A Low-Cost, Low-Power Water Velocity Sensor Utilizing Acoustic Doppler Measurement

Abstract

:1. Introduction

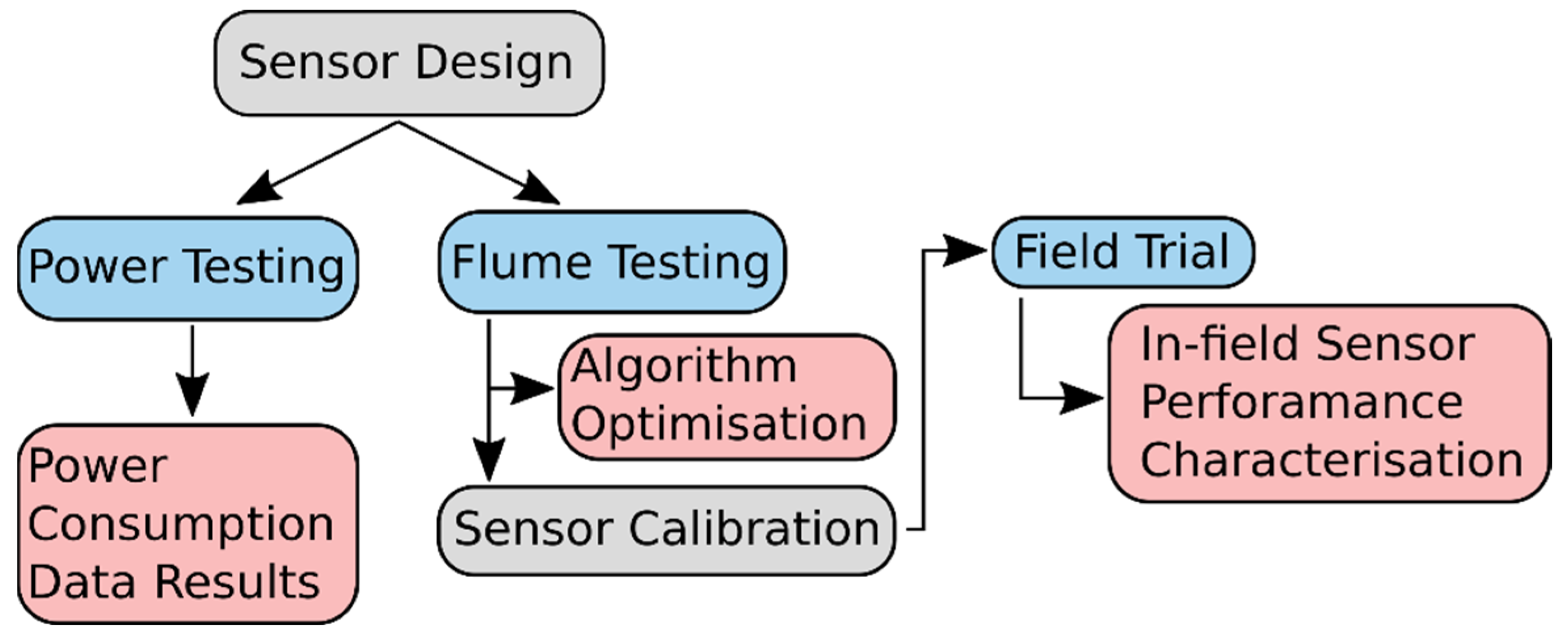

2. Materials and Methods

2.1. Sensor Design

2.1.1. Doppler Signal Generation and Detection Subsystem

2.1.2. Digital Signal Acquisition Subsystem

2.1.3. Sensor Interface Subsystem

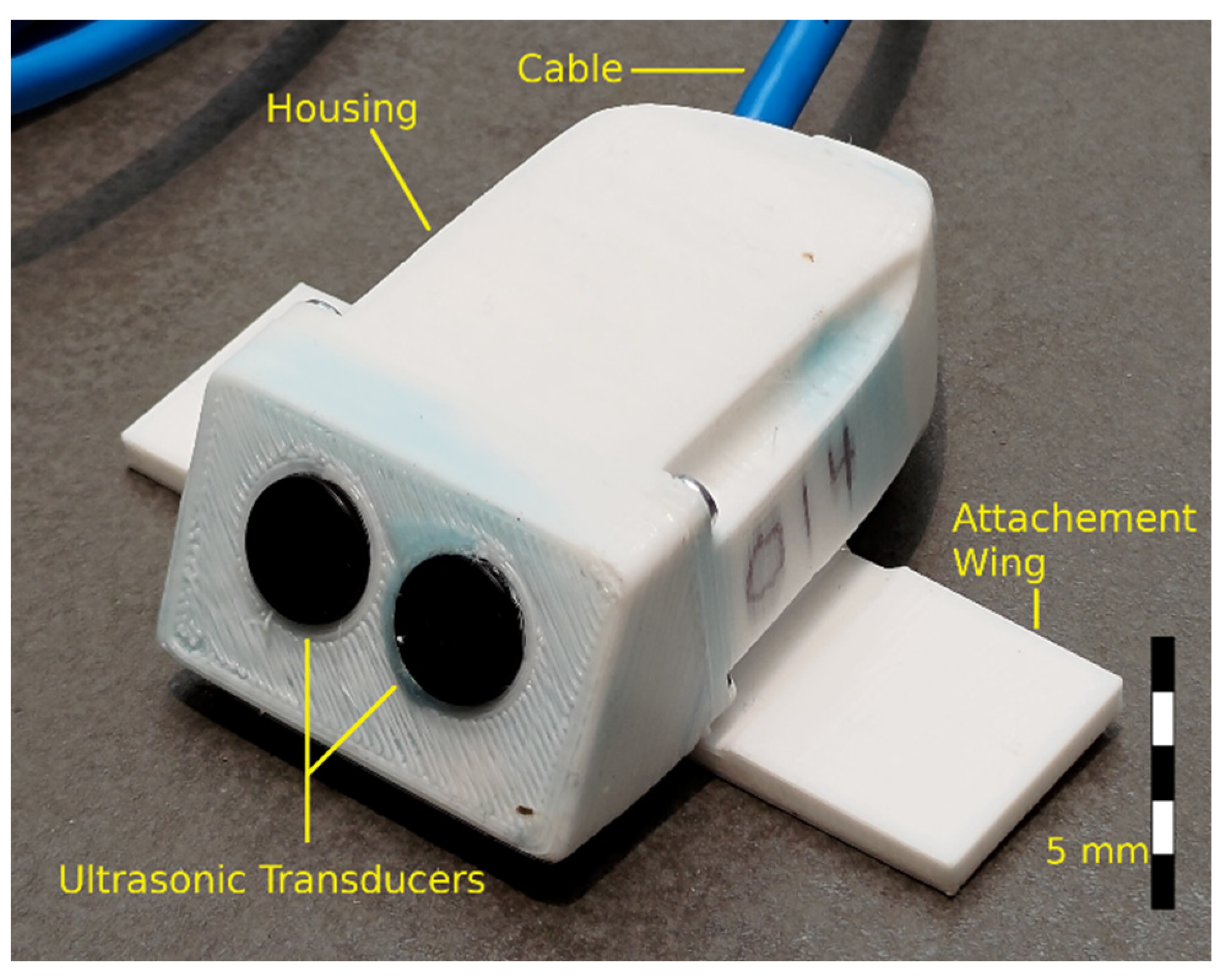

2.1.4. Physical Overview

2.1.5. Calibration

2.1.6. Digital Signal Processing Algorithm

2.2. Lab and Field Testing Setup

2.2.1. Lab Power Usage Testing

2.2.2. Flume Testing

2.2.3. Field Trial

3. Results

3.1. Lab Power Usage Testing

3.2. Field Trial

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Charbeneau, R.J.; Barrett, M.E. Evaluation of Methods for Estimating Stormwater Pollutant Loads. Water Environ. Res. 1998, 70, 1295–1302. [Google Scholar] [CrossRef]

- Prodanovic, V.; Jamali, B.; Kuller, M.; Wang, Y.; Bach, P.M.; Coleman, R.A.; Metzeling, L.; McCarthy, D.T.; Shi, B.; Deletic, A. Calibration and Sensitivity Analysis of a Novel Water Flow and Pollution Model for Future City Planning: Future Urban Stormwater Simulation (FUSS). Water Sci. Technol. 2022, 85, 961–969. [Google Scholar] [CrossRef] [PubMed]

- Mannina, G.; Viviani, G. An Urban Drainage Stormwater Quality Model: Model Development and Uncertainty Quantification. J. Hydrol. 2010, 381, 248–265. [Google Scholar] [CrossRef]

- Feng, S.; Roguet, A.; McClary-Gutierrez, J.S.; Newton, R.J.; Kloczko, N.; Meiman, J.G.; McLellan, S.L. Evaluation of Sampling, Analysis, and Normalization Methods for SARS-CoV-2 Concentrations in Wastewater to Assess COVID-19 Burdens in Wisconsin Communities. Acs EsT Water 2021, 1, 1955–1965. [Google Scholar] [CrossRef]

- Langeveld, J.; Schilperoort, R.; Heijnen, L.; Koopmans, M.; de Graaf, M.; Medema, G. Normalisation of SARS-CoV-2 Concentrations in Wastewater: The Use of Flow, Conductivity and CrAssphages. medRxiv 2021. [Google Scholar] [CrossRef]

- Ahmed, U.; Mumtaz, R.; Anwar, H.; Mumtaz, S.; Qamar, A.M. Water Quality Monitoring: From Conventional to Emerging Technologies. Water Supply 2019, 20, 28–45. [Google Scholar] [CrossRef]

- Banna, M.H.; Imran, S.; Francisque, A.; Najjaran, H.; Sadiq, R.; Rodriguez, M.; Hoorfar, M. Online Drinking Water Quality Monitoring: Review on Available and Emerging Technologies. Crit. Rev. Environ. Sci. Technol. 2014, 44, 1370–1421. [Google Scholar] [CrossRef]

- Fulton, J.W.; Anderson, I.E.; Chiu, C.-L.; Sommer, W.; Adams, J.D.; Moramarco, T.; Bjerklie, D.M.; Fulford, J.M.; Sloan, J.L.; Best, H.R.; et al. QCam: SUAS-Based Doppler Radar for Measuring River Discharge. Remote Sens. 2020, 12, 3317. [Google Scholar] [CrossRef]

- Bonhomme, C.; Petrucci, G. Should We Trust Build-up/Wash-off Water Quality Models at the Scale of Urban Catchments? Water Res. 2017, 108, 422–431. [Google Scholar] [CrossRef]

- Hassard, F.; Lundy, L.; Singer, A.C.; Grimsley, J.; Di Cesare, M. Innovation in Wastewater Near-Source Tracking for Rapid Identification of COVID-19 in Schools. Lancet Microbe 2021, 2, e4–e5. [Google Scholar] [CrossRef]

- On the Derivation of Flow Rating Curves in Data-Scarce Environments|Elsevier Enhanced Reader. Available online: https://reader.elsevier.com/reader/sd/pii/S0022169418303111?token=E7BF89DB02F822C933091A38091751208C04D135804463AABDF46E53F598519B735CAC22AECF982A37CAD1857634B495&originRegion=us-east-1&originCreation=20220916025705 (accessed on 16 September 2022).

- Baldassarre, G.D.; Montanari, A. Uncertainty in River Discharge Observations: A Quantitative Analysis. Hydrol Earth Syst Sci 2009, 9, 913–921. [Google Scholar] [CrossRef]

- Alimenti, F.; Bonafoni, S.; Gallo, E.; Palazzi, V.; Vincenti Gatti, R.; Mezzanotte, P.; Roselli, L.; Zito, D.; Barbetta, S.; Corradini, C.; et al. Noncontact Measurement of River Surface Velocity and Discharge Estimation With a Low-Cost Doppler Radar Sensor. IEEE Trans. Geosci. Remote Sens. 2020, 58, 5195–5207. [Google Scholar] [CrossRef]

- Chang, C.-C.; Wu, C.-T.; Lin, Y.-B.; Gu, M.-H. Water Velocimeter and Turbidity-Meter Using Visible Light Communication Modules. In Proceedings of the SENSORS, 2013 IEEE, Baltimore, MD, USA, 3–6 November 2013; pp. 1–4. [Google Scholar]

- Waghmare, A.; Naik, A.A. Water Velocity Measurement Using Contact and Non-Contact Type Sensor. In Proceedings of the 2015 Communication, Control and Intelligent Systems (CCIS), Mathura, India, 7–8 November 2015; pp. 334–338. [Google Scholar]

- Harija, H.; George, B.; Tangirala, A.K. A Cantilever-Based Flow Sensor for Domestic and Agricultural Water Supply System. IEEE Sens. J. 2021, 21, 27147–27156. [Google Scholar] [CrossRef]

- Ristolainen, A.; Tuhtan, J.A.; Kruusmaa, M. Continuous, Near-Bed Current Velocity Estimation Using Pressure and Inertial Sensing. IEEE Sens. J. 2019, 19, 12398–12406. [Google Scholar] [CrossRef]

- Bolognesi, M.; Farina, G.; Alvisi, S.; Franchini, M.; Pellegrinelli, A.; Russo, P. Measurement of Surface Velocity in Open Channels Using a Lightweight Remotely Piloted Aircraft System. Geomat. Nat. Hazards Risk 2017, 8, 73–86. [Google Scholar] [CrossRef]

- Zhao, W.; Jiang, Y.; Huang, C. A New Ultrasonic Flowmeter with Low Power Consumption for Small Pipeline Applications. In Proceedings of the 2016 IEEE International Instrumentation and Measurement Technology Conference Proceedings, Taipei, Taiwan, 23-26 May 2016; pp. 1–6. [Google Scholar]

- Godley, A. Flow Measurement in Partially Filled Closed Conduits. Flow Meas. Instrum. 2002, 13, 197–201. [Google Scholar] [CrossRef]

- Brody, W.R.; Meindl, J.D. Theoretical Analysis of the CW Doppler Ultrasonic Flowmeter. IEEE Trans. Biomed. Eng. 1974, BME-21, 183–192. [Google Scholar] [CrossRef]

- Kouame, D.; Girault, J.M.; Patat, F. High Resolution Processing Techniques for Ultrasound Doppler Velocimetry in the Presence of Colored Noise. I. Nonstationary Methods. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2003, 50, 257–266. [Google Scholar] [CrossRef]

- Maxim Integrated MAX7375 Datasheet. Available online: https://datasheets.maximintegrated.com/en/ds/MAX7375.pdf (accessed on 11 October 2020).

- HACH Submerged Area/Velocity Sensor and AV9000. Available online: https://au.hach.com/asset-get.download.jsa?id=8289724802 (accessed on 30 November 2020).

- SonTek SonTek-IQ Series. Available online: https://www.ysi.com/File%20Library/Documents/Brochures%20and%20Catalogs/sontek-iq-brochure.pdf (accessed on 6 July 2022).

- Technical Data OTT SLD—Side Looking Doppler Sensor 2020. Available online: https://www.ott.com/products/water-flow-3/ott-sld-side-looking-doppler-sensor-970/productAction/outputAsPdf/ (accessed on 6 July 2022).

- NXP SA612A Double-Balanced Mixer and Oscillator. Available online: https://www.nxp.com/docs/en/data-sheet/SA612A.pdf (accessed on 30 November 2020).

- Wongsaroj, W.; Hamdani, A.; Thong-un, N.; Takahashi, H.; Kikura, H. Ultrasonic Measurement of Velocity Profile on Bubbly Flow Using Fast Fourier Transform (FFT) Technique. IOP Conf. Ser. Mater. Sci. Eng. 2017, 249, 012011. [Google Scholar] [CrossRef]

- Bonakdari, H.; Zinatizadeh, A.A. Influence of Position and Type of Doppler Flow Meters on Flow-Rate Measurement in Sewers Using Computational Fluid Dynamic. Flow Meas. Instrum. 2011, 22, 225–234. [Google Scholar] [CrossRef]

- Solomon, O.M., Jr. PSD Computations Using Welch’s Method. [Power Spectral Density (PSD)]; Office of Scientific: Washington, DC, USA, 1991. [Google Scholar] [CrossRef]

- Arduino.cc Arduino UNO R3. Available online: https://docs.arduino.cc/static/e97e4d2b91c275698396fc4090e007ac/A000066-datasheet.pdf (accessed on 6 July 2022).

- Blake, J.R.; Packman, J.C. Identification and Correction of Water Velocity Measurement Errors Associated with Ultrasonic Doppler Flow Monitoring. Water Environ. J. 2008, 22, 155–167. [Google Scholar] [CrossRef]

- Virtanen, P.; Gommers, R.; Oliphant, T.E.; Haberland, M.; Reddy, T.; Cournapeau, D.; Burovski, E.; Peterson, P.; Weckesser, W.; Bright, J.; et al. SciPy 1.0: Fundamental Algorithms for Scientific Computing in Python. Nat. Methods 2020, 17, 261–272. [Google Scholar] [CrossRef] [PubMed]

- McCarthy, D.T.; Deletic, A.; Mitchell, V.G.; Fletcher, T.D.; Diaper, C. Uncertainties in Stormwater E. coli Levels. Water Res. 2008, 42, 1812–1824. [Google Scholar] [CrossRef]

- Bertrand-Krajewski, J.-L.; Bardin, J.-P.; Mourad, M.; Béranger, Y. Accounting for Sensor Calibration, Concentration Heterogeneity, Measurement and Sampling Uncertainties in Monitoring Urban Drainage Systems. Water Sci. Technol. 2003, 47, 95–102. [Google Scholar] [CrossRef]

- Zhuang, Y.; Chen, L.; Wang, X.S.; Lian, J. A Weighted Moving Average-Based Approach for Cleaning Sensor Data. In Proceedings of the 27th International Conference on Distributed Computing Systems (ICDCS ’07), Toronto, ON, Canada, 25–27 June 2007; p. 38. [Google Scholar]

- Greenspan, M.; Tschiegg, C.E. Tables of the Speed of Sound in Water. J. Acoust. Soc. Am. 1959, 31, 75–76. [Google Scholar] [CrossRef]

| Mode | Current |

|---|---|

| Measurement | 27 mA |

| Active | 12.8 mA |

| Sleep | 100 µA |

| Yearly power use (6 min measurement intervals) | 3.5 Ah |

| Power Usage | This Work | HACH Submerged Area/Velocity Sensor [24] | SonTek-IQ [25] | OTT SLD [26] |

|---|---|---|---|---|

| Energy per measurement | 0.6 J | <15 J | not specified | not specified |

| Average continuous power consumption | 2 mW | <1.2 W | >20 mW | 50–500 mW |

| Supply voltage | 5 V | 9–15 V | 9–15 V | 12–16 V |

| Velocity Range (mm/s) | Number of Points | RMS Error (%) | Mean Error (%) |

|---|---|---|---|

| 0 to 200 | 15,867 | 65 | +30 |

| 200 to 400 | 6204 | 43 | −23 |

| 400 to 600 | 2463 | 29 | −3 |

| 600 to 800 | 2516 | 23 | +10 |

| 800 to 1000 | 1130 | 17 | +1 |

| 1000 to 1200 | 70 | 20 | −11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Catsamas, S.; Shi, B.; Deletic, B.; Wang, M.; McCarthy, D.T. A Low-Cost, Low-Power Water Velocity Sensor Utilizing Acoustic Doppler Measurement. Sensors 2022, 22, 7451. https://doi.org/10.3390/s22197451

Catsamas S, Shi B, Deletic B, Wang M, McCarthy DT. A Low-Cost, Low-Power Water Velocity Sensor Utilizing Acoustic Doppler Measurement. Sensors. 2022; 22(19):7451. https://doi.org/10.3390/s22197451

Chicago/Turabian StyleCatsamas, Stephen, Baiqian Shi, Boris Deletic, Miao Wang, and David T. McCarthy. 2022. "A Low-Cost, Low-Power Water Velocity Sensor Utilizing Acoustic Doppler Measurement" Sensors 22, no. 19: 7451. https://doi.org/10.3390/s22197451