Explainable AI Algorithms for Vibration Data-Based Fault Detection: Use Case-Adadpted Methods and Critical Evaluation

Abstract

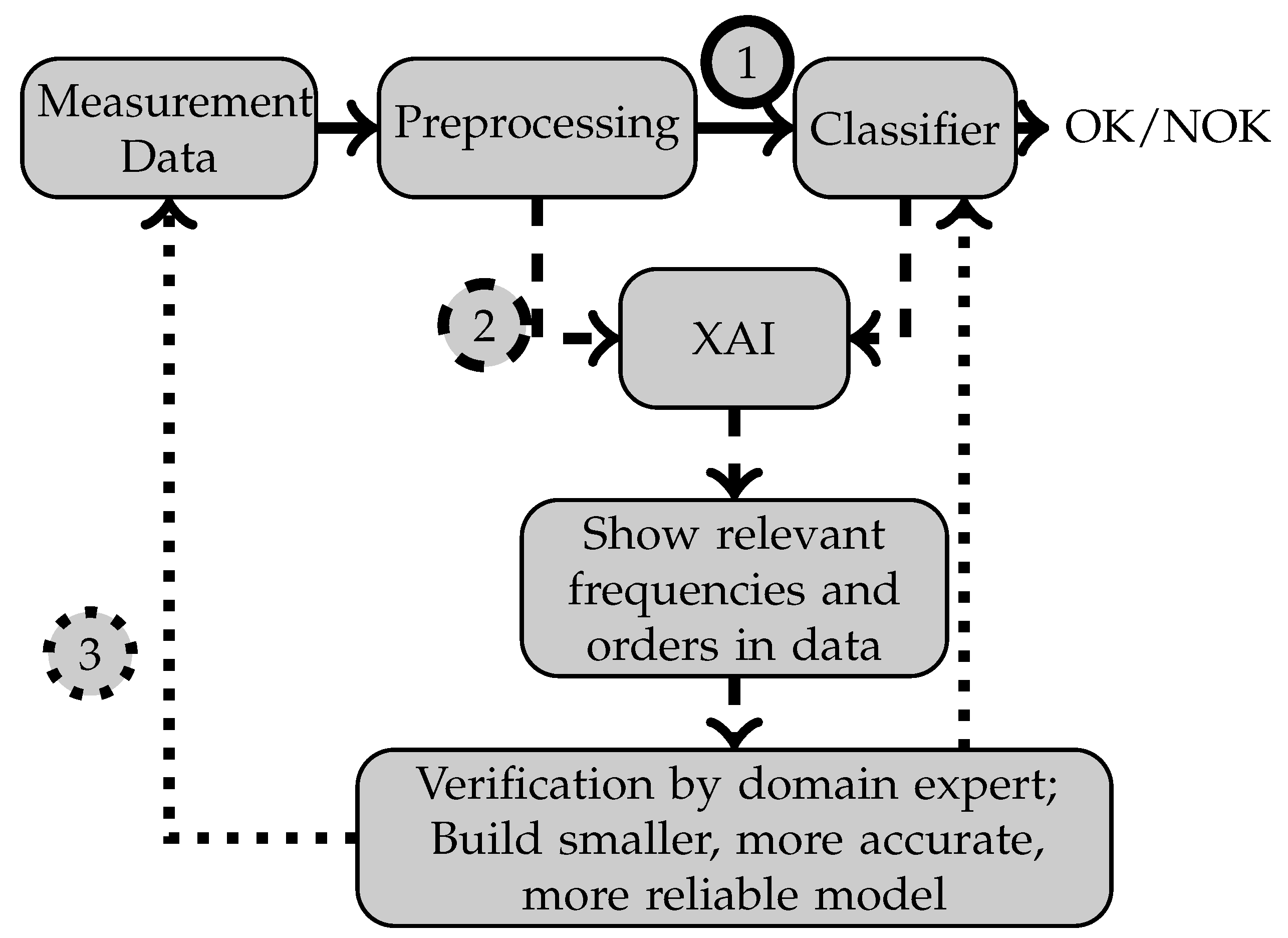

:1. Introduction

- We created a synthetic data set based on sinusoidal data, allowing for an intuitive comparison of XAI algorithms applied to a supervised classification task based on this data set to a ground truth. Visualized as frequency-RPM map as well as an order-RPM map, rotation speed-dependent and -independent modes can be separated visually.

- We investigated the XAI algorithms GradCAM, LRP, and modified version of LIME in a comparative manner based on a visual and quantitative evaluation using the mentioned synthetic data set and a real-world imbalance detection data set.

- As a side result, the highest classification accuracy on the imbalance data set reported so far was improved to .

2. Methods

2.1. Data Transformations into Frequency-RPM and Order-RPM Representations

2.2. Classification Algorithms

2.3. XAI Algorithms

2.4. Visualization

3. Results

3.1. Data Sets

3.1.1. Sine Cut-Off Classification

3.1.2. Imbalance Classification

3.2. Classification Accuracy

3.3. XAI Evaluation: Sine Cut-Off Classification

- Spectral modes: Spectral positions with top 80% of intensity.

- Relevant pixels: The absolute value of the subtraction of both spectra is calculated. The pixels with the top 80% values of the resulting map are referred to as relevant pixels.

- Irrelevant pixels are pixels with values >0.1 in the data from the normal class which are not at the same time relevant pixels.

- Highlighted pixels are pixels in the heatmaps with top 80% intensity.

3.4. XAI Evaluation: Imbalance Classification

4. Discussion

5. Conclusive Remarks

- All considered XAI methods were partially able provide class-specific saliency maps which extract the class-distinguishing features while omitting those without class-specific information.

- Due to known class-specific information in the spectra, the synthetic sine cut-off data set allows for a quantitative and qualitative comparison of the characteristics of XAI algorithms applied to 1D-periodic data such as vibration-based condition monitoring with variable rotation speed.

- Frequency-RPM and order-RPM maps are an effective means to visually separate rotation speed-dependent modes and constant frequency system resonances.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

- Mean: Mean value of the data from the original class at the perturbed sections

- Total Mean: Mean value of the complete data of the original class

- Noise: Noise with the value range from the data of the original class at the perturbed sections

- Total Noise: Noise with the value range from the complete data of the original class

References

- Hashemian, H.M. State-of-the-Art Predictive Maintenance Techniques. IEEE Trans. Instrum. Meas. 2011, 60, 226–236. [Google Scholar] [CrossRef]

- Nguyen, K.T.; Medjaher, K. A new dynamic predictive maintenance framework using deep learning for failure prognostics. Reliab. Eng. Syst. Saf. 2019, 188, 251–262. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Yang, D.; Wang, H. Data-Driven Methods for Predictive Maintenance of Industrial Equipment: A Survey. IEEE Syst. J. 2019, 13, 2213–2227. [Google Scholar] [CrossRef]

- Renwick, J.T.; Babson, P.E. Vibration Analysis—A Proven Technique as a Predictive Maintenance Tool. IEEE Trans. Ind. Applicat. 1985, IA-21, 324–332. [Google Scholar] [CrossRef]

- Carden, E.P.; Fanning, P. Vibration Based Condition Monitoring: A Review. Struct. Health Monit. 2004, 3, 355–377. [Google Scholar] [CrossRef]

- Vishwakarma, M.; Purohit, R.; Harshlata, V.; Rajput, P. Vibration Analysis & Condition Monitoring for Rotating Machines: A Review. Mater. Today Proc. 2017, 4, 2659–2664. [Google Scholar] [CrossRef]

- Janssens, O.; Slavkovikj, V.; Vervisch, B.; Stockman, K.; Loccufier, M.; Verstockt, S.; Van Hoecke, S. Convolutional Neural Network Based Fault Detection for Rotating Machinery. J. Sound Vib. 2016, 377, 331–345. [Google Scholar] [CrossRef]

- Swanson, E.; Powell, C.D.; Weissman, S. A practical review of rotating machinery critical speeds and modes. Sound Vib. 2005, 39, 16–17. [Google Scholar]

- Brandt, A. Rotating Machinery Analysis. Signal Analysis and Experimental Procedures; John Wiley and Sons Ltd.: Chichester, UK, 2011. [Google Scholar] [CrossRef]

- Kateris, D.; Moshou, D.; Pantazi, X.E.; Gravalos, I.; Sawalhi, N.; Loutridis, S. A machine learning approach for the condition monitoring of rotating machinery. J. Mech. Sci. Technol. 2014, 28, 61–71. [Google Scholar] [CrossRef]

- Wang, Y.; Peter, W.T.; Tang, B.; Qin, Y.; Deng, L.; Huang, T.; Xu, G. Order spectrogram visualization for rolling bearing fault detection under speed variation conditions. Mech. Syst. Signal Process. 2019, 122, 580–596. [Google Scholar] [CrossRef]

- McInerny, S.A.; Dai, Y. Basic vibration signal processing for bearing fault detection. IEEE Trans. Educ. 2003, 46, 149–156. [Google Scholar] [CrossRef]

- Randall, R.B.; Antoni, J. Rolling element bearing diagnostics—A tutorial. Mech. Syst. Signal Process. 2011, 25, 485–520. [Google Scholar] [CrossRef]

- Sun, J.; Yan, C.; Wen, J. Intelligent Bearing Fault Diagnosis Method Combining Compressed Data Acquisition and Deep Learning. IEEE Trans. Instrum. Meas. 2018, 67, 185–195. [Google Scholar] [CrossRef]

- Liu, H.; Li, L.; Ma, J. Rolling Bearing Fault Diagnosis Based on STFT-Deep Learning and Sound Signals. Shock Vib. 2016, 2016, 6127479. [Google Scholar] [CrossRef] [Green Version]

- Liu, R.; Yang, B.; Zio, E.; Chen, X. Artificial intelligence for fault diagnosis of rotating machinery: A review. Mech. Syst. Signal Process. 2018, 108, 33–47. [Google Scholar] [CrossRef]

- Zhao, R.; Li, W. Deep learning and its applications to machine health monitoring. Mech. Syst. Signal Process. 2019, 115, 213–237. [Google Scholar] [CrossRef]

- Mey, O.; Neudeck, W.; Schneider, A.; Enge-Rosenblatt, O. Machine Learning-Based Unbalance Detection of a Rotating Shaft Using Vibration Data. In Proceedings of the 2020 25th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Vienna, Austria, 8–11 September 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1610–1617. [Google Scholar]

- Serin, G.; Sener, B.; Ozbayoglu, A.M.; Unver, H.O. Review of tool condition monitoring in machining and opportunities for deep learning. Int. J. Adv. Manuf. Technol. 2020, 109, 953–974. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, S.; Wang, B.; Habetler, T.G. Deep Learning Algorithms for Bearing Fault Diagnostics—A Comprehensive Review. IEEE Access 2020, 8, 29857–29881. [Google Scholar] [CrossRef]

- Mey, O.; Schneider, A.; Enge-Rosenblatt, O.; Mayer, D.; Schmidt, C.; Klein, S.; Herrmann, H.G. Condition Monitoring of Drive Trains by Data Fusion of Acoustic Emission and Vibration Sensors. Processes 2021, 9, 1108. [Google Scholar] [CrossRef]

- Adadi, A.; Berrada, M. Peeking Inside the Black-Box: A Survey on Explainable Artificial Intelligence (XAI). IEEE Access 2018, 6, 52138–52160. [Google Scholar] [CrossRef]

- Guidotti, R.; Monreale, A.; Ruggieri, S.; Turini, F.; Giannotti, F.; Pedreschi, D. A Survey of Methods for Explaining Black Box Models. ACM Comput. Surv. 2019, 51, 1–42. [Google Scholar] [CrossRef] [Green Version]

- Jeyakumar, J.V.; Noor, J.; Cheng, Y.-H.; Garcia, L.; Srivastava, M. How Can I Explain This to You? An Empirical Study of Deep Neural Network Explanation Methods. In Advances in Neural Information Processing Systems; Larochelle, H.M., Ranzato, R., Hadsell, M.F., Balcan, H.L., Eds.; Curran Associates, Inc.: Red Hook, NY, USA, 2020; Volume 33, pp. 4211–4222. [Google Scholar]

- Zhang, Q.; Zhu, S. Visual interpretability for deep learning: A survey. Front. Inf. Technol. Electron. Eng 2018, 19, 27–39. [Google Scholar] [CrossRef] [Green Version]

- Selvaraju, R.R.; Cogswell, M.; Das, A.; Vedantam, R.; Parikh, D.; Batra, D. Grad-CAM: Visual Explanations from Deep Networks via Gradient-Based Localization. In Proceedings of the 2017 IEEE International Conference on Computer Vision (ICCV 2017), Venice, Italy, 22–29 October 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 618–626. [Google Scholar]

- Bach, S.; Binder, A.; Montavon, G.; Klauschen, F.; Muller, K.R.; Samek, W. On Pixel-Wise Explanations for Non-Linear Classifier Decisions by Layer-Wise Relevance Propagation. PLoS ONE 2015, 10, e0130140. [Google Scholar] [CrossRef] [Green Version]

- Ribeiro, M.T.; Singh, S.; Guestrin, C. “Why Should I Trust You?”. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; Krishnapuram, B., Ed.; ACM: New York, NY, USA, 2016; pp. 1135–1144. [Google Scholar]

- Shrikumar, A.; Greenside, P.; Kundaje, A. Learning Important Features Through Propagating Activation Differences. In Proceedings of the 34th International Conference on Machine Learning, Sydney, Australia, 6–11 August 2017; Precup, D., Ed.; PMLR: New York, NY, USA, 2017; Volume 70, pp. 3145–3153. [Google Scholar]

- Sundararajan, M.; Taly, A.; Yan, Q. Axiomatic Attribution for Deep Networks. In Proceedings of the 34th International Conference on Machine Learning, Sydney, Australia, 6–11 August 2017; Precup, D., Ed.; PMLR: New York City, NY, USA, 2017; Volume 70, pp. 3319–3328. [Google Scholar]

- Lundberg, S.M.; Lee, S.-I. A Unified Approach to Interpreting Model Predictions. In Advances in Neural Information Processing Systems; Guyon, I., Ed.; Curran Associates, Inc.: Red Hook, NY, USA, 2017; Volume 30. [Google Scholar]

- Kindermans, P.-J.; Hooker, S.; Adebayo, J.; Alber, M.; Schutt, K.T.; Dahne, S.; Kim, B. The (Un)reliability of Saliency Methods. In Explainable AI: Interpreting, Explaining and Visualizing Deep Learning; Samek, W., Montavon, G., Vedaldi, A., Hansen, L.K., Müller, K.-R., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 267–280. [Google Scholar]

- Nath, A.G.; Udmale, S.S.; Singh, S.K. Role of artificial intelligence in rotor fault diagnosis: A comprehensive review. Artif. Intell. Rev. 2021, 54, 2609–2668. [Google Scholar] [CrossRef]

- Chen, H.-Y.; Lee, C.-H. Vibration Signals Analysis by Explainable Artificial Intelligence (XAI) Approach: Application on Bearing Faults Diagnosis. IEEE Access 2020, 8, 134246–134256. [Google Scholar] [CrossRef]

- Kim, J.; Kim, J.-M. Bearing Fault Diagnosis Using Grad-CAM and Acoustic Emission Signals. Appl. Sci. 2020, 10, 2050. [Google Scholar] [CrossRef] [Green Version]

- Lin, C.-J.; Jhang, J.-Y. Bearing Fault Diagnosis Using a Grad-CAM-Based Convolutional Neuro-Fuzzy Network. Mathematics 2021, 9, 1502. [Google Scholar] [CrossRef]

- Saeki, M.; Ogata, J.; Murakawa, M.; Ogawa, T. Visual explanation of neural network based rotation machinery anomaly detection system. In Proceedings of the 2019 IEEE International Conference on Prognostics and Health Management (ICPHM), San Francisco, CA, USA, 17–20 June 2019; pp. 1–4. [Google Scholar]

- Kim, M.S.; Yun, J.P.; Park, P. An Explainable Convolutional Neural Network for Fault Diagnosis in Linear Motion Guide. IEEE Trans. Ind. Inf. 2021, 17, 4036–4045. [Google Scholar] [CrossRef]

- Yoo, Y.; Jeong, S. Vibration analysis process based on spectrogram using gradient class activation map with selection process of CNN model and feature layer. Displays 2022, 73, 102233. [Google Scholar] [CrossRef]

- Liu, C.; Meerten, Y.; Declercq, K.; Gryllias, K. Vibration-based gear continuous generating grinding fault classification and interpretation with deep convolutional neural network. J. Manuf. Process. 2022, 79, 688–704. [Google Scholar] [CrossRef]

- Kim, M.S.; Yun, J.P.; Park, P. An Explainable Neural Network for Fault Diagnosis With a Frequency Activation Map. IEEE Access 2021, 9, 98962–98972. [Google Scholar] [CrossRef]

- Grezmak, J.; Wang, P.; Sun, C.; Gao, R.X. Explainable Convolutional Neural Network for Gearbox Fault Diagnosis. Procedia CIRP 2019, 80, 476–481. [Google Scholar] [CrossRef]

- Grezmak, J.; Zhang, J.; Wang, P.; Gao, R.X. Multi-stream convolutional neural network-based fault diagnosis for variable frequency drives in sustainable manufacturing systems. Procedia Manuf. 2020, 43, 511–518. [Google Scholar] [CrossRef]

- Hasan, M.J.; Sohaib, M.; Kim, J.-M. An Explainable AI-Based Fault Diagnosis Model for Bearings. Sensors 2021, 21, 4070. [Google Scholar] [CrossRef]

- Onchis, D.M.; Gillich, G.-R. Stable and explainable deep learning damage prediction for prismatic cantilever steel beam. Comput. Ind. 2021, 125, 103359. [Google Scholar] [CrossRef]

- Sanakkayala, D.C.; Varadarajan, V.; Kumar, N.; Soni, G.; Kamat, P.; Kumar, S.; Patil, S.; Kotecha, K. Explainable AI for Bearing Fault Prognosis Using Deep Learning Techniques. Micromachines 2022, 13, 1471. [Google Scholar] [CrossRef]

- Li, X.; Zhang, W.; Ding, Q. Understanding and improving deep learning-based rolling bearing fault diagnosis with attention mechanism. Signal Process. 2019, 161, 136–154. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Z.; Peng, D.; Qin, Y. Understanding and Learning Discriminant Features based on Multiattention 1DCNN for Wheelset Bearing Fault Diagnosis. IEEE Trans. Ind. Inf. 2020, 16, 5735–5745. [Google Scholar] [CrossRef]

- Supplementary Information: Source Code Documentation of This Paper at Github. Available online: https://github.com/o-mey/xai-vibration-fault-detection (accessed on 21 October 2022).

- Zhou, B.; Khosla, A.; Lapedriza, A.; Oliva, A.; Torralba, A. Learning Deep Features for Discriminative Localization. In Proceedings of the 29th IEEE Conference on Computer Vision and Pattern Recognition (CVPR 2016), Las Vegas, NV, USA, 26 June–1 July 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 2921–2929. [Google Scholar]

- Alber, M.; Lapuschkin, S.; Seegerer, P.; Hagele, M.; Schutt, K.T.; Montavon, G.; Kindermans, P.J. iNNvestigate Neural Networks! J. Mach. Learn. Res. 2019, 20, 1–8. [Google Scholar]

- Emanuel Metzenthin. LIME For Time. Available online: https://github.com/emanuel-metzenthin/Lime-For-Time (accessed on 11 July 2022).

- Firing, E.; van der Walt, S.; Smith, N. Mpl Colormaps. Available online: https://bids.github.io/colormap/ (accessed on 21 October 2022).

- Mey, O.; Neudeck, W.; Schneider, A.; Enge-Rosenblatt, O. Vibration Measurements on a Rotating Shaft at Different Unbalance Strengths. Fordatis 2020. [Google Scholar] [CrossRef]

- Chattopadhay, A.; Sarkar, A.; Howlader, P.; Balasubramanian, V.N. Grad-CAM++: Generalized Gradient-Based Visual Explanations for Deep Convolutional Networks. In Proceedings of the 2018 IEEE Winter Conference on Applications of Computer Vision (WACV 2018), Lake Tahoe, NV, USA, 12–15 March 2017; IEEE: Piscataway, NJ, USA, 2018; pp. 839–847. [Google Scholar]

- Wang, H.; Wang, Z.; Du, M.; Yang, F.; Zhang, Z.; Ding, S.; Hu, X. Score-CAM: Score-Weighted Visual Explanations for Convolutional Neural Networks. In Proceedings of the 2020 IEEE/CVF Conference on Computer Vision and Pattern Recognition Workshops (CVPRW), Seattle, WA, USA, 14–19 June 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 111–119. [Google Scholar]

| Data Set | Domain | |

|---|---|---|

| Frequency | Order | |

| Sine Cut-Off | 1.06 | 5.26 |

| Imbalance | 0.93 | 1.23 |

| Data Set | Domain | |

|---|---|---|

| Frequency | Order | |

| Sine Cut-Off | 100% | 100% |

| Imbalance | 99.66 % | 98.49% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mey, O.; Neufeld, D. Explainable AI Algorithms for Vibration Data-Based Fault Detection: Use Case-Adadpted Methods and Critical Evaluation. Sensors 2022, 22, 9037. https://doi.org/10.3390/s22239037

Mey O, Neufeld D. Explainable AI Algorithms for Vibration Data-Based Fault Detection: Use Case-Adadpted Methods and Critical Evaluation. Sensors. 2022; 22(23):9037. https://doi.org/10.3390/s22239037

Chicago/Turabian StyleMey, Oliver, and Deniz Neufeld. 2022. "Explainable AI Algorithms for Vibration Data-Based Fault Detection: Use Case-Adadpted Methods and Critical Evaluation" Sensors 22, no. 23: 9037. https://doi.org/10.3390/s22239037

APA StyleMey, O., & Neufeld, D. (2022). Explainable AI Algorithms for Vibration Data-Based Fault Detection: Use Case-Adadpted Methods and Critical Evaluation. Sensors, 22(23), 9037. https://doi.org/10.3390/s22239037