Conference (Cat. No.01CH37220), Orlando, FL, USA, 29 May–1 June 2001; pp. 903–910. [Google Scholar] [CrossRef]

- Martineau, D.; Mazeaud, T.; Legros, M.; Dupuy, P.; Levade, C.; Vanderschaeve, G. Characterization of ageing failures on power MOSFET devices by electron and ion microscopies. Microelectron. Reliab. 2009, 49, 1330–1333. [Google Scholar] [CrossRef]

- Huang, M.; Suo, Z.; Ma, Q. Plastic ratcheting induced cracks in thin film structures. J. Mech. Phys. Solids 2002, 50, 1079–1098. [Google Scholar] [CrossRef]

- Bigl, S.; Wurster, S.; Cordill, M.J.; Kiener, D. Advanced Characterization of thermo-mechanical fatigue mechanisms of different copper film systems for wafer metallizations. Thin Solid Films 2016, 612, 153–164. [Google Scholar] [CrossRef]

- Lei, W.-S.; Kumar, A. Delamination and reliability issues in packaged devices. In Adhesion in Microelectronics, 1st ed.; Mittal, K.L., Ahsan, T., Eds.; Wiley: Hoboken, NJ, USA, 2014; pp. 267–312. [Google Scholar] [CrossRef]

- Pfost, M.; Lachner, R.; Li, H. Simulation of self-heating in advanced high-speed SiGe bipolar circuits using the temperature simulator TESI. In Proceedings of the Digest of Papers, 2004 Topical Meeting on Silicon Monolithic Integrated Circuits in RF Systems, Atlanta, GA, USA, 8–10 September 2004; pp. 95–98. [Google Scholar] [CrossRef]

- Pfost, M.; Boianceanu, C.; Lohmeyer, H.; Stecher, M. Electrothermal Simulation of Self-Heating in DMOS Transistors up to Thermal Runaway. IEEE Trans. Electron Devices 2013, 60, 699–707. [Google Scholar] [CrossRef]

- Florea, C.; Topa, V.; Simon, D. Electro-Thermal Simulation of Power DMOS Devices Operating under Fast Thermal Cycling. In Proceedings of the 2020 IEEE 26th International Symposium for Design and Technology in Electronic Packaging (SIITME), Pitesti, Romania, 21–24 October 2020; pp. 368–371. [Google Scholar] [CrossRef]

- Ritter, M.; Pfost, M. A proposal for early warning indicators to detect impending metallization failure of DMOS transistors in cyclic operation. In Proceedings of the 2015 International Conference on Microelectronic Test Structures, Tempe, AZ, USA, 23–26 March 2015; pp. 18–22. [Google Scholar] [CrossRef]

- Ritter, M.; Pham, G.; Pfost, M. On-Chip Sensors to Detect Impending Metallization Failure of LDMOS Transistors Under Repetitive Thermo-Mechanical Stress. IEEE Trans. Semicond. Manuf. 2016, 29, 193–200. [Google Scholar] [CrossRef]

- Bojita, A.; Purcar, M.; Simon, D.; Florea, C.; Boianceanu, C.; Topa, V. A Novel Multi-Scale Method for Thermo-Mechanical Simulation of Power Integrated Circuits. IEEE J. Electron Devices Soc. 2022, 10, 169–179. [Google Scholar] [CrossRef]

- Spitzer, A.; Kampen, C.; Kadow, C.; Infineon Technologies AG. Semiconductor Device with Metal Structure in an Outermost Wiring Layer and via. Germany Patent DE102014117512B4, 11 July 2019. Available online: https://patents.google.com/patent/DE102014117512A1/en (accessed on 1 April 2022).

| Test 1 | Test 2 | Test 3 | |

|---|---|---|---|

| Toven [°C] | 70 | 100 | 90 |

| Power [W] | 15 | 20 | 18 |

| Pulse length [ms] | 3.5 | 3.5 | 3.5 |

| Pulse period [ms] | 48 | 48 | 48 |

| Tsteady-state [°C] | 125 | 155 | 150 |

| Tsensor [°C] | 315 | 465 | 410 |

| Number of cycles | 18 × 106 | 5 × 105 | 6.5 × 106 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Florea, C.; Simon, D.; Bojiță, A.; Purcar, M.; Boianceanu, C.; Țopa, V. Test Structure Design for Defect Detection during Active Thermal Cycling. Sensors 2022, 22, 7223. https://doi.org/10.3390/s22197223

Florea C, Simon D, Bojiță A, Purcar M, Boianceanu C, Țopa V. Test Structure Design for Defect Detection during Active Thermal Cycling. Sensors. 2022; 22(19):7223. https://doi.org/10.3390/s22197223

Chicago/Turabian StyleFlorea, Ciprian, Dan Simon, Adrian Bojiță, Marius Purcar, Cristian Boianceanu, and Vasile Țopa. 2022. "Test Structure Design for Defect Detection during Active Thermal Cycling" Sensors 22, no. 19: 7223. https://doi.org/10.3390/s22197223

APA StyleFlorea, C., Simon, D., Bojiță, A., Purcar, M., Boianceanu, C., & Țopa, V. (2022). Test Structure Design for Defect Detection during Active Thermal Cycling. Sensors, 22(19), 7223. https://doi.org/10.3390/s22197223