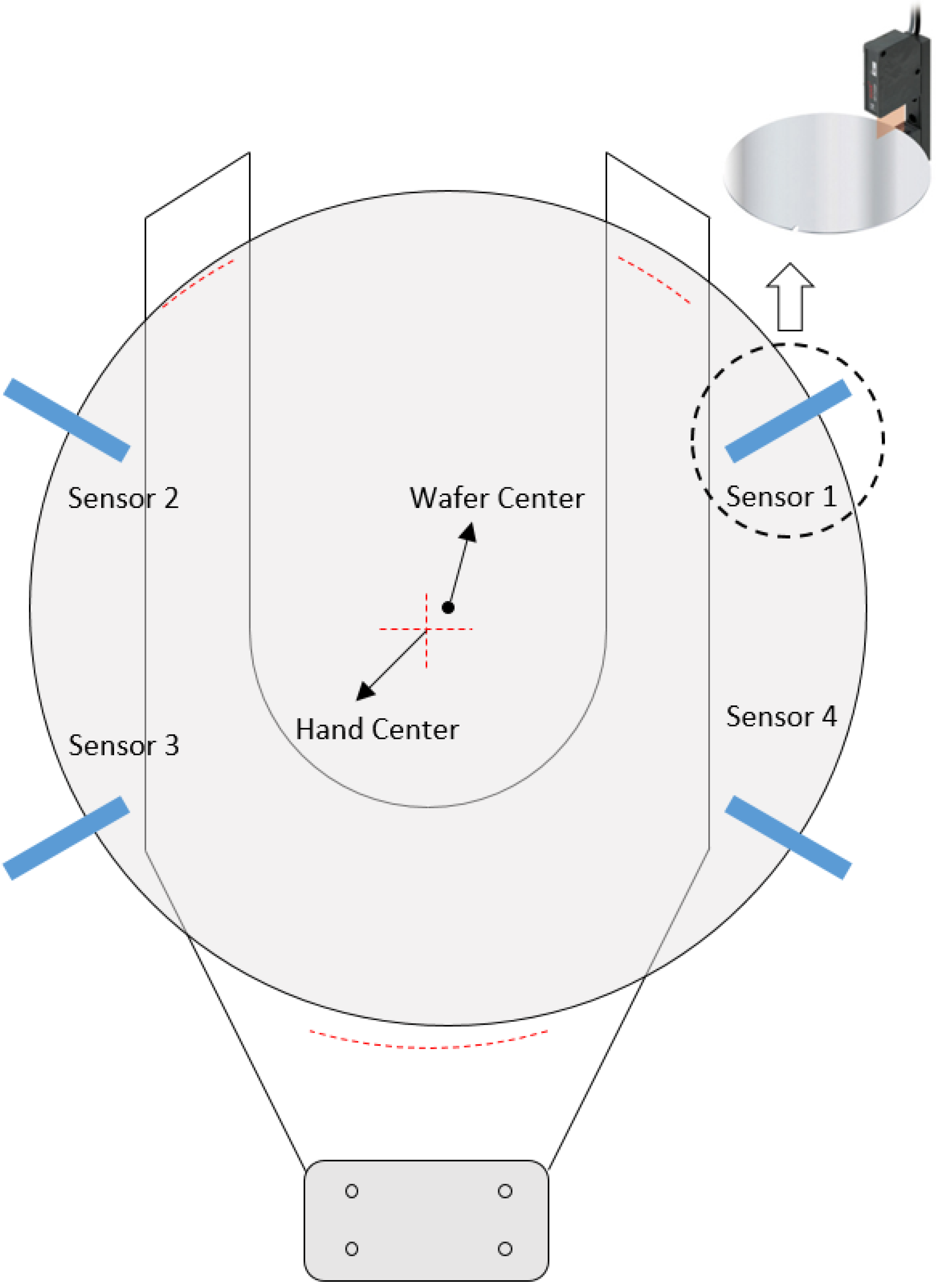

Wafer Center Alignment System of Transfer Robot Based on Reduced Number of Sensors

Abstract

:1. Introduction

2. Main Results

2.1. Center Calculation Algorithm

- Since , it follows from Assumption 2 that . Then, we can obtain

- Next, we haveDefine . Then, andis a monotonically increasing function on ([19], [page 95]) because it follows from of Assumption 1 that its derivative with respect to satisfies thatThis implies that

- If for any , it follows from and of Assumption 3 that

- Otherwise, it follows from and of Assumption 3 that

2.2. Notch Detection Algorithm

- Start

- From the algorithm of Section 2.1, find the intersections and let , , .

- If is less than , jump to 7.

- Move the robot hand holding the wafer by in the X-direction where is a positive number.

- Similar to 2, try again and define , , .

- Select as the center of wafer where j is chosen to minimize for and . Then, jump to 8.

- Select as the center of wafer.

- End.

3. Experimental Results

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jekauc, I.; Watt, M.; Hornsmith, T.; Tiffany, J. Necessity of chemical edge bead removal in modern day lithographic processing. In Proceedings of the Advances in Resist Technology and Processing XXI; Sturtevant, J.L., Ed.; International Society for Optics and Photonics, SPIE: Bellingham, WA, USA, 2004; Volume 5376, pp. 1255–1263. [Google Scholar] [CrossRef]

- Tadashi, H. Method of Detecting Position of Orientation Flat of Semiconductor Wafer. JP Patent 06236918, 23 August 1994. [Google Scholar]

- Berken, L.M. Wafer Positioning System. U.S. Patent 5740062, 14 April 1998. [Google Scholar]

- Freerks, F.W. Wafer Position Error Detection and Correction System. U.S. Patent 5980194, 9 November 1999. [Google Scholar]

- Yoo, W.S. Wafer Alignment System and Method. U.S. Patent 6516244, 4 February 2003. [Google Scholar]

- Cong, M.; Kong, X.; Du, Y.; Liu, J. Wafer Pre-Aligner System Based on Vision Information Processing. Inf. Technol. J. 2007, 6, 1245–1251. [Google Scholar] [CrossRef] [Green Version]

- Qu, D.; Qiao, S.; Rong, W.; Song, Y.; Zhao, Y. Design and Experiment of The Wafer Pre-alignment System. In Proceedings of the 2007 International Conference on Mechatronics and Automation, Harbin, China, 5–8 August 2007; pp. 1483–1488. [Google Scholar]

- Chen, Y.; Chen, Y.; Lee, J. A novel method for real-time wafer positioning during transfer process. In Proceedings of the SICE Annual Conference 2011, Tokyo, Japan, 13–18 September 2011; pp. 1933–1937. [Google Scholar]

- Chen, Y.; Lee, Y.; Lee, J.; Chen, J. Implementation of a wafer positioning system. In Proceedings of the SICE Annual Conference 2011, Tokyo, Japan, 13–18 September 2011; pp. 1938–1943. [Google Scholar]

- Chen, Y.; Chen, Y.; Lee, J. Experimental results of a wafer positioning system using machine vision after system calibration. In Proceedings of the 2012 Proceedings of SICE Annual Conference (SICE), Akita, Japan, 20–23 August 2012; pp. 1014–1017. [Google Scholar]

- He, Y.; Zhang, C.; Ye, W.; He, Z.; Chen, X.; Gao, J.; Zhang, K.; Yang, Z.; Chen, X.; Chen, Y.; et al. A direct-drive SCARA robot for wafer ceramic-substrate handling based on visual servoing. In Proceedings of the 2017 IEEE International Conference on Cybernetics and Intelligent Systems (CIS) and IEEE Conference on Robotics, Automation and Mechatronics (RAM), Ningbo, China, 19–21 November 2017; pp. 428–433. [Google Scholar]

- Xu, J.; Hu, H.; Lei, Y.; Liu, H. A Wafer Prealignment Algorithm Based on Fourier Transform and Least Square Regression. IEEE Trans. Autom. Sci. Eng. 2017, 14, 1771–1777. [Google Scholar] [CrossRef]

- Kim, J. New Wafer Alignment Process Using Multiple Vision Method for Industrial Manufacturing. Electronics 2018, 7, 39. [Google Scholar] [CrossRef] [Green Version]

- Pan, S.; Wang, S.; Xu, J.; Fan, L.; Yuan, F.; Shu, T.; Dai, F.; Yan, X.; Bu, Y.; Wang, X. Sub-pixel position estimation algorithm based on Gaussian fitting and sampling theorem interpolation for wafer alignment. Appl. Opt. 2021, 60, 9607–9618. [Google Scholar] [CrossRef] [PubMed]

- Chung, M.J.; Lee, S.J. Development of Automatic Wafer Centering System for Vacuum Transfer Robot using for Semiconductor Manufacturing. Appl. Mech. Mater. 2014, 607, 782–785. [Google Scholar] [CrossRef]

- Cheng, H.; Chen, S.; Mooring, B.W. Accuracy Analysis of Dynamic-Wafer-Handling Robotic System in Semiconductor Manufacturing. IEEE Trans. Ind. Electron. 2014, 61, 1402–1410. [Google Scholar] [CrossRef]

- Hayashi, T. Substrate Transfer Apparatus, Substrate Transfer Method, and Recording Medium Having Recorded Program for Executing the Substrate Transfer Method. U.S. Patent 1017908670000, 16 March 2016. [Google Scholar]

- Poole, D. Linear Algebra: A Modern Introduction; Available Titles CengageNOW Series; Thomson Brooks/Cole: Pacific Grove, CA, USA, 2005. [Google Scholar]

- Rudin, W. Principles of Mathematical Analysis; International Series in Pure and Applied Mathematics; McGraw-Hill: New York, NY, USA, 1976. [Google Scholar]

- Yamamoto, S.; Kamei, K. Apparatus for Detecting Position of a Notch in a Semiconductor Wafer. U.S. Patent US5438209A, 1 August 1995. [Google Scholar]

| Wafer Center X, Y | Proposed | Conventional | ||

|---|---|---|---|---|

| X-Dir | Y-Dir | X-Dir | Y-Dir | |

| (0,0) | 0.0145 | 0.0087 | 0.0153 | 0.0083 |

| (1.8,0) | 0.0143 | 0.0068 | 0.0213 | 0.0059 |

| (0.9,0.8) | 0.0144 | 0.0067 | 0.0125 | 0.0071 |

| (0,1.6) | 0.0116 | 0.0047 | 0.0157 | 0.0072 |

| (−0.9,0.8) | 0.0119 | 0.0076 | 0.0141 | 0.0072 |

| (−1.8,0) | 0.0215 | 0.0071 | 0.0202 | 0.0066 |

| (−0.9,−0.8) | 0.0122 | 0.0051 | 0.0106 | 0.0052 |

| (0,−1.6) | 0.0088 | 0.0067 | 0.0089 | 0.0062 |

| (0.9,−0.8) | 0.0162 | 0.0070 | 0.0177 | 0.0068 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H. Wafer Center Alignment System of Transfer Robot Based on Reduced Number of Sensors. Sensors 2022, 22, 8521. https://doi.org/10.3390/s22218521

Kim H. Wafer Center Alignment System of Transfer Robot Based on Reduced Number of Sensors. Sensors. 2022; 22(21):8521. https://doi.org/10.3390/s22218521

Chicago/Turabian StyleKim, Hyungjong. 2022. "Wafer Center Alignment System of Transfer Robot Based on Reduced Number of Sensors" Sensors 22, no. 21: 8521. https://doi.org/10.3390/s22218521