A Novel Multivariate Cutting Force-Based Tool Wear Monitoring Method Using One-Dimensional Convolutional Neural Network

Abstract

:1. Introduction

2. Methodologies

2.1. Multivariate Variational Mode Decomposition

2.2. The Proposed Modified Multiscale Permutation Entropy

2.3. One-Dimensional Convolutional Neural Network

- (1)

- Convolutional Layer

- (2)

- Pooling Layer

- (3)

- Batch Normalization

3. A Novel Multivariate Cutting Force-Based Tool Wear Monitoring Method Using One-Dimensional Convolutional Neural Network Is Proposed

4. Application Research by Experimental Data Analysis

4.1. Experimental Data Description

4.2. Quantitative Feature Extraction Based on Multivariate Cutting Force Signals

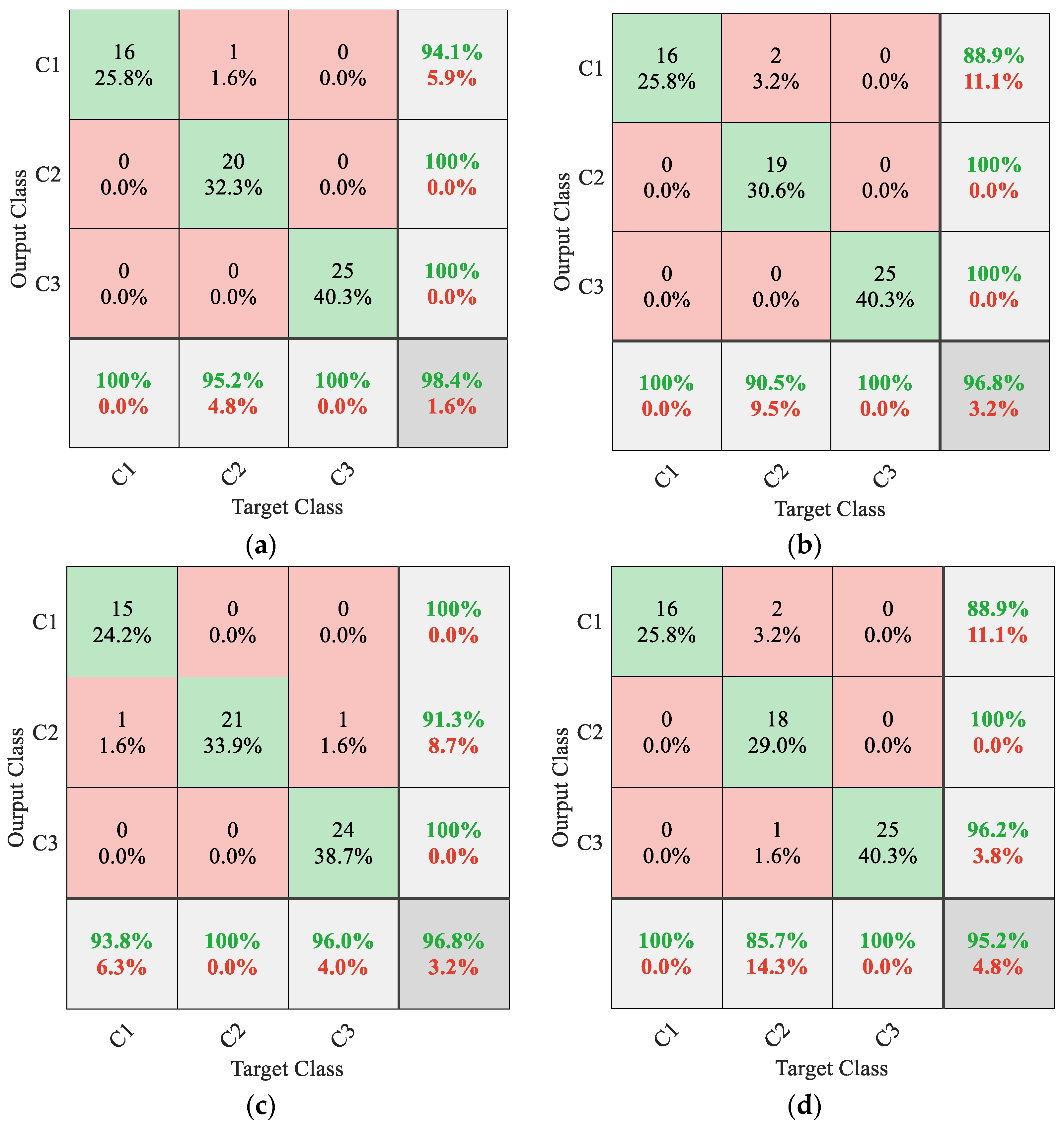

4.3. Tool Wear Condition Monitoring by One-Dimensional Convolutional Neural Network

5. Conclusions and Discussion

- (1)

- Multivariate cutting force signals were used as monitoring signals to realize tool wear monitoring in this paper. Multivariate cutting force signals contain comprehensive dynamic information on tool wear, which is suitable for extracting wear characteristics. At the same time, the research on multiple signals agrees with the rapid development trend of multi-sensor acquisition systems.

- (2)

- MVMD and MMPE were combined to extract the characteristic information of tool wear. MVMD can decompose multivariate cutting force signals adaptively and can effectively separate the frequency components of multiple signals. MMPE can accurately characterize the nonlinear characteristics of tool wear as condition indicators.

- (3)

- 1D CNN has strong adaptive feature extraction ability, which can reduce the error of empirical judgment and make the recognition effect more accurate and intelligent. Compared with the traditional machine learning model, 1D CNN has higher recognition ability and better monitoring effects.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kuntoğlu, M.; Aslan, A.; Pimenov, D.Y.; Usca, Ü.A.; Salur, E.; Gupta, M.K.; Mikolajczyk, T.; Giasin, K.; Kapłonek, W.; Sharma, S. A Review of Indirect Tool Condition Monitoring Systems and Decision-Making Methods in Turning: Critical Analysis and Trends. Sensors 2021, 21, 108. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; An, Q. An in-depth study of tool wear monitoring technique based on image segmentation and texture analysis. Measurement 2016, 79, 44–52. [Google Scholar] [CrossRef]

- García-Ordás, M.T.; Alegre, E.; González-Castro, V.; Alaiz-Rodríguez, R. A computer vision approach to analyze and classify tool wear level in milling processes using shape descriptors and machine learning techniques. Int. J. Adv. Manuf. Technol. 2017, 90, 1947–1961. [Google Scholar] [CrossRef] [Green Version]

- Nouri, M.; Fussell, B.K.; Ziniti, B.L.; Linder, E. Real-time tool wear monitoring in milling using a cutting condition independent method. Int. J. Mach. Tools Manuf. 2015, 89, 1–13. [Google Scholar] [CrossRef]

- Yu, J.; Liang, S.; Tang, D.; Liu, H. A weighted hidden Markov model approach for continuous-state tool wear monitoring and tool life prediction. Int. J. Adv. Manuf. Technol. 2017, 91, 201–211. [Google Scholar] [CrossRef]

- Caggiano, A. Tool wear prediction in Ti-6Al-4V machining through multiple sensor monitoring and PCA features pattern recognition. Sensors 2018, 18, 823. [Google Scholar] [CrossRef] [Green Version]

- Gierlak, P.; Burghardt, A.; Szybicki, D.; Szuster, M.; Muszyńska, M. On-line manipulator tool condition monitoring based on vibration analysis. Mech. Syst. Signal Process. 2017, 89, 14–26. [Google Scholar] [CrossRef]

- Lin, X.; Zhou, B.; Zhu, L. Sequential spindle current-based tool condition monitoring with support vector classifier for milling process. Int. J. Adv. Manuf. Technol. 2017, 92, 3319–3328. [Google Scholar] [CrossRef]

- Zhou, Y.; Sun, W. Tool wear condition monitoring in milling process based on current sensors. IEEE Access 2020, 8, 95491–95502. [Google Scholar] [CrossRef]

- Benkedjouh, T.; Zerhouni, N.; Rechak, S. Tool wear condition monitoring based on continuous wavelet transform and blind source separation. Int. J. Adv. Manuf. Technol. 2018, 97, 3311–3323. [Google Scholar] [CrossRef]

- Laddada, S.; Si-Chaib, M.O.; Benkedjouh, T.; Drai, R. Tool wear condition monitoring based on wavelet transform and improved extreme learning machine. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 234, 1057–1068. [Google Scholar] [CrossRef]

- Babouri, M.K.; Ouelaa, N.; Djebala, A. Experimental study of tool life transition and wear monitoring in turning operation using a hybrid method based on wavelet multi-resolution analysis and empirical mode decomposition. Int. J. Adv. Manuf. Technol. 2016, 82, 2017–2028. [Google Scholar] [CrossRef]

- Wolszczak, P.; Łygas, K.; Litak, G. Monitoring of cutting conditions with the empirical mode decomposition. Adv. Sci. Technol. Res. J. 2017, 11, 96–103. [Google Scholar] [CrossRef]

- Bazi, R.; Benkedjouh, T.; Habbouche, H.; Rechak, S.; Zerhouni, N. A hybrid CNN-BiLSTM approach-based variational mode decomposition for tool wear monitoring. Int. J. Adv. Manuf. Technol. 2022, 119, 3803–3817. [Google Scholar] [CrossRef]

- Yuan, J.; Liu, L.; Yang, Z.; Zhang, Y. Tool wear condition monitoring by combining variational mode decomposition and ensemble learning. Sensors 2020, 20, 6113. [Google Scholar] [CrossRef]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Shih, H.H.; Zheng, Q.; Liu, H.H. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. Proc. R. Soc. London. Ser. A Math. Phys. Eng. Sci. 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Yuan, R.; Lv, Y.; Lu, Z.; Li, S.; Li, H. Robust fault diagnosis of rolling bearing via phase space reconstruction of intrinsic mode functions and neural network under various operating conditions. Struct. Health Monit. 2022. [Google Scholar] [CrossRef]

- Dragomiretskiy, K.; Zosso, D. Variational mode decomposition. IEEE Trans. Signal Process. 2013, 62, 531–544. [Google Scholar] [CrossRef]

- Lv, Y.; Yuan, R.; Song, G. Multivariate empirical mode decomposition and its application to fault diagnosis of rolling bearing. Mech. Syst. Signal Process. 2016, 81, 219–234. [Google Scholar] [CrossRef]

- Yuan, R.; Lv, Y.; Yang, D.; Lu, Z. A new strategy to eliminate interference of varying operating conditions during multivariate signal processing-based fault diagnosis approach. J. Phys. Conf. Ser. 2022, 2184, 012016. [Google Scholar] [CrossRef]

- Rehman, N.; Aftab, H. Multivariate variational mode decomposition. IEEE Trans. Signal Process. 2019, 67, 6039–6052. [Google Scholar] [CrossRef] [Green Version]

- Yuan, R.; Lv, Y.; Wang, T.; Li, S.; Li, H. Looseness monitoring of multiple M1 bolt joints using multivariate intrinsic multiscale entropy analysis and Lorentz signal-enhanced piezoelectric active sensing. Struct. Health Monit. 2022, 21, 2851–2873. [Google Scholar] [CrossRef]

- Zheng, J.; Dong, Z.; Pan, H.; Ni, Q.; Liu, T.; Zhang, J. Composite multi-scale weighted permutation entropy and extreme learning machine based intelligent fault diagnosis for rolling bearing. Measurement 2019, 143, 69–80. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, X.; Luan, Z.; Xu, X. Rolling bearing fault diagnosis based on EEMD sample entropy and PNN. J. Eng. 2019, 2019, 8696–8700. [Google Scholar] [CrossRef]

- Yang, D.; Lv, Y.; Yuan, R.; Yang, K.; Zhong, H. A novel vibro-acoustic fault diagnosis method of rolling bearings via entropy-weighted nuisance attribute projection and orthogonal locality preserving projections under various operating conditions. Appl. Acoust. 2022, 196, 108889. [Google Scholar] [CrossRef]

- Bandt, C.; Pompe, B. Permutation entropy: A natural complexity measure for time series. Phys. Rev. Lett. 2002, 88, 174102. [Google Scholar] [CrossRef]

- Aziz, W.; Arif, M. Multiscale permutation entropy of physiological time series. In Proceedings of the 2005 Pakistan Section Multitopic Conference, Karachi, Pakistan, 24–25 December 2005; pp. 1–6. [Google Scholar]

- Ye, M.; Yan, X.; Jia, M. Rolling bearing fault diagnosis based on VMD-MPE and PSO-SVM. Entropy 2021, 23, 762. [Google Scholar] [CrossRef]

- Li, Y.; Song, H.; Liu, J.; Zhang, W.; Xiong, Q. A Study on Fault Diagnosis Method for Train Axle Box Bearing Based on Modified Multiscale Permutation Entropy. J. China Railw. Soc. 2020, 42, 33–39. [Google Scholar]

- Yang, D.; Lv, Y.; Yuan, R.; Li, H.; Zhu, W. Robust fault diagnosis of rolling bearings via entropy-weighted nuisance attribute projection and neural network under various operating conditions. Struct. Health Monit. 2022, 21, 2890–2909. [Google Scholar] [CrossRef]

- Duan, J.; Duan, J.; Zhou, H.; Zhan, X.; Li, T.; Shi, T. Multi-frequency-band deep CNN model for tool wear prediction. Meas. Sci. Technol. 2021, 32, 065009. [Google Scholar] [CrossRef]

- Liu, H.; Liu, Z.; Jia, W.; Zhang, D.; Wang, Q.; Tan, J. Tool wear estimation using a CNN-transformer model with semi-supervised learning. Meas. Sci. Technol. 2021, 32, 125010. [Google Scholar] [CrossRef]

- Wang, H.; Yin, Z.; Ke, Z.; Guo, Y.; Dong, H. Wear monitoring of helical milling tool based on one-dimensional convolutional neural network. J. Zhejiang Univ. (Eng. Sci.) 2020, 54, 931–939. [Google Scholar]

- Nguyen, T.T.; Phan, T.T.V.; Ho, D.D.; Pradhan, A.M.S.; Huynh, T.C. Deep learning-based autonomous damage-sensitive feature extraction for impedance-based prestress monitoring. Eng. Struct. 2022, 259, 114172. [Google Scholar] [CrossRef]

- Abdeljaber, O.; Avci, O.; Kiranyaz, S.; Gabbouj, M.; Inman, D.J. Real-time vibration-based structural damage detection using one-dimensional convolutional neural networks. J. Sound Vib. 2017, 388, 154–170. [Google Scholar] [CrossRef]

- Kuo, P.H.; Lin, C.Y.; Luan, P.C.; Yau, H.T. Dense-block structured convolutional neural network based analytical prediction system of cutting tool wear. IEEE Sens. J. 2022, 22, 20257–20267. [Google Scholar] [CrossRef]

- Xu, X.; Wang, J.; Ming, W.; Chen, M.; An, Q. In-process tap tool wear monitoring and prediction using a novel model based on deep learning. Int. J. Adv. Manuf. Technol. 2021, 112, 453–466. [Google Scholar] [CrossRef]

- Wang, F.; Song, G.; Mo, Y.L. Shear loading detection of through bolts in bridge structures using a percussion-based one-dimensional memory-augmented convolutional neural network. Comput.-Aided Civ. Infrastruct. Eng. 2021, 36, 289–301. [Google Scholar] [CrossRef]

- Li, Z.; Lv, Y.; Yuan, R.; Zhang, Q. An intelligent fault diagnosis method of rolling bearings via variational mode decomposition and common spatial pattern-based feature extraction. IEEE Sens. J. 2022, 22, 15169–15177. [Google Scholar] [CrossRef]

- Ricci, R.; Pennacchi, P. Diagnostics of gear faults based on EMD and automatic selection of intrinsic mode functions. Mech. Syst. Signal Process. 2011, 25, 821–838. [Google Scholar] [CrossRef] [Green Version]

- 2010 PHM Society Conference Data Challenge. Available online: https://phmsociety.org/phm_competition/2010-phm-society-conference-data-challenge/ (accessed on 1 May 2022).

- He, Z.; Shi, T.; Xuan, J. Milling tool wear prediction using multi-sensor feature fusion based on stacked sparse autoencoders. Measurement 2022, 190, 110719. [Google Scholar] [CrossRef]

- Li, X.; Liu, X.; Yue, C.; Liu, S.; Zhang, B.; Li, R.; Liang, S.Y.; Wang, L. A data-driven approach for tool wear recognition and quantitative prediction based on radar map feature fusion. Measurement 2021, 185, 110072. [Google Scholar] [CrossRef]

- Yan, R.; Gao, R.X. Approximate entropy as a diagnostic tool for machine health monitoring. Mech. Syst. Signal Process. 2007, 21, 824–839. [Google Scholar] [CrossRef]

- Wang, F.; Song, G. A novel percussion-based method for multi-bolt looseness detection using one-dimensional memory augmented convolutional long short-term memory networks. Mech. Syst. Signal Process. 2021, 161, 107955. [Google Scholar] [CrossRef]

- Wang, F.; Song, G. 1D-TICapsNet: An audio signal processing algorithm for bolt early looseness detection. Struct. Health Monit. 2020. [Google Scholar] [CrossRef]

- Wu, X.; Liu, Y.; Zhou, X.; Mou, A. Automatic identification of tool wear based on convolutional neural network in face milling process. Sensors 2019, 19, 3817. [Google Scholar] [CrossRef]

| Operational Parameter | Value |

|---|---|

| CNC milling machine | Roders Tech RFM760 |

| Dynamometer | Kistler 9265B |

| Spindle speed | 10,400 r/min |

| Feed rate | 1555 mm/min |

| Z depth of cut (axial) | 0.2 mm |

| Y depth of cut (radial) | 0.125 mm |

| Sampling frequency | 50 kHz |

| Wear Condition | Wear Label | Number of Millings |

|---|---|---|

| Initial wear | C1 | 1~81 |

| Normal wear | C2 | 82~188 |

| Severe wear | C3 | 189~315 |

| Methods | Average Classification Accuracy |

|---|---|

| VMD + MMPE + 1D CNN (X-axis) | 92.91% |

| VMD + MMPE + 1D CNN (Z-axis) | 93.23% |

| VMD + MMPE + 1D CNN (Y-axis) | 94.03% |

| 1D CNN | 93.28% |

| MVMD + MPE + 1D CNN | 95.48% |

| MEMD + MMPE + 1D CNN | 96.61% |

| MVMD + MMPE + GA-SVM | 96.77% |

| MVMD + MMPE + 1D CNN | 97.42% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Yuan, R.; Lv, Y.; Li, L.; Song, H. A Novel Multivariate Cutting Force-Based Tool Wear Monitoring Method Using One-Dimensional Convolutional Neural Network. Sensors 2022, 22, 8343. https://doi.org/10.3390/s22218343

Yang X, Yuan R, Lv Y, Li L, Song H. A Novel Multivariate Cutting Force-Based Tool Wear Monitoring Method Using One-Dimensional Convolutional Neural Network. Sensors. 2022; 22(21):8343. https://doi.org/10.3390/s22218343

Chicago/Turabian StyleYang, Xu, Rui Yuan, Yong Lv, Li Li, and Hao Song. 2022. "A Novel Multivariate Cutting Force-Based Tool Wear Monitoring Method Using One-Dimensional Convolutional Neural Network" Sensors 22, no. 21: 8343. https://doi.org/10.3390/s22218343