Guidelines on Asset Management of Offshore Facilities for Monitoring, Sustainable Maintenance, and Safety Practices

Abstract

:1. Introduction

2. Asset Maintenance Management

2.1. Asset Management

2.2. Accident Reporting

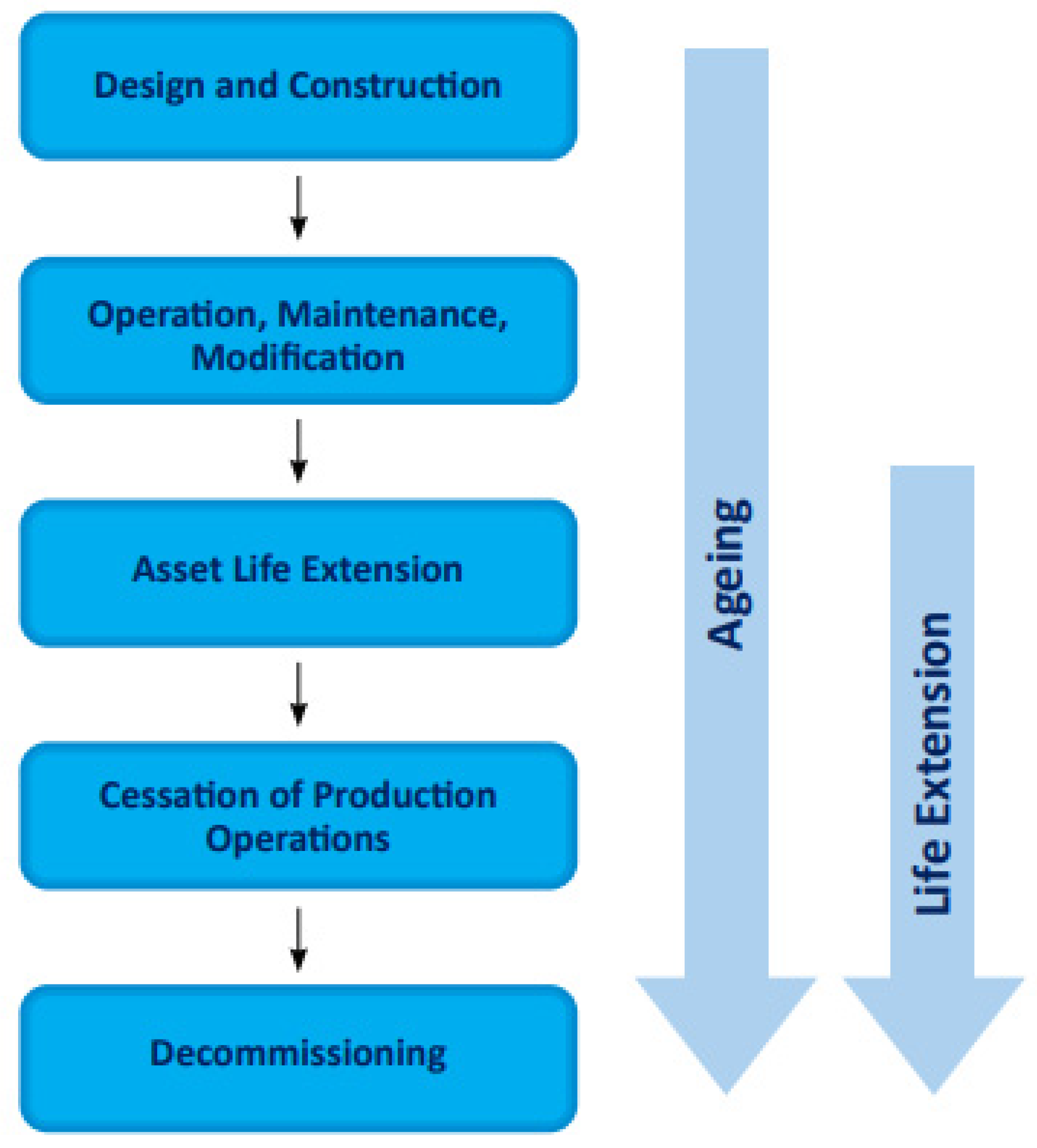

2.3. Asset Life Extension (ALE)

- A clear understanding of how the asset will be used during the extension period.

- There should be a well-defined route in preparing the economic analysis.

- Clarity on the asset’s fitness for service as it approaches design life, remnant life assessment, life extension requirement, and gap closure requirement.

- Life extension classification can be prepared based on the type of study. For instance, a typical life extension classification for an offshore wind farm is seen in Figure 5.

2.4. Risk Assessment

- Amassing of operational risk assessments (ORA), which are sometimes decoupled since they were considered separately rather than in tandem, possibly resulting in unforeseen elevated hazards.

- Risk evaluation of significant disaster risk

- Quantitative/qualitative risk analysis (QRA)

- Occupational safety, health, and working conditions

- External environments

- Response and emergency preparations.

2.5. Gap Assessment

- Identifying risks and key barriers.

- Inspect the integrity and operation of the barriers.

- Evaluate the barrier’s present performance in terms of intent.

- Examine the performance of obstacles in the past.

- Examine the present condition of maintenance and identify any gaps.

2.6. Emergency Response System

2.7. Aging Management/Obsolescence

2.8. Asset Integrity Management

2.9. Techno-Economic Report

- For three (3) alternative crude oil price options, there will be no further production enhancement action.

- There will be the shortest extension period for various crude oil price choices.

- For various crude oil price possibilities, the longest extension period is calculated based on the longest remnant life of a discipline.

- There are three additional scenarios for extending the period between the shortest and longest periods for various crude oil price alternatives.

- Capital expenditure (CAPEX) and operational expenditure (OPEX) sensitivity analysis for a variety of scenarios.

2.10. Safe Practices on Asset Management

3. Sustainable Elements of Asset Management

3.1. Human Factors

3.2. Organizational Factors

3.3. The Learning Organization

3.4. Personal and Occupational Health

3.5. Health, Safety, and Environment (HSE) Management System

3.6. Process Safety

3.7. Operational Factors

- Introducing new (or foreign) materials into production systems (such as marine riser fluids, pigging fluids, off-spec water injection, chemical tracers, downhole sand consolidation, and chemicals for enhanced oil recovery (EOR), etc.).

- Modifications to engineering standards and design codes.

- Degraded construction materials due to mechanisms that are related to corrosion.

- Mechanisms of cracks, fatigue, wear, or erosion.

- Mechanisms of ‘slow burning’ deterioration or degradation.

- Equipment obsolescence leading to a probable shortage of spares, excessive replacement costs, etc.

- Failure to record the accurate state of safety critical elements (SCE) throughout time.

- Inadequate data trends to estimate future hazards to safety and business continuity.

- Inadequate data trends for forecasting the probability of risks, reliability, and other failure assessments of the offshore structure or asset.

- Failure to normalize deviance that is related to human factors (accepting degraded conditions as the ‘new normal’).

- Lack of technical expertise in the industry, which is a combination of experience, training, qualifications, and competence.

3.8. Assurance and Verification

3.9. Audits and Monitoring

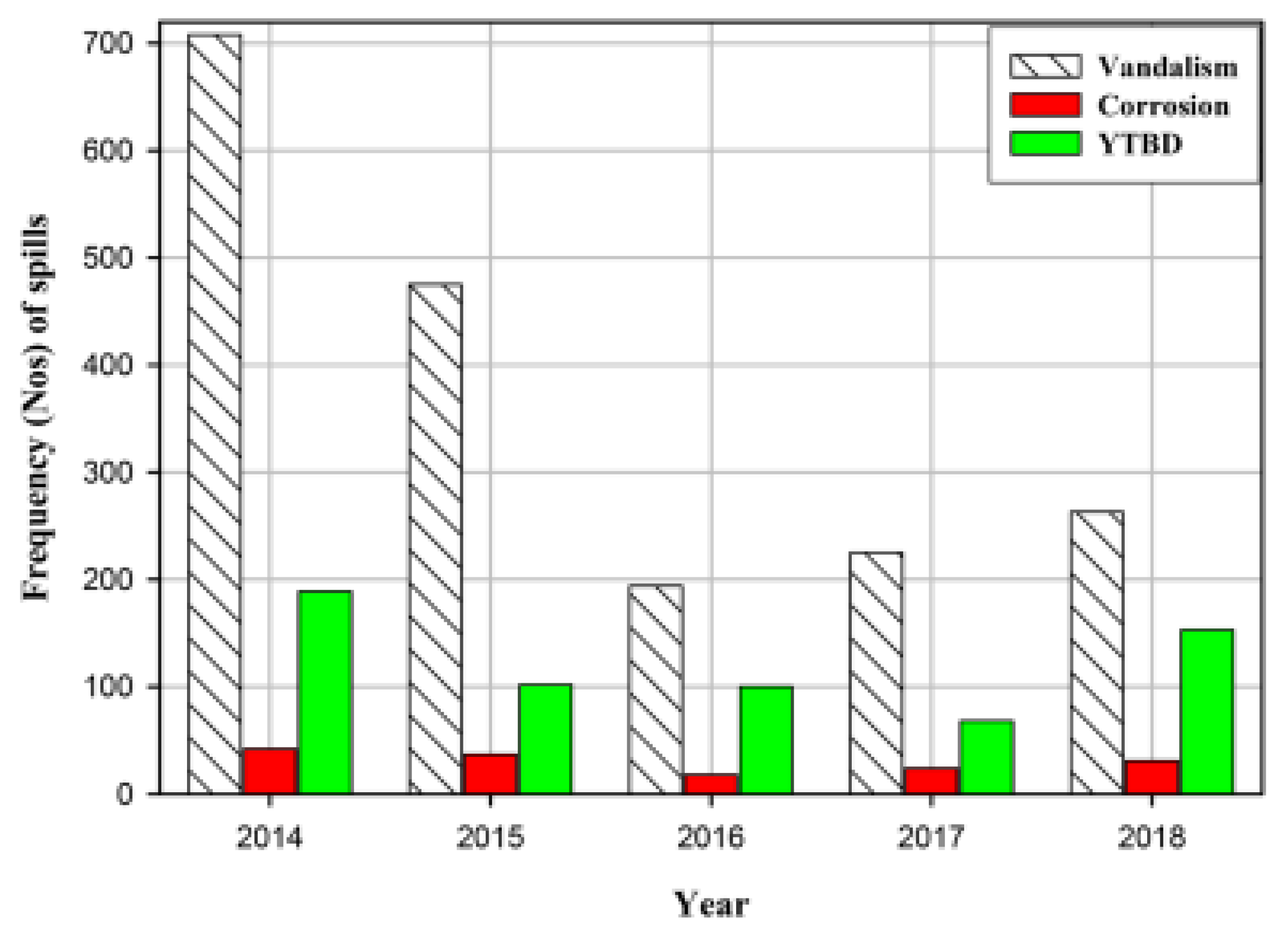

3.10. Asset Integrity Management on Pipelines

4. Proposed Guidelines and Policy Implications

5. Sustainable Maintenance and Reliability-Centered Maintenance

6. Dynamic Positioning Using Sensors on Offshore Facilities

7. Fault Monitoring Using Sensors on Offshore Facilities

8. Patents on Sensors for Monitoring Offshore Facilities

9. Standards on Asset Management and Sensors for Monitoring Offshore Facilities

10. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Gallun, R.A.; Wright, C.J.; Nichols, L.M.; Stevenson, J.W. Fundamentals of Oil and Gas Accounting, 4th ed.; PennWell Books: Tulsa, OK, USA, 2001. [Google Scholar]

- Bull, A.S.; Love, M.S. Worldwide oil and gas platform decommissioning: A review of practices and reefing options. Ocean Coast. Manag. 2019, 168, 274–306. [Google Scholar] [CrossRef]

- Kaiser, M.J. A Review of Exploration, Development, and Production Cost Offshore Newfoundland. Nat. Resour. Res. 2021, 30, 1253–1290. [Google Scholar] [CrossRef]

- Kaiser, M.J.; de Klerk, A.; Gary, J.E.; Handwerk, G.E. Petroleum Refining: Technology, Economics, Markets, 6th ed.; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Kaiser, M.J.; Snyder, B. Capital investment and operational decision making in the offshore contract drilling industry. Eng. Econ. 2013, 58, 35–58. [Google Scholar] [CrossRef]

- Kaiser, M.J.; Pulsipher, A.G. Generalized Functional Models for Drilling Cost Estimation. SPE J. Drill. Complet. 2007, 22, 67–73. [Google Scholar] [CrossRef]

- Kaiser, M.J.; Narra, S. An empirical evaluation of economic limits in the deepwater U.S. Gulf of Mexico. J. Nat. Gas Sci. Eng. 2019, 63, 1–14. [Google Scholar]

- D’Souza, R.B.; Shiladitya, B. Field Development Planning and Floating Platform Concept Selection for Global Deepwater Developments. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2011. [Google Scholar] [CrossRef]

- ISO-55000; Asset Management—Overview, Principles and Terminology. 2014, International-Organization-for-Standardization. Technical Committee: ISO/TC 251 Asset Management. International Organization for Standardization (ISO): Geneva, Switzerland, 2014; p. 19.

- El-Reedy, M. Asset Integrity Management for Offshore and Onshore Structures; Elsevier Publishers: London, UK, 2022. [Google Scholar]

- Diop, I.; Abdul-Nour, G.; Komljenovic, D. Overview of Strategic Approach to Asset Management and Decision-Making. Int. J. Eng. Res. Technol. (IJERT) 2021, 10, 64–89. Available online: https://www.ijert.org/research/overview-of-strategic-approach-to-asset-management-and-decision-making-IJERTV10IS120059.pdf (accessed on 16 July 2022). [CrossRef]

- Munn, K.; Goh, S.; Basson, M.; Thorpe, D. Asset management competency requirements in Australian local government: A systematic literature review. Australas. J. Eng. Educ. 2021, 26, 167–200. [Google Scholar] [CrossRef]

- Amadi-Echendu, J.; Willett, R.; Brown, K.; Hope, T.; Lee, J.; Mathew, J.; Vyas, N.; Yang, B.S. What Is Engineering Asset Management? In Definitions, Concepts and Scope of Engineering Asset Management. Engineering Asset Management Review; Amadi-Echendu, J., Brown, K., Willett, R., Mathew, J., Eds.; Springer: London, UK, 2010; Volume 1. [Google Scholar]

- Mardiasmo, D.; Tywoniak, S.; Brown, K.; Burgess, K. Asset Management and Governance—An Analysis of Fleet Management Process Issues in an Asset-Intensive Organization. In Proceedings of the 1st International Conference on Infrastructure Systems and Services: Building Networks for a Brighter Future (INFRA 2008), Rotterdam, The Netherlands, 10–12 November 2008; Available online: https://espace.curtin.edu.au/bitstream/handle/20.500.11937/11698/203713_203713.pdf?sequence=2&isAllowed=y (accessed on 16 July 2022).

- Lohr, C.; Pena, M. Stones Development: A Pioneering Management Philosophy for Enhancing Project Performance and Safety. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 2017. [Google Scholar] [CrossRef]

- Lohr, C.; Penney, I. Stones Development: World Class Safety Performance in Singapore. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 2017. [Google Scholar] [CrossRef]

- Shahruddin, T.S.; Jenkins, R.W.; McFadyen, M.K.; Dechant, S.; Weber, J.D. Kikeh Development: Project Overview. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 2008. [Google Scholar] [CrossRef]

- U.S. Coast Guard. Collapse and Sinking of Mobile Offshore Drilling Unit Ranger I in the Gulf of Mexico on 10 May 1979 with Loss of Life: Marine Casualty Report; Accession Number: ADA101641; U.S. Coast Guard: Washington, DC, USA, 1981; Available online: https://apps.dtic.mil/sti/pdfs/ADA101641.pdf (accessed on 24 June 2022).

- Whelan, S. Petrobras P-36 Accident Rio de Janeiro, Brazil. J. Undergrad. Eng. Res. Scholarsh. 2013, 1, 1–7. Available online: https://journals.library.mun.ca/ojs/index.php/prototype/article/view/499/554 (accessed on 24 June 2022).

- NAP. Macondo Well-Deepwater Horizon Blowout: Lessons for Improving Offshore Drilling Safety; National Academy of Engineering and National Research Council; The National Academies Press (NAP): Washington, DC, USA, 2012; Available online: https://nap.nationalacademies.org/catalog/13273/macondo-well-deepwater-horizon-blowout-lessons-for-improving-offshore-drilling (accessed on 24 June 2022).

- USGov. Deep Water: The Gulf Oil Disaster and the Future of Offshore Drilling (Report to the President); National Commission on the BP Deepwater Horizon Oil Spill and Offshore Drilling; US Government: Washington, DC, USA, 2011. Available online: https://digital.library.unt.edu/ark:/67531/metadc123527/m2/1/high_res_d/DEEPWATER_ReporttothePresident_FINAL.pdf (accessed on 24 June 2022).

- Cullen, W.D. The Public Inquiry into the Piper Alpha Disaster: Volume 1; Department of Energy and H.M.S.O.: London, UK, 1990. Available online: https://www.hse.gov.uk/offshore/piper-alpha-public-inquiry-volume1.pdf (accessed on 24 June 2022).

- Cullen, W.D. The Public Inquiry into the Piper Alpha Disaster: Volume 2; Department of Energy and H.M.S.O.: London, UK, 1990. Available online: https://www.hse.gov.uk/offshore/piper-alpha-public-inquiry-volume2.pdf (accessed on 24 June 2022).

- ConocoPhillips. Emergency Preparedness; ConocoPhillips: Tananger, Norway, 2022; Available online: https://www.conocophillips.com/operations/safety-health-security/commitment-to-safety/emergency-preparedness/ (accessed on 16 July 2022).

- ConocoPhillips. Health, Safety and Environment; ConocoPhillips: Tananger, Norway, 2022; Available online: https://www.conocophillips.no/social-responsibility/health-safety-and-environment/ (accessed on 16 July 2022).

- ConocoPhillips. HSE Management System; ConocoPhillips: Tananger, Norway, 2022; Available online: https://www.conocophillips.com/operations/safety-health-security/commitment-to-safety/hse-management-system/ (accessed on 16 July 2022).

- ConocoPhillips. A Learning Organization; ConocoPhillips: Tananger, Norway, 2022; Available online: https://www.conocophillips.com/operations/safety-health-security/commitment-to-safety/learning-organization/ (accessed on 16 July 2022).

- ConocoPhillips. Process Safety; ConocoPhillips: Tananger, Norway, 2022; Available online: https://www.conocophillips.com/operations/safety-health-security/commitment-to-safety/process-safety/ (accessed on 16 July 2022).

- Templeton, G.; Konings, S.; Wilkie, C.; Benton, P.; Marcas, G.; McInally, A.; Rob, I. Gryphon Field Development—Past, Present and Future. In Proceedings of the SPE Offshore Europe Oil and Gas Conference and Exhibition, Aberdeen, UK, 8–11 September 2009. [Google Scholar] [CrossRef]

- Ologun, E.U.; Wong, K.Y.; Chung Ee, J.Y.; Mammedov, Y.D. Incorporating Sustainability and Maintenance for Performance Assessment of Offshore Oil and Gas Platforms: A Perspective. Sustainability 2022, 14, 807. [Google Scholar] [CrossRef]

- Garbie, I.H.; Al-Shaqsi, R. Building sustainable models and assessments into petroleum companies: Theory and application. Int. J. Ind. Syst. Eng. 2019, 33, 473–512. [Google Scholar] [CrossRef]

- Wan Mahmood, W.H.; Ab Rahman, M.N.; Deros, B.M.; Mazli, H. Maintenance management system for upstream operations in oil and gas industry: A case study. Int. J. Ind. Syst. Eng. 2011, 9, 317–329. [Google Scholar] [CrossRef]

- Moan, T. Reliability-based management of inspection, maintenance and repair of offshore structures. Struct. Infrastruct. Eng. 2005, 1, 33–62. [Google Scholar] [CrossRef]

- Moan, T. Life cycle structural integrity management of offshore structures. Struct. Infrastruct. Eng. 2018, 14, 911–927. [Google Scholar] [CrossRef]

- Moan, T. Integrity management of offshore structures and its implication on computation of structural action effects and resistance. IOP Conf. Ser. Mater. Sci. Eng. 2017, 276, 012033. [Google Scholar] [CrossRef]

- Parker, T.C.; Sofidiya, A. Erha and Erha North Development: Overview. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2007. [Google Scholar] [CrossRef]

- Rui, Z.; Li, C.; Peng, F.; Ling, K.; Chen, G.; Zhou, X.; Chang, H. Development of industry performance metrics for offshore oil and gas project. J. Nat. Gas. Sci. Eng. 2017, 39, 44–53. [Google Scholar] [CrossRef]

- Frangopol, D.M.; Liu, M. Maintenance and management of civil infrastructure based on condition, safety, optimization, and life-cycle cost. Struct. Infrastruct. Eng. 2007, 3, 29–41. [Google Scholar] [CrossRef]

- Boutrot, J.; Legregeois, N. Integrity Management Services for Floating Units from Design to Decommissioning. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2016. [Google Scholar] [CrossRef]

- Rocher, A.; Perrollet, C.; Muir, K. Asset Integrity Management—From General Requirements to Subsea Facilities: Total Block 17 Experience. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2011. [Google Scholar] [CrossRef]

- Corcoran, C.; Stroubakis, D. Asset Integrity Management—Raising the Bar on Safety. In Proceedings of the SNAME 23rd Offshore Symposium, Houston, TX, USA, 14 February 2018; Available online: https://onepetro.org/SNAMETOS/proceedings-abstract/TOS18/1-TOS18/D013S003R001/3880 (accessed on 16 July 2022).

- Adair, S.; Filmalter, E.; Mahlangu, F. Asset Integrity Management in the Digital Age. In Proceedings of the 19th World Petroleum Congress, Madrid, Spain, 29 June–3 July 2008; Available online: https://onepetro.org/WPCONGRESS/proceedings-abstract/WPC19/All-WPC19/WPC-19-1759/172823 (accessed on 16 July 2022).

- Botto, A.; Rees, J.; Hull, M. Holistic Approach to Subsea Integrity Management & Reliability and their Application to Greenfield and Brownfield Projects. In Proceedings of the Offshore Technology Conference, Rio de Janeiro, Brazil, 4–6 October 2011. [Google Scholar] [CrossRef]

- Biasotto, P.; Rouhan, A. Feedback from Experience on Structural Integrity of Floating Offshore Installations. In Proceedings of the Offshore Technology Conference, Rio de Janeiro, Brazil, 4–6 October 2011. [Google Scholar] [CrossRef]

- Noli, G.; Fuggini, C.; Donisi, D.; Rossi, A.; Berardis, S. Offshore Facilities Integrity Monitoring and Management. In Proceedings of the Offshore Mediterranean Conference and Exhibition, Ravenna, Italy, 25–27 March 2015. [Google Scholar]

- Newman, M.S.J.; Reeder, M.L.; Woodruff, A.H.W.; Hatton, I.R. The geology of the Gryphon Oil Field. Geol. Soc. Lond. Pet. Geol. Conf. Ser. 1993, 4, 123–133. [Google Scholar] [CrossRef]

- Hashemi, S.J.; Javadpour, S.; Bajestani, M.N.; Zahiri, M.R. Development and Application of Pressure Systems Integrity Management through Risk Based Inspection Audits in Abadan Refinery. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 3–6 November 2008. [Google Scholar] [CrossRef]

- Hart, N.J.; Ageneau, G.; Hardie, J. Development of the Gryphon Field Massive Injection Wing—Technical Challenges and Risks. In Proceedings of the SPE Offshore Europe Oil and Gas Conference and Exhibition, Aberdeen, Scotland, UK, 4–7 September 2007. [Google Scholar] [CrossRef]

- Vinnem, J.-E.; Røed, W. Offshore Risk Assessment, Volume 1: Principles, Modelling and Applications of QRA Studies; Springer Series in Reliability Engineering; Springer: London, UK, 2020. [Google Scholar] [CrossRef]

- Vinnem, J.-E. Offshore Risk Assessment, Volume 2: Principles, Modelling and Applications of QRA Studies; Springer Series in Reliability Engineering; Springer: London, UK, 2014. [Google Scholar] [CrossRef]

- Hassel, M.; Utne, I.B.; Vinnem, J.E. Allision risk analysis of offshore petroleum installations on the Norwegian Continental Shelf—An empirical study of vessel traffic patterns. WMU J. Marit. Affairs 2017, 16, 175–195. [Google Scholar] [CrossRef] [Green Version]

- Poulassichidis, T. Application of Risk Based Inspection to Offshore Facilities. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 4–7 October 2009. [Google Scholar] [CrossRef]

- Reynolds, J.T. Risk Based Inspection—Where Are We Today? In Proceedings of the CORROSION 2000. Orlando, FL, USA, 26–31 March 2000; Available online: https://onepetro.org/NACECORR/proceedings-abstract/CORR00/All-CORR00/NACE-00690/111761 (accessed on 16 July 2022).

- Areeniyom, P. The Use of Risk-Based Inspection for Aging Pipelines in Sirikit Oilfield. In Proceedings of the International Petroleum Technology Conference, Bangkok, Thailand, 15–17 November 2011. [Google Scholar] [CrossRef]

- Dewanto, K.; Christian, R.; Wibowo, R. Development and Implementation of Risk Based Inspection Methodology in Managing Inspection of Pressurized Production Facilities. In Proceedings of the SPE Asia Pacific Conference on Integrated Modelling for Asset Management, Kuala Lumpur, Malaysia, 29–30 March 2004. [Google Scholar] [CrossRef]

- Clement, D.L.; Soemarman, W.; Sulistiyono, M. Business Integration of Safety, Health and Environmental Management. In Proceedings of the SPE Health, Safety and Environment in Oil and Gas Exploration and Production Conference, New Orleans, LA, USA, 9–12 June 1996. [Google Scholar] [CrossRef]

- Lamki, A.M.N.; Binks, S.L.M. Application of HSE Management in a Multi-Cultural Environment. In Proceedings of the SPE Health, Safety and Environment in Oil and Gas Exploration and Production Conference, New Orleans, LA, USA, 9–12 June 1996. [Google Scholar] [CrossRef]

- Visser, J.P. Managing Safety in the Oil Industry—The Way Ahead. In Proceedings of the 14th World Petroleum Congress, Stavanger, Norway, 29 May–1 June 1994. [Google Scholar]

- Downey, I.L. E & P FORUM Health, Safety and Environmental Management System Guidelines. In Proceedings of the SPE Offshore Europe, Aberdeen, UK, 5–8 September 1995. [Google Scholar] [CrossRef]

- Al-Failakawi, A.H.; Bala, S.S.A. Business Partners’ Safety: Obligation or Opportunity? In Proceedings of the ASSE Professional Development Conference and Exposition. Orlando, FL, USA, 8–11 June 2014. [Google Scholar]

- Doherty, B.D.; Fragu, L.P. Sustainable HSE Performance: Successful Management Systems and Monitoring Tools in the Middle East LNG Industry. In Proceedings of the SPE International Conference on Health, Safety and Environment in Oil and Gas Exploration and Production, Rio de Janeiro, Brazil, 12–14 April 2010. [Google Scholar] [CrossRef]

- Walters, K.W.; Wallace, J. Moving Beyond Management System Descriptions to Achieve a Step Change in HSE Performance. In Proceedings of the SPE International Health, Safety & Environment Conference, Abu Dhabi, United Arab Emirates, 2–4 April 2006. [Google Scholar] [CrossRef]

- Doulabi, H.; Khamseh, A.; Torabi, T. A System Dynamics Approach to Designing Technological Innovation Management Model in Downstream Petrochemical Industries. J. Syst. Manag. 2020, 6, 113–148. [Google Scholar] [CrossRef]

- Vijayalakshmi, B.S. Development of Sustainable Production Indicators Using the Analytical Hierarchy Process for the Petrochemical Industry in Malaysia. Ph.D. Thesis, University of Malaya, Kuala Lumpur, Malaysia, 2016. Available online: http://studentsrepo.um.edu.my/6685/3/3uropa3.pdf (accessed on 16 July 2022).

- Samuel, V.B.; Agamuthu, P.; Hashim, M. Indicators for assessment of sustainable production: A case study of the petrochemical industry in Malaysia. Ecol. Indic. 2013, 24, 392–402. [Google Scholar] [CrossRef]

- Aryanasl, A.; Ghodousi, J.; Arjmandi, R.; Mansouri, N. Components of sustainability considerations in management of petrochemical industries. Environ. Monit. Assess. 2017, 189, 274. [Google Scholar] [CrossRef] [PubMed]

- Sari, E.; Shaharoun, A.M.; Ma’aram, A.; Mohd Yazid, A. Sustainable maintenance performance measures: A pilot survey in Malaysian automotive companies. In Proceedings of the Procedia CIRP, Sydney, Australia, 7–9 April 2015; Elsevier: Amsterdam, The Netherlands, 2015; Volume 26, pp. 443–448. [Google Scholar]

- Seidel, S.; Recker, J.C.; Pimmer, C.; vom Brocke, J. Enablers and barriers to the organizational adoption of sustainable business practices. In Proceedings of the 16th Americas Conference on Information Systems: Sustainable IT Collaboration around the Globe, Swissôtel Lima, Lima, Peru, 12–15 August 2010; pp. 12–15. [Google Scholar]

- Muchiri, P.; Pintelon, L.; Gelders, L.; Martin, H. Development of maintenance function performance measurement framework and indicators. Int. J. Prod. Econ. 2011, 131, 295–302. [Google Scholar] [CrossRef]

- Najafi, M. In Pipeline Infrastructure Renewal and Asset Management; McGraw Hill: New York, NY, USA, 2016.

- Frangopol, D.M. Life-cycle performance, management, and optimisation of structural systems under uncertainty: Accomplishments and challenges. Struct. Infrastruct. Eng. 2011, 7, 389–413. [Google Scholar] [CrossRef]

- Drożyner, P. The impact of the implementation of management system on the perception of role and tasks of maintenance services and effectiveness of their functioning. J. Qual. Maint. Eng. 2021, 27, 430–450. [Google Scholar] [CrossRef]

- Moldan, B.; Janoušková, S.; Hák, T. How to understand and measure environmental sustainability: Indicators and targets. Ecol. Indic. 2012, 17, 4–13. [Google Scholar] [CrossRef]

- Mascarenhas, A.; Coelho, P.; Subtil, E.; Ramos, T.B. The role of common local indicators in regional sustainability assessment. Ecol. Indic. 2010, 10, 646–656. [Google Scholar] [CrossRef]

- Fernandez-Sanchez, G.; Rodriquez-Lopez, F. A methodology to identify sustainability indicators in construction project management application to infrastructure projects in Spain. Ecol. Indic. 2010, 10, 1193–1201. [Google Scholar] [CrossRef]

- Almeida CM, V.B.; Agostinho, F.; Giannetti, B.F.; Huisingh, D. Integrating cleaner production into sustainability strategies: An introduction to this special volume. J. Clean. Prod. 2015, 96, 1–9. [Google Scholar] [CrossRef]

- Ling, F.Y.Y.; Low, S.P.; Wang, S.Q.; Lim, H.H. Key project management practices affecting Singaporean firms’ project performance in China. Int. J. Proj. Manag. 2009, 27, 59–71. [Google Scholar] [CrossRef]

- Luu, V.T.; Kim, S.-Y.; Huynh, T.-A. Improving project management performance of large contractors using benchmarking approach. Int. J. Proj. Manag. 2008, 26, 758–769. [Google Scholar] [CrossRef]

- Rui, Z.; Peng, F.; Ling, K.; Chang, H.; Chen, G.; Zhou, X. Investigation into the performance of oil and gas projects. J. Nat. Gas Sci. Eng. 2017, 38, 12–20. [Google Scholar] [CrossRef]

- Yun, S.; Choi, J.; de Oliveira, D.P.; Mulva, S.P. Development of performance metrics for phase-based capital project benchmarking. Int. J. Proj. Manag. 2016, 34, 389–402. [Google Scholar] [CrossRef]

- Chakrabarti, S.K. Handbook of Offshore Engineering, 1st ed.; Elsevier: Plainfield, IL, USA, 2005; Volume 1. [Google Scholar]

- El-Reedy, M. Offshore Structures: Design, Construction and Maintenance; Elsevier Publishers: London, UK, 2012. [Google Scholar] [CrossRef]

- Bai, Y.; Bai, Q. Subsea Engineering Handbook; Elsevier: Oxford, UK, 2010. [Google Scholar]

- Wilson, J. Dynamics of Offshore Structures, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2002. [Google Scholar]

- Chandrasekaran, S. Dynamic Analysis and Design of Offshore Structures, 2nd ed.; Springer: Singapore, 2018; ISBN 9789811060892. [Google Scholar] [CrossRef]

- Barltrop, N.D.P.; Adams, A.J. Dynamics of Fixed Marine Structures, 3rd ed.; Butterworth Heinemann: Oxford, UK, 1991. [Google Scholar]

- Offshore Technology. The Longest Standing Fixed Offshore Platforms; Verdict: New York, NY, USA, 2019; Available online: https://www.offshore-technology.com/analysis/the-longest-standing-fixed-offshore-platforms/ (accessed on 16 July 2022).

- Brebbia, C.A.; Walker, S. Dynamic Analysis of Offshore Structures, 1st ed.; Newnes-Butterworth & Co. Publishers Ltd.: London, UK, 1979. [Google Scholar]

- Leffler, W.L.; Pattarozzi, R.; Sterling, G. Deepwater Petroleum Exploration & Production: A Nontechnical Guide; PennWell: Tulsa, OK, USA, 2011; ISBN 9781593702533. [Google Scholar]

- Fang, H.; Duan, M. Offshore Operation Facilities; Elsevier Publishers: London, UK, 2014. [Google Scholar] [CrossRef]

- Aird, P. Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology Application; Gulf Professional Publishing: London, UK, 2019. [Google Scholar] [CrossRef]

- Samie, N.N. Practical Engineering Management of Offshore Oil and Gas Platforms; Gulf Professional Publishing: London, UK, 2016. [Google Scholar] [CrossRef]

- Clews, R.J. Project Finance for the International Petroleum Industry; Academic Press: Cambridge, MA, USA, 2016; ISBN 978-0-12-800158-5. [Google Scholar]

- Chandrasekaran, S.; Jain, A.K. Ocean Structures, Construction, Materials, and Operations; CRC Press: Boca Raton, FL, USA, 2016; ISBN 978-149-87-9742-9. [Google Scholar]

- Laik, S. Offshore Petroleum Drilling and Production, 1st ed.; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Speight, J.G. Handbook of Offshore Oil and Gas Operations; Gulf Professional Publishing: London, UK, 2011. [Google Scholar] [CrossRef]

- Primrose, M.J.; Bentley, P.D.; van der Graaf, G.C.; Sykes, R.M. The HSE Management System in Practice-lmplementation. In Proceedings of the SPE Health, Safety and Environment in Oil and Gas Exploration and Production Conference, New Orleans, LA, USA, 9–12 June 1996. [Google Scholar] [CrossRef]

- Madkour, A.A. Operating Company’s (HSE) Management System (Guidelines, Practices & Results). In Proceedings of the SPE International Conference on Health, Safety and Environment in Oil and Gas Exploration and Production, Stavanger, Norway, 26–28 June 2000. [Google Scholar] [CrossRef]

- Weldon, D.; Wallace, J. The What and How for HSE Management Systems. In Proceedings of the SPE International Health, Safety & Environment Conference, Abu Dhabi, United Arab Emirates, 2–4 April 2006. [Google Scholar] [CrossRef]

- Gibson, D.W. Enhanced Environmental Management for Land Based Seismic Acquisition using a Quality, Health, Safety and Environmental Management System. In Proceedings of the SPE International Conference on Health, Safety, and Environment in Oil and Gas Exploration and Production, Calgary, AB, Canada, 29–31 March 2004. [Google Scholar] [CrossRef]

- Onianwa, A.T.; Onwuzurike-azu, C.; Fowler, A.; Pagett, R.; Ogunnaike, B. Development and Implementation of HSE Management System (HSE-MS) in a Deepwater Company—Shell Nigeria Exploration & Production Company (SNEPCO) Experience. In Proceedings of the SPE International Conference on Health, Safety and Environment in Oil and Gas Exploration and Production, Kuala Lumpur, Malaysia, 20–22 March 2002. [Google Scholar] [CrossRef]

- Leuterman, A.J.J.; Candler, J.E.; Ceron, R.; Rabke, S. Improving Environmental and Occupational Health Performance through a HSE Management System—A Seven Year Case Study. In Proceedings of the SPE International Conference on Health, Safety, and Environment in Oil and Gas Exploration and Production, Nice, France, 15–17 April 2008. [Google Scholar] [CrossRef]

- Campbell, H.; Polo, J.; Guillaume, B. HSE Management System: Keep It Simple! In Proceedings of the International Conference on Health, Safety and Environment in Oil and Gas Exploration and Production. Perth, Australia, 11–13 September 2012. [Google Scholar] [CrossRef]

- Macini, P.; Mesini, E. History of petroleum and petroleum engineering. In Petroleum Engineering—Upstream; Encyclopedia of Life Support Systems (EOLSS) Publishers Co., Ltd.: Oxford, UK, 2018; Volume 4, Available online: http://www.eolss.net/sample-chapters/c08/e6-193-24.pdf (accessed on 16 July 2022).

- Kontorovich, A.E.; Eder, L.V.; Filimonova, V.; Mishenin, M.V.; Nemov, V.Y. Oil industry of major historical centre of the Volga-Ural petroleum province: Past, current state, and long-run prospects. Russ. Geol. Geophys. 2016, 57, 1653–1667. [Google Scholar] [CrossRef]

- Udosen, C.; Etok, A.S.; George, I.N. Fifty Years Of Oil Exploration In Nigeria: The Paradox Of Plenty. Glob. J. Soc. Sci. 2009, 8, 37–47. Available online: https://www.ajol.info/index.php/gjss/article/view/79416/69711 (accessed on 16 July 2022). [CrossRef]

- Krzywiec, P. The birth and development of the oil and gas industry in the Northern Carpathians (up until 1939). In History of the European Oil and Gas Industry; Craig, J., Gerali, F., MacAulay, F., Sorkhabi, R., Eds.; The Geological Society: London, UK, 2018; Volume 465, pp. 165–190. [Google Scholar] [CrossRef]

- Spencer, A.; Chew, K. Petroleum exploration history: Discovery pattern versus manpower, technology and the development of exploration principles. First Break 2009, 27, 35–41. [Google Scholar] [CrossRef]

- Li, J.-F.; Ye, J.-L.; Qin, X.-W.; Qiu, H.-J.; Wu, N.-Y.; Lu, H.-L.; Xie, W.-W.; Lu, J.-A.; Peng, F.; Xu, Z.-Q.; et al. The first offshore natural gas hydrate production test in South China Sea. China Geol. 2018, 1, 5–16. [Google Scholar] [CrossRef]

- Craig, J.; Gerali, F.; Macaulay, F.; Sorkhabi, R. The history of the European oil and gas industry (1600s–2000s). In History of the European Oil and Gas Industry; Craig, J., Gerali, F., Macaulay, F., Sorkhabi, R., Eds.; Geological Society: London, UK, 2018; Volume 465, pp. 1–24. [Google Scholar] [CrossRef]

- Craig, J. History of Oil: The Birth of the Modern Oil Industry (1859–1939). In Encyclopedia of Petroleum Geoscience; Sorkhabi, R., Ed.; Springer Nature: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Craig, J. Drilling: History of Onshore Drilling and Technology. In Encyclopedia of Petroleum Geoscience; Sorkhabi, R., Ed.; Springer Nature: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Craig, J. History of Oil: The Premodern Era (Thirteenth to Mid-Nineteenth Centuries). In Encyclopedia of Petroleum Geoscience; Sorkhabi, R., Ed.; Springer Nature: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Craig, J. Barrel. In Encyclopedia of Petroleum Geoscience; Sorkhabi, R., Ed.; Springer Nature: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Craig, J. History of Oil: Regions and Uses of Petroleum in the Classical and Medieval Periods. In Encyclopedia of Petroleum Geoscience; Sorkhabi, R., Ed.; Springer Nature: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Glennie, K.W. History of exploration in the southern North Sea. In Petroleum Geology of the Southern North Sea: Future Potential. Special Publications 123; Ziegler, K., Turner, P., Daines, S.R., Eds.; Geological Society: London, UK, 1997; pp. 5–16. [Google Scholar] [CrossRef]

- Kaiser, M.J. Offshore oil and gas records circa 2020. Ships Offshore Struct. 2020, 17, 205–241. [Google Scholar] [CrossRef]

- Kaiser, M.J. A review of deepwater pipeline construction in the U.S. Gulf of Mexico–Contracts, cost, and installation methods. J. Mar. Sci. Appl. 2016, 15, 288–306. [Google Scholar] [CrossRef]

- Haritos, N. Introduction to the analysis and design of offshore structures—An overview. Electron. J. Struct. Eng. (eJSE) 2007, 7, 55–65. Available online: https://ejsei.com/EJSE/article/download/65/64 (accessed on 12 February 2022). [CrossRef]

- Yu, L.C.; King, L.S.; Hoon, A.T.C.; Yean, P.C.C. A Review Study of Oil and Gas Facilities for Fixed and Floating Offshore Platforms. Res. J. Appl. Sci. Eng. Technol. 2015, 6, 672–679. [Google Scholar] [CrossRef]

- Amiri, N.; Shaterabadi, M.; Reza Kashyzadeh, K.; Chizari, M. A Comprehensive Review on Design, Monitoring, and Failure in Fixed Offshore Platforms. J. Mar. Sci. Eng. 2021, 9, 1349. [Google Scholar] [CrossRef]

- Al-Sharif, A.A. Design, fabrication and installation of fixed offshore platforms in the Arabian Gulf. In Proceedings of the Fourth Saudi Engineering Conference, Saudi Arabian Oil Company, Dhahran, Saudi Arabia, 5–8 November 1995; pp. 99–105. [Google Scholar]

- Ladeira, I.; Márquez, L.; Echeverry, S.; Le Sourne, H.; Rigo, P. Review of methods to assess the structural response of offshore wind turbines subjected to ship impacts. Ships Offshore Struct. 2022. ahead of print. [Google Scholar] [CrossRef]

- Saiful Islam, A.B.M.; Jameel, M.; Jumaat, M.Z.; Shirazi, S.; Salman, F.A. Review of offshore energy in Malaysia and floating Spar platform for sustainable exploration. Renew. Sustain. Energy Rev. 2012, 16, 6268–6284. [Google Scholar] [CrossRef]

- Al-Yafei, E.F. Sustainable Design for Offshore Oil and Gas Platforms: A Conceptual Framework for Topside Facilities Projects. Ph.D. Thesis, School of Energy, Geoscience, Infrastructure & Society, Heriot Watt University, Edinburgh, UK, 2018. Available online: https://www.ros.hw.ac.uk/bitstream/handle/10399/3513/Al-YafeiE_0418_egis.pdf?sequence=1&isAllowed=y (accessed on 12 February 2022).

- Kreidler, T.D. The Offshore Petroleum Industry: The Formative Years, 1945–1962. Ph.D. Thesis, History Department, Texas Tech University, Lubbock, TX, USA, 1997. Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.455.2343&rep=rep1&type=pdf (accessed on 12 February 2022).

- Cavendish, W. Arup Integrity Management: A Digital Approach for Safe and Effective Integrity Management; ARUP: Houston, TX, USA, 2021; Available online: https://www.arup.com/expertise/services/digital/arup-integrity-management (accessed on 24 June 2022).

- Sadeghi, K. Significant guidance for design and construction of marine and offshore structures. GAU J. Soc. Appl. Sci. 2008, 4, 67–92. Available online: https://www.researchgate.net/publication/250310894_Significant_Guidance_for_Design_and_Construction_of_Marine_and_Offshore_Structures (accessed on 16 July 2022).

- Sadeghi, K.; Dilek, H. An Introduction to the design of Offshore Structures. Acad. Res. Int. 2019, 10, 19–27. Available online: http://www.savap.org.pk/journals/ARInt./Vol.10(1)/ARInt.2019(10.1-03).pdf (accessed on 12 February 2022).

- Khan, R.; Mad, A.B.; Osman, K.; Aziz, M.A.A. Maintenance Management of Aging Oil and Gas Facilities. In Maintenance Management; Márquez, F.P.G., Papaelias, M., Eds.; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef]

- Gowda, S.S.; Hassinen, P. Development of Offshore Structures—An Overview. IABSE Congress Report {Rapport du Congrès AIPC = IVBH Kongressbericht}, 14(1992). 1992. Available online: https://www.e-periodica.ch/cntmng?pid=bse-cr-002%3A1992%3A14%3A%3A43 (accessed on 16 July 2022).

- Kosleck, S.; Clauss, G.F.; Lee, Y.J. Deepwater Solutions for Offshore Production Technology (Offshore-Förderplattformen: Entwicklungen für die Tiefsee). In Proceedings of the Annual General Conference of the German Society for Maritime Technology, Hamburg, Germany, 17–19 November 2004; Yearbook of the STG 2004. German Society for Maritime Technology: Hamburg, Germany, 2004. Available online: https://www.researchgate.net/publication/283297430_Deepwater_Solutions_for_Offshore_Production_Technology_Offshore-Forderplattformen_Entwicklungen_fur_die_Tiefsee (accessed on 16 July 2022).

- Walker, S.; Tarantola, S. Guidelines for Inspections of Offshore Installations; European Union: Luxembourg, 2018; Available online: https://euoag.jrc.ec.europa.eu/files/attachments/guidelines_for_inspections_of_offshore_installations_online.pdf (accessed on 16 July 2022).

- Yew, W.K.; Ismail, S.; Sabri, H.A.R.; Rahim, A.R.A. Project Management of Oil and Gas Project in Malaysia. In Proceedings of the International Association for Asia Pacific Studies 5th Annual Conference, Incheon, Korea, 27–28 November 2014; Available online: https://www.researchgate.net/publication/333102792_Project_Management_of_Oil_and_Gas_Project_in_Malaysia (accessed on 16 July 2022).

- Ronalds, B.F. Applicability ranges for offshore oil and gas production facilities. Mar. Struct. 2005, 18, 251–263. [Google Scholar] [CrossRef]

- Reddy, D.; Swamidas, A. Essentials of Offshore Structures: Theory and Applications, 1st ed.; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Wang, C.M.; Utsunomiya, T.; Wee, S.C.; Choo, Y.S. Research on floating wind turbines: A literature survey. IES J. Part A Civ. Struct. Eng. 2010, 3, 267–277. [Google Scholar] [CrossRef]

- Mustapa, M.A.; Yaakob, O.B.; Ahmed, Y.M.; Rheem, C.-K.; Koh, K.K.; Adnan, F.A. Wave energy device and breakwater integration: A review. Renew. Sustain. Energy Rev. 2017, 77, 43–58. [Google Scholar] [CrossRef]

- Bai, Y.; Bai, Q. Subsea Engineering Handbook, 2nd ed.; Gulf Professional Publishing: London, UK, 2018. [Google Scholar] [CrossRef]

- Muyiwa, O.A.; Sadeghi, K. Construction planning of an offshore petroleum platform. GAU J. Soc. Appl. Sci. 2007, 2, 82–85. [Google Scholar]

- Holmes, T.; Connolly, S.; Wilday, J.; Hare, J.; Walsh, P. Managing fire and explosion hazards on offshore ageing installations. In Proceedings of the IChemE Symposium Series No. 155, Hazards XXI, Manchester, UK, 10–12 November 2009; pp. 595–602. Available online: https://www.icheme.org/media/9581/xxi-paper-085.pdf (accessed on 15 August 2022).

- Sadeghi, K. An Overview of Design, Analysis, Construction and Installation of Offshore Petroleum Platforms Suitable for Cyprus Oil/Gas Fields. GAU J. Soc. Appl. Sci. 2007, 2, 1–16. Available online: https://cemtelecoms.iqpc.co.uk/media/6514/786.pdf (accessed on 12 February 2022).

- Chandrasekaran, S.; Gaurav, S. Design Aids for Offshore Structures under Special Environmental Loads, Including Fire Resistance; Springer: Singapore, 2017; ISBN 9789813221076087. [Google Scholar]

- Amaechi, C.V.; Chesterton, C.; Butler, H.O.; Wang, F.; Ye, J. Review on the design and mechanics of bonded marine hoses for Catenary Anchor Leg Mooring (CALM) buoys. Ocean Eng. 2021, 242, 110062. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Chesterton, C.; Butler, H.O.; Wang, F.; Ye, J. An Overview on Bonded Marine Hoses for sustainable fluid transfer and (un)loading operations via Floating Offshore Structures (FOS). J. Mar. Sci. Eng. 2021, 9, 1236. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Wang, F.; Ja’E, I.A.; Aboshio, A.; Odijie, A.C.; Ye, J. A literature review on the technologies of bonded hoses for marine applications. Ships Offshore Struct. 2022, 1–32, ahead-of-print. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Chesterton, C.; Butler, H.O.; Gillet, N.; Wang, C.; Ja’E, I.A.; Reda, A.; Odijie, A.C. Review of Composite Marine Risers for Deep-Water Applications: Design, Development and Mechanics. J. Compos. Sci. 2022, 6, 96. [Google Scholar] [CrossRef]

- Toh, W.; Bin Tan, L.; Jaiman, R.K.; Tay, T.E.; Tan, V.B.C. A comprehensive study on composite risers: Material solution, local end fitting design and global response. Mar. Struct. 2018, 61, 155–169. [Google Scholar] [CrossRef]

- Pham, D.-C.; Sridhar, N.; Qian, X.; Sobey, A.J.; Achintha, M.; Shenoi, A. A review on design, manufacture and mechanics of composite risers. Ocean Eng. 2016, 112, 82–96. [Google Scholar] [CrossRef]

- Ochoa, O.O.; Salama, M.M. Offshore composites: Transition barriers to an enabling technology. Compos. Sci. Technol. 2005, 65, 2588–2596. [Google Scholar] [CrossRef]

- Anastasiades, K.; Michels, S.; Van Wuytswinkel, H.; Blom, J.; Audenaert, A. Barriers for the circular reuse of steel in the Belgian construction sector: An industry-wide perspective. Proc. Inst. Civ. Eng.—Manag. Procure. Law 2022, 1–14. [Google Scholar] [CrossRef]

- Dareing, D.W. Mechanics of Drillstrings and Marine Risers; ASME Press: New York, NY, USA, 2012; pp. 1–396. Available online: https://asmedigitalcollection.asme.org/ebooks/book/112/Mechanics-of-Drillstrings-and-Marine-Risers (accessed on 15 February 2022).

- Sparks, C. Fundamentals of Marine Riser Mechanics: Basic Principles and Simplified Analyses, 2nd ed.; PennWell Books: Tulsa, OK, USA, 2018. [Google Scholar]

- Bai, Y.; Bai, Q. Subsea Pipelines and Risers, 1st ed.; 2013 Reprint; Elsevier Ltd.: Oxford, UK, 2005. [Google Scholar]

- Bai, Y.; Bai, Q.; Ruan, W. Flexible Pipes: Advances in Pipes and Pipelines; Wiley Scrivener Publishing: Beverly, CA, USA.

- Sævik, S. On Stresses and Fatigue in Flexible Pipes. Ph.D. Thesis, NTH Trondheim, Norwegian Inst Technology, Dept Marine Structures Norway, Trondheim, Norway, 1992. Available online: https://trid.trb.org/view/442338 (accessed on 15 February 2022).

- Amaechi, C.V. Novel Design, Hydrodynamics and Mechanics of Marine Hoses in Oil/Gas Applications. Ph.D. Thesis, Lancaster University, Engineering Department, Lancaster, UK, 2022. [Google Scholar]

- Byrom, T.G. Casing and Liners for Drilling and Completion: Design and Application. A Volume in Gulf Drilling Guides, 2nd ed.; Gulf Professional Publishing: London, UK, 2015. [Google Scholar] [CrossRef]

- Grace, R.D. Blowout and Well Control Handbook; Gulf Professional Publishing: London, UK, 2017. [Google Scholar] [CrossRef]

- Joshi, S.D. Horizontal Well Technology; Pennwell Books: Tusla, OK, USA, 1991. [Google Scholar]

- Stewart, G. Well Test Design and Analysis; Pennwell Books: Tusla, OK, USA, 2011. [Google Scholar]

- Azar, J.J.; Samuel, R. Drilling Engineering; Pennwell Books: Tusla, OK, USA, 2007. [Google Scholar]

- Renpu, W. Advanced Well Completion Engineering; Gulf Professional Publishing: London, UK, 2011. [Google Scholar] [CrossRef]

- Caenn, R.; Darley, H.C.H.; Gray, G.R. Composition and Properties of Drilling and Completion Fluids, 7th ed.; Gulf Professional Publishing: London, UK, 2017. [Google Scholar] [CrossRef]

- Devereux, S. Practical Well Planning and Drilling Manual; Pennwell Books: Tusla, OK, USA, 1998. [Google Scholar]

- Veatch, R.W., Jr.; King, G.E.; Holditch, S.A. Essentials of Hydraulic Fracturing: Vertical and Horizontal Wellbores; Pennwell Books: Tusla, OK, USA, 2017. [Google Scholar]

- Raymond, M.S.; Leffler, W.L. Oil & Gas Production in Nontechnical Language; Pennwell Books: Tusla, OK, USA, 2017. [Google Scholar]

- Crumpton, H. Well Control for Completions and Interventions; Gulf Professional Publishing: London, UK, 2017. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Reda, A.; Butler, H.O.; Ja’E, I.A.; An, C. Review on Fixed and Floating Offshore Structures. Part I: Types of Platforms with Some Applications. J. Mar. Sci. Eng. 2022, 10, 1074. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Reda, A.; Butler, H.O.; Ja’E, I.A.; An, C. Review on Fixed and Floating Offshore Structures. Part II: Sustainable Design Approaches and Project Management. J. Mar. Sci. Eng. 2022, 10, 973. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Reda, A.; Ja’E, I.A.; Wang, C.; An, C. Guidelines on Composite Flexible Risers: Monitoring Techniques and Design Approaches. Energies 2022, 15, 4982. [Google Scholar] [CrossRef]

- Soares, C.G.; Garbatov, Y. Reliability of maintained ship hulls subjected to corrosion and fatigue under combined loading. J. Constr. Steel Res. 1999, 52, 93–115. [Google Scholar] [CrossRef]

- Soares, C.G.; Garbatov, Y. Fatigue reliability of the ship hull girder accounting for inspection and repair. Reliab. Eng. Syst. Saf. 1996, 51, 341–351. [Google Scholar] [CrossRef]

- Hussein, A.; Soares, C.G. Reliability and residual strength of double hull tankers designed according to the new IACS common structural rules. Ocean Eng. 2009, 36, 1446–1459. [Google Scholar] [CrossRef]

- Chojaczyk, A.A.; Teixeira, A.P.; Neves, L.C.; Cardoso, J.B.; Soares, C.G. Review and application of Artificial Neural Networks models in reliability analysis of steel structures. Struct. Saf. 2015, 52, 78–89. [Google Scholar] [CrossRef]

- Gaspar, B.; Teixeira, A.P.; Soares, C.G. Assessment of the efficiency of Kriging surrogate models for structural reliability analysis. Probabilistic Eng. Mech. 2014, 37, 24–34. [Google Scholar] [CrossRef]

- Soares, C.G.; Garbatov, Y. Reliability of maintained, corrosion protected plates subjected to non-linear corrosion and compressive loads. Mar. Struct. 1999, 12, 425–445. [Google Scholar] [CrossRef]

- Teixeira, A.P.; Soares, C.G.; Netto, T.A.; Estefen, S.F. Reliability of pipelines with corrosion defects. Int. J. Press. Vessel. Pip. 2008, 85, 228–237. [Google Scholar] [CrossRef]

- Aboshio, A.; Uche, A.O.; Akagwu, P.; Ye, J. Reliability-based design assessment of offshore inflatable barrier structures made of fibre-reinforced composites. Ocean Eng. 2021, 233, 109016. [Google Scholar] [CrossRef]

- Fischer, K.P.; Bue, B.P.; Brattas, L.P.; Steensland, O.P. Norwegian Continental Shelf North Of 62° N: Environmental Conditions and Corrosion Control. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 1980. [Google Scholar] [CrossRef]

- Weeter, R.F. Downhole Corrosion—Prevention and Treatment. In Proceedings of the International Petroleum Exhibition and Technical Symposium, Beijing, China, 17–24 March 1982. [Google Scholar] [CrossRef]

- Winning, I.G.; Taylor, A.; Ronceray, M. Corrosion Mitigation—The Corrosion Engineers Options. In Proceedings of the SPE International Conference on Oilfield Corrosion, Aberdeen, UK, 24–25 May 2010. [Google Scholar] [CrossRef]

- Sun, H.; Blumer, D.J.; Swidzinski, M.; Davis, J. Evaluating Corrosion Inhibitors for Sour Gas Subsea Pipelines. In Proceedings of the International Petroleum Technology Conference, Doha, Qatar, 7–9 December 2009. [Google Scholar] [CrossRef]

- Amani, M.; Dawood, H. A Comprehensive Review of Corrosion and its Inhibition in the Oil and Gas Industry. In Proceedings of the SPE Kuwait Oil and Gas Show and Conference, Mishref, Kuwait, 11–14 October 2015. [Google Scholar] [CrossRef]

- Landers, H.D. The economics of corrosion control in oil and gas production. In Proceedings of the 6th World Petroleum Congress, Frankfurt am Main, Germany, 19–26 June 1963. [Google Scholar]

- Rippon, I.J.; Pots, B.F.; Girgis, M.; Goerz, K. Failure Modes and Effect Analysis of a Sour Corrosion Control System. In Proceedings of the CORROSION 2006, San Diego, CA, USA, 12–16 March 2006. [Google Scholar]

- Norsworthy, R. NACE Criteria and Effective Corrosion Control of External Corrosion on Pipelines. In Proceedings of the CORROSION 2009, Atlanta, GA, USA, 22–26 March 2009. [Google Scholar]

- Norsworthy, R. Causes of External Corrosion on Coated and Cathodically Protected Pipelines. In Proceedings of the CORROSION 2009, Atlanta, GA, USA, 22–26 March 2009. [Google Scholar]

- HSE. Ageing Plant and Life Extension; Health and Safety Executive: London, UK, 2012. Available online: https://www.iosh.co.uk/~/media/Documents/Networks/Group/Offshore/Ageing_plant_and_life_extension.pdf?la=en (accessed on 17 July 2022).

- HSE. Offshore Statistics & Regulatory Activity Report 2020; Health and Safety Executive: London, UK, 2020. Available online: https://www.hse.gov.uk/offshore/statistics/hsr2020.pdf (accessed on 17 July 2022).

- HSE. Offshore Statistics & Regulatory Activity Report 2019; Health and Safety Executive: London, UK, 2019. Available online: https://www.hse.gov.uk/offshore/statistics/hsr2019.pdf (accessed on 17 July 2022).

- HSE. Offshore Statistics & Regulatory Activity Report 2018; Health and Safety Executive: London, UK, 2017. Available online: https://www.hse.gov.uk/offshore/statistics/hsr2018.pdf (accessed on 17 July 2022).

- HSE. Offshore safety statistics bulletin 2010/11; Health and Safety Executive: London, UK, 2011. Available online: https://www.hse.gov.uk/offshore/statistics/stat1011.htm (accessed on 17 July 2022).

- Hazardex. HSE UK Offshore Safety Report for 2018. Hazardex. 2020. Available online: https://www.hazardexonthenet.net/article/177200/HSE-UK-offshore-safety-report-for-2018.aspx (accessed on 17 July 2022).

- HSE. Effect on RIDDOR Statistics Following Recent Legal and System Changes; Health and Safety Executive: London, UK, 2022. Available online: https://www.hse.gov.uk/statistics/riddor-notification.htm (accessed on 17 July 2022).

- Yeter, B.; Garbatov, Y. Optimal Life Extension Management of Offshore Wind Farms Based on the Modern Portfolio Theory. Oceans 2021, 2, 566–582. [Google Scholar] [CrossRef]

- Piel, J.H.; Stetter, C.; Heumann, M.; Westbomke, M.; Breitner, M.H. Lifetime Extension, Repowering or Decommissioning? Decision Support for Operators of Ageing Wind Turbines. IOP Conf. Ser. J. Phys. Conf. Ser. 2013, 1222, 012033. [Google Scholar] [CrossRef]

- Pakenham, B.; Ermakova, A.; Mehmanparast, A. A Review of Life Extension Strategies for Offshore Wind Farms Using Techno-Economic Assessments. Energies 2021, 14, 1936. [Google Scholar] [CrossRef]

- Ziegler, L.; Gonzalez, E.; Rubert, T.; Smolka, U.; Melero, J.J. Lifetime extension of onshore wind turbines: A review covering Germany, Spain, Denmark, and the UK. Renew. Sustain. Energy Rev. 2018, 82, 1261–1271. [Google Scholar] [CrossRef]

- Ziegler, L.; Lange, J.; Smolka, U.; Muskulus, M. The decision on the time to switch from lifetime extension to repowering. In Proceedings of the Wind Europe Summit 2016, Hamburg, Germany, 27–29 September 2016. [Google Scholar]

- Rubert, T.; McMillan, D.; Niewczas, P. A decision support tool to assist with lifetime extension of wind turbines. Renew. Energy 2018, 120, 423–433. [Google Scholar] [CrossRef]

- Rubert, T.; Niewczas, P.; McMillan, D. Life extension for wind turbine structures and foundations. In Proceedings of the International Conference on Offshore Renewable Energy 2016, Glasgow, UK, 21–30 June 2016; Available online: https://strathprints.strath.ac.uk/57846/1/Rubert_Niewczas_McMillan_CORE_2016_life_extension_for_wind_turbine_structures.pdf (accessed on 16 July 2022).

- Casey, J. Asset Life Extension: Viable in the Long Term for Oil and Gas? Verdict: New York, NY, USA, 2020; Available online: https://www.offshore-technology.com/features/asset-life-extension-viable-in-the-long-term-for-oil-and-gas/ (accessed on 6 May 2022).

- Schumacher, C.; Weber, F. How to extend the lifetime of wind turbines. Renewable Energy World, 20 September 2019. Available online: https://www.renewableenergyworld.com/2019/09/20/how-to-extend-the-lifetime-of-wind-turbines/ (accessed on 12 May 2022).

- Astolfi, D.; Byrne, R.; Castellani, F. Estimation of the Performance Aging of the Vestas V52 Wind Turbine through Comparative Test Case Analysis. Energies 2021, 14, 915. [Google Scholar] [CrossRef]

- Astolfi, D.; Byrne, R.; Castellani, F. Analysis of Wind Turbine Aging through Operation Curves. Energies 2020, 13, 5623. [Google Scholar] [CrossRef]

- Siemens. Life Extension Program; Siemens Gamesa: Zamudio, Spain, 2014; Available online: https://www.siemensgamesa.com/-/media/siemensgamesa/downloads/en/products-and-services/services/life-extension/siemens-gamesa-wind-service-life-extension-flyer-en.pdf (accessed on 15 May 2022).

- OGUK. Guidelines on the Management of Ageing and Life Extension of Offshore Structures—Issue 1 April 2012; Oil & Gas UK (OGUK): London, UK, 2014; Available online: https://oeuk.org.uk/product/guidelines-on-the-management-of-ageing-and-life-extension-of-offshore-structures-issue-1/ (accessed on 16 July 2022).

- OGUK. Guidelines on the Management of Ageing and Life Extension for UKCS Oil and Gas Installations—Issue 1 April 2012; Oil & Gas UK (OGUK): London, UK, 2012; Available online: https://oeuk.org.uk/wp-content/uploads/2020/09/OGUK-Guidelines-on-the-Management-of-Ageing-and-Life-Extension-for-UKCS-Oil-and-Gas-Installations-Issue-1-1.pdf (accessed on 16 July 2022).

- EI. A Framework for Monitoring the Management of Ageing Effects on Safety Critical Elements. EI Research Report, 1st ed.; Energy Institute: London, UK, 2009; Available online: https://publishing.energyinst.org/__data/assets/file/0011/10280/Pages-from-Monitoring-the-management-of-ageing-effects-on-safety-critical-elements-Nov-2009.pdf (accessed on 16 July 2022).

- EI. Performance Standards for Structural Safety Critical Elements, 1st ed.; Energy Institute: London, UK, 2022; Available online: https://publishing.energyinst.org/topics/asset-integrity/performance-standards-for-structural-safety-critical-elements (accessed on 16 July 2022).

- EI. Guidelines for Management of Safety Critical Elements (SCEs), 3rd ed.; Energy Institute: London, UK, 2020; Available online: https://publishing.energyinst.org/__data/assets/file/0012/690789/Pages-from-web-versionGuidelines-for-management-of-safety-critical-elements_LM2.pdf (accessed on 16 July 2022).

- EI. Guidelines for the Management of Safety Critical Elements, 2nd ed.; Energy Institute: London, UK, 2007; Available online: https://pdfcoffee.com/safety-critical-elements-managament-pdf-free.html (accessed on 16 July 2022).

- EI. Guidelines for the Identification and Management of Environmental Barriers, 2nd ed.; Energy Institute: London, UK, 2020; Available online: https://publishing.energyinst.org/topics/environment/guidelines-for-the-identification-and-management-of-environmental-barriers (accessed on 16 July 2022).

- EI. Guidelines on the Corrosion Management of Offshore Oil and Gas Production Facilities: Addressing Asset Ageing and Life Extension (ALE), 1st ed.; Energy Institute: London, UK, 2017; Available online: https://publishing.energyinst.org/__data/assets/file/0009/305874/Sample-pages-Guidelines-corrosion-management-ALE.pdf (accessed on 16 July 2022).

- DNV. DNV-CG-0121 Offshore Classification Based on Performance Criteria Determined from Risk Assessment Methodology; DNV: Oslo, Norway, 2021; Available online: https://rules.dnv.com/docs/pdf/DNV/CG/2021-09/DNV-CG-0121.pdf (accessed on 16 July 2022).

- NORSOK Y-002:2010; Life Extension for Transportation Systems; Standards Norway: Lysaker, Norway, 2010. Available online: www.standard.no/nettbutikk/produktkatalogen/produktpresentasjon/?ProductID=476408 (accessed on 16 July 2022).

- ISO/TS 12747:2011; Recommended Practice for Pipeline Life Extension. ISO (International Organization for Standardization): Geneva, Switzerland, 2011. Available online: www.iso.org/iso/home/store/catalogue_tc/catalogue_detail.htm?csnumber=51657) (accessed on 16 July 2022).

- ISO 13702:2015; Petroleum and Natural Gas Industries—Control and Mitigation of Fires and Explosions on Offshore Production Installations—Requirements and Guidelines. ISO (International Organization for Standardization): Geneva, Switzerland, 2015.

- ISO 31073:2022; Risk Management—Vocabulary. ISO (International Organization for Standardization): Geneva, Switzerland, 2022.

- HSE. Key Programme 3—Asset Integrity Programme. A Report by the Offshore Division of HSE’s Hazardous Installations Directorate; Health and Safety Executive: London, UK, 2007; pp. 1–73. Available online: https://www.hse.gov.uk/offshore/kp3.pdf (accessed on 16 July 2022).

- HSE. Key Programme 4 (KP4): Ageing and Life Extension Programme. Executive Summary. A Report by the Energy Division of HSE’s Hazardous Installations Directorate. November 2012; Health and Safety Executive: London, UK, 2012; pp. 1–47. Available online: https://www.hse.gov.uk/offshore/ageing/kp4-report.pdf (accessed on 16 July 2022).

- HSE. Plant Ageing: Management of Equipment Containing Hazardous Fluids or Pressure; Research Report 509; TWI Ltd., ABB Engineering Services, SCS (INTL) Ltd.; Allianz Cornhill Engineering for the Health and Safety Executive; Health and Safety Executive: London, UK, 2006. Available online: https://www.hse.gov.uk/research/rrpdf/rr509.pdf (accessed on 27 May 2022).

- HSE. Plant Ageing Study: Phase 1 Report; Research Report 823; ESR Technology Limited for the Health and Safety Executive; Health and Safety Executive: London, UK, 2010. Available online: https://www.hse.gov.uk/research/rrpdf/rr823.pdf (accessed on 27 May 2022).

- HSE. Reducing Error and Influencing Behaviour; Research Report HSG48; TSO@ Blackwell and other Accredited Agents & Health and Safety Executive: London, UK, 1999. Available online: https://www.hse.gov.uk/pubns/priced/hsg48.pdf (accessed on 27 May 2022).

- Dalzell, G.; Roberts, T.A.; Jagger, S.; Walsh, P. Guidance on Fire and Explosion Hazards Associated with Ageing Offshore Oil and Gas Platforms; Health & Safety Laboratory (HSL) Report PS/06/24 {Internal Report}; Health and Safety Executive: Buxton, UK, 2007.

- Chang, K.C.; Kuo, P.T.; Hsu, K.R. License Renewal and Aging Management. In Companion Guide to the ASME Boiler and Pressure Vessel Code, 3rd ed.; Rao, K.R., Ed.; ASME Press: New York, NY, USA, 2009; Volume 3. [Google Scholar]

- Brkić, D.; Praks, P. Probability Analysis and Prevention of Offshore Oil and Gas Accidents: Fire as a Cause and a Consequence. Fire 2021, 4, 71. [Google Scholar] [CrossRef]

- HSE. Guidance of Management of Ageing and Thorough Reviews of Ageing Installations; Offshore Information Sheet No. 4/2009; HSE: London, UK, 2009. Available online: http://www.hse.gov.uk/offshore/infosheets/is4-2009.pdf (accessed on 24 June 2022).

- HMSO. The Offshore Installations (Prevention of Fire and Explosions, and Emergency Response) Regulations 1995; SI 1995 no. 743; HMSO: London, UK, 1995. Available online: http://www.opsi.gov.uk/si/si1995/Uksi_19950743_en_2.htm (accessed on 24 June 2022).

- HMSO. The Offshore Installations (Safety Case) Regulations 2005; SI 2005 no. 3117; HMSO: London, UK, 2005. Available online: https://www.legislation.gov.uk/uksi/2005/3117/contents (accessed on 24 June 2022).

- Walker, S.; Konstantinidou, M.; Contini, S.; Zhovtyak, E.; Tarantola, S. Guidance for the Assessment of Reports on Major Hazards Based on the Requirements of Directive 2013/30/EU—Summary and Highlights of the JRC Training Course under the Virtual Centre of Offshore Safety Expertise; EUR 28693 EN; Publications Office of the European Union, Luxembourg, 2017; JRC107405; ISBN 978-92-79-70670-7. Available online: https://euoag.jrc.ec.europa.eu/files/attachments/training_booklet_guidelines_for_the_assessment_of_romh_-_final_-_online.pdf (accessed on 24 June 2022).

- HSE. Guidance for the Topic Assessment of the Major Accident Hazard Aspects of Safety Cases; HSE: London, UK, 2006. Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.419.1267&rep=rep1&type=pdf (accessed on 24 June 2022).

- HSE. Assessment Principles for Offshore Safety Cases (APOSC): Offshore Major Accident Regulator; HSE: London, UK, 2021. Available online: https://www.hse.gov.uk/omar/assets/docs/aposc.pdf (accessed on 24 June 2022).

- HSE. Assessment principles for offshore safety cases (APOSC); HSE: London, UK, 2006. Available online: https://www.csb.gov/assets/1/7/uk_hse_safety_case_assessment_principle_aposc190306_(2).pdf (accessed on 24 June 2022).

- HSE. Guidance on Risk Assessment for Offshore Installations; Offshore Information Sheet No. 3/2006; HSE: London, UK, 2006. Available online: https://www.hse.gov.uk/offshore/sheet32006.pdf (accessed on 24 June 2022).

- Sharif, A.; Aloui, C.; Yarovaya, L. COVID-19 pandemic, oil prices, stock market, geopolitical risk and policy uncertainty nexus in the US economy: Fresh evidence from the wavelet-based approach. Int. Rev. Financ. Anal. 2020, 70, 101496. [Google Scholar] [CrossRef]

- Engebretsen, R.; Anderson, C. The Impact of Coronavirus (COVID-19) and the Global Oil Price Shock on the Fiscal Position of Oil-Exporting Developing Countries; Organization for Economic Co-Operation and Development (OECD): Paris, France, 2020; Available online: https://www.oecd.org/coronavirus/policy-responses/the-impact-of-coronavirus-covid-19-and-the-global-oil-price-shock-on-the-fiscal-position-of-oil-exporting-developing-countries-8bafbd95/ (accessed on 12 May 2022).

- Kelly, S. Oil Price Crashes into Negative Territory for the First Time in History Amid Pandemic. Reuters. 20 April 2020. Available online: https://reut.rs/35Pq49T (accessed on 12 May 2022).

- Millefiori, L.M.; Braca, P.; Zissis, D.; Spiliopoulos, G.; Marano, S.; Willett, P.K.; Carniel, S. COVID-19 impact on global maritime mobility. Sci. Rep. 2021, 11, 18039. [Google Scholar] [CrossRef]

- Moriarty, L.F.; Plucinski, M.; Marston, B.J.; Kurbatova, E.V.; Knust, B.; Murray, E.L.; Pesik, N.; Rose, D.; Fitter, D.; Kobayashi, M.; et al. Public Health Responses to COVID-19 Outbreaks on Cruise Ships—Worldwide, February–March 2020. Morb. Mortal. Wkly. Rep. 2020, 69, 347–352. [Google Scholar] [CrossRef]

- Sackey, A.D.; Tchouangeup, B.; Lamptey, B.L.; van der Merwe, B.; Lee, R.O.-D.; Mensah, R.; Fuseini, M.C.; Sackey, A.D. Outlining the challenges of Covid-19 health crises in Africa’s maritime industry: The case of maritime operations in marine warranty surveying practice. Marit. Stud. 2021, 20, 207–223. [Google Scholar] [CrossRef] [PubMed]

- Lerche, J.; Lorentzen, S.; Enevoldsen, P.; Neve, H. The impact of COVID -19 on offshore wind project productivity—A case study. Renew. Sustain. Energy Rev. 2022, 158, 112188. [Google Scholar] [CrossRef]

- Depellegrin, D.; Bastianini, M.; Fadini, A.; Menegon, S. The effects of COVID-19 induced lockdown measures on maritime settings of a coastal region. Sci. Total Environ. 2020, 740, 140123. [Google Scholar] [CrossRef] [PubMed]

- Olukolajo, M.A.; Oyetunji, A.K.; Oluleye, I.B. Covid-19 protocols: Assessing construction site workers compliance. J. Eng. Des. Technol. 2021, 20, 115–131. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Amaechi, E.C.; Amechi, S.C.; Oyetunji, A.K.; Kgosiemang, I.M.; Mgbeoji, O.J.; Ojo, A.S.; Abelenda, A.M.; Milad, M.; Adelusi, I.; et al. Management of Biohazards and Pandemics: COVID-19 and Its Implications in the Construction Sector. Comput. Water Energy Environ. Eng. 2022, 11, 34–63. [Google Scholar] [CrossRef]

- Shih, W.C. Global Supply Chains in a Post-Pandemic World. Harvard Business Review, September–October 2020. Available online: https://hbr.org/2020/09/global-supply-chains-in-a-post-pandemic-world (accessed on 16 July 2022).

- Werner, R.; Jan, G.; Hannes, G.; Jürgen, E.; Nico, P. Post COVID-19 Value Chains: Options for Reshoring Production Back to Europe in a Globalised Economy; European Union: Brussels, Belgium, 2021. [Google Scholar] [CrossRef]

- Candina, J.; Fernández, D.G.; Hall, S.; Verre, F. Reinventing Upstream Oil and Gas Operations after the COVID-19 Crisis. McKinsey & Company, 20 August 2020. Available online: https://www.mckinsey.com/industries/oil-and-gas/our-insights/reinventing-upstream-oil-and-gas-operations-after-the-covid-19-crisis (accessed on 16 July 2022).

- Barbosa, F.; Bresciani, G.; Graham, P.; Nyquist, S.; Yanosek, K. Oil and Gas after COVID-19: The Day of Reckoning or a New Age of Opportunity? McKinsey & Company: Chicago, IL, USA, 2020; Available online: https://www.mckinsey.com/industries/oil-and-gas/our-insights/oil-and-gas-after-covid-19-the-day-of-reckoning-or-a-new-age-of-opportunity (accessed on 16 July 2022).

- Tang, C.-S.; Paleologos, E.K.; Vitone, C.; Du, Y.-J.; Li, J.-S.; Jiang, N.-J.; Deng, Y.-F.; Chu, J.; Shen, Z.; Koda, E.; et al. Environmental geotechnics: Challenges and opportunities in the post-COVID-19 world. Environ. Geotech. 2021, 8, 172–192. [Google Scholar] [CrossRef]

- Bouri, E.; Demirer, R.; Gupta, R.; Pierdzioch, C. Infectious Diseases, Market Uncertainty and Oil Market Volatility. Energies 2020, 13, 4090. [Google Scholar] [CrossRef]

- Agomuoh, A.E.; Ossia, C.V.; Chukwuma, F.O. Asset Integrity Management in Mitigating Oil and Gas Pipeline Vandalism in the Niger Delta Region—Deep Burial Solution. World J. Eng. Technol. 2021, 9, 565–578. [Google Scholar] [CrossRef]

- IQ. What Is Asset Integrity? Oil and Gas IQ. 2019. Available online: https://www.oilandgasiq.com/oil-gas/news/what-is-asset-integrity (accessed on 16 July 2022).

- HSE. Managing Health and Safety in Construction: Construction (Design and Management) Regulations 2015. Guidance on Regulations. Series L153; Health and Safety Executive: London, UK, 2015; pp. 1–90. Available online: https://www.hse.gov.uk/pubns/priced/l153.pdf (accessed on 16 July 2022).

- HSE. Health and Safety in Construction. A Report by the Offshore Division of HSE’s Hazardous Installations Directorate. Series HSG150; Health and Safety Executive: London, UK, 2006; pp. 1–141. Available online: https://www.hse.gov.uk/pubns/priced/hsg150.pdf (accessed on 16 July 2022).

- Amaechi, C.V. Health, Safety and Biohazards in Construction: How Safe Is the Work Place? Risks and Hazards in Our Environment; LAP LAMBERT Academic Publishing: Saarbrücken, Germany, 2016; Available online: https://eprints.lancs.ac.uk/id/eprint/136434/ (accessed on 16 July 2022).

- Comer, P.J.; Eades, M.J. The Application of Risk Assessment in Offshore Projects. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 1991. [Google Scholar] [CrossRef]

- Kian-Hua, S.; Su-Fook, L.; Yun-Chung, L. ALARP Demonstration in UCG Trial Production Operations (TPO) Facility Design. In Proceedings of the International Petroleum Technology Conference, Beijing, China, 26–28 March 2013. [Google Scholar] [CrossRef]

- Wiig, E.; Berthelsen, I.; Donovan, K. The Troll HSE Risk Management System. In Proceedings of the SPE Health, Safety and Environment in Oil and Gas Exploration and Production Conference, New Orleans, LA, USA, 9–12 June 1996. [Google Scholar] [CrossRef]

- Chetrit, A. Major Risks Analysis with a Scenario Based Methodology. In Proceedings of the SPE International Conference on Health, Safety, and Environment in Oil and Gas Exploration and Production, Nice, France, 15–17 April 2008. [Google Scholar] [CrossRef]

- Whiting, J.F. Effective Risk Assessment in TA, JHA, JSA, JSEA, WMS, TAKE 5, and Incident Investigation. In Proceedings of the ASSE Professional Development Conference and Exposition, Las Vegas, NV, USA, 24–27 June 2013; Available online: https://onepetro.org/ASSPPDCE/proceedings-abstract/ASSE13/All-ASSE13/ASSE-13-612/76281 (accessed on 16 July 2022).

- Mata, O. The Role of Quantitative Risk Analysis QRA in Risk Management. In Proceedings of the SPE Latin-American and Caribbean Health, Safety, Environment and Social Responsibility Conference, Lima, Peru, 26–27 June 2013. [Google Scholar] [CrossRef]

- Kandil, M.E. Efforts to Persevere a Risk Assessment/Integrity Assurance for its Aged Hydrocarbon Transfer Pipe-lines. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–3 October 2001. [Google Scholar] [CrossRef]

- Cherubin, P.; Scataglini, L.; Decarli, L.; Chisari, V.; Bandini, R. A New Methodology for Major Accident Hazard Risk Assessment According to Eu Directive on Offshore Safety. In Proceedings of the Offshore Mediterranean Conference and Exhibition, Ravenna, Italy, 27–29 March 2019; Available online: https://onepetro.org/OMCONF/proceedings-abstract/OMC19/All-OMC19/OMC-2019-0939/1471 (accessed on 16 July 2022).

- Abas, N.H.; Jalani, A.F.A.; Affandi, H.M. Construction Stakeholders’ Perceptions of Occupational Safety and Health Risks in Malaysia. Int. J. Sustain. Constr. Eng. Technol. 2020, 11, 300–311. [Google Scholar] [CrossRef]

- Mayfield, J.A. Process Improvement Based on a Gap Assessment of NASA and O&G Risk Management Processes. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2019. [Google Scholar] [CrossRef]

- Donaldson, B.; Shah, B.; Daher, E. Comprehensive Gap Assessment of Complete Safety Management Systems with Systematic Analysis and Recommendations—A Successful Case Study. In Proceedings of the SPE Latin American and Caribbean Health, Safety, Environment and Sustainability Conference, Bogotá, Colombia, 7–8 July 2015. [Google Scholar] [CrossRef]

- Bendickson, N. Don’t Wait for an Intervention--Use CSA “Safety Management Cycle” to Identify Opportunities. In Proceedings of the ASSE Professional Development Conference and Exposition, Dallas, TX, USA, 7–10 June 2015; Available online: https://onepetro.org/ASSPPDCE/proceedings-abstract/ASSE15/All-ASSE15/ASSE-15-651/78297 (accessed on 16 July 2022).

- Diara, M.; Ngunjiri, S.; Strohkorb, J. Effective Prevention of Tuberculosis Transmission in Oil and Gas Workplaces: A Programmatic Approach. In Proceedings of the SPE International Conference and Exhibition on Health, Safety, Security, Environment, and Social Responsibility, Abu Dhabi, United Arab Emirates, 16–18 April 2018. [Google Scholar] [CrossRef]

- Singhal, G.; Dibua, O.; Murray, D.; Culembourg, L.; Erb, P.; Wensel, E.; Makogon, T. Review of Technology Status and Challenges Associated with Ultra Deep Water Developments. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2019. [Google Scholar] [CrossRef]

- Holtman, J.G.; Kalb, A.T. Enhancement of Corporate Operational Excellence Management System Audit Protocols to Drive Audit Consistency. In Proceedings of the SPE International Conference on Health, Safety, and Environment, Long Beach, CA, USA, 17–19 March 2014. [Google Scholar] [CrossRef]

- Hall, J.N. Safety Survey Using Piper Alpha Disaster Evidence. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 1991. [Google Scholar] [CrossRef]

- Luck, C.J.; Sellers, J.G. Safety and Environmental Auditing for Existing Offshore Facilities. In Proceedings of the SPE OffShore Europe, Aberdeen, UK, 10–13 September 1985. [Google Scholar] [CrossRef]

- Techasirithaworn, M.; Tachavarakul, V.; Krittaphol, N.; Grassian, D. Life Extension of the Jasmine and BanYen Oil Field Exceeding Expectations While Managing Constraints. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 9–12 November 2020. [Google Scholar] [CrossRef]

- Boutrot, J.; Giorgiutti, Y.; Rezende, F.; Barras, S. Reliable and Accurate Determination of Life Extension for Offshore Units. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 2017. [Google Scholar] [CrossRef]

- Morandini, C.; Floury, J. Pragmatic and Consistent Approach to Life Extension of Floating Structures. In Proceedings of the Offshore Technology Conference Asia, Kuala Lumpur, Malaysia, 20–23 March 2018. [Google Scholar] [CrossRef]

- Boutrot, J.; Legregeois, N. Integrity Management of Ageing Offshore Assets: An Integrated Approach Towards Life Extension and Operational Efficiency. In Proceedings of the SNAME 20th Offshore Symposium, Houston, TX, USA, 17 February 2015; Available online: https://onepetro.org/SNAMETOS/proceedings-abstract/TOS15/1-TOS15/D013S009R001/3725 (accessed on 16 July 2022).

- Hua, D.S.; Gibbs, B. Effective Development of Life Extension Programs for Aging Offshore Facilities. In Proceedings of the SNAME 19th Offshore Symposium, Houston, TX, USA, 6 February 2014; Available online: https://onepetro.org/SNAMETOS/proceedings-abstract/TOS14/1-TOS14/D013S002R002/3669 (accessed on 16 July 2022).

- Nashikkar, D.; Mo, W.; Achanta, V.; Lyon, S. Riser and Subsea Offshore Asset Field Life Extension. In Proceedings of the SNAME 20th Offshore Symposium, Houston, TX, USA, 17 February 2015; Available online: https://onepetro.org/SNAMETOS/proceedings-abstract/TOS15/1-TOS15/D013S009R004/3728 (accessed on 24 June 2022).

- Szalewski, P.; Malinowski, G.; Lu, J.Y. Demonstrating Target Safety Level for Life Extension of Offshore Structures. In Proceedings of the SNAME 24th Offshore Symposium, Houston, TX, USA, 20 February 2019; Available online: https://onepetro.org/SNAMETOS/proceedings-abstract/TOS19/1-TOS19/D013S008R001/3579 (accessed on 16 July 2022).

- Gordon, R. Considerations for Mooring Life Extension. In Proceedings of the SNAME 20th Offshore Symposium, Houston, TX, USA, 17 February 2015; Available online: https://onepetro.org/SNAMETOS/proceedings-abstract/TOS15/1-TOS15/D013S009R003/3727 (accessed on 16 July 2022).

- Yao, A.; Zhang, Q. Review of Offshore Mooring System Life Extension—Challenges and Recommendations. In Proceedings of the SNAME 24th Offshore Symposium, Houston, TX, USA, 20 February 2019; Available online: https://onepetro.org/SNAMETOS/proceedings-abstract/TOS19/1-TOS19/D013S004R001/3571 (accessed on 16 July 2022).

- Forsyth, M.; Bruno, P. Life Extension of Pierce Field Production Facilities, North Sea, UK. In Proceedings of the SPE Annual Caspian Technical Conference and Exhibition, Astana, Kazakhstan, 31 October–2 November 2018. [Google Scholar] [CrossRef]

- Galbraith, D.N.; Sharp, J.V.; Terry, E. Managing life extension in Ageing offshore Installations. In Proceedings of the SPE Offshore Europe Oil and Gas Exhibition and Conference, Aberdeen, UK, 6–9 September 2005. [Google Scholar] [CrossRef]

- Kajuputra, A.E.; Shiiun, W.B.; Shamsuddin, M.A. The Importance of SIMS in Structural Integrity Review and Life Extension Requirement for Existing Fixed Offshore Structure. In Proceedings of the Offshore Technology Conference Asia, Kuala Lumpur, Malaysia, 22–25 March 2016. [Google Scholar] [CrossRef]

- Westlake, H.S.; Puskar, F.J.; O’Connor, P.E.; Bucknel, J.R. The Role of Ultimate Strength Assessments in the Structural Integrity Management (SIM) of Offshore Structures. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 2006. [Google Scholar] [CrossRef]

- O’Connor, P.E.; Bucknell, J.R.; DeFrance, S.J.; Westlake, H.S.; Westlake, F.J. Structural Integrity Management (SIM) of Offshore Facilities. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2005. [Google Scholar] [CrossRef]

- Westlake, H.S.; Puskar, F.J.; O’Connor, P.E.; Bucknell, J.R. The Development of a Recommended Practice for Structural Integrity Management (SIM) of Fixed Offshore Platforms. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 2006. [Google Scholar] [CrossRef]

- Defranco, S.; O’Connor, P.; Puskar, F.; Bucknell, J.R.; Digre, K.A. API RP 2SIM: Recommended Practice for Structural Integrity Management of Fixed Offshore Platforms. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 3–6 May 2010. [Google Scholar] [CrossRef]

- Kongchang, A.; Danthainum, A.; Chattratichart, T.; Sonachai, P.; Thavornsuk, T.; Katanyoowongcharoen, S.; Sriparagul, J.; Kosanunt, P. Alternative Framework for Structural Integrity Management of Jacket Platform Beyond its Design Life. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 13–16 November 2017. [Google Scholar] [CrossRef]

- Ritchie, D.M. The Role of Asset Integrity and Life Extension in Major Accident Prevention. In Proceedings of the SPE Offshore Europe Oil and Gas Conference and Exhibition, Aberdeen, UK, 6–8 September 2011. [Google Scholar] [CrossRef]

- Nezamian, A.; Iqbal, K. Requalification and Extension of Service Life and Integrity Requirements for Offshore Structures in Middle East. In Proceedings of the International Petroleum Technology Conference, Doha, Qatar, 6–9 December 2015. [Google Scholar] [CrossRef]

- Fairbairn, L.; Pegram, A.; Nishapati, M. E-Safety Case—Improving Communication and Application of HSE Data. In Proceedings of the SPE International Health, Safety & Environment Conference, Abu Dhabi, United Arab Emirates, 7–10 April 2006. [Google Scholar] [CrossRef]

- Scanlon, M. Revised Industry Guidance on Managing Safety Critical Elements. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 11–14 November 2019. [Google Scholar] [CrossRef]

- Bentley, N.L.; Seaman, C.H.; Brower, D.V.; Tang, H.H.; Le, S.Q. Development and Testing of a Friction-Based Post-Installable Fiber-Optic Monitoring System for Subsea Applications. In Proceedings of the ASME 2017 36th International Conference on Ocean, Offshore and Arctic Engineering, Trondheim, Norway, 25–30 June 2017; Pipelines, Risers, and Subsea Systems, V05BT04A050. ASME: New York, NY, USA, 2017; Volume 5B. [Google Scholar] [CrossRef]

- Cortina, M.; Pavli, E.; Antinolfi, G.; La Rosa, L.; Rainaldi, I.; Petrone, A. An Overarching Strategy for Safety Critical Elements Assessment and Management. In Proceedings of the SPE International Conference on Health, Safety, and Environment, Long Beach, CA, USA, 17–19 March 2014. [Google Scholar] [CrossRef]

- Bhat, S. Safety-Critical Elements/Performance Standards—Engineering. LinkedIn Pulse, 8 June 2021. Available online: https://www.linkedin.com/pulse/safety-critical-elementsperformance-standards-engineering-bhat?trk=public_profile_article_view (accessed on 16 July 2022).

- Dhar, R. Performance Standards for Safety Critical Elements—Are We Doing Enough? In Proceedings of the SPE European Health, Safety and Environmental Conference in Oil and Gas Exploration and Production, Vienna, Austria, 22–24 February 2011. [Google Scholar] [CrossRef]

- Denney, D. Performance Standards for Safety-Critical Elements—Are We Doing Enough? J. Pet. Technol. 2011, 63, 74–76. [Google Scholar] [CrossRef]

- Pillai, S. Best Practices in Integrity Management of Safety Critical Systems. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 11–14 November 2016. [Google Scholar] [CrossRef]

- Wilson, A. Safety Case in the Gulf of Mexico: Method and Benefits for Old and New Facilities. J. Pet. Technol. 2015, 67, 111–113. [Google Scholar] [CrossRef]

- McIntosh, A.M. Features of a Safety Case for a Complex of Platforms with NNM’s. In Proceedings of the SPE Offshore Europe, Aberdeen, UK, 7–10 September 1993. [Google Scholar] [CrossRef]

- Hart, P.M.I.; Smith, D.W.; Thomas, E.J. Preparation of Combined Operations Safety Cases: Experience and Lessons Learnt. In Proceedings of the SPE Offshore Europe, Aberdeen, UK, 5–8 September 1995. [Google Scholar] [CrossRef]