Slip Flow Analysis in an Experimental Chamber Simulating Differential Pumping in an Environmental Scanning Electron Microscope

Abstract

:1. Introduction

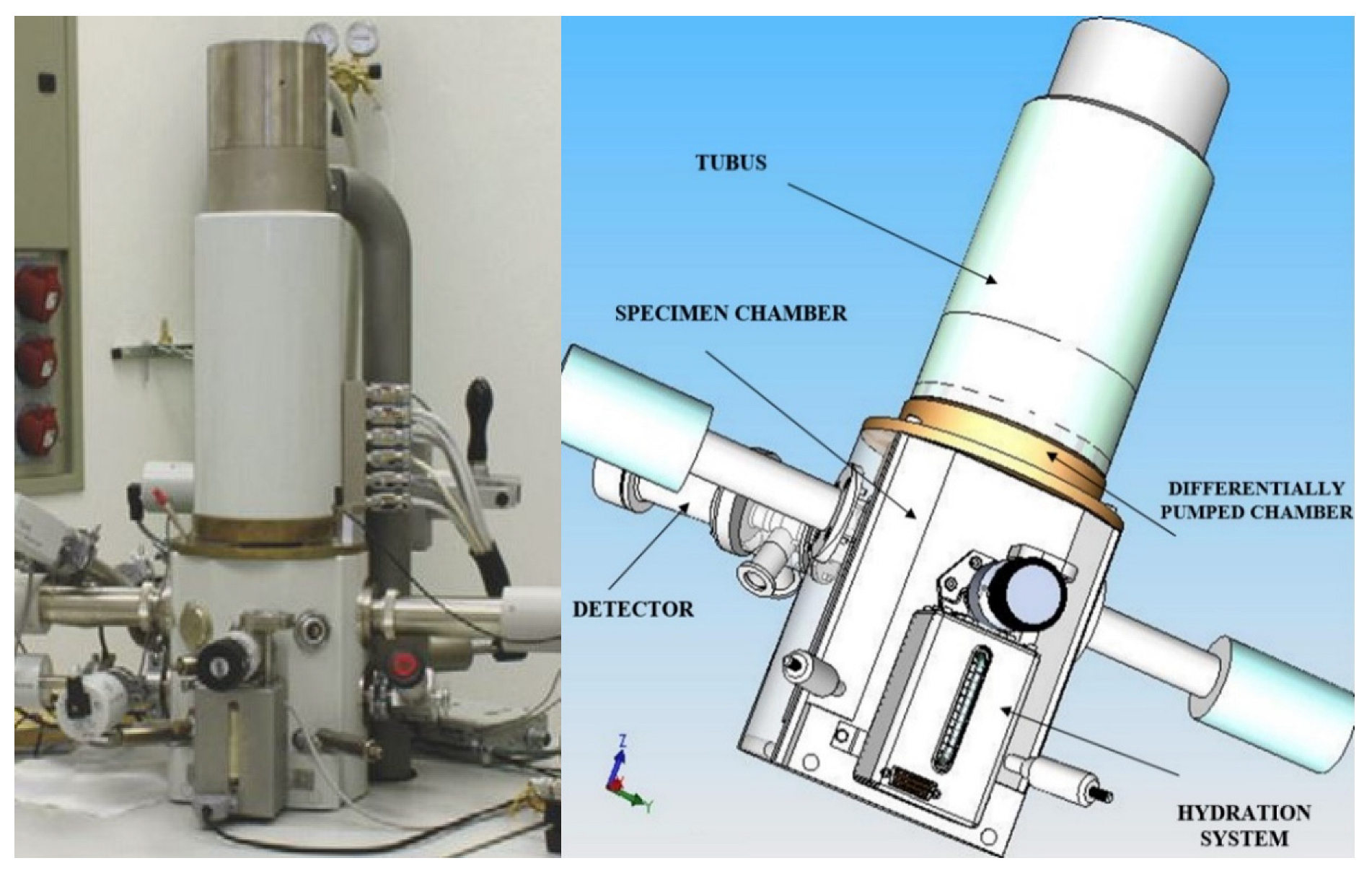

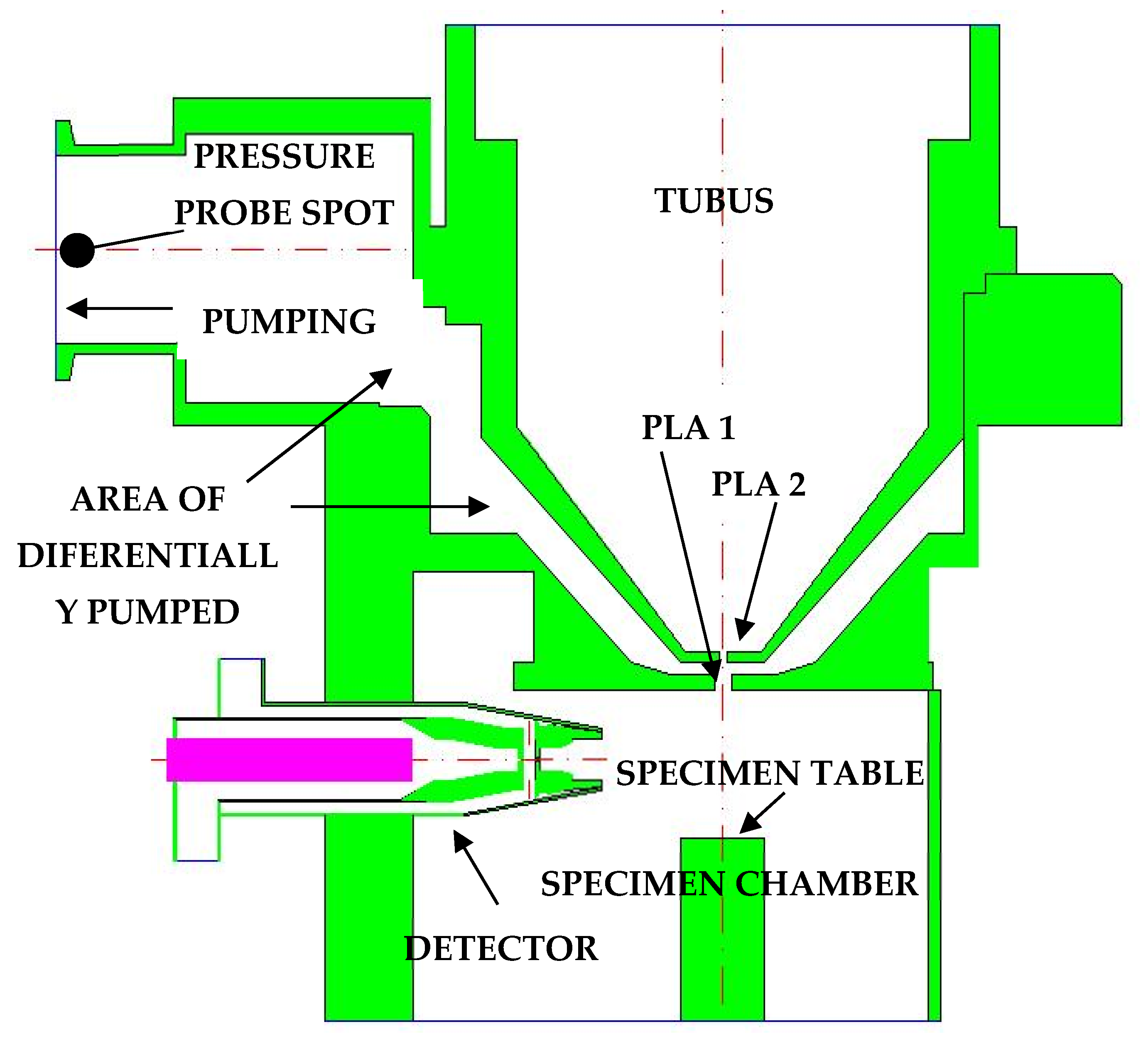

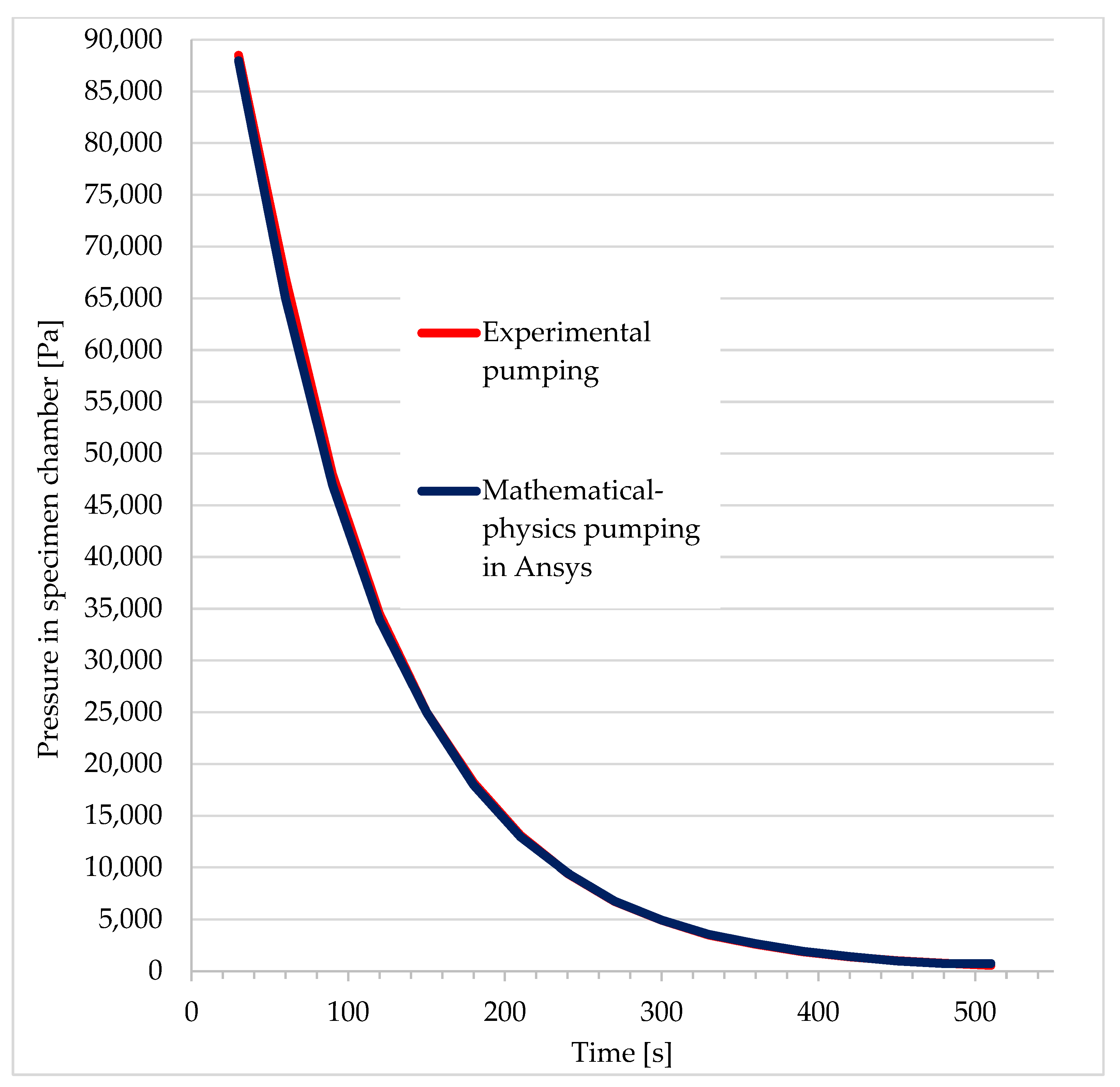

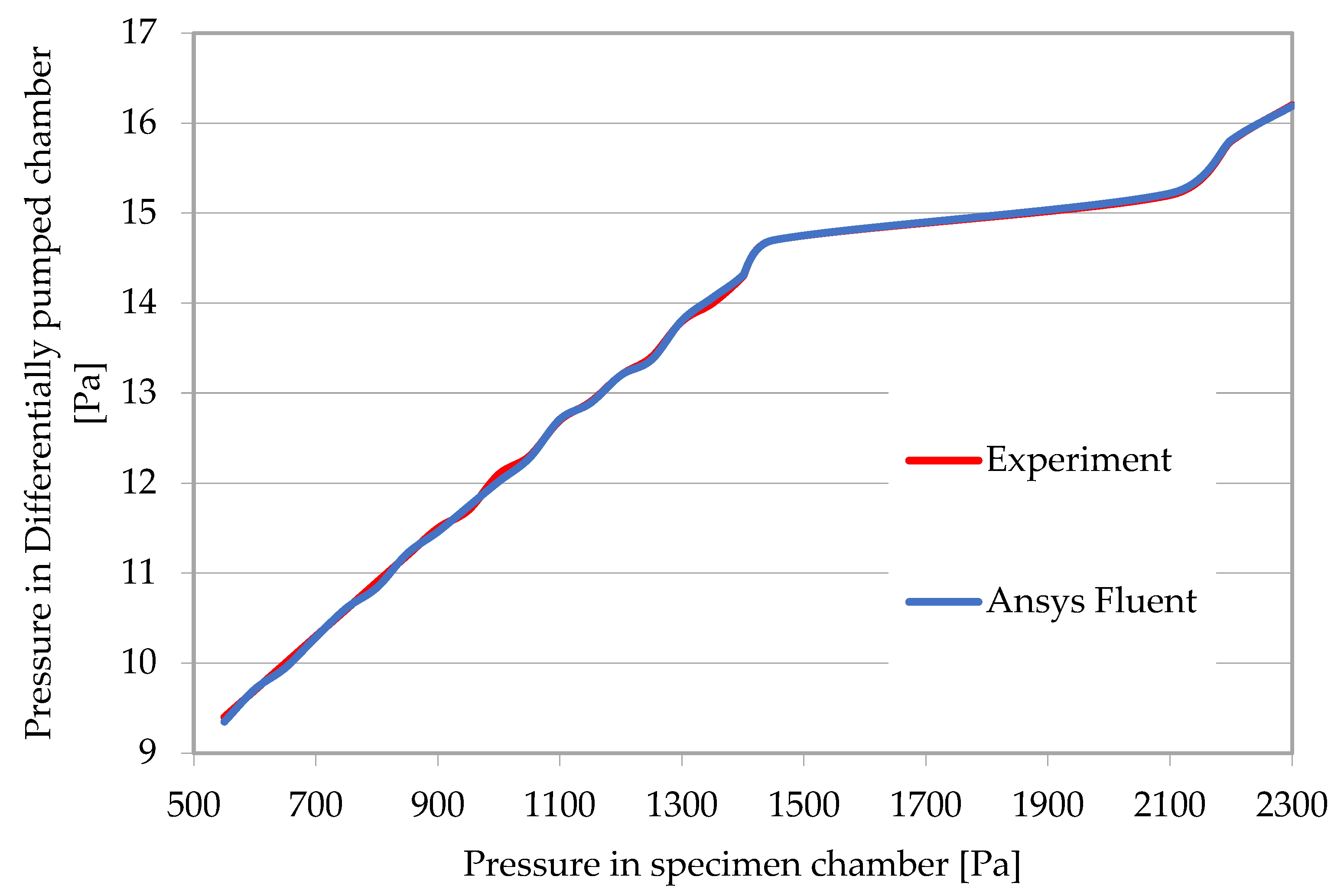

2. Initial Experiment

- Provides exact resolution of contact and shock discontinuities

- Preserves positivity of scalar quantities

- Free of oscillations at stationary and moving shocks

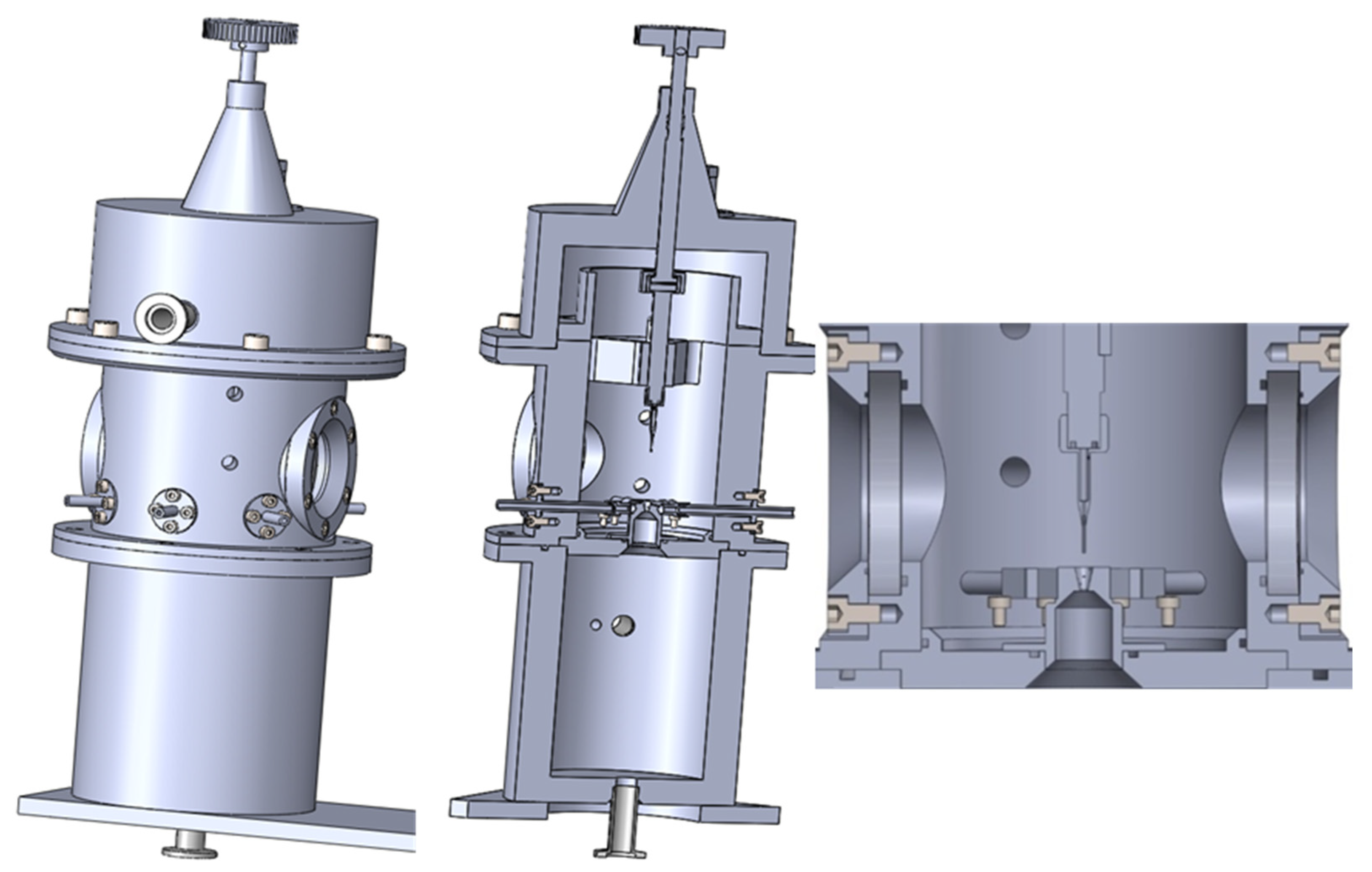

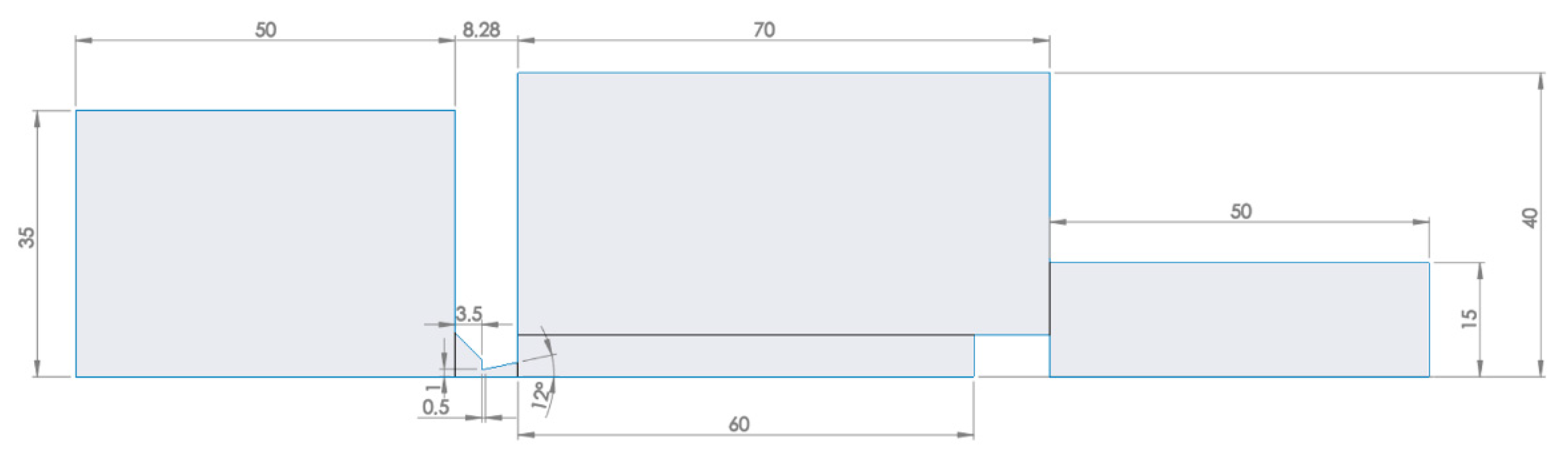

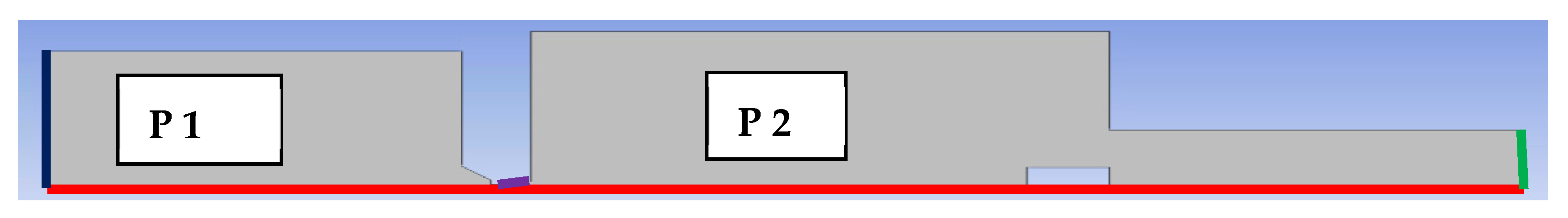

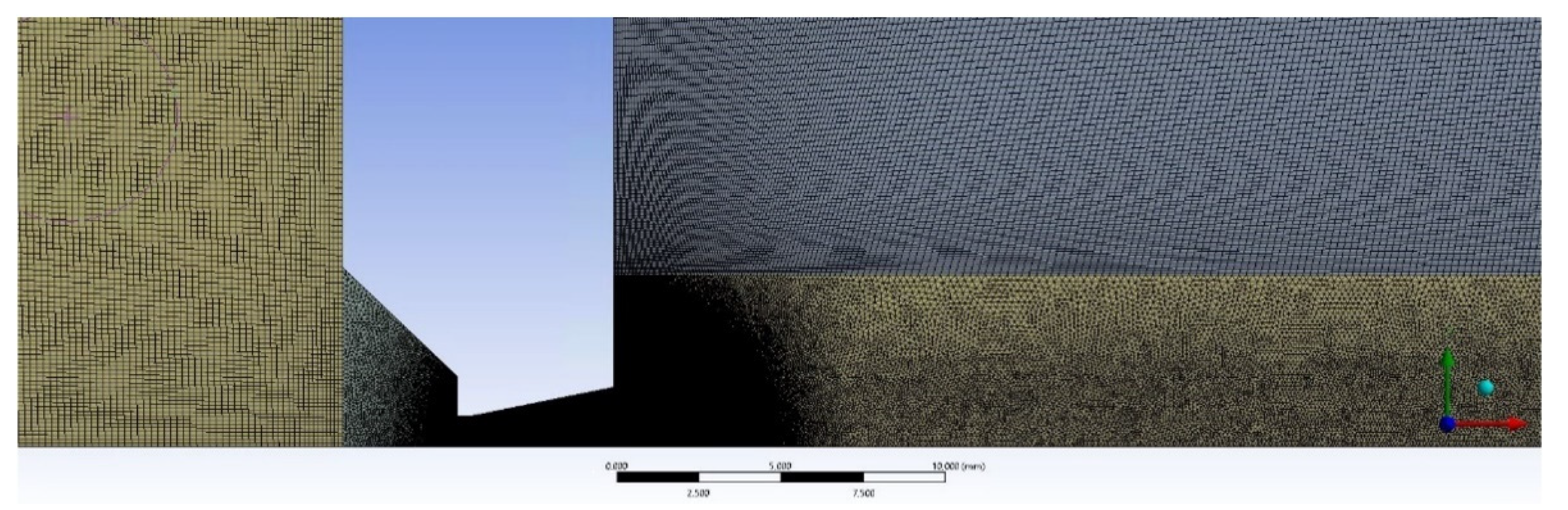

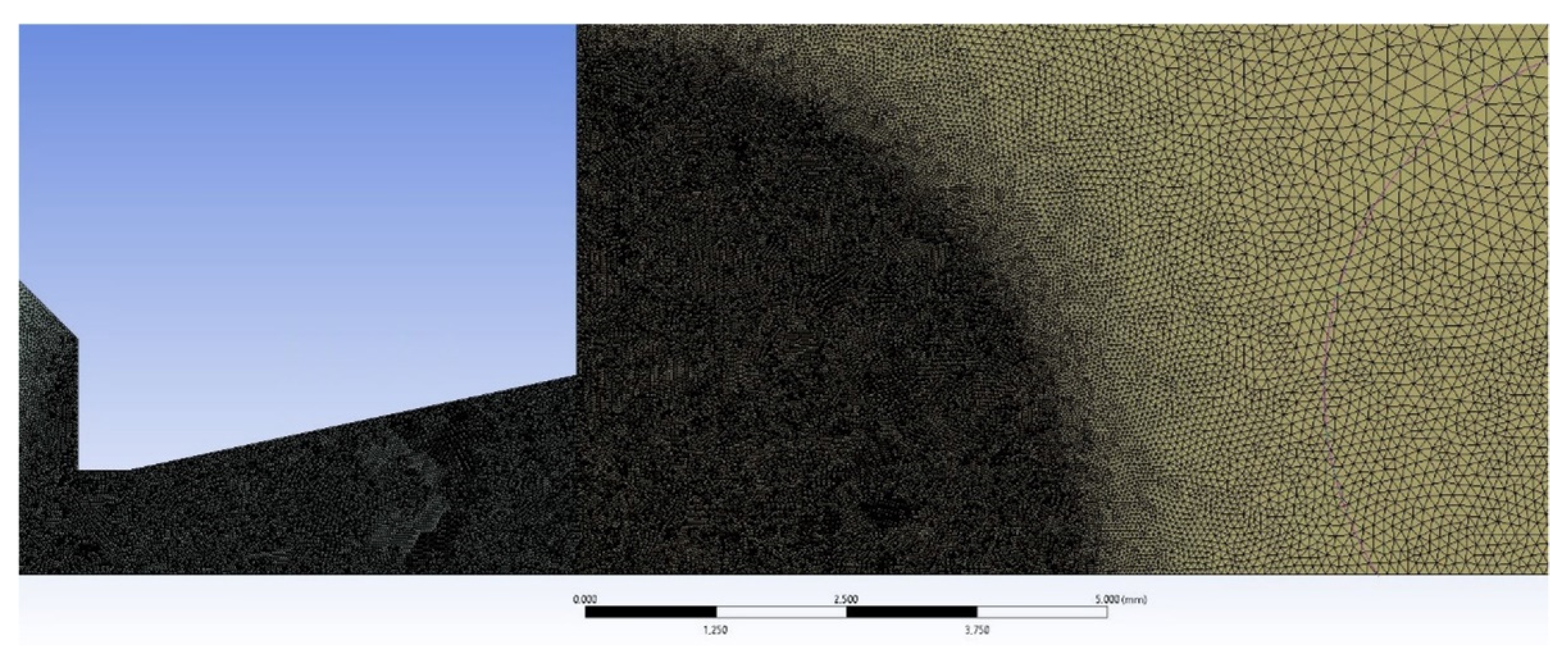

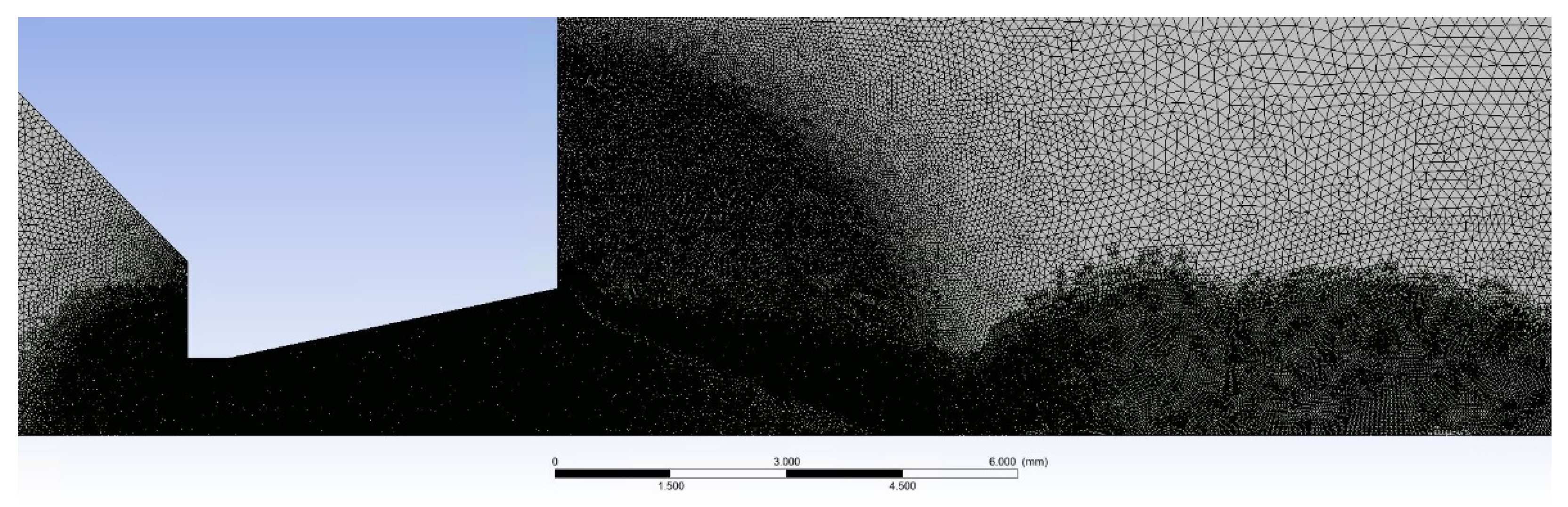

3. Experimental Chamber

4. Ansys Fluent

- Kn < 0.01 Continuous (viscous) flow

- 0.01 < Kn < 0.1 Slip flow

- 0.1 < Kn < 0.5 Transient flow

- Kn > 0.5 Movement of free molecules

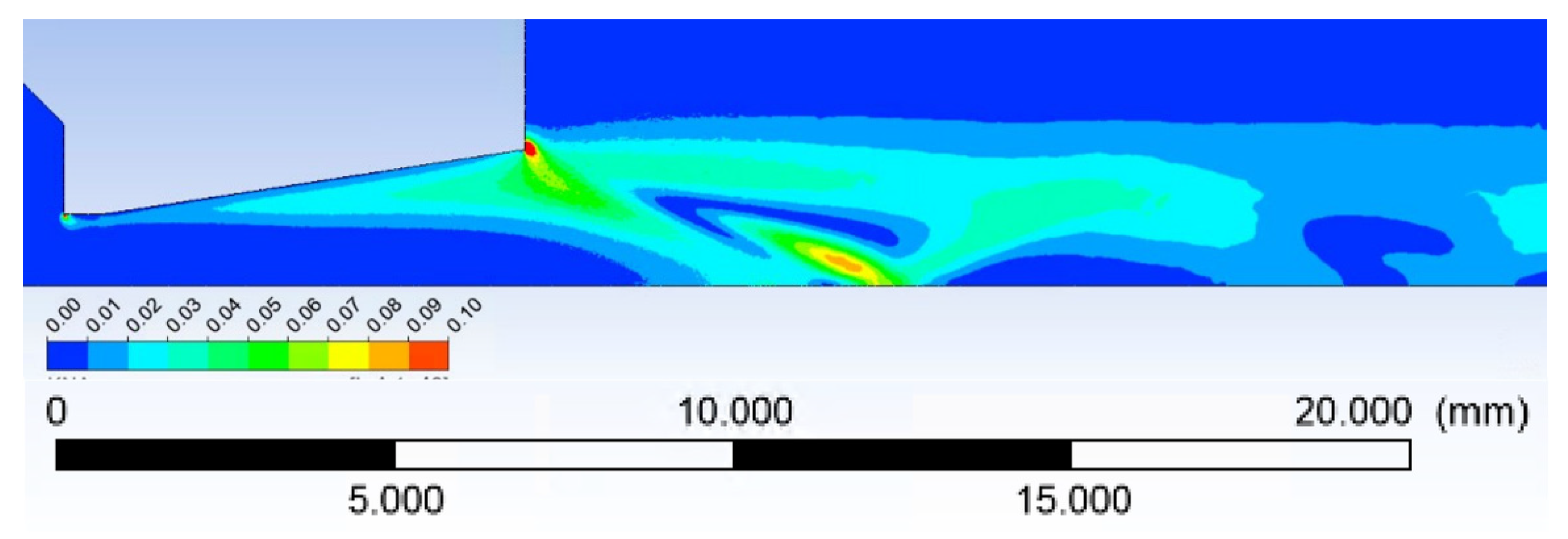

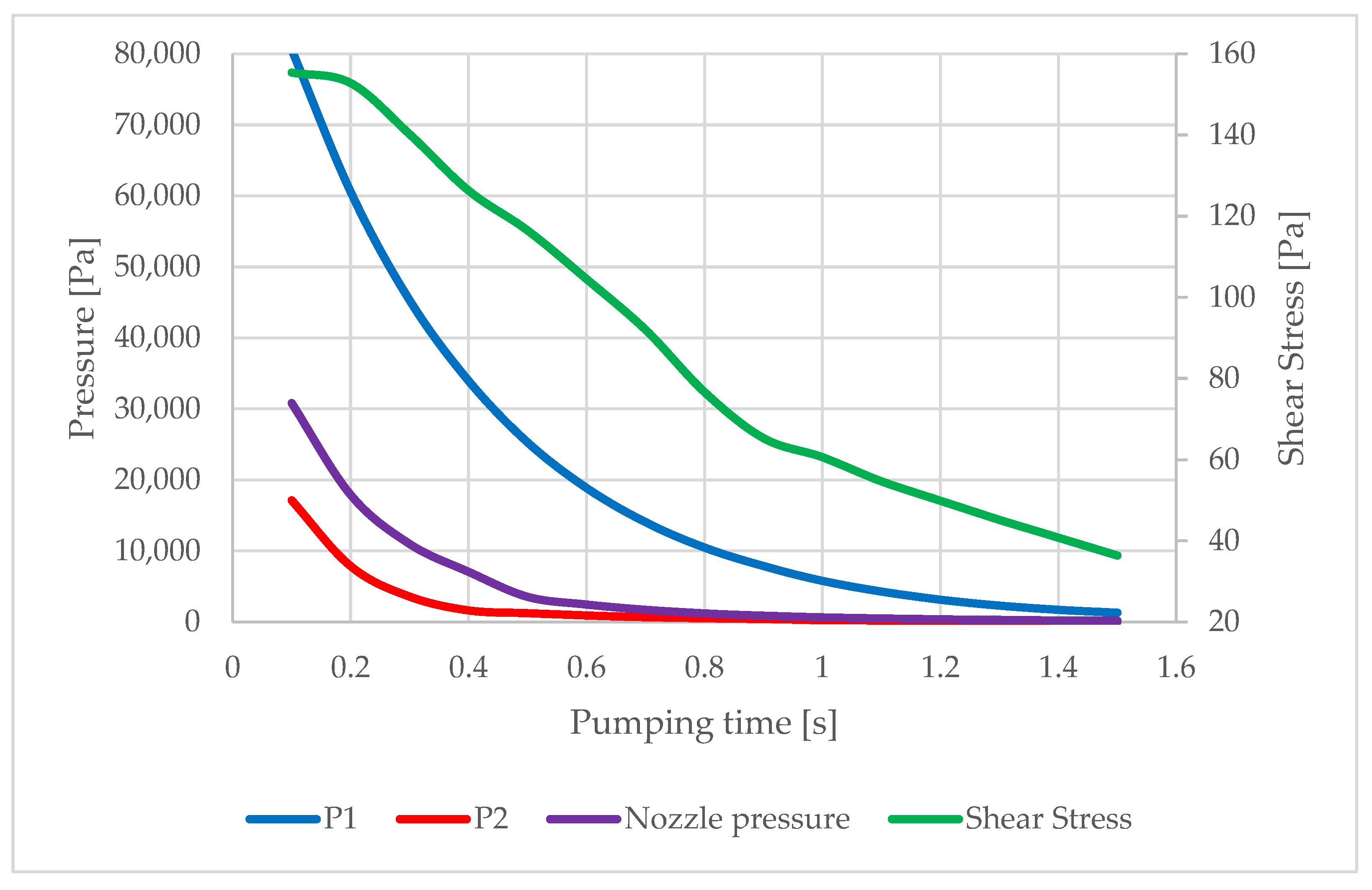

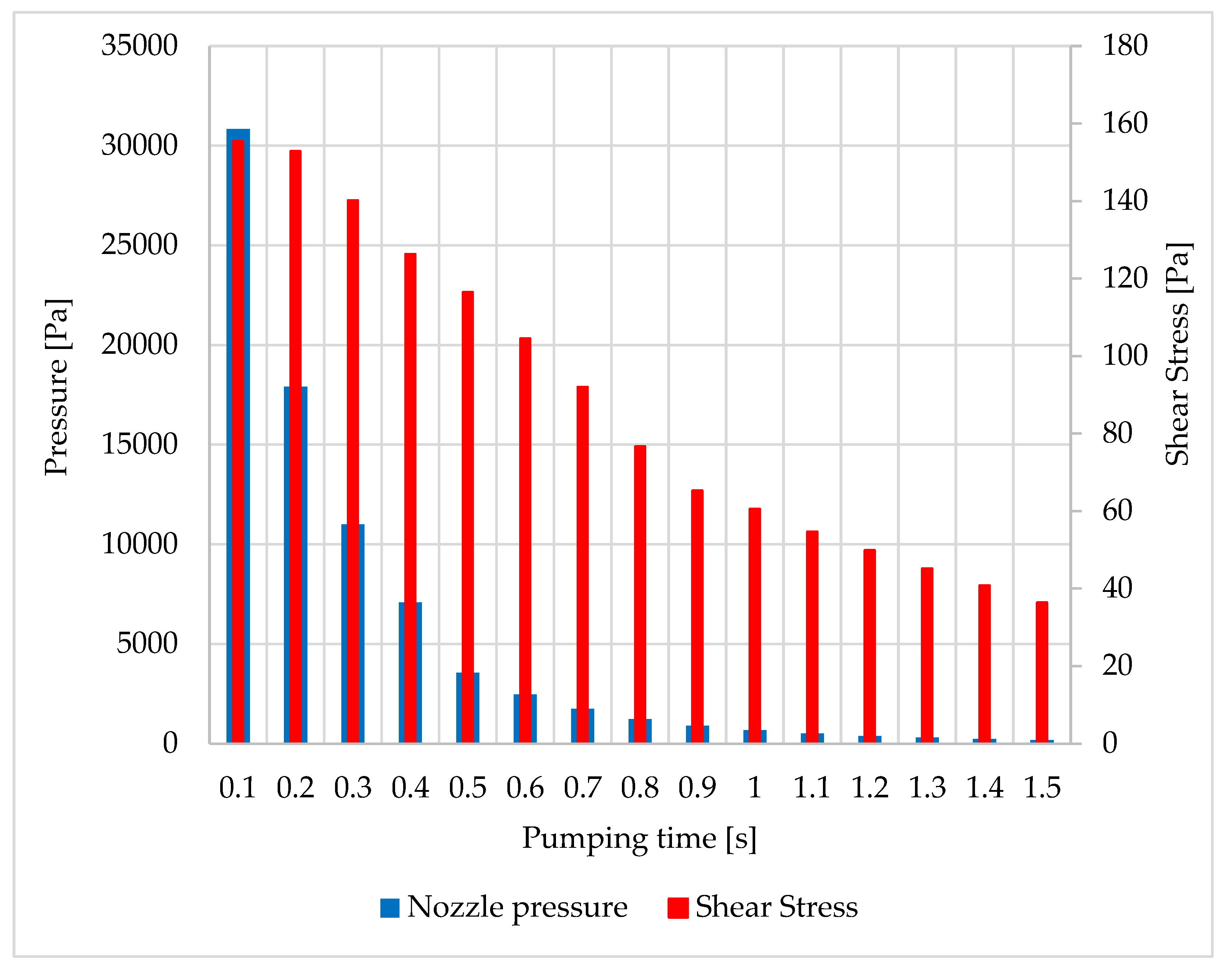

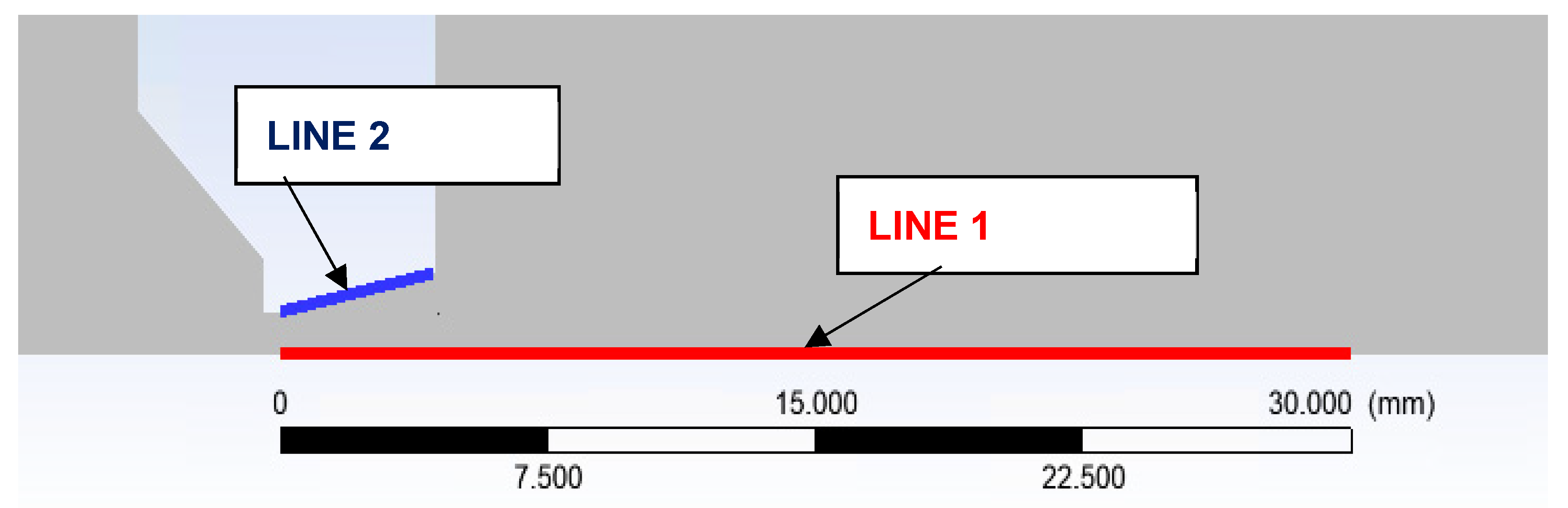

5. Shear Stress Analysis in Experimental Nozzle

- P1 = 2000 Pa

- P2 = 100 Pa

- Specific Heat: 1006.43 J∙kg−1∙K−1

- Thermal Conductivity: 0.0242 W∙m−1∙K−1

- Viscosity: 1.7894∙10−5 kg∙m−1∙s−1

- Molecular Weight: 28.966 kg∙kmol−1

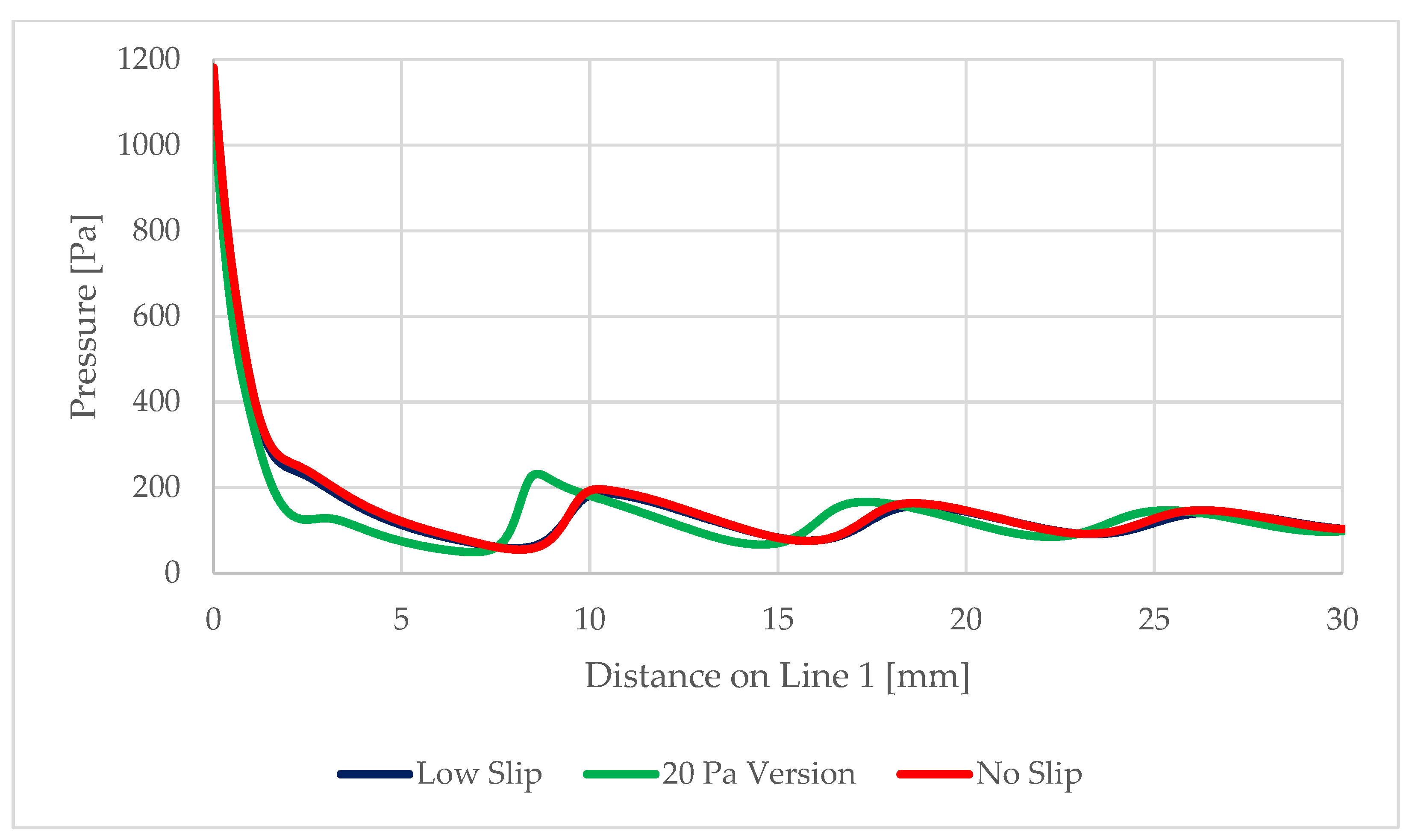

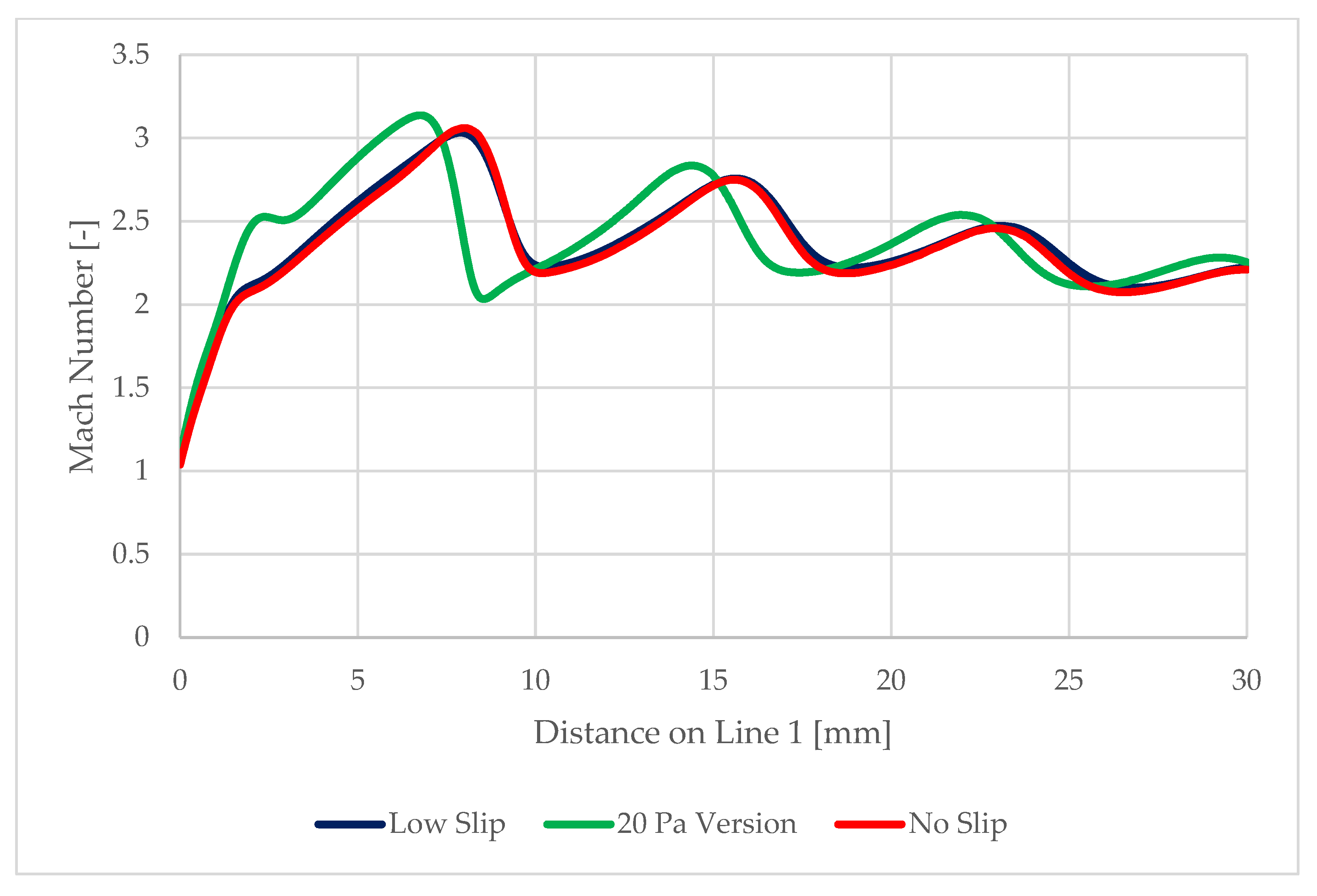

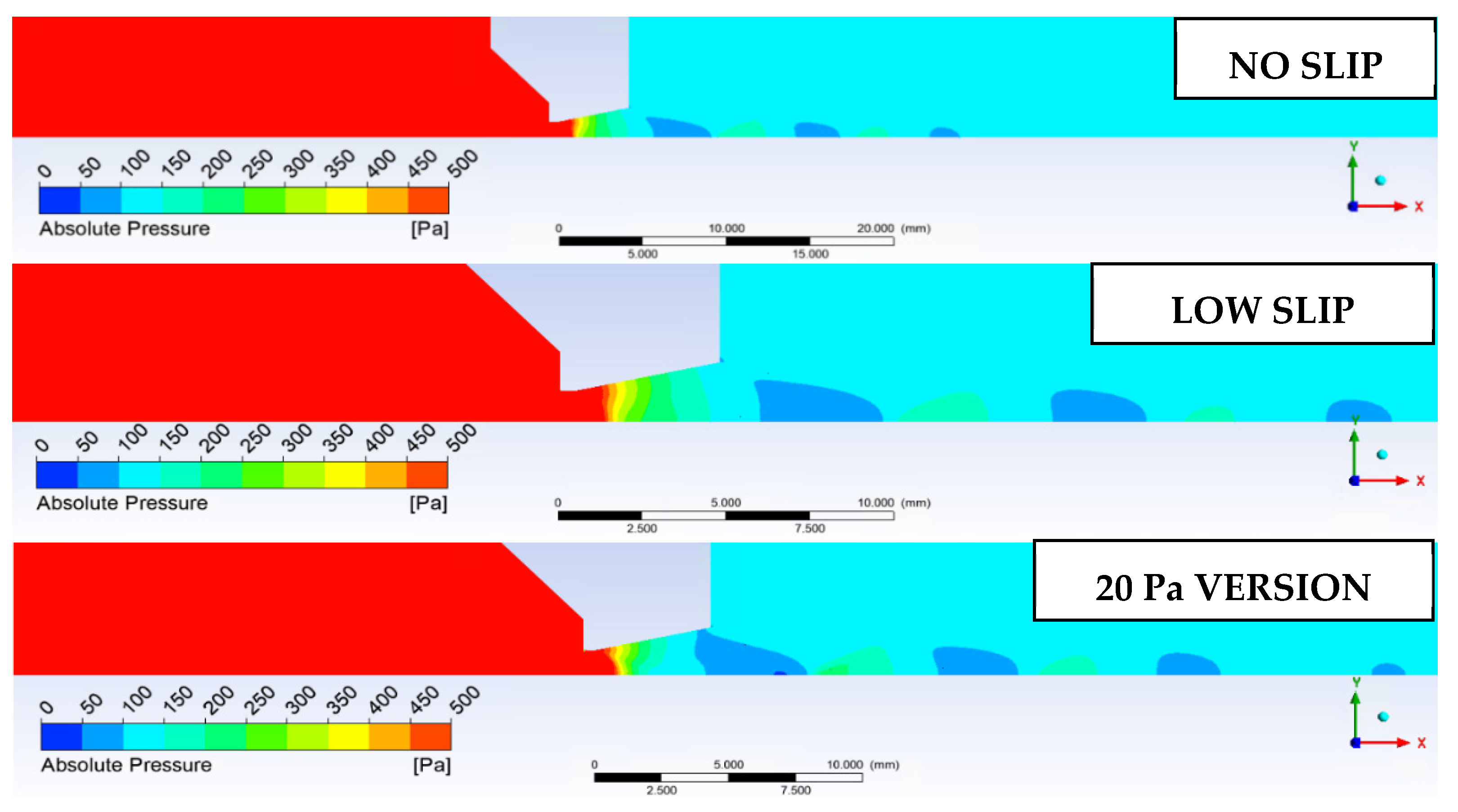

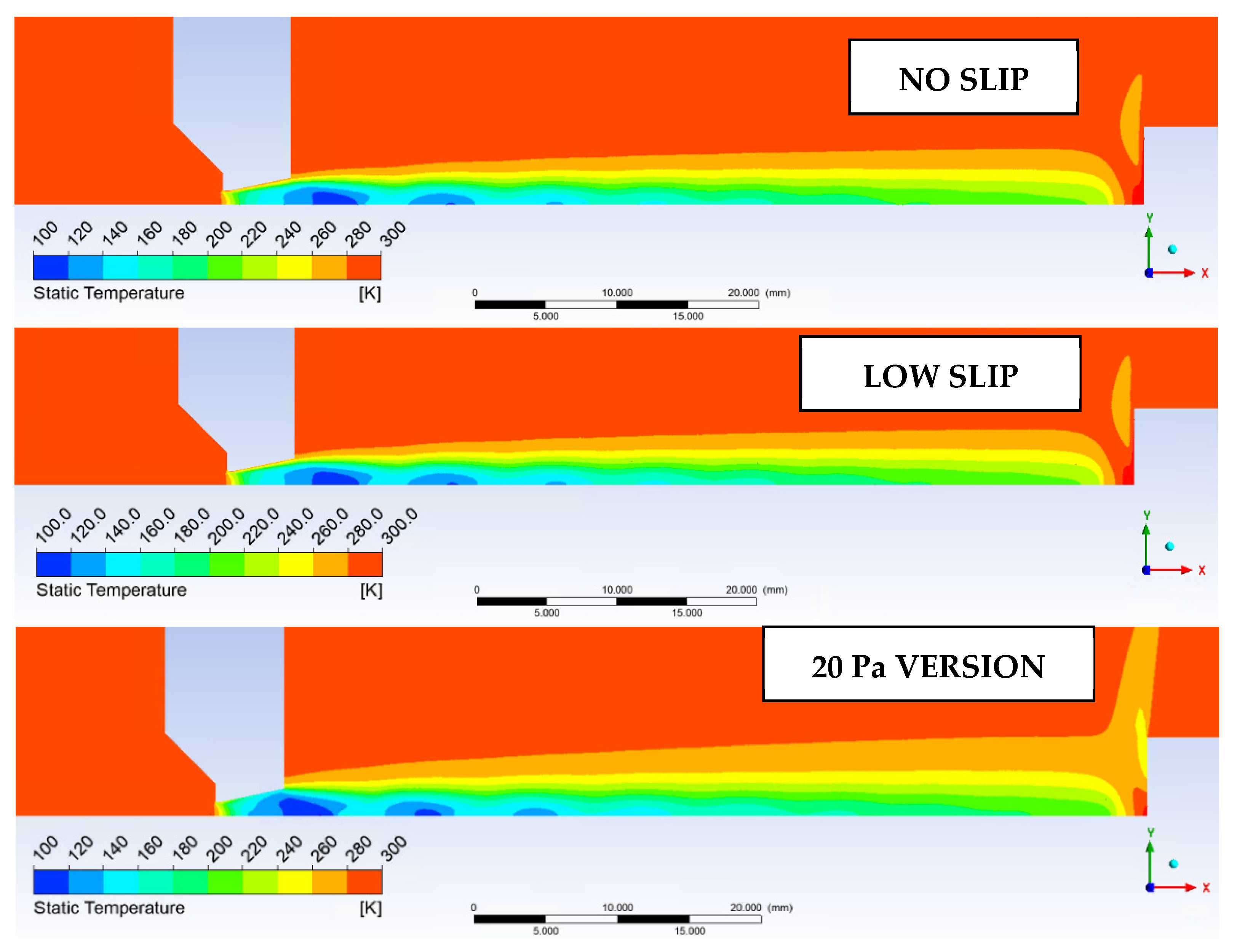

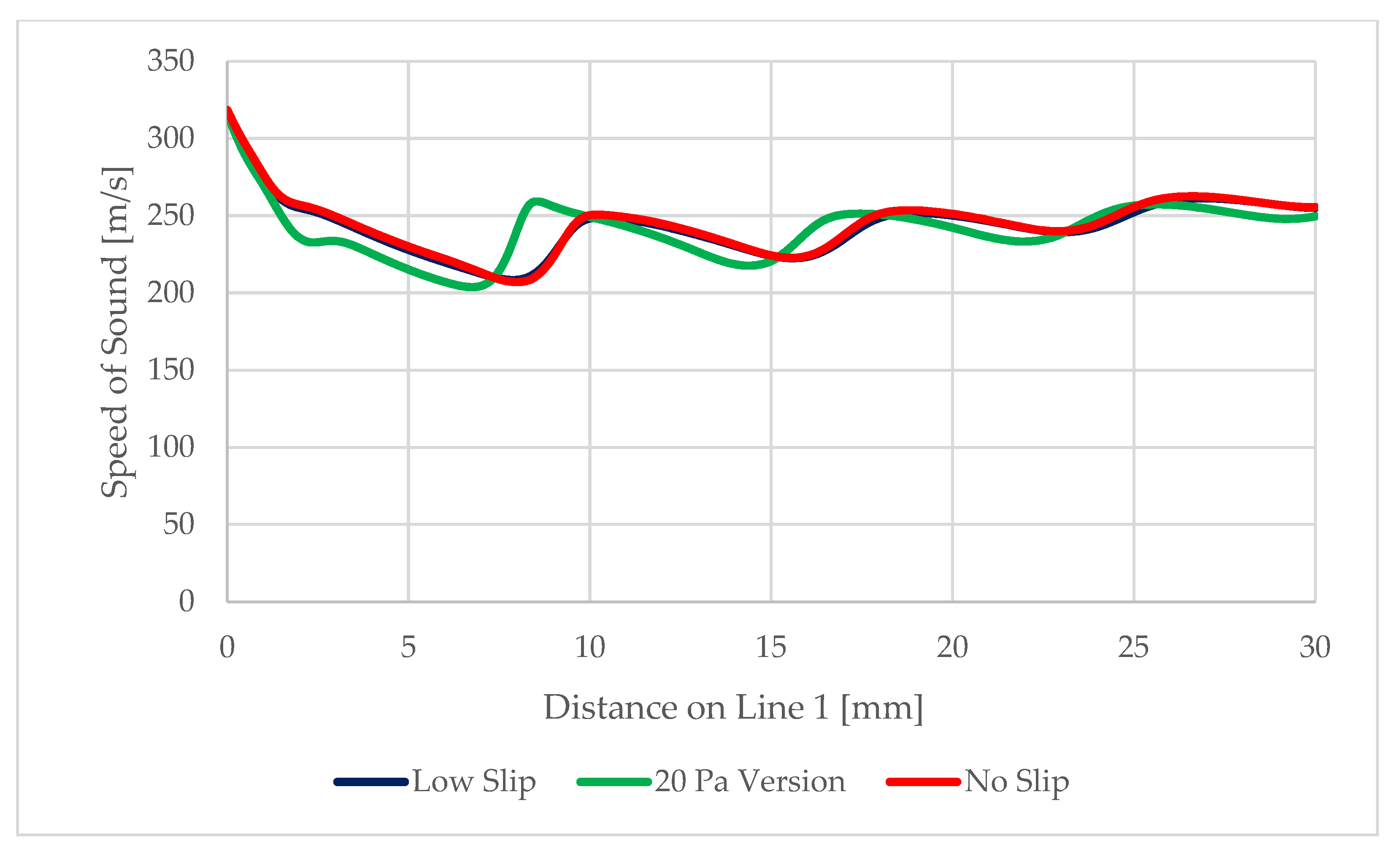

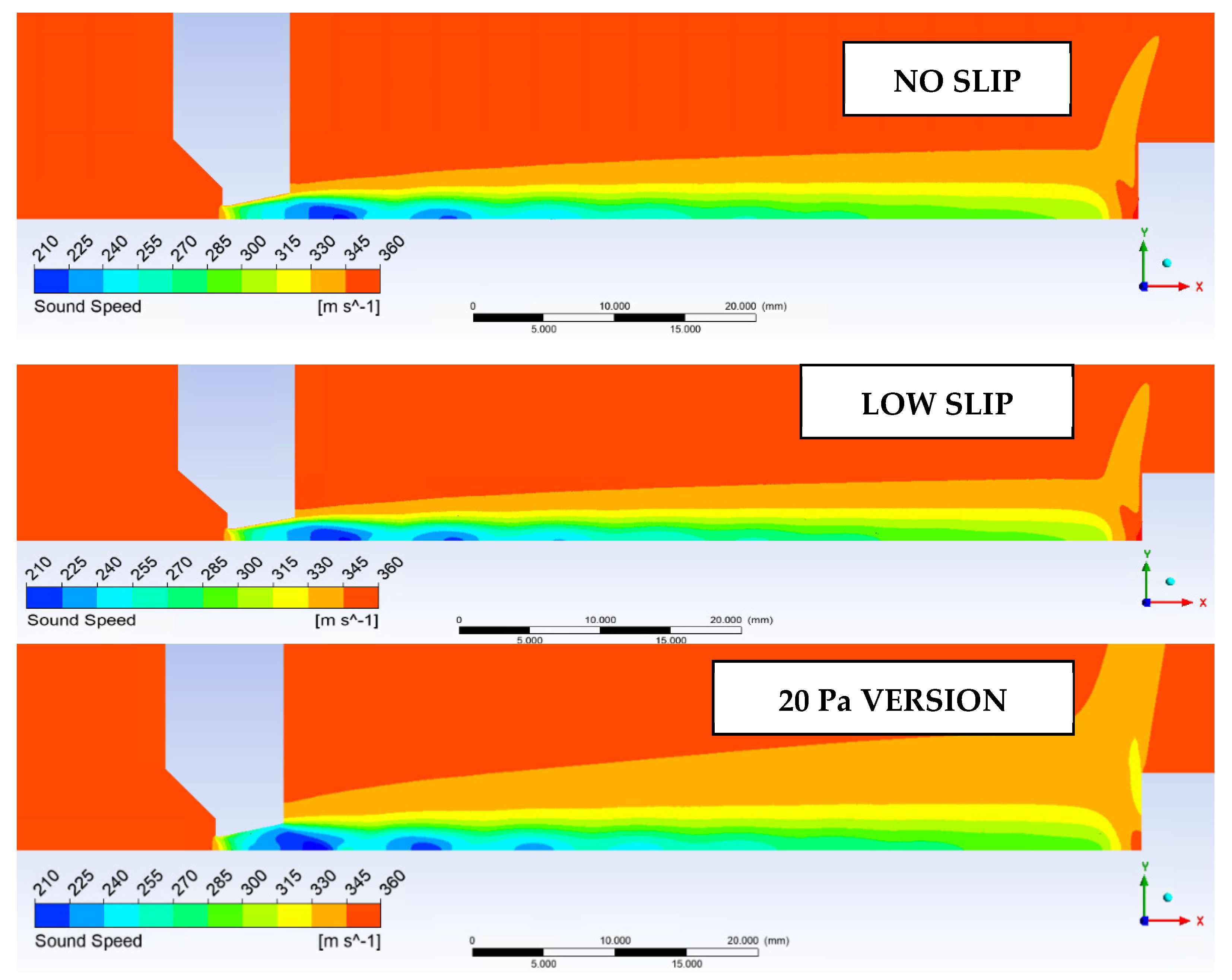

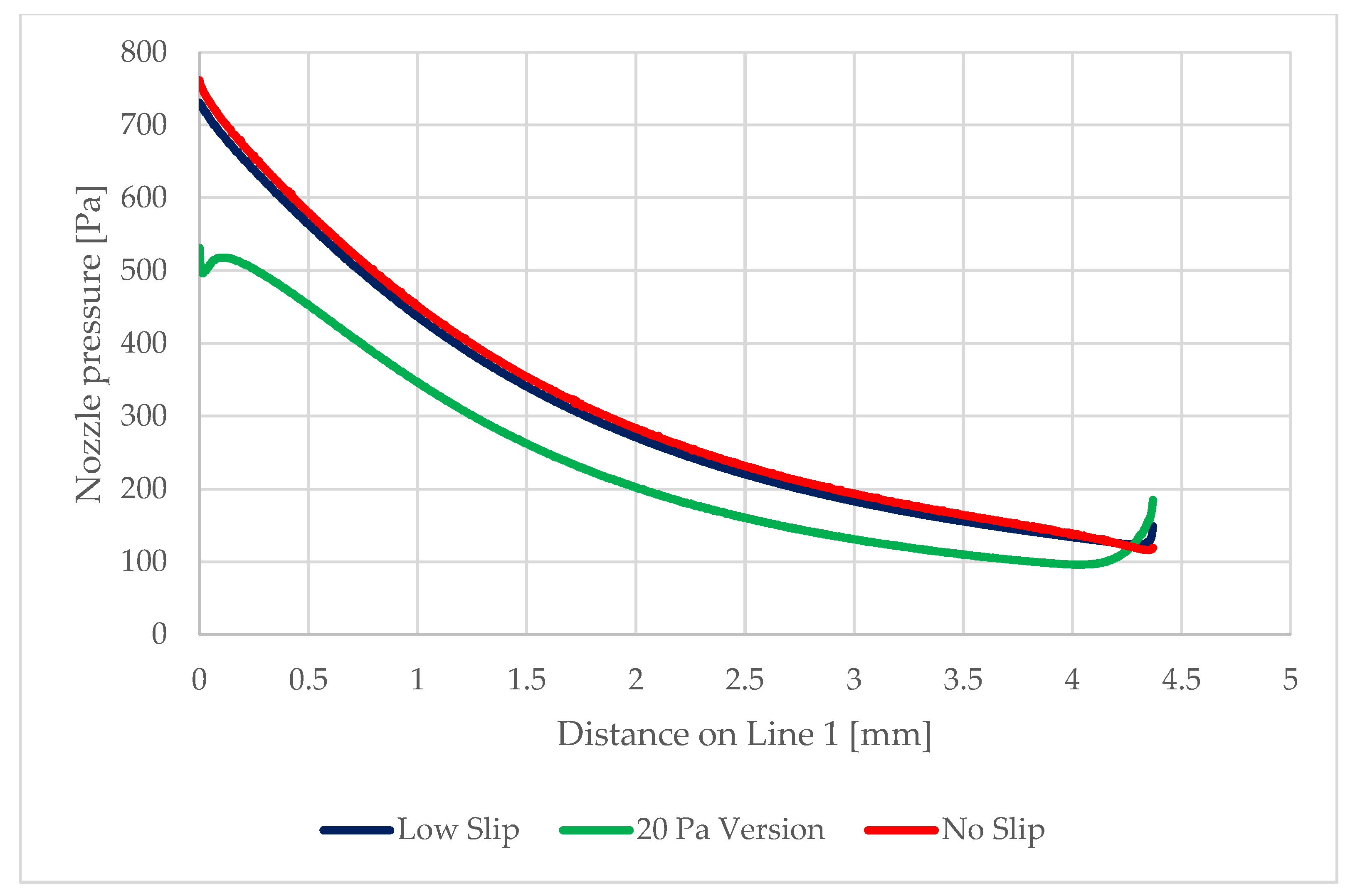

Evaluation of Slip Flow Variants

- Continuity-10−3

- X-velocity-10−3

- Y-velocity-10−3

- Energy-10−3

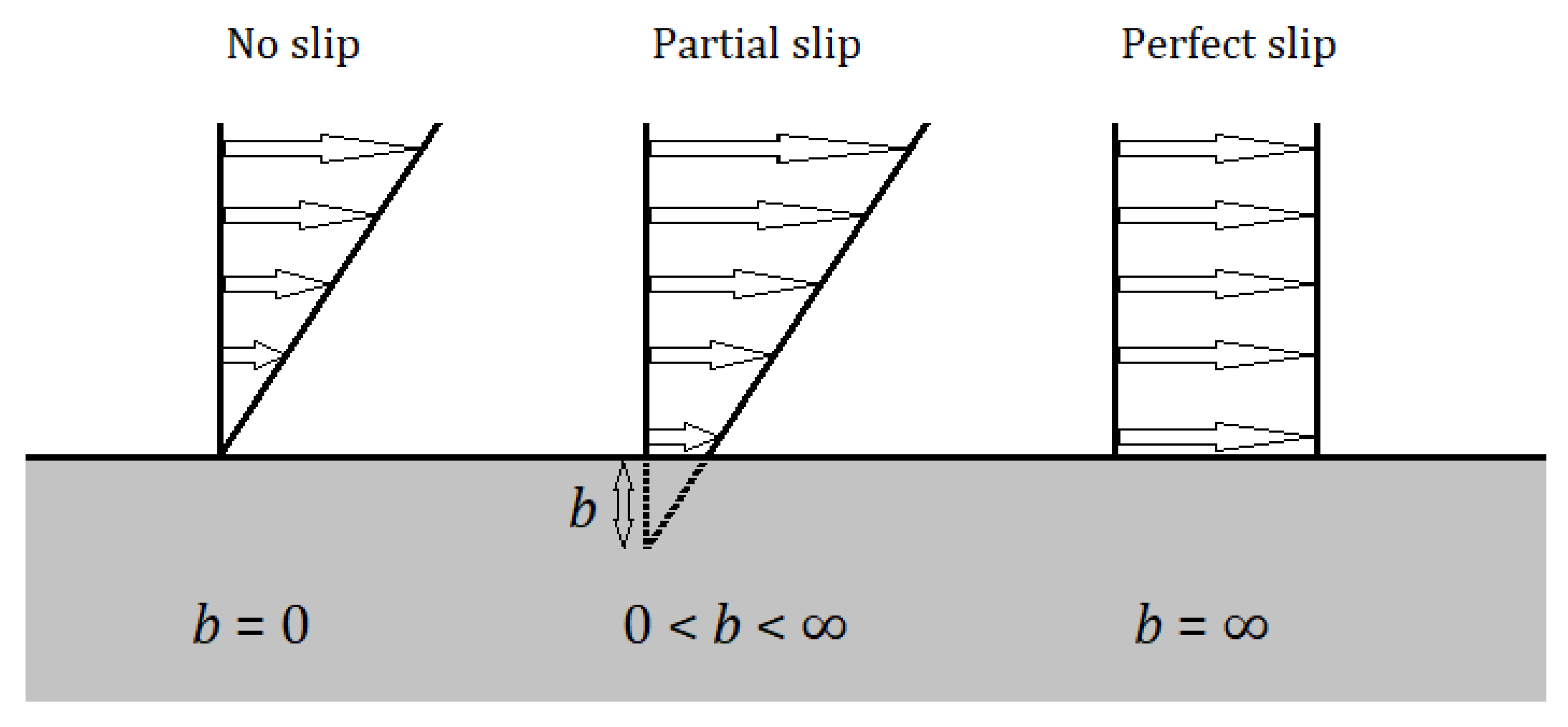

- For the first variant—No Slip—the walls are set to no-slip mode. This variant was chosen as a reference to compare the nature of the flow with no-slip with subsequent variants with slip.

- For the second variant—Low-Pressure Boundary Slip—slip flow mode is set on the walls in Ansys Fluent, respecting the lower pressure condition using Maxwell’s model [13]:where U and V represent velocity components that are parallel and perpendicular to the wall. The indices g, w and c indicate the velocities of the gas, the wall and the center of the cell, respectively. δ is the distance from the center of the cell to the wall. Lc is the characteristic length. αv is the momentum accommodation coefficient of the gas mixture, and its value is calculated as the mass-weighted average of each gas in the system.This option was chosen as an evaluation of the solution of a given mathematical Maxwell model for ESEM conditions with the expected effect of a low slip.

- For the third variant—20 Pa version—the nozzle walls are given the shear stress evaluated from the nozzle walls from the first variant, converted to a value of 20 Pa, as the lowest that occurs on the wall at a given ratio.This option was chosen to evaluate the transferred data from a time-varying task during which shear stress on the walls during the pumping process was evaluated. The lowest value of shear stress on the nozzle wall was selected from a given time step and transferred to that task.

- Static pressure development

- Static temperature

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tihlaříková, E.; Neděla, V.; Dordevic, B. In-situ preparation of plant samples in ESEM for energy dispersive x-ray microanalysis and repetitive observation in SEM and ESEM. Sci. Rep. 2019, 9, 2300. [Google Scholar] [CrossRef] [Green Version]

- Neděla, V.; Hřib, J.; Havel, L.; Hudec, J.; Runštuk, J. Imaging of Norway spruce early somatic embryos with the ESEM, Cryo-SEM and laser scanning microscope. Micron 2016, 84, 67–71. [Google Scholar] [CrossRef] [PubMed]

- Vyroubal, P.; Maxa, J.; Neděla, V.; Jirák, J.; Hladká, K. Apertures with Laval Nozzle and Circular Orifice in Secondary Electron Detector for Environmental Scanning Electron Microscope. Adv. Mil. Technol. 2013, 8, 59–69. [Google Scholar]

- Neděla, V.; Konvalina, I.; Lencová, B.; Zlámal, J. Comparison of calculated, simulated and measured signal amplification in variable pressure SEM. Nucl. Instrum. Methods Phys. Res. Sect. A 2011, 645, 79–83. [Google Scholar] [CrossRef]

- Neděla, V.; Konvalina, I.; Oral, M.; Hudec, J. The Simulation of Energy Distribution of Electrons Detected by Segmental Ionization Detector in High Pressure Conditions of ESEM. Microsc. Microanal. 2015, 21, 264–269. [Google Scholar] [CrossRef] [Green Version]

- Jirák, J.; Neděla, V.; Černoch, P.; Čudek, P.; Runštuk, J. Scintillation SE detector for variable pressure scanning electron microscopes. J. Microsc. 2010, 239, 233–238. [Google Scholar] [CrossRef] [PubMed]

- Neděla, V.; Tihlaříková, E.; Runštuk, J.; Hudec, J. High-efficiency detector of secondary and backscattered electrons for low-dose imaging in the ESEM. Ultramicroscopy 2018, 184, 1–11. [Google Scholar] [CrossRef]

- Neděla, V.; Tihlaříková, E.; Maxa, J.; Imrichová, K.; Bučko, M.; Gemeiner, P. Simulation-based optimisation of thermodynamic conditions in the ESEM for dynamical in-situ study of spherical polyelectrolyte complex particles in their native state. Ultramicroscopy 2020, 211, 112954. [Google Scholar] [CrossRef]

- Stelate, A.; Tihlaříková, E.; Schwarzerová, K.; Neděla, V.; Petrášek, J. Correlative Light-Environmental Scanning Electron Microscopy of Plasma Membrane Efflux Carriers of Plant Hormone Auxin. Biomolecules 2021, 11, 1407. [Google Scholar] [CrossRef]

- Bilek, M.; Maxa, J.; Hlavata, P.; Bayer, R. Modeling and simulation of a velocity field within supersonic flows in low-pressure areas. ECS Trans. 2017, 81, 311–316. [Google Scholar] [CrossRef]

- Šabacká, P.; Neděla, V.; Maxa, J.; Bayer, R. Application of Prandtl’s Theory in the Design of An Experimental Chamber for Static Pressure Measurements. Sensors 2021, 21, 6849. [Google Scholar] [CrossRef] [PubMed]

- Barth, T.J.; Jespersen, D. The design and application of upwind schemes on unstructured meshes. In Proceedings of the AIAA 27th Aerospace Sciences Meeting, Reno, NV, USA, 9–12 January 1989. Technical Report AIAA-89-0366. [Google Scholar]

- Ansys Fluent Theory Guide. Available online: www.ansys.com (accessed on 21 October 2022).

- Bayer, R.; Maxa, J.; Šabacká, P. Energy Harvesting Using Thermocouple and Compressed Air. Sensors 2021, 21, 6031. [Google Scholar] [CrossRef] [PubMed]

- Uruba, V. Turbulence. Available online: http://www2.it.cas.cz/~{}uruba/docs/Aero/Turbulence_45.pdf (accessed on 12 October 2021).

- Roy, S.; Raju, R. Modeling gas flow through microchannels and nanopores. J. Appl. Phys. 2003, 93, 4870–4879. [Google Scholar] [CrossRef]

- Van Eck, H.J.N.; Koppers, W.R.; van Rooij, G.; Goedheer, W.J.; Engeln, R.; Schram, D.C.; Cardozo, N.J.L.; Kleyn, A.W. Modeling and experiments on differential pumping in linear plasma generators operating at high gas flows. J. Appl. Phys. 2009, 105, 063307. [Google Scholar] [CrossRef] [Green Version]

- Gupta, G.; Rana, P. Comparative Study on Rosseland’s Heat Flux on Three-Dimensional MHD Stagnation-Point Multiple Slip Flow of Ternary Hybrid Nanofluid over a Stretchable Rotating Disk. Mathematics 2022, 10, 3342. [Google Scholar] [CrossRef]

- Tomy, A.M.; Dadzie, S.K. Diffusion-Slip Boundary Conditions for Isothermal Flows in Micro- and Nano-Channels. Micromachines 2022, 13, 1425. [Google Scholar] [CrossRef] [PubMed]

- Akram, S.; Athar, M.; Saeed, K.; Razia, A.; Alghamdi, M.; Muhammad, T. Impact of Partial Slip on Double Diffusion Convection of Sisko Nanofluids in Asymmetric Channel with Peristaltic Propulsion and Inclined Magnetic Field. Nanomaterials 2022, 12, 2736. [Google Scholar] [CrossRef] [PubMed]

- Danilatos, G.D. Velocity and ejector-jet assisted differential pumping: Novel design stages for environmental SEM. Micron 2012, 43, 600–611. [Google Scholar] [CrossRef]

- Guo, W.; Hou, G. Three-Dimensional Simulations of Anisotropic Slip Microflows Using the Discrete Unified Gas Kinetic Scheme. Entropy 2022, 24, 907. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.-C. Asymmetric Electrokinetic Energy Conversion in Slip Conical Nanopores. Nanomaterials 2022, 12, 1100. [Google Scholar] [CrossRef] [PubMed]

- Salga, J.; Hoření, B. Tabulky Proudění Plynu; UNOB: Brno, Czech Republic, 1997. [Google Scholar]

| Pressure in Specimen Chambre [Pa] | Pressure at the Probe in the Differentially Pumped Chamber–Experiment [Pa] | Pressure at the Probe in the Differentially Pumped Chamber–Ansys [Pa] |

|---|---|---|

| 2300 | 16.2 | 16.19 |

| 2200 | 15.8 | 15.81 |

| 2100 | 15.2 | 15.22 |

| 1450 | 14.7 | 14.7 |

| 1400 | 14.3 | 14.31 |

| 1350 | 14 | 14.06 |

| 1300 | 13.8 | 13.81 |

| 1250 | 13.4 | 13.37 |

| 1200 | 13.2 | 13.2 |

| 1150 | 12.9 | 12.89 |

| 1100 | 12.7 | 12.71 |

| 1050 | 12.3 | 12.28 |

| 1000 | 12.1 | 12.02 |

| 950 | 11.7 | 11.74 |

| 900 | 11.5 | 11.46 |

| 850 | 11.2 | 11.22 |

| 800 | 10.9 | 10.84 |

| 750 | 10.6 | 10.61 |

| 700 | 10.3 | 10.29 |

| 650 | 10 | 9.95 |

| 600 | 9.7 | 9.71 |

| 550 | 9.4 | 9.35 |

| Time [s] | Chamber Values | Nozzle Wall Values | ||||

|---|---|---|---|---|---|---|

| P1 | P2 | Shear Stress [Pa] | Shear Stress x [Pa] | Shear Stress y [Pa] | P Nozzle [Pa] | |

| 0.1 | 80,578 | 17,120 | 155.4 | 134.1 | 30.1 | 30,831.5 |

| 0.2 | 60,554 | 7852 | 152.8 | 134.6 | 29.5 | 17,907.3 |

| 0.3 | 45,302 | 3600 | 140.2 | 126.2 | 27.1 | 11,006.6 |

| 0.4 | 33,957 | 1651 | 126.3 | 116 | 24.6 | 7076.5 |

| 0.5 | 25,302 | 1261.7 | 116.5 | 108.6 | 22.8 | 3564.9 |

| 0.6 | 18,886.9 | 943.9 | 104.5 | 97.7 | 20.4 | 2474.5 |

| 0.7 | 14,054.2 | 705 | 92 | 86.6 | 18 | 1739.4 |

| 0.8 | 10,487.3 | 558.7 | 76.7 | 72.7 | 15 | 1225.6 |

| 0.9 | 7893 | 437 | 65.3 | 62.6 | 12.7 | 903.8 |

| 1.0 | 5805 | 267.8 | 60.6 | 58.9 | 11.8 | 667.2 |

| 1.1 | 4290.8 | 221.4 | 54.7 | 53.5 | 10.6 | 507.5 |

| 1.2 | 3159 | 156 | 49.9 | 48.9 | 9.6 | 386.7 |

| 1.3 | 2332.5 | 118.3 | 45.2 | 44.3 | 8.6 | 298.7 |

| 1.4 | 1736.8 | 90.17 | 40.8 | 40 | 7.7 | 232.1 |

| 1.5 | 1308 | 69.2 | 36.4 | 35.7 | 6.8 | 184.8 |

| No-Slip | Low-PBS | 20 Pa Version | ||||

|---|---|---|---|---|---|---|

| Pressure [Pa] | Temperature [K] | Pressure [Pa] | Temperature [K] | Pressure [Pa] | Temperature [K] | |

| Probe 1 | 620.2 | 278.7 | 603.4 | 277.7 | 481.3 | 224 |

| Probe 2 | 431.1 | 276.3 | 416.2 | 274.9 | 328.5 | 195.7 |

| Probe 3 | 306.4 | 273.8 | 293.6 | 272 | 221.2 | 174.5 |

| Probe 4 | 227.1 | 271.6 | 215.5 | 269.6 | 156.1 | 160.2 |

| Probe 5 | 176.3 | 270 | 166.6 | 267.7 | 118.3 | 152.2 |

| Probe 6 | 137.3 | 268 | 133.6 | 266.1 | 96.4 | 150.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Šabacká, P.; Maxa, J.; Bayer, R.; Vyroubal, P.; Binar, T. Slip Flow Analysis in an Experimental Chamber Simulating Differential Pumping in an Environmental Scanning Electron Microscope. Sensors 2022, 22, 9033. https://doi.org/10.3390/s22239033

Šabacká P, Maxa J, Bayer R, Vyroubal P, Binar T. Slip Flow Analysis in an Experimental Chamber Simulating Differential Pumping in an Environmental Scanning Electron Microscope. Sensors. 2022; 22(23):9033. https://doi.org/10.3390/s22239033

Chicago/Turabian StyleŠabacká, Pavla, Jiří Maxa, Robert Bayer, Petr Vyroubal, and Tomáš Binar. 2022. "Slip Flow Analysis in an Experimental Chamber Simulating Differential Pumping in an Environmental Scanning Electron Microscope" Sensors 22, no. 23: 9033. https://doi.org/10.3390/s22239033

APA StyleŠabacká, P., Maxa, J., Bayer, R., Vyroubal, P., & Binar, T. (2022). Slip Flow Analysis in an Experimental Chamber Simulating Differential Pumping in an Environmental Scanning Electron Microscope. Sensors, 22(23), 9033. https://doi.org/10.3390/s22239033