Ultraviolet-C Photoresponsivity Using Fabricated TiO2 Thin Films and Transimpedance-Amplifier-Based Test Setup

Abstract

1. Introduction

2. Materials and Methods

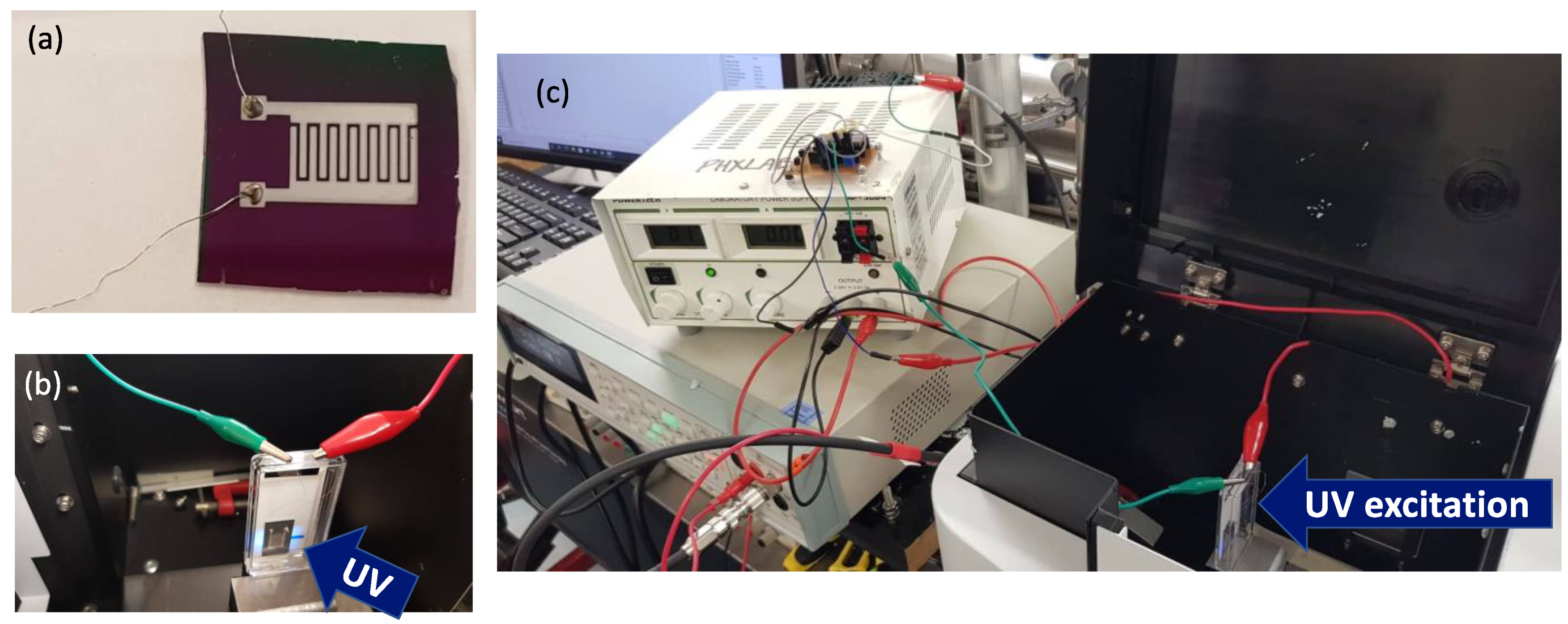

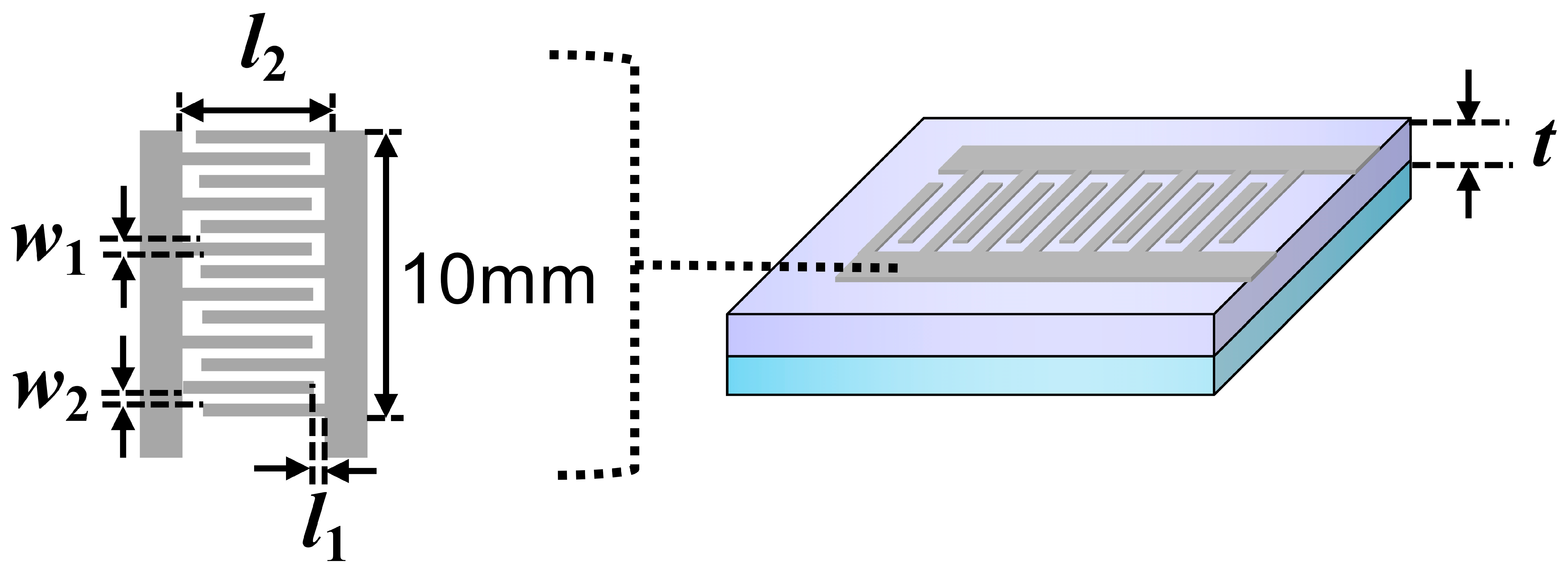

2.1. Preparation of TiO2 Thin-Film Photoconductive Detector

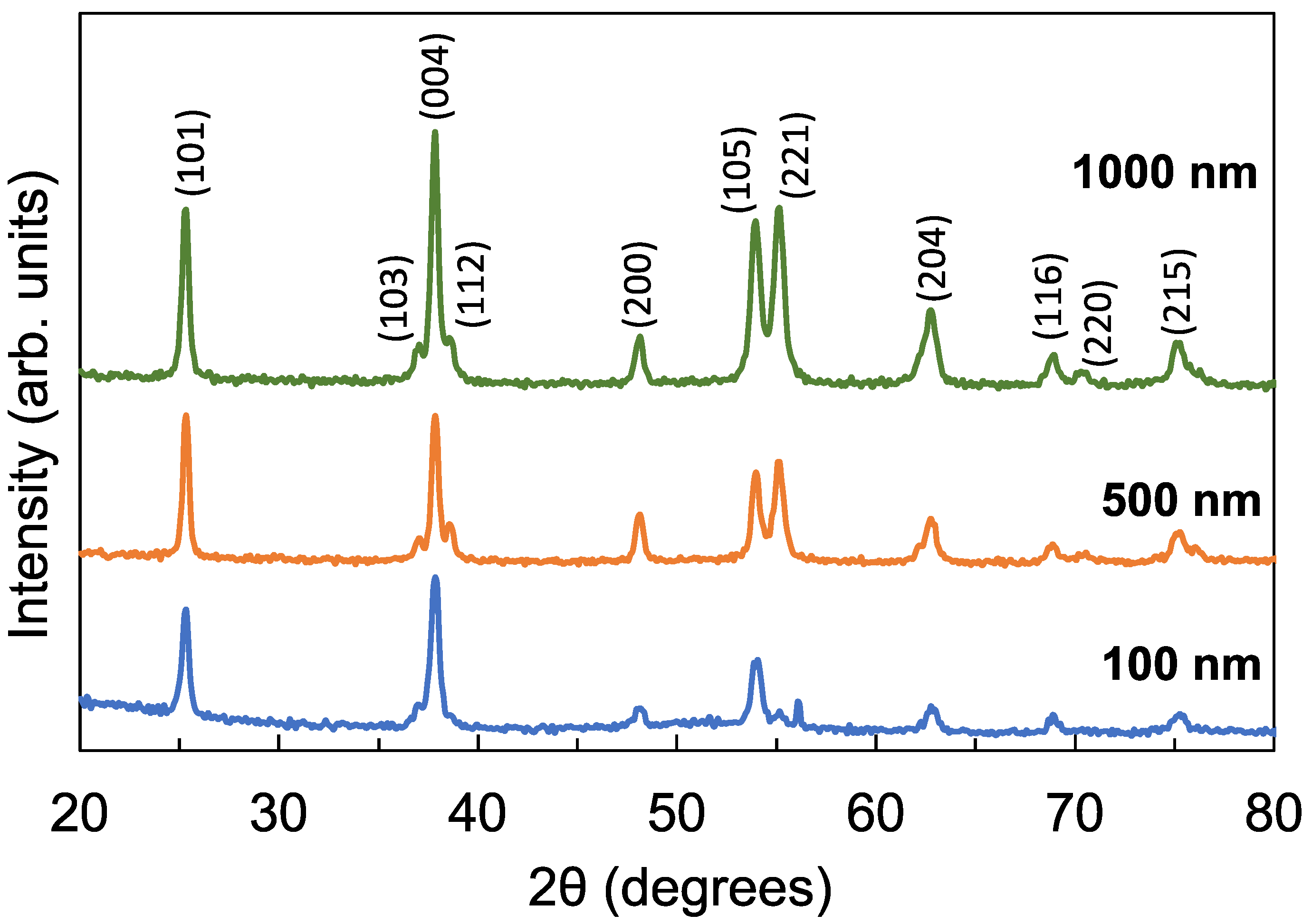

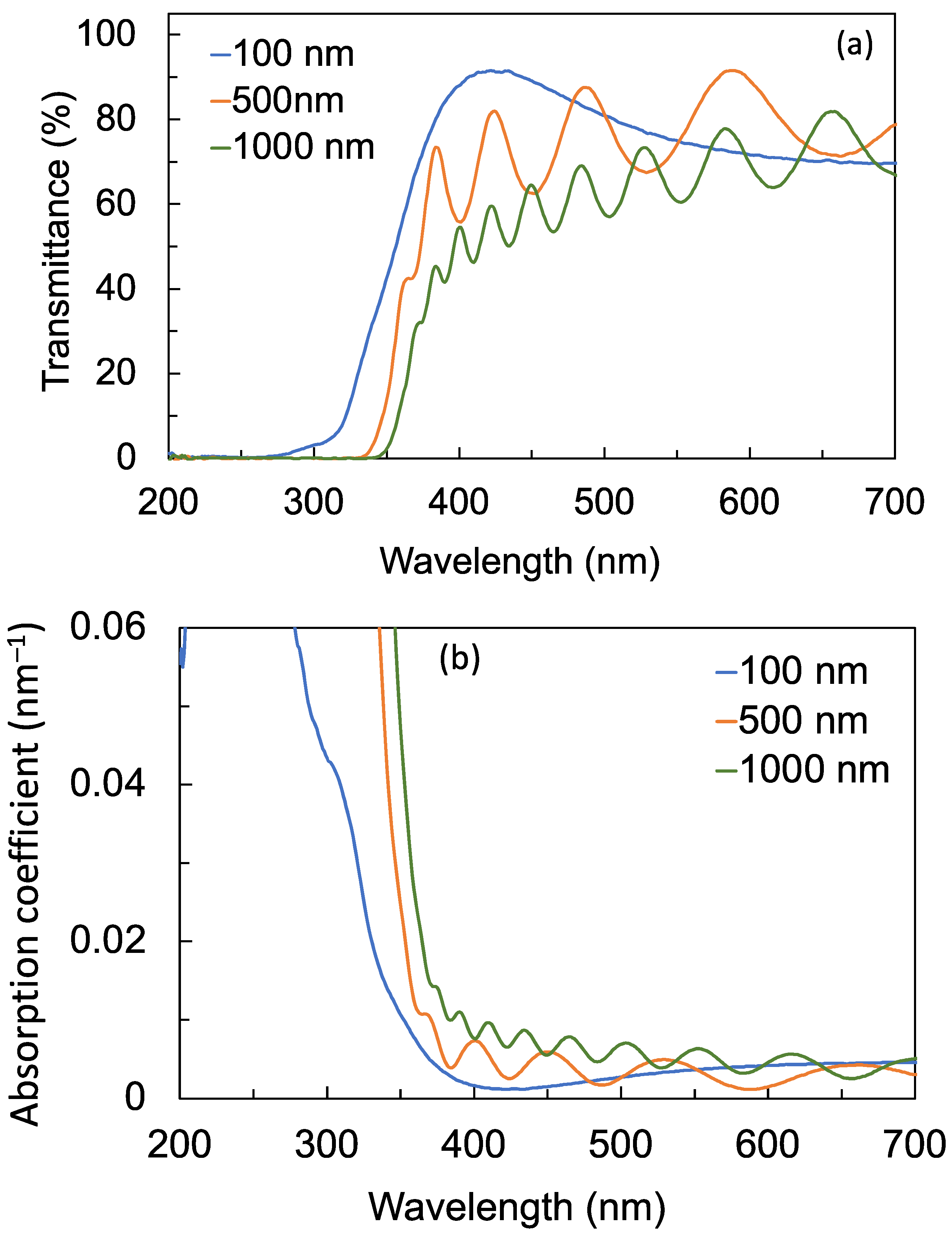

2.2. Characterization of the Structural and Optical Properties of the TiO2 Thin Films

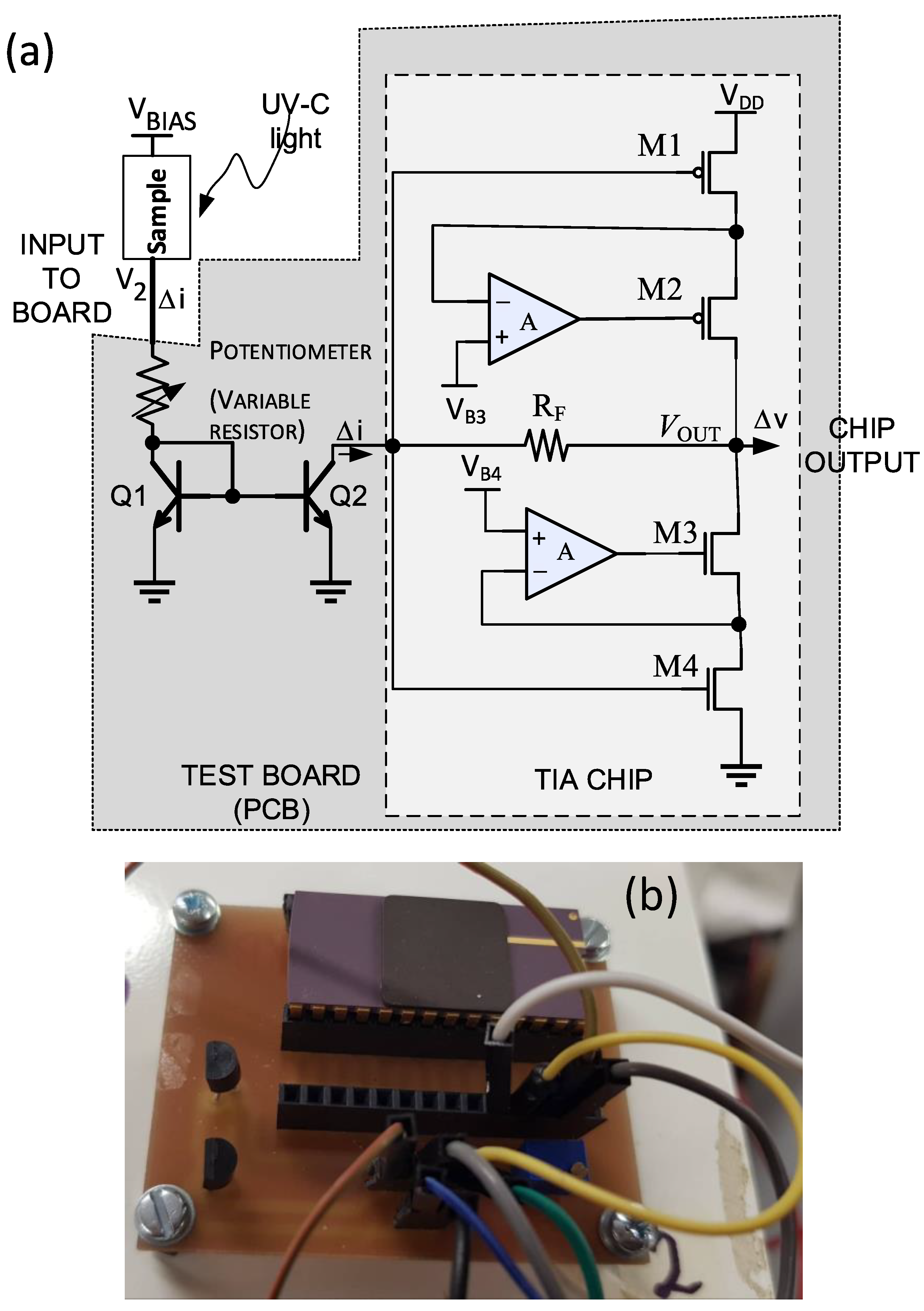

2.3. Transimpedance Amplifier-Based Test Setup and Evaluation of Photoconductivity of the TiO2 Detectors

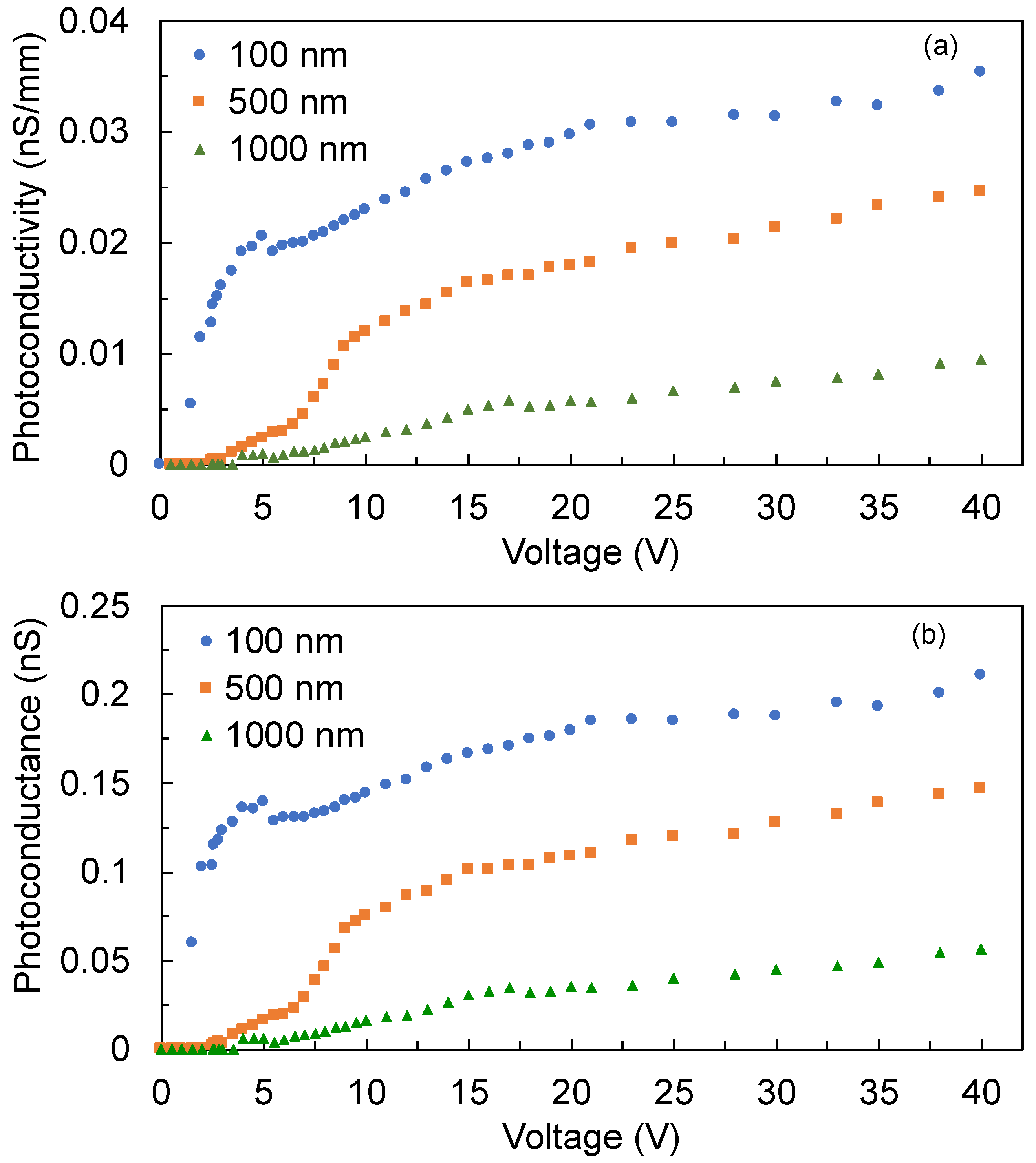

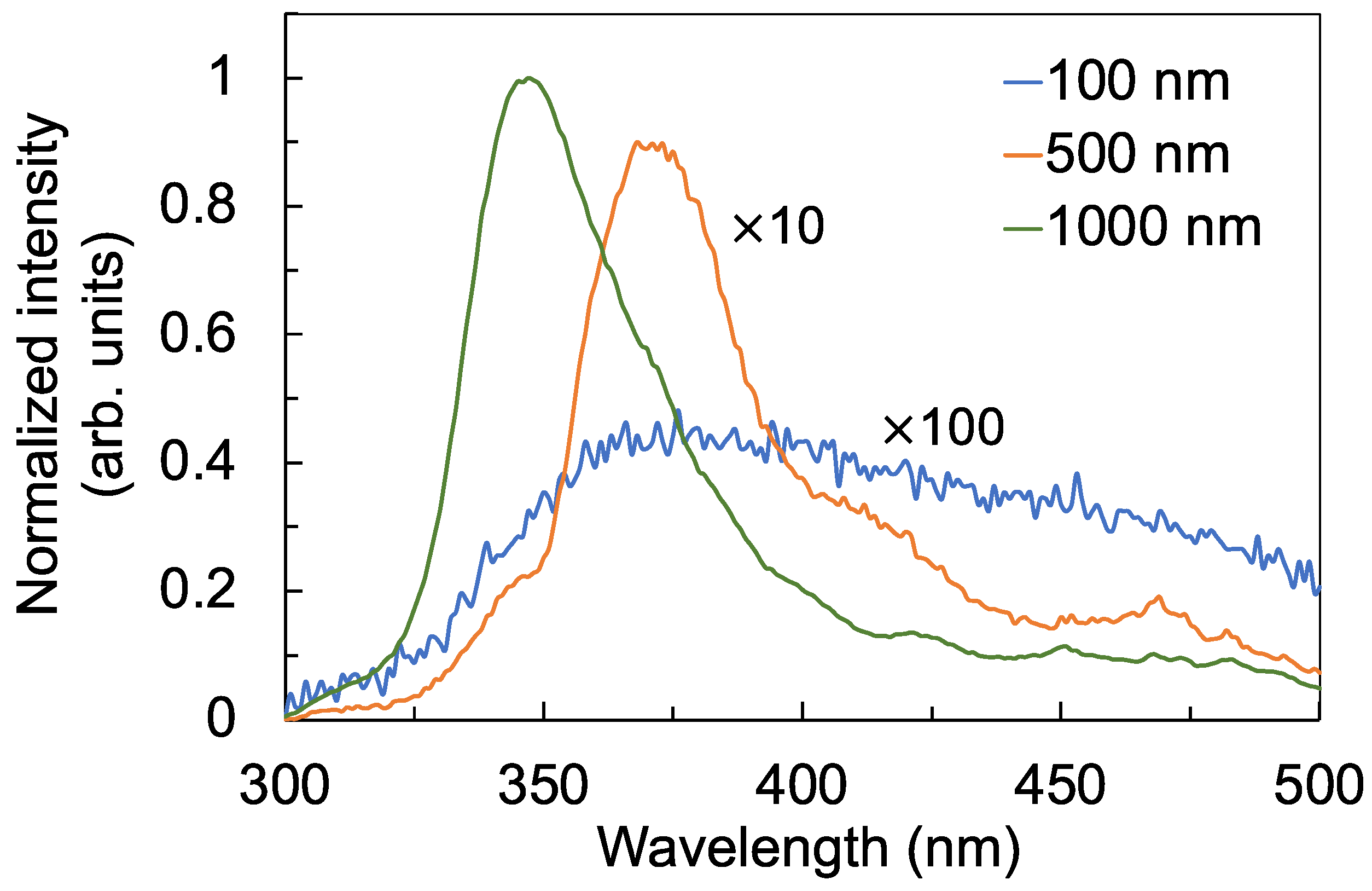

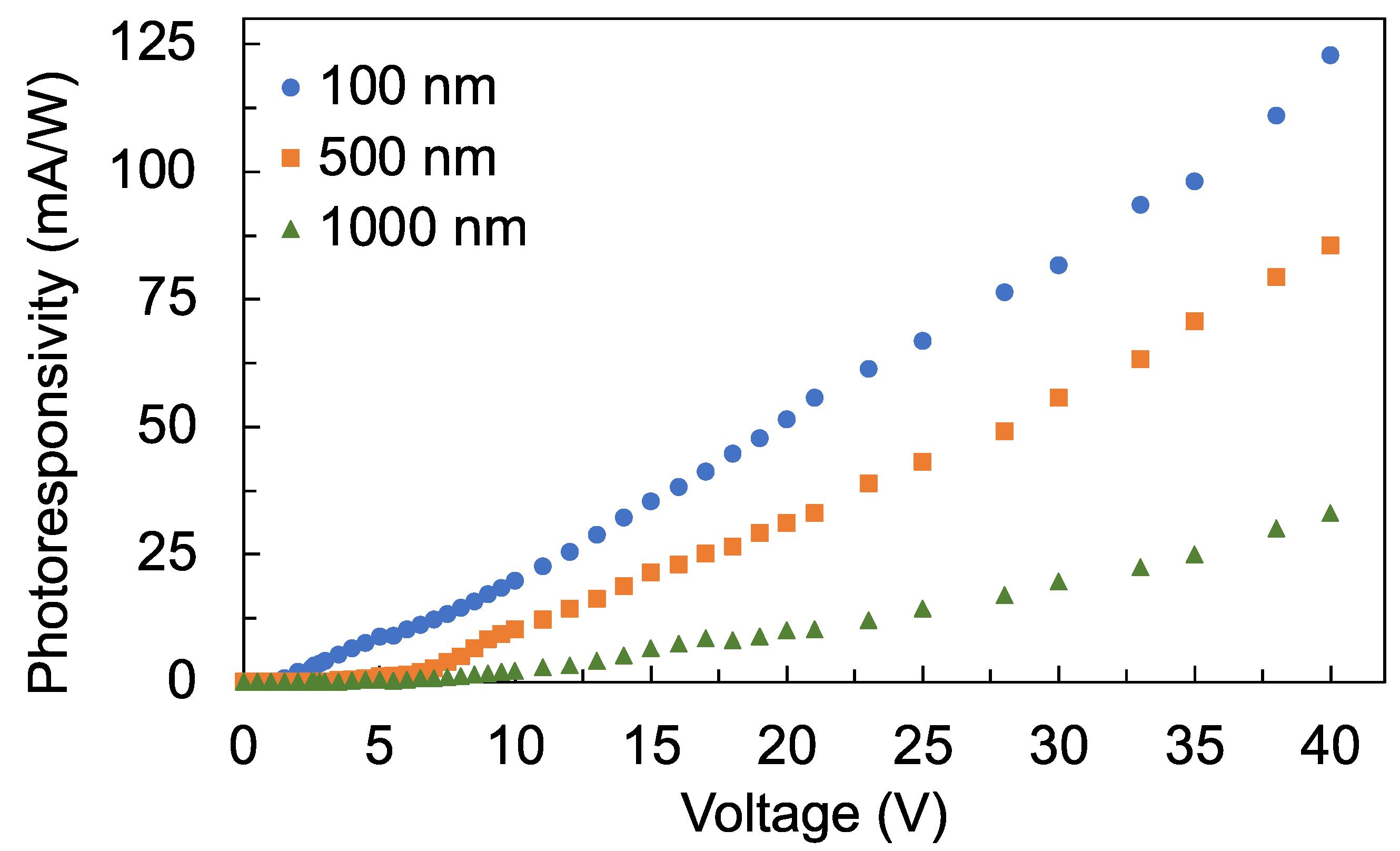

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Reed, N.G. The History of Ultraviolet Germicidal Irradiation for Air Disinfection. Public Health Rep. 2010, 125, 15–27. [Google Scholar] [CrossRef]

- Walker, C.M.; Ko, G.P. Effect of Ultraviolet Germicidal Irradiation on Viral Aerosols. Environ. Sci. Technol. 2007, 41, 5460–5465. [Google Scholar] [CrossRef]

- Tseng, C.C.; Li, C.S. Inactivation of viruses on surfaces by ultraviolet germicidal irradiation. J. Occup. Environ. Hyg. 2007, 4, 400–405. [Google Scholar] [CrossRef] [PubMed]

- Kowalski, W. Ultraviolet Germicidal Irradiation Handbook: UVGI for Air and Surface Disinfection; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Adeli, B. Not If, But When: UV LED Beverage Disinfection. IUVA News, 6 September 2020; 10–11. [Google Scholar]

- The Ultraviolet Disinfection Handbook; Bolton, J.R., Cotton, C.A., Eds.; American Water Works Association: Denver, CO, USA, 2008. [Google Scholar]

- Shining a light on COVID-19. Nat. Photonics 2020, 14, 337. [CrossRef]

- Biasin, M.; Bianco, A.; Pareschi, G.; Cavalleri, A.; Cavatorta, C.; Fenizia, C.; Galli, P.; Lessio, L.; Lualdi, M.; Tombetti, E.; et al. UV-C irradiation is highly effective in inactivating SARS-CoV-2 replication. Sci. Rep. 2021, 11, 6260. [Google Scholar] [CrossRef] [PubMed]

- De Abajo, F.J.G.; Hernandez, R.J.; Kaminer, I.; Meyerhans, A.; Rosell-Llompart, J.; Sanchez-Elsner, T. Back to Normal: An Old Physics Route to Reduce SARS-CoV-2 Transmission in Indoor Spaces. ACS Nano 2020, 14, 7704–7713. [Google Scholar] [CrossRef]

- Raeiszadeh, M.; Adeli, B. A Critical Review on Ultraviolet Disinfection Systems against COVID-19 Outbreak: Applicability, Validation, and Safety Considerations. ACS Photonics 2020, 7, 2941–2951. [Google Scholar] [CrossRef]

- Jean, J.; Rodriguez-Lopez, M.I.; Jubinville, E.; Nunez-Delicado, E.; Gomez-Lopez, V.M. Potential of pulsed light technology for control of SARS-CoV-2 in hospital environments. J. Photochem. Photobiol. B Biol. 2021, 215, 112106. [Google Scholar] [CrossRef] [PubMed]

- Ontiveros, C.C.; Shoults, D.C.; MacIsaac, S.; Rauch, K.D.; Sweeney, C.L.; Stoddart, A.K.; Gagnon, G.A. Specificity of UV-C LED disinfection efficacy for three N95 respirators. Sci. Rep. 2021, 11, 15350. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Hasan, S.M. A New Floating-gate Radiation Sensor and Readout Circuit in Standard Single-Poly 130-nm CMOS Technology. IEEE Trans. Nucl. Sci. 2019, 66, 1906–1915. [Google Scholar] [CrossRef]

- Suzuki, K.; Cadatal-Raduban, M.; Kase, M.; Ono, S. Band gap engineering of CaxSr1-xF2 and its application as filterless vacuum ultraviolet photodetectors with controllable spectral responses. Opt. Mater. 2019, 88, 576–579. [Google Scholar] [CrossRef]

- Yu, X.; Kato, S.; Ito, H.; Ono, S.; Kase, M.; Cadatal-Raduban, M. Filterless tunable photoconductive ultraviolet radiation detector using CeF3 thin films grown by pulsed laser deposition. AIP Adv. 2020, 10, 045309. [Google Scholar] [CrossRef]

- Yu, X.; Cadatal-Raduban, M.; Kato, S.; Kase, M.; Ono, S. Femtosecond PLD-grown YF3 nanoparticle thin films as improved filterless VUV photoconductive detectors. Nanotechnology 2020, 32, 015501. [Google Scholar] [CrossRef] [PubMed]

- Shaikh, S.K.; Inamdar, S.I.; Ganbavle, V.V.; Rajpure, Y.K. Chemical bath deposited ZnO thin film based UV photoconductive detector. J. Alloys Compd. 2016, 664, 242–249. [Google Scholar] [CrossRef]

- Pearton, S.J.; Zopler, J.C.; Shul, R.J.; Ren, F. GaN: Processing, defects, and devices. J. Appl. Phys. 1999, 86, 1. [Google Scholar] [CrossRef]

- Li, J.; Fan, Z.Y.; Dahal, R.; Nakarmi, M.L.; Lin, J.Y.; Jiang, H.X. 200nm deep ultraviolet photodetectors based on AlN. Appl. Phys. Lett. 2006, 89, 213510. [Google Scholar] [CrossRef]

- Zheng, W.; Huang, F.; Zheng, R.; Wu, H. Low-dimensional structure vacuum-ultraviolet-sensitive (λ < 200 nm) Photodetector with fast-response speed based on high-quality AlN micro/nanowire. Adv. Mater. 2015, 27, 3921–3927. [Google Scholar] [PubMed]

- Zhang, W.J.; Chong, Y.M.; Bello, I.; Lee, S.T. Nucleation, growth and characterization of cubic boron nitride (cBN) films. J. Phys. D Appl. Phys. 2007, 40, 6159. [Google Scholar] [CrossRef]

- Samantaray, C.B.; Singh, R.N. Review of synthesis and properties of cubic boron nitride (c-BN) thin films. Int. Mater. Rev. 2005, 50, 313–344. [Google Scholar] [CrossRef]

- Li, Y.; Guo, J.; Zheng, W.; Huang, F. Amorphous boron nitride for vacuum-ultraviolet photodetection. Appl. Phys. Lett. 2020, 117, 023504. [Google Scholar] [CrossRef]

- Zheng, W.; Lin, R.; Zhang, Z.; Huang, F. Vacuum-ultraviolet Photodetection in few-layered h-BN. ACS Appl. Mater. Interfaces 2018, 10, 27116–27123. [Google Scholar] [CrossRef] [PubMed]

- Watanabe, K.; Taniguchi, T.; Niiyama, T.; Miya, K.; Taniguchi, M. Far-ultraviolet plane-emission handheld device based on hexagonal boron nitride. Nat. Photonics 2009, 3, 591. [Google Scholar] [CrossRef]

- Balducci, A.; Marinelli, M.; Milani, E.; Morgada, M.E.; Tucciarone, A.; Verona-Rinati, G.; Angelone, M.; Pillon, M. Extreme ultraviolet single-crystal diamond detectors by chemical vapor deposition. Appl. Phys. Lett. 2005, 86, 193509. [Google Scholar] [CrossRef]

- Uchida, K.; Ishihara, H.; Nippashi, K.; Matsuoka, M.; Hayashi, K. Measurement of vacuum ultraviolet radiation with diamond photo detectors. J. Light Vis. Eng. 2004, 28, 97. [Google Scholar] [CrossRef][Green Version]

- Lin, C.-N.; Lu, Y.-J.; Yang, X.; Tian, Y.-Z.; Gao, C.-J.; Sun, J.-L.; Dong, L.; Zhong, F.; Hu, W.-D.; Shan, C.-X. Diamond-based all-carbon Photodetectors for solar-blind imaging. Adv. Opt. Mater. 2018, 6, 1800068. [Google Scholar] [CrossRef]

- Bedikyan, L.; Zakhariev, S.; Kejzlar, P.; Volesky, L.; Zakharieva, M.; Petkov, N.; Louda, P. Preparation and characterization of TiO2 thin films for UV sensor. MM Sci. J. 2015, 12, 201520. [Google Scholar] [CrossRef]

- Cadatal-Raduban, M.; Yamanoi, K.; Olejnicek, J.; Kohuot, M.; Kato, S.; Horiuchi, Y.; Kato, T.; Haoze, Y.; Sarukura, N.; Ono, S. Titanium dioxide thin films as vacuum ultraviolet photoconductive detectors with enhanced photoconductivity by gamma-ray irradiation. Thin Solid Film. 2021, 726, 138637. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, H.; Lv, K.; Chen, W.; Zhou, J.; Shen, L.; Ruan, S. Ultraviolet photodetector with high internal gain enhanced by TiO2/SrTiO3 heterojunction. Opt. Exp. 2012, 20, 5936–5941. [Google Scholar] [CrossRef]

- Mercado, C.C.; Knorr, F.J.; McHale, J.L.; Usmani, S.M.; Ichimura, A.S.; Saraf, L.V. Location of Hole and Electron Traps on Nanocrystalline Anatase TiO2. J. Phys. Chem. C 2012, 116, 10796–10804. [Google Scholar] [CrossRef]

- Cadatal-Raduban, M.; Kato, T.; Horiuchi, Y.; Olejnicek, J.; Kohout, M.; Yamanoi, K.; Ono, S. Effect of substrate and thickness on the photoconductivity of nanoparticle titanium dioxide thin film vacuum ultraviolet photoconductive detector. Nanomaterials 2021, 12, 10. [Google Scholar] [CrossRef]

- Singh, C.; Panda, E. Variation of electrical properties in thickening Al-doped ZnO films: Role of defect chemistry. RSC Adv. 2016, 6, 48910–48918. [Google Scholar] [CrossRef]

- Tseng, Z.-L.; Kao, P.-C.; Chen, Y.-C.; Juang, Y.-D.; Kuo, Y.-M.; Chu, S.-Y. Effect of thicknesses on the structure, conductivity, and transparency of Al-doped ZnO anodes in organic light-emitting diodes. J. Electrochem. Soc. 2011, 158, J310–J315. [Google Scholar] [CrossRef]

- Saravanan, K.; Krishnan, R.; Hsieh, S.H.; Wang, H.T.; Wang, Y.F.; Pong, W.F.; Asoka, K.; Avasthi, D.K.; Kanjilal, D. Effect of defects and film thickness on the optical properties of ZnO-Au hybrid films. RSC Adv. 2015, 5, 40813–40819. [Google Scholar] [CrossRef]

- Cheng, L.-C.; Wu, M.-R.; Huang, C.-Y.; Juang, T.-K.; Liu, P.-L.; Horng, R.-H. Effect of defects on the properties of ZnGa2O4 thin-film transistors. ACS Appl. Electron. Mater. 2019, 1, 253–259. [Google Scholar] [CrossRef]

- Kumar, N.; Patel, M.; Nguyen, T.T.; Kim, S.; Kim, J. Effect of TiO2 layer thickness of TiO2/NiO transparent photovoltaics. Photovoltaics 2021, 29, 943–952. [Google Scholar] [CrossRef]

- Jia, L.; Zheng, W.; Huang, F. Vacuum-ultraviolet photodetectors. PhotoniX 2020, 1, 22. [Google Scholar] [CrossRef]

- Xing, J.; Wei, H.; Guo, E.-J.; Yang, F. Highly sensitive fast-response UV photodetectors based on epitaxial TiO2 films. J. Phys. D Appl. Phys. 2011, 44, 375104. [Google Scholar] [CrossRef]

- Liu, M.; Kim, H.K. Ultraviolet detection with ultrathin ZnO epitaxial films treated with oxygen plasma. Appl. Phys. Lett. 2004, 84, 173–175. [Google Scholar] [CrossRef]

- Liang, S.; Sheng, H.; Liu, Y.; Huo, Z.; Lu, Y.; Shen, H. ZnO Schottky ultraviolet photodetectors. J. Cryst. Growth 2001, 225, 110–113. [Google Scholar] [CrossRef]

| Thickness (nm) | Strain | Crystallite Size (nm) | Crystallinity (%) |

|---|---|---|---|

| 100 | 2.4 × 10−3 | 9.6 | 50 |

| 500 | 4.5 × 10−3 | 23.5 | 78 |

| 1000 | 5.2 × 10−3 | 26.6 | 81 |

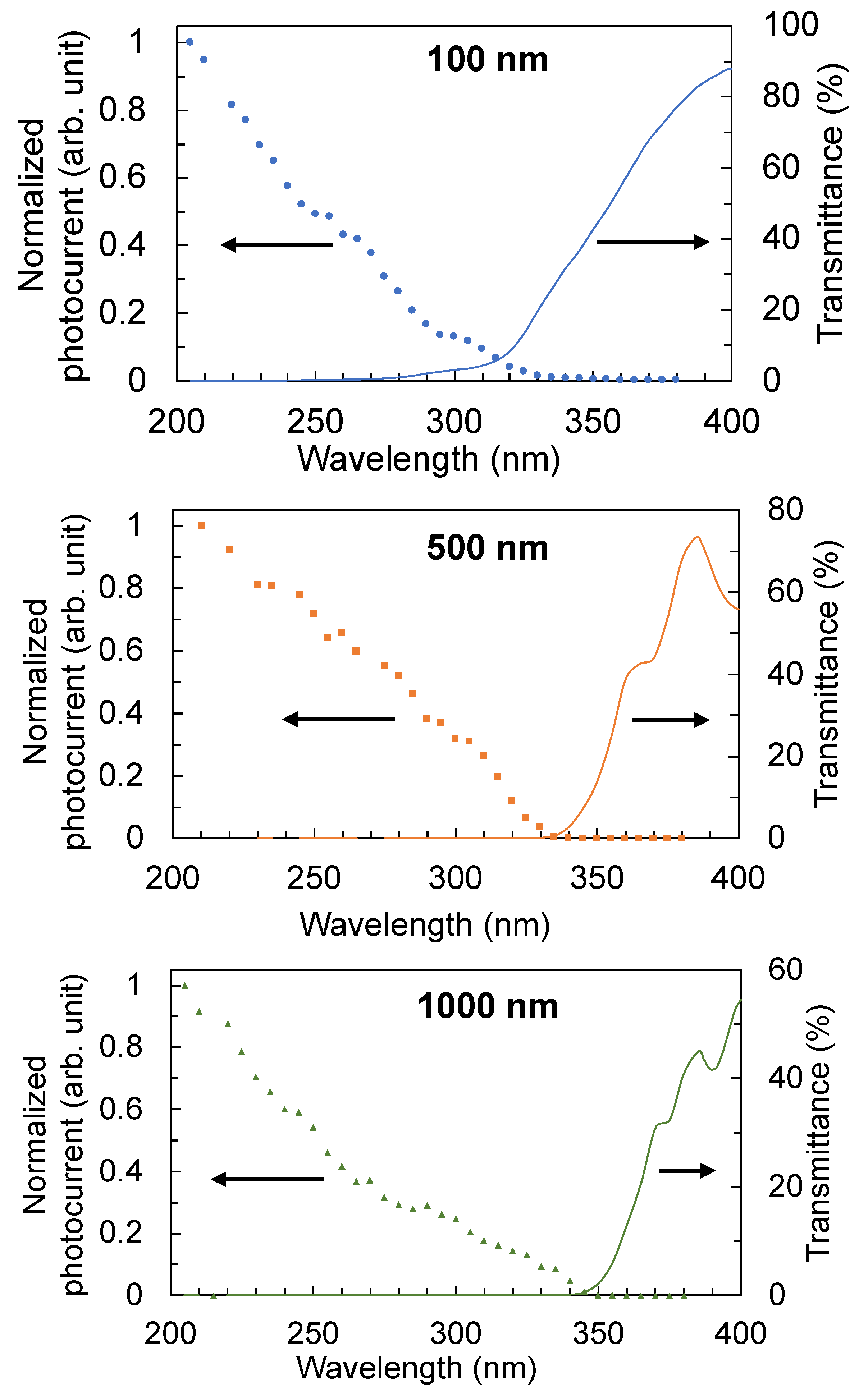

| Thickness (nm) | Transmission Edge (nm) | Band Gap (eV) |

|---|---|---|

| 100 | 320 | 3.49 |

| 500 | 335 | 3.44 |

| 1000 | 345 | 3.34 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cadatal-Raduban, M.; Pope, J.; Olejníček, J.; Kohout, M.; Harrison, J.A.; Hasan, S.M.R. Ultraviolet-C Photoresponsivity Using Fabricated TiO2 Thin Films and Transimpedance-Amplifier-Based Test Setup. Sensors 2022, 22, 8176. https://doi.org/10.3390/s22218176

Cadatal-Raduban M, Pope J, Olejníček J, Kohout M, Harrison JA, Hasan SMR. Ultraviolet-C Photoresponsivity Using Fabricated TiO2 Thin Films and Transimpedance-Amplifier-Based Test Setup. Sensors. 2022; 22(21):8176. https://doi.org/10.3390/s22218176

Chicago/Turabian StyleCadatal-Raduban, Marilou, Jade Pope, Jiří Olejníček, Michal Kohout, John A. Harrison, and S. M. Rezaul Hasan. 2022. "Ultraviolet-C Photoresponsivity Using Fabricated TiO2 Thin Films and Transimpedance-Amplifier-Based Test Setup" Sensors 22, no. 21: 8176. https://doi.org/10.3390/s22218176

APA StyleCadatal-Raduban, M., Pope, J., Olejníček, J., Kohout, M., Harrison, J. A., & Hasan, S. M. R. (2022). Ultraviolet-C Photoresponsivity Using Fabricated TiO2 Thin Films and Transimpedance-Amplifier-Based Test Setup. Sensors, 22(21), 8176. https://doi.org/10.3390/s22218176