Three-Dimensional Acoustic Device for Testing the All-Directional Anisotropic Characteristics of Rock Samples

Abstract

:1. Introduction

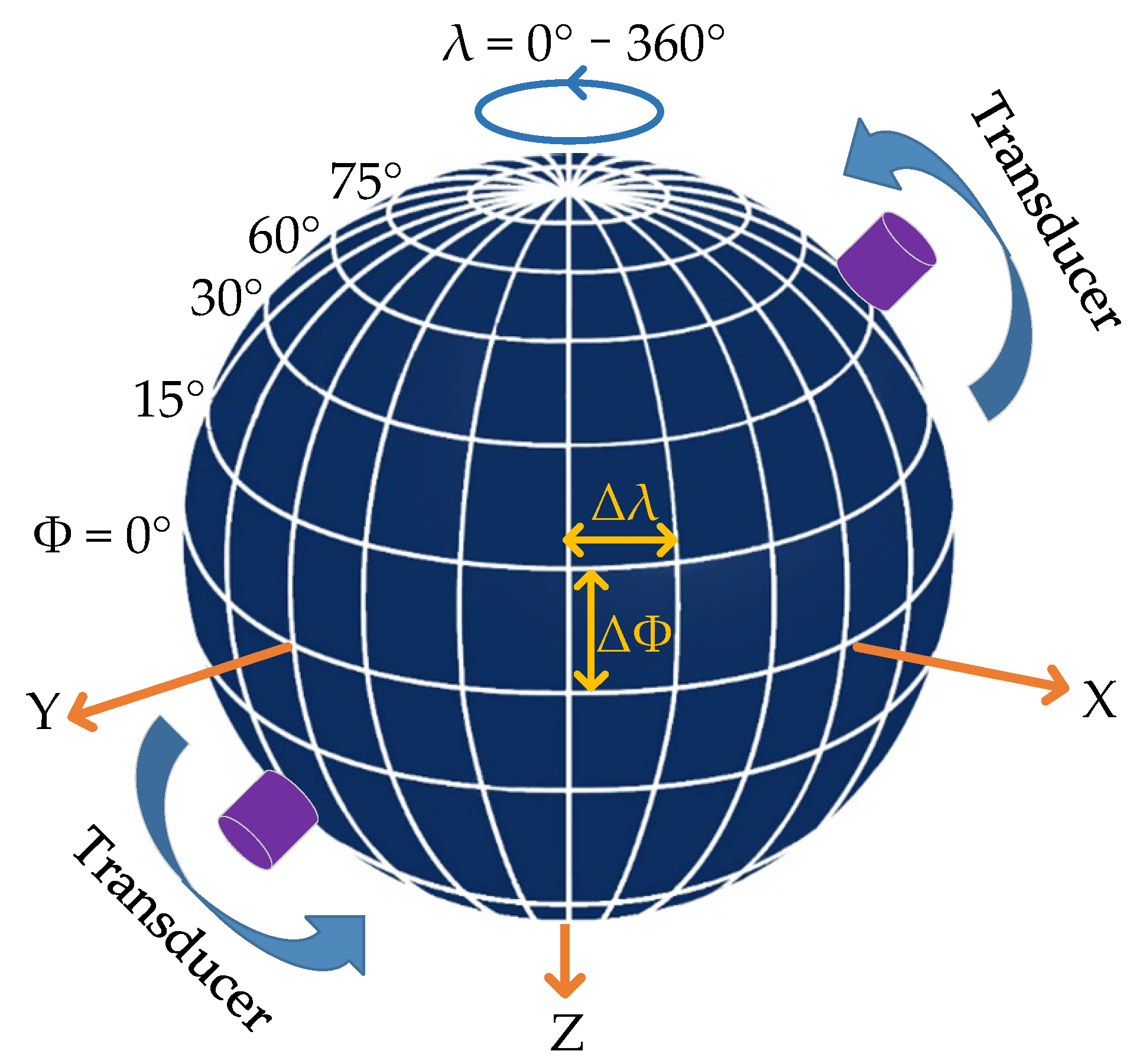

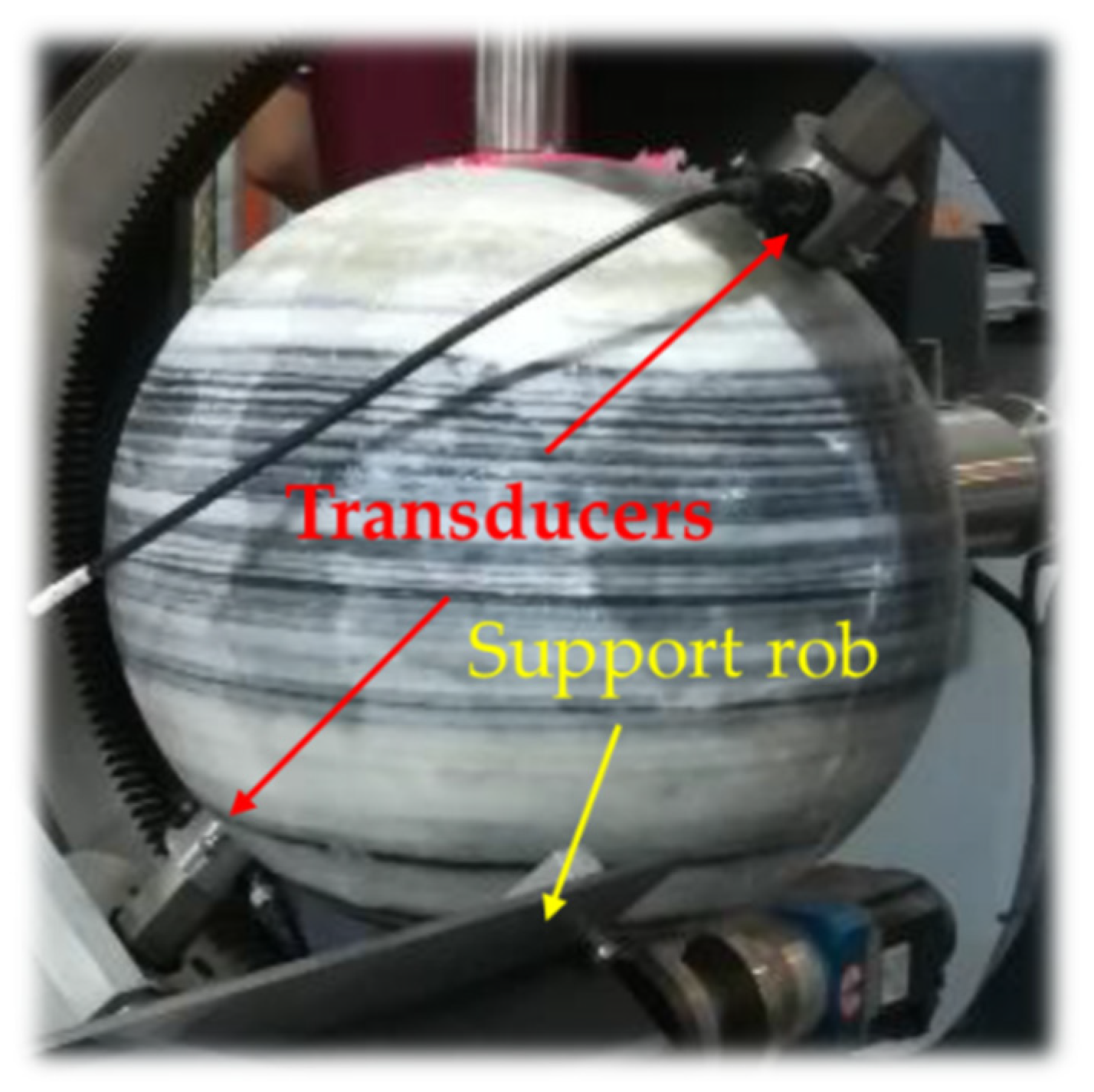

2. Design and Test of the 3-D Measurement Device

2.1. Structural Design of the Device

2.2. Workflow of the Measurement Device

- Measure the radius of the rock sample and enter this data into the computer control software.

- Push the rock sample into the instrument and lock it vertically and horizontally. Thereafter, automatically lift the rock sample with the support rod to a suitable position.

- Place the pair of transducers into the holders and fix them to the initial measurement positions.

- Produce electrical excitation signals with the signal generator that are amplified by the amplifier and loaded on the transmitting transducers to generate acoustic signals.

- Propagate the acoustic signals into the rock. These reach the receiving transducers and are then collected by the oscilloscope and uploaded to the computer.

- Rotate the transducers synchronously in the vertical direction by a latitude of ϕ and repeat steps 3–5 until all the measurements in one circle are finished.

- Loosen the rock sample, rotate it by a longitude of λ in the horizontal direction, and re-lock it again. Then, repeat steps 3–6 until the measurements are completed in all directions.

3. Examples of Measurements by the Device

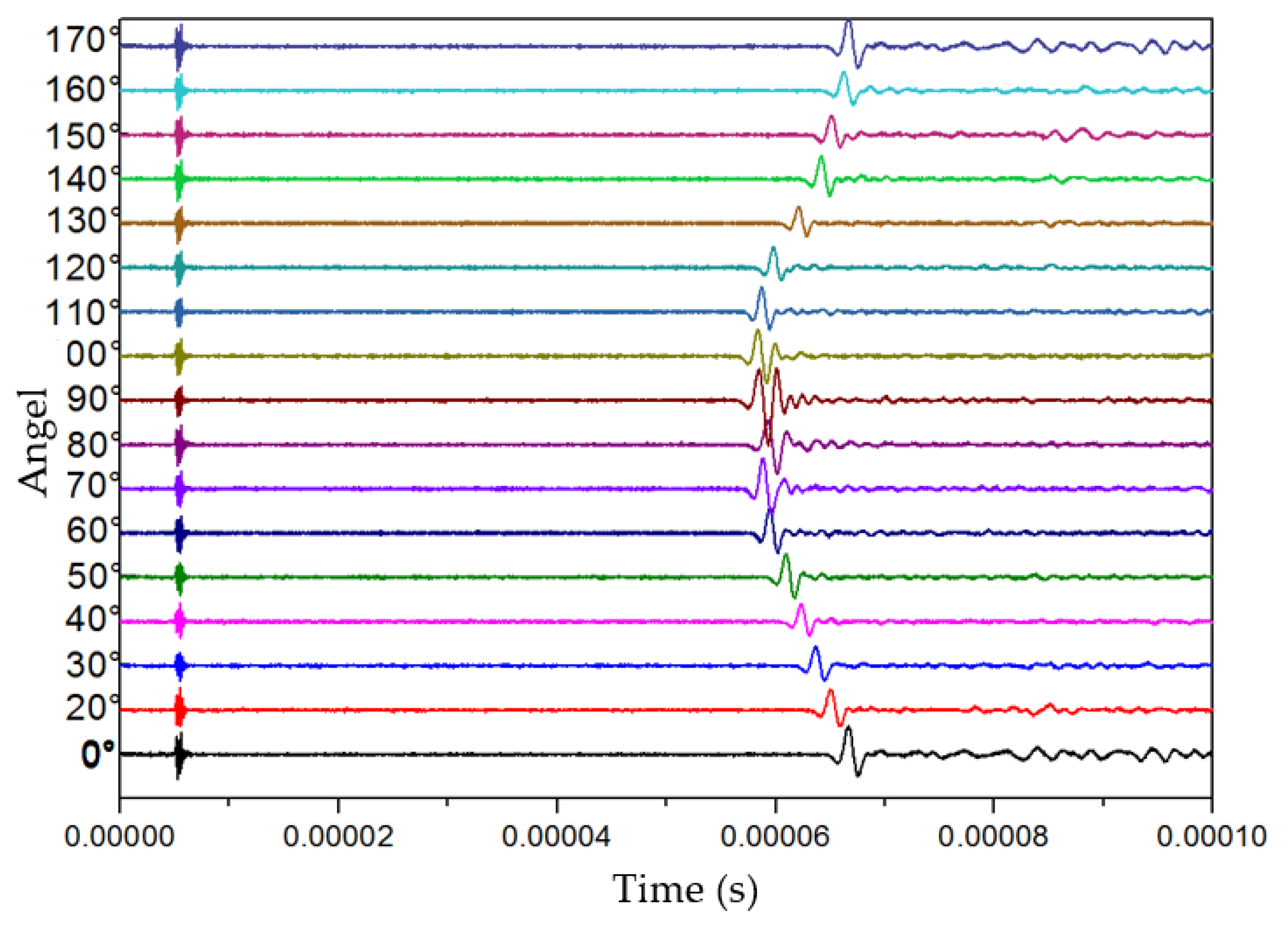

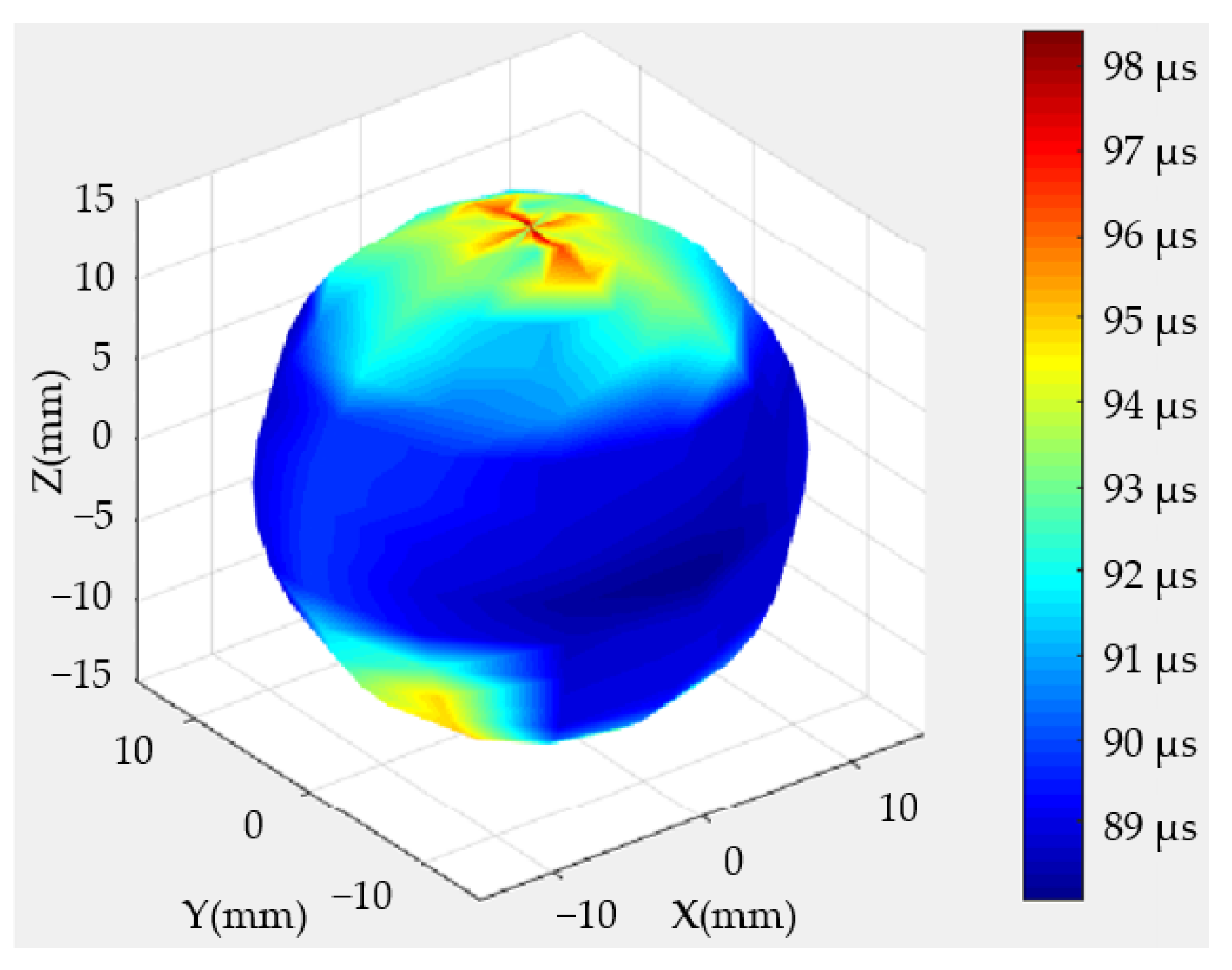

3.1. Measurement of Longitudinal Waves

3.2. Measurement of Shear Waves

4. Discussion

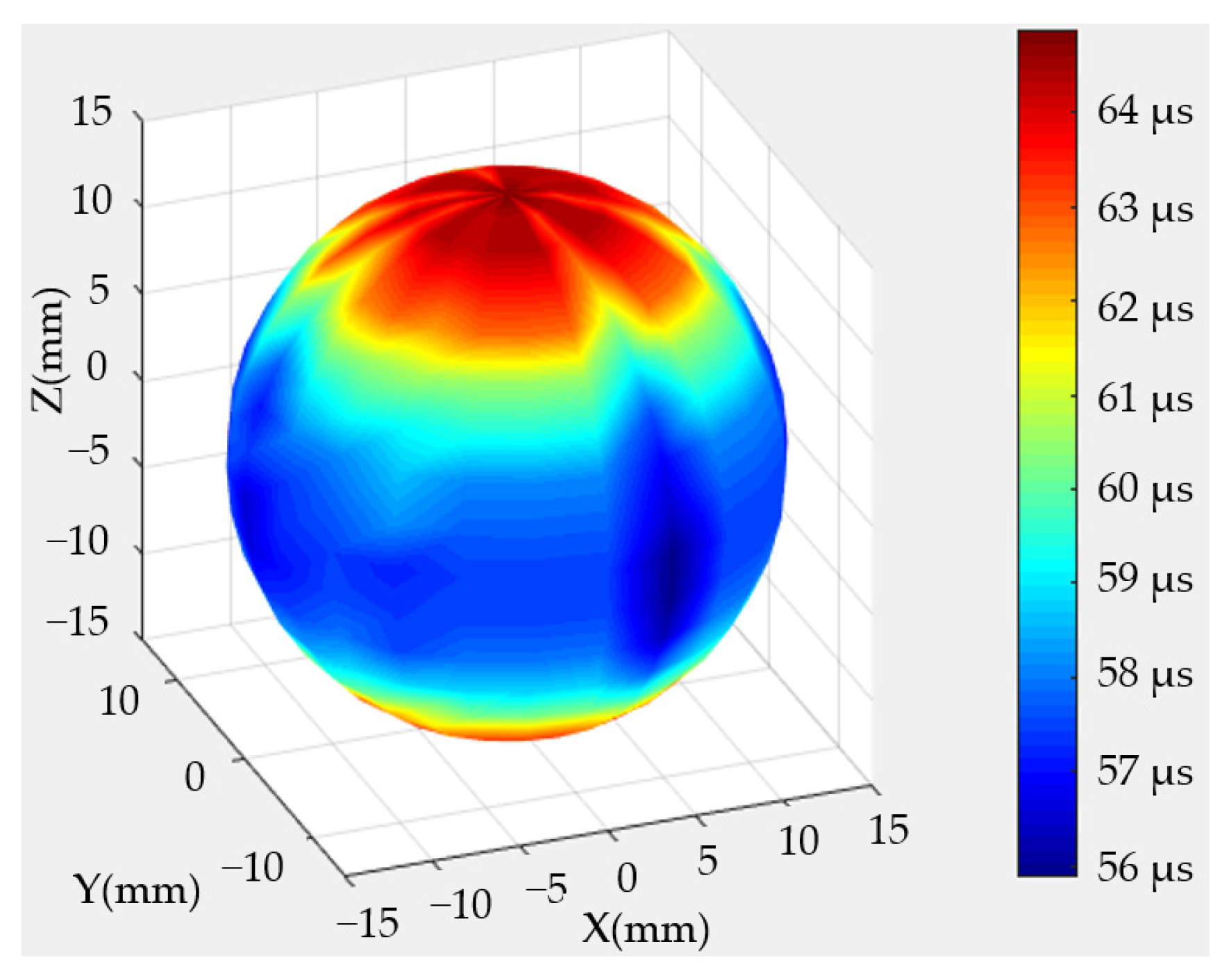

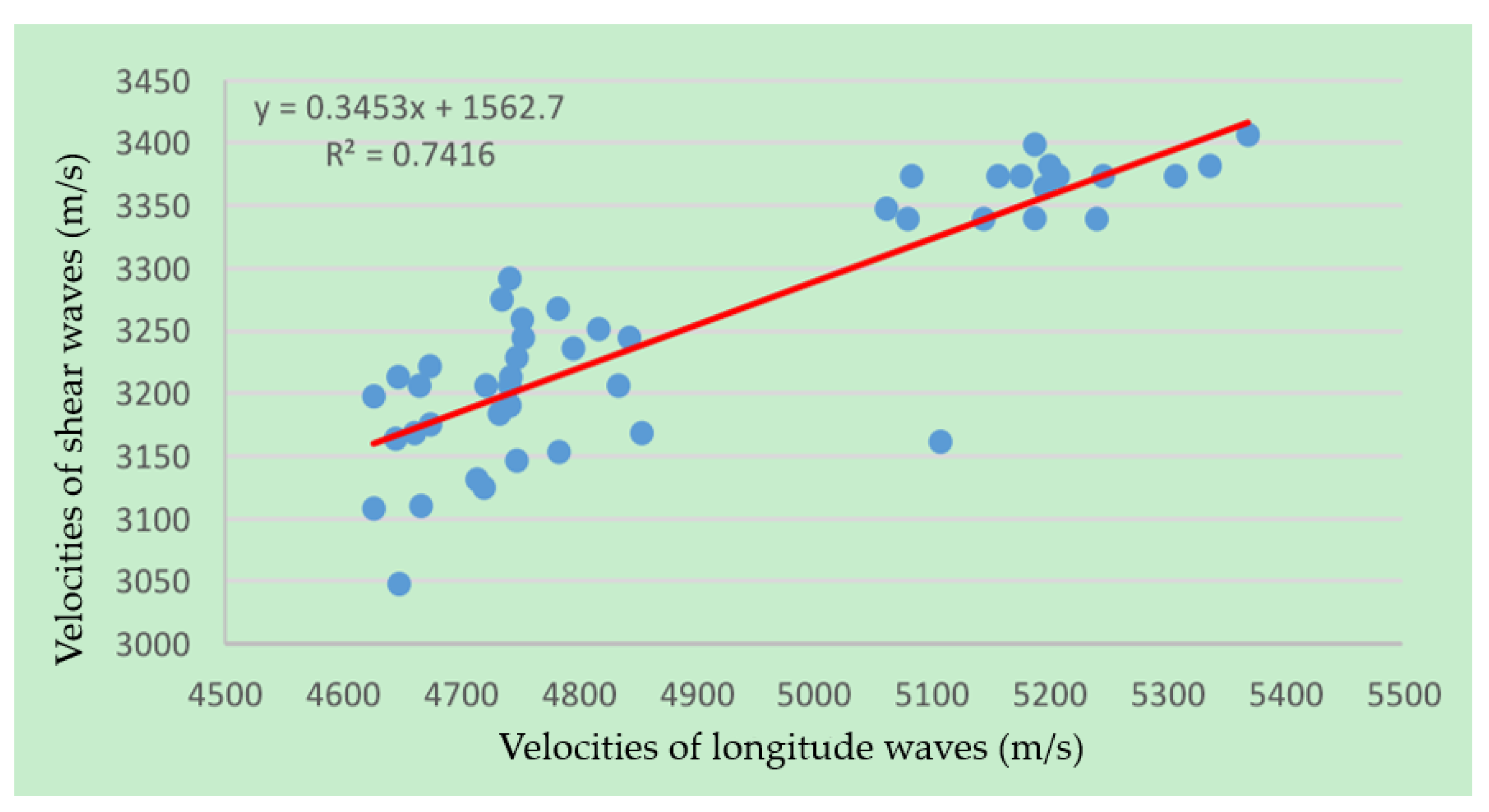

4.1. Calculation of Velocities

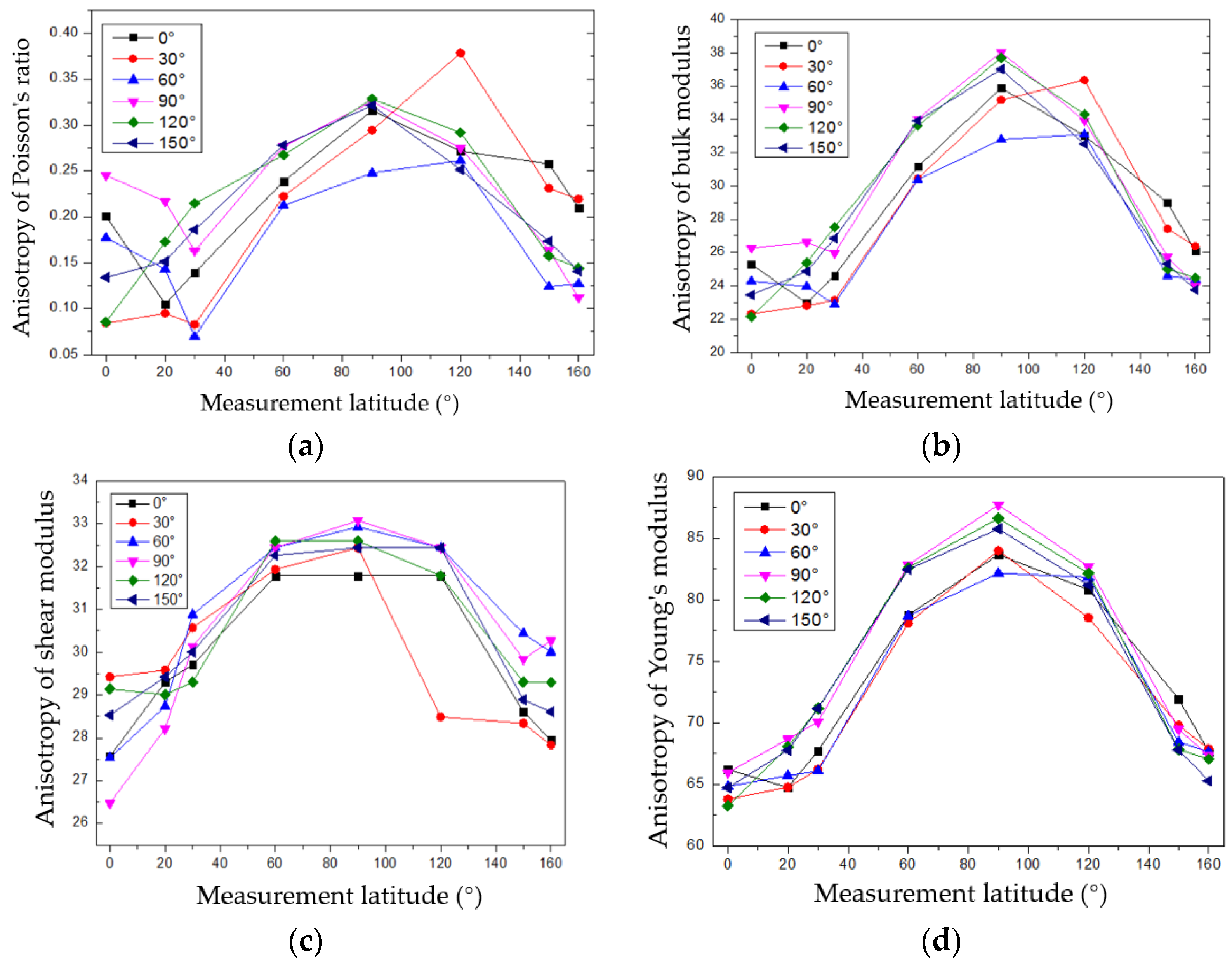

4.2. Calculation of Elastic Physical Parameters

5. Conclusions

- The measured granite rock samples exhibited anisotropy characteristics. The velocities of its longitude and shear waves changed with the measured latitude circle, and the velocities were biggest when the circles were parallel to the bedding direction of the rock sample. The anisotropy characteristics were very small in the longitude orientations, and little velocity change happened.

- The velocities of the longitudinal and shear waves were positively related. The calculated goodness of fit was 0.7416. The relationship between the compressional and shear wave velocities of the granite samples was similar to those of sandstone and mudstone.

- The anisotropy characteristics of Poisson’s ratio, bulk modulus, shear modulus, and Young’s modulus were calculated based on the measured velocities of the longitudinal and shear waves. These data play an important role in guiding formation fracturing and analyzing the stability of borehole walls in the processes of exploration and exploitation.

- The design principle of the 3-D acoustic measurement device could also be used in devices for other kinds of measurements, such as resistivity, permeability, and computed tomography measurements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kawamura, T.; Sakamoto, Y.; Ohtake, M.; Yamamoto, Y.; Haneda, H.; Komai, T. Dissociation behavior of hydrate core sample using thermodynamic inhibitor–Part 2: Experimental investigation using long core samples. Int. J. Offshore Polar Eng. 2008, 18, 156–159. [Google Scholar]

- Behney, A.C.; O’Shaughnessy, R.; Eichholz, M.W.; Stafford, J.D. Influence of Item Distribution Pattern and Abundance on Efficiency of Benthic Core Sampling. Wetlands 2014, 34, 1109–1121. [Google Scholar] [CrossRef]

- Inada, N.; Yamamoto, K. Data report: Hybrid Pressure Coring System tool review and summary of recovery result from gas-hydrate related coring in the Nankai Project. Mar. Pet. Geol. 2015, 66, 323–345. [Google Scholar] [CrossRef]

- Jones, L.E.A.; Wang, H.F. Ultrasonic velocities in Cretaceous shales from the Williston Basin. Geophysics 1981, 46, 288–297. [Google Scholar] [CrossRef]

- Simmons, G. Velocity of shear waves in rocks to 10 kilobars, 1. J. Geophys. Res. 1964, 69, 1123–1130. [Google Scholar] [CrossRef]

- Birch, F. The velocity of compressional waves in rocks to 10 kilobars: 1. J. Geophys. Res. 1960, 65, 1083–1102. [Google Scholar] [CrossRef]

- Christensen, N.I. Compressional wave velocities in metamorphic rocks at pressures to 10 kilobars. J. Geophys. Res. 1965, 70, 6147–6164. [Google Scholar] [CrossRef]

- Thomsen, L. Weak elastic anisotropy. Geophysics 1986, 51, 1954–1966. [Google Scholar] [CrossRef]

- Johnston, J.E.; Christensen, N.I. Seismic anisotropy of shales. J. Geophys. Res. Solid Earth 1995, 100, 5991–6003. [Google Scholar] [CrossRef] [Green Version]

- King, M.S. Recent developments in seismic rock physics. Int. J. Rock Mech. Min. Sci. 2009, 46, 1341–1348. [Google Scholar] [CrossRef]

- Shakerian, M.; Marica, F.; Afrough, A.; Goora, F.G.; Li, M.; Vashaee, S.; Balcom, B.J. A high-pressure metallic core holder for magnetic resonance based on Hastelloy-C. Rev. Sci. Instrum. 2017, 88, 123703. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Tan, B.; Liu, X. A Consistency Evaluation and Calibration Method for Piezoelectric Transmitters. Sensors 2017, 17, 985. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, K.; Ju, X.D.; Tan, B.H.; Lu, J.Q.; Men, B.Y.; Wu, W.H.; Chen, J.Y. New excitation method for acoustic logging transmitters. J. Geophys. Eng. 2017, 14, 751–757. [Google Scholar] [CrossRef] [Green Version]

- Zhang, K.; Li, F.; Wu, J.; Tan, B.; Liu, L. Pulse width research on half-sine excitation signal for bending vibrator. J. Geophys. Eng. 2022, 19, 67–74. [Google Scholar] [CrossRef]

- Zhu, K.; Ma, J.; Qi, X.; Shen, B.; Liu, Y.; Sun, E.; Zhang, R. Enhancement of Ultrasonic Transducer Bandwidth by Acoustic Impedance Gradient Matching Layer. Sensors 2022, 22, 8025. [Google Scholar] [CrossRef] [PubMed]

- Tan, B.; Zhang, K.; Su, Y.; Li, S.; Zhang, L. Research on acoustic logging while drilling transmitting technologies. J. Geophys. Eng. 2022, 19, 511–520. [Google Scholar] [CrossRef]

- Sinha, B.K. Rock Static Moduli from Borehole Sonic Data in Stress-Dependent Formations. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2022, 69, 2371–2380. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, K.; Li, S.; Su, Y.; Tan, B.; Wu, W.; Xin, S. Three-Dimensional Acoustic Device for Testing the All-Directional Anisotropic Characteristics of Rock Samples. Sensors 2022, 22, 9473. https://doi.org/10.3390/s22239473

Zhang K, Li S, Su Y, Tan B, Wu W, Xin S. Three-Dimensional Acoustic Device for Testing the All-Directional Anisotropic Characteristics of Rock Samples. Sensors. 2022; 22(23):9473. https://doi.org/10.3390/s22239473

Chicago/Turabian StyleZhang, Kai, Shengqing Li, Yuanda Su, Baohai Tan, Wenjie Wu, and Shoutao Xin. 2022. "Three-Dimensional Acoustic Device for Testing the All-Directional Anisotropic Characteristics of Rock Samples" Sensors 22, no. 23: 9473. https://doi.org/10.3390/s22239473

APA StyleZhang, K., Li, S., Su, Y., Tan, B., Wu, W., & Xin, S. (2022). Three-Dimensional Acoustic Device for Testing the All-Directional Anisotropic Characteristics of Rock Samples. Sensors, 22(23), 9473. https://doi.org/10.3390/s22239473