Towards Online Ageing Detection in Transformer Oil: A Review

Abstract

:1. Introduction

2. Review Methodology

3. Types of Transformer Oil

4. Transformer Oil Ageing Characterisation Techniques

4.1. Breakdown Voltage (BDV) Test

4.2. Fourier Transform Infrared Spectroscopy (FTIR)

4.3. Dissolved Gas Analysis (DGA)

4.4. Photoluminescence (PL) Spectroscopy and Ultraviolet-Visible Spectroscopy (UV-Vis)

4.5. Total Acid Number (TAN)

4.6. Interfacial Tension (IFT)

5. Classification of Service-Aged Insulating Oil

6. Accelerated Thermal Ageing

7. Cross-Capacitive and Fibre Optic Ageing Detection Sensors

7.1. Cross-Capacitive Sensor

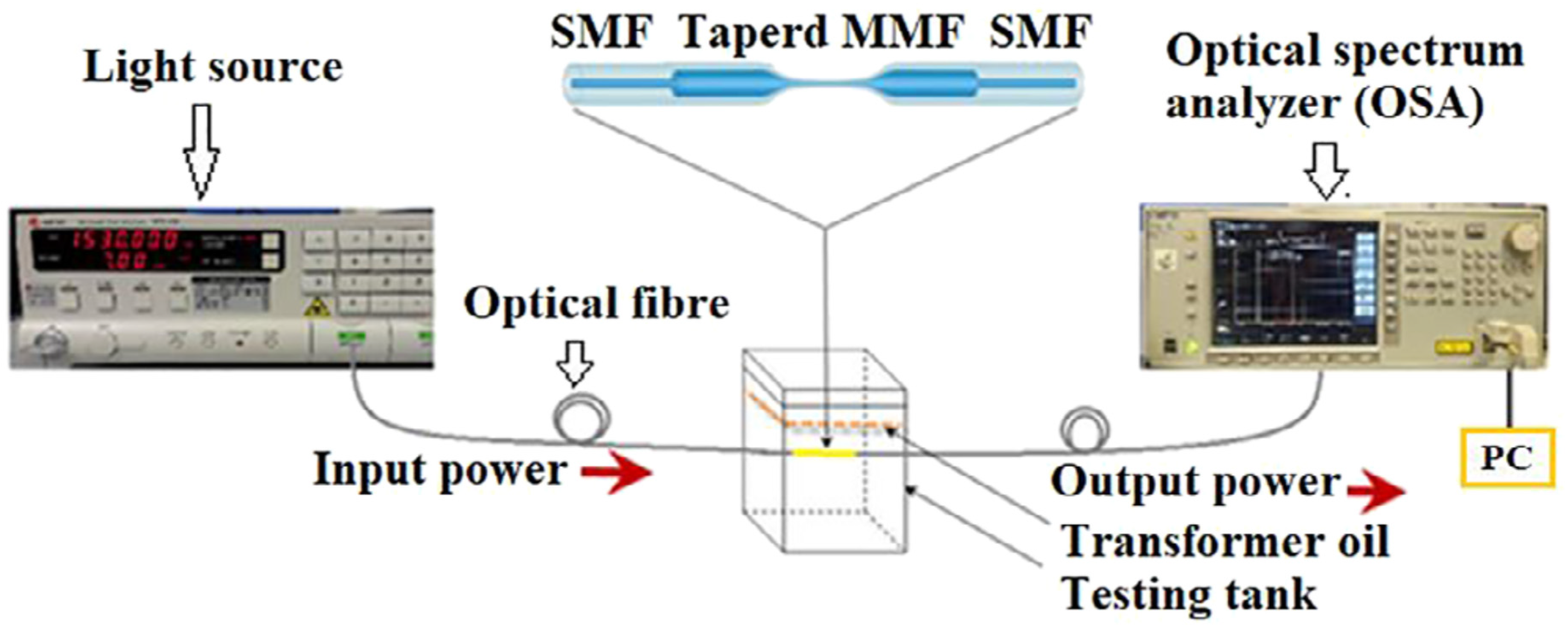

7.2. Fibre Optic Sensor

Evanescent Wave Absorption Principle for Online Ageing Detection

8. Superhydrophobicity and Online Ageing Detection

9. Machine Learning Models for Online Ageing Detection

10. IoT and Online Ageing Detection

11. Example of Related Systems

11.1. A Non-Destructive, Non-Intrusive Design Using an Antenna

11.2. An Intrusive Ageing Detection Design Using a Cross-Capacitance Sensor

11.3. An Intrusive Ageing Detection Design Using Fibre Optic Technology

12. Discussion, Conclusions, and Future Work

12.1. Discussion and Conclusions

12.2. Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviation

| ABP | Ageing ByProducts |

| ATT | Accelerated Thermal Temperature |

| BOT | Base Operating Temperature |

| BDV | Breakdown Voltage |

| DDF | Dielectric Dissipation Factor |

| DFB | Distributed Feedback |

| DSC | Differential Scanning Calorimetry |

| DGA | Dissolved Gas Analysis |

| EFA-FOS | Evanescent Field Absorption-based Fibre Optic Sensor |

| FMECA | Failure Mode Effect and Criticality Analysis |

| FTIR | Fourier Transform Infrared Spectroscopy |

| HMWCA | High Molecular Weight Carboxylic Acids |

| IoT | Internet of Things |

| LED | Light Emitting Diode |

| LIBS | Laser Induced Breakdown Spectroscopy |

| LMWCA | Low Molecular Weight Carboxylic Acids |

| MO | Mineral Oil |

| MTTR | Mean Time to Repair |

| NN | Neutralisation Number |

| OFS | Optical Fibre Sensor |

| OQIN | Oil Quality Index |

| TAN | Total Acid Number |

| TF | Time Factor |

| TGA | Thermogravimetric Analysis |

| UV-Vis | Ultraviolet-Visible Spectroscopy |

| VCSELs | Vertical Cavity Surface Emitting Lasers |

| WCA | Water Contact Angle |

References

- Khalil, M. Qualitative and Quantitative FMECA on 220 kV Power Transformers. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2018; pp. 1–8. [Google Scholar]

- Balamurugan, S.; Ananthanarayanan, R. Condition Monitoring Techniques of Dielectrics in Liquid Immersed Power Transformers—A Review. In Proceedings of the 2018 IEEE Industry Applications Society Annual Meeting (IAS), Portland, OR, USA, 23–27 September 2018; pp. 1–7. [Google Scholar]

- Paul, D.; Goswami, A.K. Determination of Health Index of Insulating Oil of In-Service Transformer & Reactors based on IFT Predicted by Multi-Gene Symbolic Regression. IEEE Trans. Ind. Appl. 2022, 58, 5935–5943. [Google Scholar]

- Martins, M.A.G.; Gomes, A.R. Comparative study of the thermal degradation of synthetic and natural esters and mineral oil: Effect of oil type in the thermal degradation of insulating kraft paper. IEEE Electr. Insul. Mag. 2012, 2, 22–28. [Google Scholar] [CrossRef]

- Hadjadj, Y.; Fofana, I.; Sabau, J.; Briosso, E. Assessing insulating oil degradation by means of turbidity and UV/VIS spectrophotometry measurements. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2653–2660. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, W.; Zhou, W.; Zhang, R.; Song, R.; Yang, D. A Few-shot Learning Method for Aging Diagnosis of Oil-paper Insulation by Raman Spectroscopy Based on Graph Theory. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 1892–1900. [Google Scholar] [CrossRef]

- Alshehawy, A.; Mansour, D.-E.; Ghali, M.; Lehtonen, M.; Darwish, M. Photoluminescence Spectroscopy Measurements for Effective Condition Assessment of Transformer Insulating Oil. Processes 2021, 9, 732. [Google Scholar] [CrossRef]

- Qian, Y.; Wang, Y.; Zhao, Y.; Fan, S.; Fu, Q.; Wang, H. Application of Infrared Spectroscopy in Oil Quality Detection. In Proceedings of the 2020 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Beijing, China, 6–10 September 2020; pp. 1–4. [Google Scholar]

- Sangineni, R.; Nayak, S.K.; Becerra, M. A Non-intrusive and Non-destructive Technique for Condition Assessment of Transformer Liquid Insulation. IEEE Trans. Dielectr. Electr. Insul. 2022, 29, 693–700. [Google Scholar] [CrossRef]

- Razzaq, A.; Zainuddin, H.; Hanaffi, F.; Chyad, R.M.; Abdul Razak, H.; Latiff, A.A. Measurement of ester-based transformer oil aging using tapered single mode-multimode-single mode fiber structure. Microw. Opt. Technol. Lett. 2020, 62, 559–564. [Google Scholar] [CrossRef]

- Rao, U.M.; Fofana, I.; Betie, A.; Senoussaoui, M.L.; Brahami, M.; Briosso, E. Condition monitoring of in-service oil-filled transformers: Case studies and experience. IEEE Electr. Insul. Mag. 2019, 35, 33–42. [Google Scholar] [CrossRef]

- Mihajlovic, D.; Ivancevic, V.; Vasovic, V.; Lukic, J. Cellulose Degradation and Transformer Fault Detection by the Application of Integrated Analyses of Gases and Low Molecular Weight Alcohols Dissolved in Mineral Oil. Energies 2022, 15, 5669. [Google Scholar] [CrossRef]

- Polužanski, V.; Kartalović, N.; Nikolić, B. Impact of Power Transformer Oil-Temperature on the Measurement Uncertainty of All-Acoustic Non-Iterative Partial Discharge Location. Materials 2021, 14, 1385. [Google Scholar] [CrossRef]

- Sarathi, R.; Koperundevi, G. Understanding the Discharge Activities in Transformer Oil under AC and DC Voltage Adopting UHF Technique. Int. J. Chem. Mol. Eng. 2008, 2, 49–56. [Google Scholar]

- Niasar, M.G.; Edin, H.; Wang, X.; Clemence, R. Partial Discharge Characteristics Due to Air and Water Vapor Bubbles in Oil. Int. Symp. High Volt. Eng. 2011, 11–21. Available online: https://www.researchgate.net/publication/264561918_Partial_discharge_characteristics_due_to_air_and_water_vapor_bubbles_in_oil (accessed on 13 June 2022).

- Alshehawy, A.M.; Mansour, D.-E.A.; Ghali, M. Condition Assessment of Aged Transformer Oil Using Photoluminescence-Based Features. In Proceedings of the 2021 IEEE 5th International Conference on Condition Assessment Techniques in Electrical Systems (CATCON), Kozhikode, India, 3–5 December 2021; pp. 282–285. [Google Scholar]

- Sai, R.S.; Rafi, J.; Farook, S.; Kumar, N.; Parthasarathy, M.; Bakkiyaraj, R.A. Degradation studies of electrical, physical and chemical properties of aged transformer oil. J. Phys. Conf. Ser. 2020, 1706, 012056. [Google Scholar] [CrossRef]

- Fofana, I. 50 years in the development of insulating liquids. IEEE Electr. Insul. Mag. 2013, 29, 13–25. [Google Scholar] [CrossRef]

- Munajad, A.; Subroto, C. Fourier Transform Infrared (FTIR) Spectroscopy Analysis of Transformer Paper in Mineral Oil-Paper Composite Insulation under Accelerated Thermal Aging. Energies 2018, 11, 364. [Google Scholar] [CrossRef] [Green Version]

- Bandara, K.; Ekanayake, C.; Saha, T.K. Compare the performance of natural ester with synthetic ester as transformer insulating oil. In Proceedings of the 2015 IEEE 11th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Sydney, Australia, 19–22 July 2015; pp. 975–978. [Google Scholar]

- Perrier, C.; Marugan, M.; Beroual, A. DGA comparison between ester and mineral oils. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1609–1614. [Google Scholar] [CrossRef]

- Mehta, D.M.; Kundu, P.; Chowdhury, A.; Lakhiani, V.K.; Jhala, A.S. A review of critical evaluation of natural ester vis-a-vis mineral oil insulating liquid for use in transformers: Part II. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1705–1712. [Google Scholar] [CrossRef]

- Gockenbach, E.; Borsi, H. Natural and Synthetic Ester Liquids as alternative to mineral oil for power transformers. In Proceedings of the 2008 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Quebec, QC, Canada, 26–29 October 2008; pp. 521–524. [Google Scholar]

- Jing, Y.; Timoshkin, I.V.; Wilson, M.P.; Given, M.J.; MacGregor, S.J.; Wang, T.; Lehr, J.M. Dielectric properties of natural ester, synthetic ester midel 7131 and mineral oil diala D. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 644–652. [Google Scholar] [CrossRef] [Green Version]

- Housel, T. Synthetic Esters: Engineered to Perform. 2022. Available online: https://www.machinerylubrication.com/Read/29703/synthetic-esters-perform (accessed on 6 September 2022).

- Maharana, M.; Nayak, S.K.; Sahoo, N. Karanji oil as a potential dielectrics liquid for transformer. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1871–1879. [Google Scholar] [CrossRef]

- Naranpanawe, W.M.L.B.; Fernando, M.A.R.M.; Kumara, J.R.S.S.; Naramapanawa, E.M.S.N.; Kalpage, C.S. Performance analysis of natural esters as transformer liquid insulation-Coconut, castor and sesame oils. In Proceedings of the 2013 IEEE 8th International Conference on Industrial and Information Systems, Kandy, Sri Lanka, 17–20 December 2013; pp. 105–109. [Google Scholar]

- Monzón-Verona, J.M.; González-Domínguez, P.I.; García-Alonso, S.; Vaswani Reboso, J. Characterization of Dielectric Oil with a Low-Cost CMOS Imaging Sensor and a New Electric Permittivity Matrix Using the 3D Cell Method. Sensors 2021, 21, 7380. [Google Scholar] [CrossRef]

- Hadjadj, Y.; Fofana, I.; Jalbert, J. Insulating oil decaying assessment by FTIR and UV-Vis spectrophotometry measurements. In Proceedings of the 2013 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Shenzhen, China, 20–23 October 2013; pp. 1310–1313. [Google Scholar]

- BS EN 60060-1:2010; High-Voltage Test Techniques. General Definitions and Test Requirements. 2011. Available online: https://bsol.bsigroup.com/en/Bsol-Item-Detail-Page/?pid=000000000030200685 (accessed on 13 June 2022).

- BS EN 60422:2006; Mineral Insulating Oils in Electrical Equipment. Supervision and Maintenance Guidance. 2009. Available online: https://bsol.bsigroup.com/en/Bsol-Item-Detail-Page/?pid=000000000030081812 (accessed on 13 June 2022).

- Hayber, E.; Tabaru, T.E.; Güçyetmez, M. Evanescent Field Absorption-Based Fiber Optic Sensor for Detecting Power Transformer Oil Degradation. Fiber Integr. Opt. 2021, 40, 229–248. [Google Scholar] [CrossRef]

- Smith, B.C. Fundamentals of Fourier Transform Infrared Spectroscopy; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Alshehawy, A.M.; Mansour, D.-E.A.; Ghali, M.; Rezk, A. Evaluating the impact of aging in field transformer oil using optical spectroscopy techniques. In Proceedings of the 2017 IEEE 19th International Conference on Dielectric Liquids (ICDL), Manchester, UK, 25–29 June 2017; pp. 1–4. [Google Scholar]

- Liu, Y.; Bao, K.; Wang, Q.; Zio, E. Application of FTIR Method to Monitor the Service Condition of Used Diesel Engine Lubricant Oil. In Proceedings of the 2019 4th International Conference on System Reliability and Safety (ICSRS), Rome, Italy, 20–22 November 2019; pp. 175–180. [Google Scholar]

- BS EN 60567:1993; IEC 60567:1992: Guide for the Sampling of Gases and of Oil from Oil-Filled Electrical Equipment and for the Analysis of Free and Dissolved Gases. 1993. Available online: https://bsol.bsigroup.com/en/Bsol-Item-Detail-Page/?pid=000000000000292653 (accessed on 13 June 2022).

- IEC 60599:1999; Mineral Oil-Impregnated Electrical Equipment in Service-Guide to the Interpretation of Dissolved and Free Gases Analysis. 2000. Available online: https://bsol.bsigroup.com/en/ (accessed on 13 June 2022).

- N’cho, J.S.; Fofana, I. Review of Fiber Optic Diagnostic Techniques for Power Transformers. Energies 2020, 13, 1789. [Google Scholar] [CrossRef] [Green Version]

- Adams, M.J.; Romeo, M.J.; Rawson, P. FTIR analysis and monitoring of synthetic aviation engine oils. Talanta 2007, 73, 629–634. [Google Scholar] [CrossRef]

- IEEE Guide for Acceptance and Maintenance of Insulating Oil in Equipment. 2006. Available online: https://ieeexplore.ieee.org/document/7442048 (accessed on 13 June 2022).

- BS EN 62021-1:2003; Insulating Liquids. Determination of Acidity. Automatic Potentiometric Titration. 2003. Available online: https://bsol.bsigroup.com/en/Bsol-Item-Detail-Page/?pid=000000000030069710 (accessed on 13 June 2022).

- BS EN 62021-2:2007; Insulating Liquids. Determination of Acidity. Colourimetric Titration. 2007. Available online: https://bsol.bsigroup.com/en/Bsol-Item-Detail-Page/?pid=000000000030156457 (accessed on 13 June 2022).

- Danesh, A. PVT and Phase Behaviour of Petroleum Reservoir Fluids; Elsevier: Amsterdam, The Netherlands, 2001. [Google Scholar]

- Interfacial Tension Measurement. 2022. Available online: https://www.biolinscientific.com/measurements/interfacial-tension#:~:text=Interfacial%20tension%20measurement%20between%20two,is%20immersed%20in%20another%20liquid (accessed on 13 June 2022).

- Fofana, I.; Bouaïcha, A.; Hadjadj, Y.; N’Cho, J.S.; Aka-Ngnui, T.; Béroual, A. Early stage detection of insulating oil decaying. In Proceedings of the 2010 Annual Report Conference on Electrical Insulation and Dielectic Phenomena, Cancun, Mexico, 16–19 October 2011; pp. 1–4. [Google Scholar]

- Gray, I. A Guide to Transformer Oil Analysis. Transformer Chemistry Services. IAR Gray 2009, 1–12. [Google Scholar]

- BS EN IEC 62961:2018; Insulating Liquids. Test Methods for the Determination of Interfacial Tension of Insulating Liquids. Determination with the Ring Method. 2018. Available online: https://bsol.bsigroup.com/en/Bsol-Item-Detail-Page/?pid=000000000030352874 (accessed on 13 June 2022).

- Wilhelmy Plate Method. 2022. Available online: https://www.kruss-scientific.com/en/know-how/glossary/wilhelmy-plate-method (accessed on 13 June 2022).

- Bailey, A. Surface and Interfacial Tension. 2022. Available online: https://thermopedia.com/content/30/ (accessed on 13 June 2022).

- Ghosh, D.; Khastgir, D. Degradation and Stability of Polymeric High-Voltage Insulators and Prediction of Their Service Life through Environmental and Accelerated Aging Processes. ACS Omega 2018, 3, 11317–11330. [Google Scholar] [CrossRef] [PubMed]

- Vasovic, V.; Lukic, J.; Mihajlovic, D.; Pejovic, B.; Radakovic, Z.; Radoman, U.; Orlovic, A. Aging of transformer insulation—Experimental transformers and laboratory models with different moisture contents: Part I—DP and furans aging profiles. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 1840–1846. [Google Scholar] [CrossRef]

- Fofana, I.; Bouaïcha, A.; Farzaneh, M.; Volat, C.; Sabau, J. On the stability of mineral insulating oils under electrical stress. In Proceedings of the 2009 IEEE Electrical Insulation Conference, Montreal, QC, Canada, 31 May–3 June 2009. [Google Scholar]

- Bouaicha, A.; Fofana, I.; Farzaneh, M. Application of modern diagnostic techniques to assess the condition of oil and pressboard. In Proceedings of the 2008 IEEE International Conference on Dielectric Liquids, Poitiers, France, 30 June–3 July 2008; pp. 1–4. [Google Scholar]

- D1934; Standard Test Method for Oxidative Aging of Electrical Insulating Petroleum Oils by Open-Beaker Method. 2012. Available online: http://www.astm.org/Standards/D1934 (accessed on 13 June 2022).

- El-Hag, A. Application of Machine Learning in Outdoor Insulators Condition Monitoring and Diagnostics. IEEE Instrum. Meas. Mag. 2021, 24, 101–108. [Google Scholar] [CrossRef]

- Rahman, O.; Islam, T.; Khera, N.; Khan, S.A. A Novel Application of the Cross-Capacitive Sensor in Real-Time Condition Monitoring of Transformer Oil. IEEE Trans. Instrum. Meas. 2021, 70, 1–12. [Google Scholar] [CrossRef]

- Rahman, O.; Islam, T.; Ahmad, A.; Parveen, S.; Kheraand, N.; Khan, S.A. Cross Capacitance Sensor for Insulation Oil Testing. IEEE Sens. J. 2021, 21, 20980–20989. [Google Scholar] [CrossRef]

- Mahanta, D.K.; Laskar, S. Water Quantity-Based Quality Measurement of Transformer Oil Using Polymer Optical Fiber as Sensor. IEEE Sens. J. 2018, 18, 1506–1512. [Google Scholar] [CrossRef]

- Maria de Fátima, F.D.; Radwan, A. Optical Fiber Sensors for IoT and Smart Devices; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Lee, B.H.; Kim, Y.H.; Park, K.S.; Eom, J.B.; Kim, M.J.; Rho, B.S.; Choi, H.Y. Interferometric Fiber Optic Sensors. Sensors 2012, 12, 2467–2486. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Riziotis, C.; El Sachat, A.; Markos, C.; Velanas, P.; Meristoudi, A.; Papadopoulos, A. Assessment of fiber optic sensors for aging monitoring of industrial liquid coolants. Opt. Compon. Mater. XII 2015, 9359, 308–315. [Google Scholar] [CrossRef]

- Arshad; Momen, G.; Farzaneh, M.; Nekahi, A. Properties and applications of superhydrophobic coatings in high voltage outdoor insulation: A review. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3630–3646. [Google Scholar] [CrossRef]

- Sharma, K.; Hooda, A.; Goyat, M.; Rai, R.; Mittal, A. A review on challenges, recent progress and applications of silica nanoparticles based superhydrophobic coatings. Ceram. Int. 2022, 48, 5922–5938. [Google Scholar] [CrossRef]

- Esmeryan, K.D.; I Radeva, E.; Avramov, I.D. Durable superhydrophobic carbon soot coatings for sensor applications. J. Phys. D Appl. Phys. 2015, 49, 025309. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar Sahani, A. Role of superhydrophobic coatings in biomedical applications. Mater. Today Proc. 2021, 45, 5655–5659. [Google Scholar] [CrossRef]

- Song, J.; Fan, L. Temperature dependence of the contact angle of water: A review of research progress, theoretical understanding, and implications for boiling heat transfer. Adv. Colloid Interface Sci. 2021, 288, 102339. [Google Scholar] [CrossRef] [PubMed]

- Sethi, S.K.; Manik, G. Recent Progress in Super Hydrophobic/Hydrophilic Self-Cleaning Surfaces for Various Industrial Applications: A Review. Polym.-Plast. Technol. Eng. 2018, 57, 1932–1952. [Google Scholar] [CrossRef]

- Shirtcliffe, N.J.; McHale, G.; Atherton, S.; Newton, M.I. An introduction to superhydrophobicity. Adv. Colloid Interface Sci. 2010, 161, 124–138. [Google Scholar] [CrossRef] [Green Version]

- Li, X.-M.; Reinhoudt, D.; Crego-Calama, M. What do we need for a superhydrophobic surface? A review on the recent progress in the preparation of superhydrophobic surfaces. Chem. Soc. Rev. 2007, 36, 1350–1368. [Google Scholar] [CrossRef]

- Lakshmi, R.; Bharathidasan, T.; Basu, B.J. Superhydrophobic sol–gel nanocomposite coatings with enhanced hardness. Appl. Surf. Sci. 2011, 257, 10421–10426. [Google Scholar] [CrossRef]

- Fernández-Blázquez, J.P.; Fell, D.; Bonaccurso, E.; del Campo, A. Superhydrophilic and superhydrophobic nanostructured surfaces via plasma treatment. J. Colloid Interface Sci. 2011, 357, 234–238. [Google Scholar] [CrossRef] [PubMed]

- Jafari, R.; Asadollahi, S.; Farzaneh, M. Applications of Plasma Technology in Development of Superhydrophobic Surfaces. Plasma Chem. Plasma Process. 2012, 33, 177–200. [Google Scholar] [CrossRef]

- Song, X.; Zhai, J.; Wang, Y.; Jiang, L. Fabrication of Superhydrophobic Surfaces by Self-Assembly and Their Water-Adhesion Properties. J. Phys. Chem. B 2005, 109, 4048–4052. [Google Scholar] [CrossRef] [PubMed]

- Ji, J.; Fu, J.; Shen, J. Fabrication of a Superhydrophobic Surface from the Amplified Exponential Growth of a Multilayer. Adv. Mater. 2007, 19, 2411. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, H.; Sun, J.; Shen, J. Layer-by-Layer Deposition of Poly(diallyldimethylammonium chloride) and Sodium Silicate Multilayers on Silica-Sphere-Coated Substrate—Facile Method to Prepare a Superhydrophobic Surface. Chem. Mater. 2007, 19, 948–953. [Google Scholar] [CrossRef]

- Momen, G.; Farzaneh, M.; Jafari, R. Wettability behaviour of RTV silicone rubber coated on nanostructured aluminium surface. Appl. Surf. Sci. 2011, 257, 6489–6493. [Google Scholar] [CrossRef]

- Ishizaki, T.; Hieda, J.; Saito, N.; Saito, N.; Takai, O. Corrosion resistance and chemical stability of super-hydrophobic film deposited on magnesium alloy AZ31 by microwave plasma-enhanced chemical vapor deposition. Electrochim. Acta 2010, 55, 7094–7101. [Google Scholar] [CrossRef]

- Wu, H.; Luo, J.; Huang, X.; Wang, L.; Guo, Z.; Liang, J.; Zhang, S.; Xue, H.; Gao, J. Superhydrophobic, Mechanically Durable Coatings for Controllable Light and Magnetism Driven Actuators. J. Colloid Interface Sci. 2021, 603, 282–290. [Google Scholar] [CrossRef] [PubMed]

- Kissell, R.; Poserina, J. Chapter 2—Regression Models. In Optimal Sports Math, Statistics, and Fantasy; Kissell, R., Poserina, J., Eds.; Academic Press: Cambridge, MA, USA, 2017; pp. 39–67. [Google Scholar]

- Su, X.; Yan, X.; Tsai, C. Linear regression. WIREs Comp. Stat. 2012, 4, 275–294. [Google Scholar] [CrossRef]

- Tong, J.C.; Ranganathan, S. Computational T cell vaccine design. In Computer-Aided Vaccine Design; Tong, J.C., Ranganathan, S., Eds.; Woodhead Publishing: Cambridge, UK, 2013; pp. 59–86. [Google Scholar]

- de Ville, B. Decision trees. WIREs Comp. Stat. 2013, 5, 448–455. [Google Scholar] [CrossRef]

- Titterington, M. Neural networks. WIREs Comp. Stat. 2010, 2, 1–8. [Google Scholar] [CrossRef]

- Polužanski, V.; Kovacevic, U.; Bacanin, N.; Rashid, T.A.; Stojanovic, S.; Nikolic, B. Application of Machine Learning to Express Measurement Uncertainty. Appl. Sci. 2022, 12, 8581. [Google Scholar] [CrossRef]

- Siddique, T.; Mahmud, M.S.; Keesee, A.M.; Ngwira, C.M.; Connor, H. A Survey of Uncertainty Quantification in Machine Learning for Space Weather Prediction. Geosciences 2022, 12, 27. [Google Scholar] [CrossRef]

- Li, S.; Xu, L.D.; Zhao, S. The internet of things: A survey. Inf. Syst. Front. 2014, 17, 243–259. [Google Scholar] [CrossRef]

- Smanchat, S. Internet of things: A review of applications and technologies. Suranaree J. Sci. Technol. 2014, 21, 359–374. [Google Scholar]

- Lo, C.; Chen, C.; Zhong, R.Y. A review of digital twin in product design and development. Adv. Eng. Inform. 2021, 48, 101297. [Google Scholar] [CrossRef]

- Bandyopadhyay, D.; Sen, J. Internet of Things: Applications and Challenges in Technology and Standardization. Wirel. Pers Commun. 2011, 58, 49–69. [Google Scholar] [CrossRef] [Green Version]

- Razali, M.A.A.; Kassim, M.; Sulaiman, N.A.; Saaidin, S. A ThingSpeak IoT on Real Time Room Condition Monitoring System. In Proceedings of the 2020 IEEE International Conference on Automatic Control and Intelligent Systems (I2CACIS), Shah Alam, Malaysia, 20 June 2020; pp. 206–211. [Google Scholar]

- Nasution, T.H.; Muchtar, M.A.; Seniman, S.; Siregar, I. Monitoring temperature and humidity of server room using Lattepanda and ThingSpeak. J. Phys. Conf. Ser. 2019, 1235, 12068. [Google Scholar] [CrossRef]

- Miry, A.H.; Aramice, G.A. Water monitoring and analytic based thingspeak. Int. J. Electr. Comput. Eng. (Malacca Malacca) 2020, 10, 3588. [Google Scholar] [CrossRef]

- Kelechi, A.H.; Alsharif, M.H.; Agbaetuo, C.; Ubadike, O.; Aligbe, A.; Uthansakul, P.; Kannadasan, R.; Aly, A.A. Design of a Low-Cost Air Quality Monitoring System Using Arduino and ThingSpeak. Comput. Mater. Contin. 2022, 70, 151–169. [Google Scholar] [CrossRef]

- Sachenko, A.; Osolinskyi, O.; Bykovyy, P.; Dobrowolski, M.; Kochan, V. Development of the Flexible Traffic Control System Using the LabView and ThingSpeak. In Proceedings of the 2020 IEEE 11th International Conference on Dependable Systems, Services and Technologies (DESSERT), Kyiv, Ukraine, 14–18 May 2020; pp. 326–330. [Google Scholar]

- Ravindran, V.; Ponraj, R.; Krishnakumar, C.; Ragunathan, S.; Ramkumar, V.; Swaminathan, K. IoT-Based Smart Transformer Monitoring System with Raspberry Pi. In Proceedings of the 2021 Innovations in Power and Advanced Computing Technologies (i-PACT), Malaya, Kuala Lumpur, 27–29 November 2021; pp. 1–7. [Google Scholar]

- Mahanta, D.K.; Rahman, I. IoT Based Transformer Oil Temperature Monitoring System. In Proceedings of the 2022 International Conference on Sustainable Computing and Data Communication Systems (ICSCDS), Erode, India, 7–9 April 2022; pp. 975–978. [Google Scholar]

| Themes |

|---|

| 1. Review of various transformer oil types |

| 2. Review of transformer ageing characterisation techniques |

| 3. Review of various ageing classification techniques |

| 4. Accelerated thermal ageing technique |

| 5. Fiber-Optic Sensor |

| 6. Superhydrophobicity and online ageing detection |

| 7. Machine learning models for online ageing detection |

| 8. IoT and online ageing |

| 9. Review of related systems |

| Search Index | Specific Content |

|---|---|

| Research Question | How can ageing detection in transformer oil systems be improved? |

| Database | RefWorks Proquest, Elsevier Science Direct, IEEE Xplore, Google Scholar, GCU. Library (host to many databases) |

| Article Type | Scientific articles published in peer-reviewed journals and conferences, technical papers, patents, and generic materials relevant to the field. |

| Search Strings | HV, Insulator, Ageing, Sensor, Transformer Oil, Superhydrophobicity, IoT |

| Search Language | English |

| Research Theme Result Ratio | 96 out of 182 |

| Screening Procedure | Relevance to research topic/question(s) judged progressively by the contents of the title, abstract, conclusion/discussion, introduction, and methodology. |

| Themes | References |

|---|---|

| 1. Transformer oil types | [4,18,19,20,21,22,23,24,25,26,27] |

| 2. Review of transformer ageing characterisation techniques | [7,16,17,21,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49] |

| 3. Review of various ageing classification techniques | [29,46] |

| 4. Accelerated thermal ageing technique | [7,50,51,52,53,54] |

| 5. Sample ageing detection sensors | [32,38,55,56,57,58,59,60,61] |

| 6. An overview of superhydrophobicity | [62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78] |

| 7. Machine Learning and Uncertainty Quantification | [79,80,81,82,83,84,85] |

| 8. IoT and online ageing | [86,87,88,89,90,91,92,93,94,95,96] |

| 9. Review of related systems | [9,10,57] |

| S/N | Class | Variable | Range |

|---|---|---|---|

| 1. | Good Oil/Class A | NN | 0.00 to 0.03 |

| IFT | 45 to 30 | ||

| OQIN | 1500 to 1000 | ||

| 2. | Proposition A Oil/Class B | NN | 0.05 to 0.10 |

| IFT | 29.90 to 27.10 | ||

| OQIN | 600 to 271 | ||

| 3. | Marginal Oil/Class C | NN | 0.11 to 0.15 |

| IFT | 27 to 24 | ||

| OQIN | 245 to 160 | ||

| 4. | Bad Oil/Class D | NN | 0.16 to 0.40 |

| IFT | 23.9 to 18 | ||

| OQIN | 150 to 45 | ||

| 5. | Very Bad Oil/Class E | NN | 0.41 to 0.65 |

| IFT | 17.90 to 14 | ||

| OQIN | 44 to 22 | ||

| 6. | Extremely Bad Oil/Class F | NN | 0.66 to 1.50 |

| IFT | 13.90 to 9 | ||

| OQIN | 21 to 6 | ||

| 7. | Oil in Disastrous Condition/Class G | NN | 1.51 or more |

| IFT | 8.50 or less | ||

| OQIN | 6 or less |

| S/N | Sensor Type | Input/Output | Intrinsic/Destructive | Benefit/Limitation |

|---|---|---|---|---|

| 1. | Cross-Capacitive Sensors | Capacitance/Voltage | Yes/No | 1. Adaptable for various ageing feature detections. 2. Good Repeatability. 3. Requires a data card (AD7150). 4. It is temperature-independent. 5. Only sensitive to the parameter measured (transformer oil). 6. Prone to electromagnetic interference. |

| 2. | Fibre Optic Sensors | Light/Voltage or Current | Yes/No | 1. Potentially easy to install. 2. Allows for offline/online sensing. 3. Resistant to ionising radiation, electromagnetic interference and radio-frequency interference. 4. Explosion-proof. 5. Extended ageing detection applications. 6. Lightweight and high sensitivity. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elele, U.; Nekahi, A.; Arshad, A.; Fofana, I. Towards Online Ageing Detection in Transformer Oil: A Review. Sensors 2022, 22, 7923. https://doi.org/10.3390/s22207923

Elele U, Nekahi A, Arshad A, Fofana I. Towards Online Ageing Detection in Transformer Oil: A Review. Sensors. 2022; 22(20):7923. https://doi.org/10.3390/s22207923

Chicago/Turabian StyleElele, Ugochukwu, Azam Nekahi, Arshad Arshad, and Issouf Fofana. 2022. "Towards Online Ageing Detection in Transformer Oil: A Review" Sensors 22, no. 20: 7923. https://doi.org/10.3390/s22207923

APA StyleElele, U., Nekahi, A., Arshad, A., & Fofana, I. (2022). Towards Online Ageing Detection in Transformer Oil: A Review. Sensors, 22(20), 7923. https://doi.org/10.3390/s22207923