Atmospheric Pressure Solvothermal Synthesis of Nanoscale SnO2 and Its Application in Microextrusion Printing of a Thick-Film Chemosensor Material for Effective Ethanol Detection

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

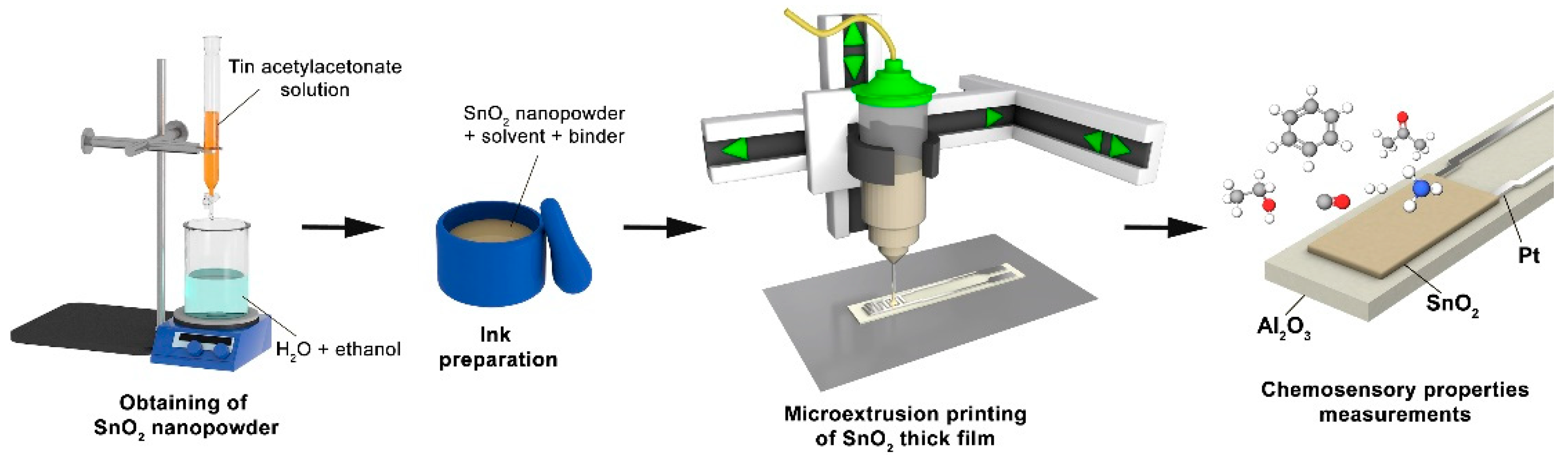

2.2. APS Synthesis of Nanosized SnO2

2.3. Microextrusion Printing of SnO2 Thick Film

2.4. Instrumentation

3. Results and Discussion

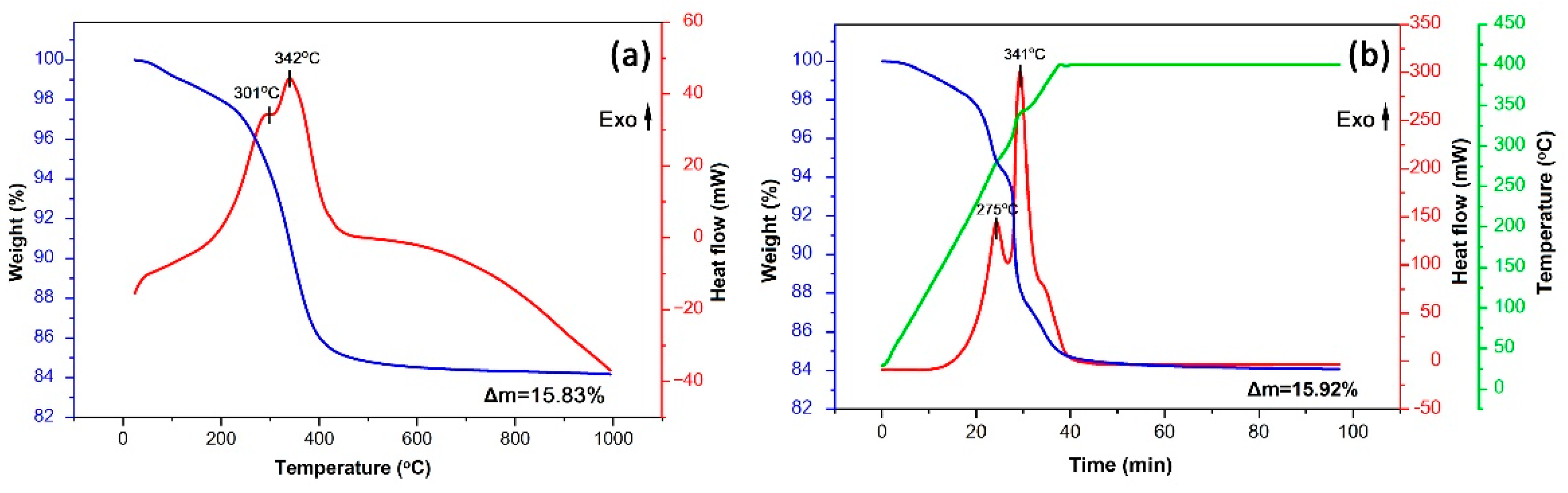

3.1. Thermal Behavior of the Semiproduct

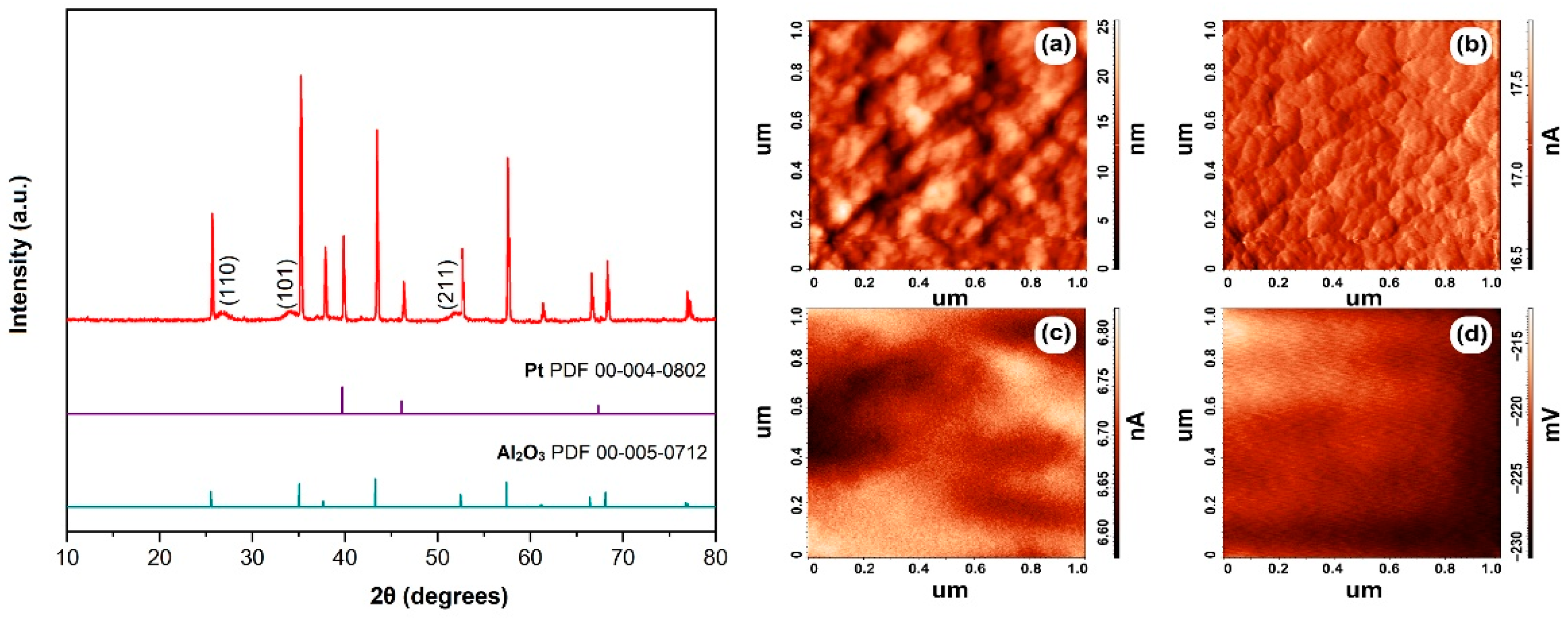

3.2. Crystal Structure, Spectral Properties and Microstructure of the Semiproduct and SnO2 Nanopowder

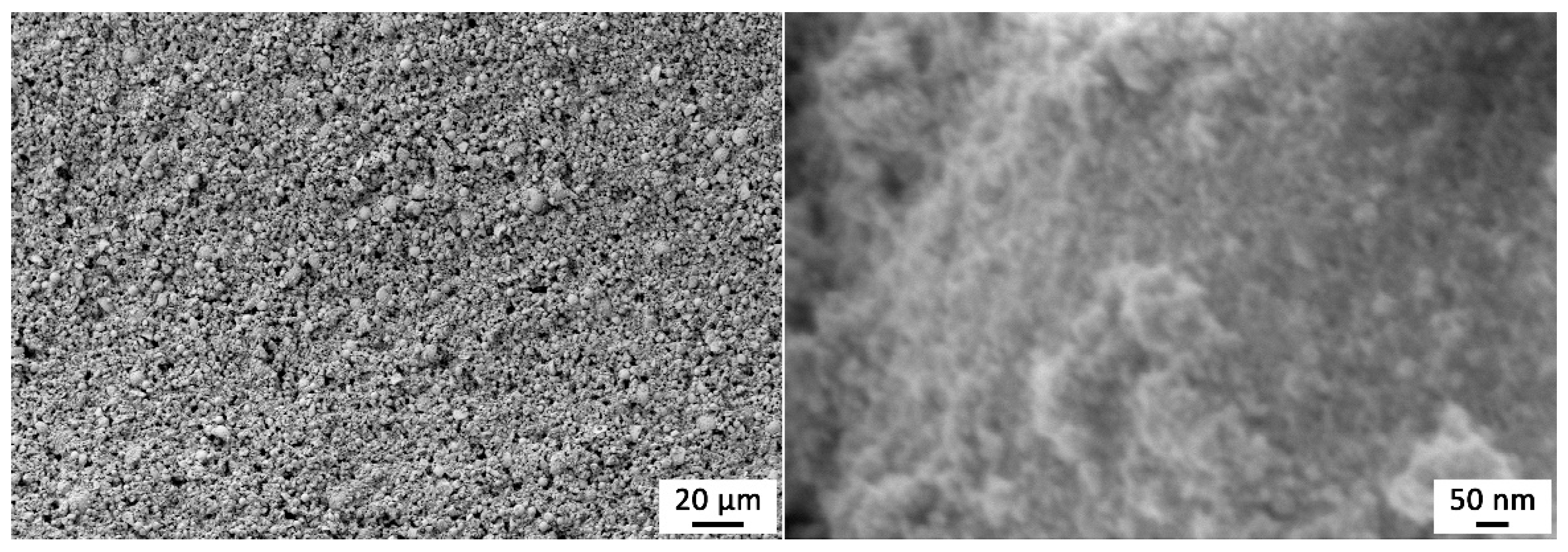

3.3. Crystal Structure and Microstructure of Thick SnO2 Film

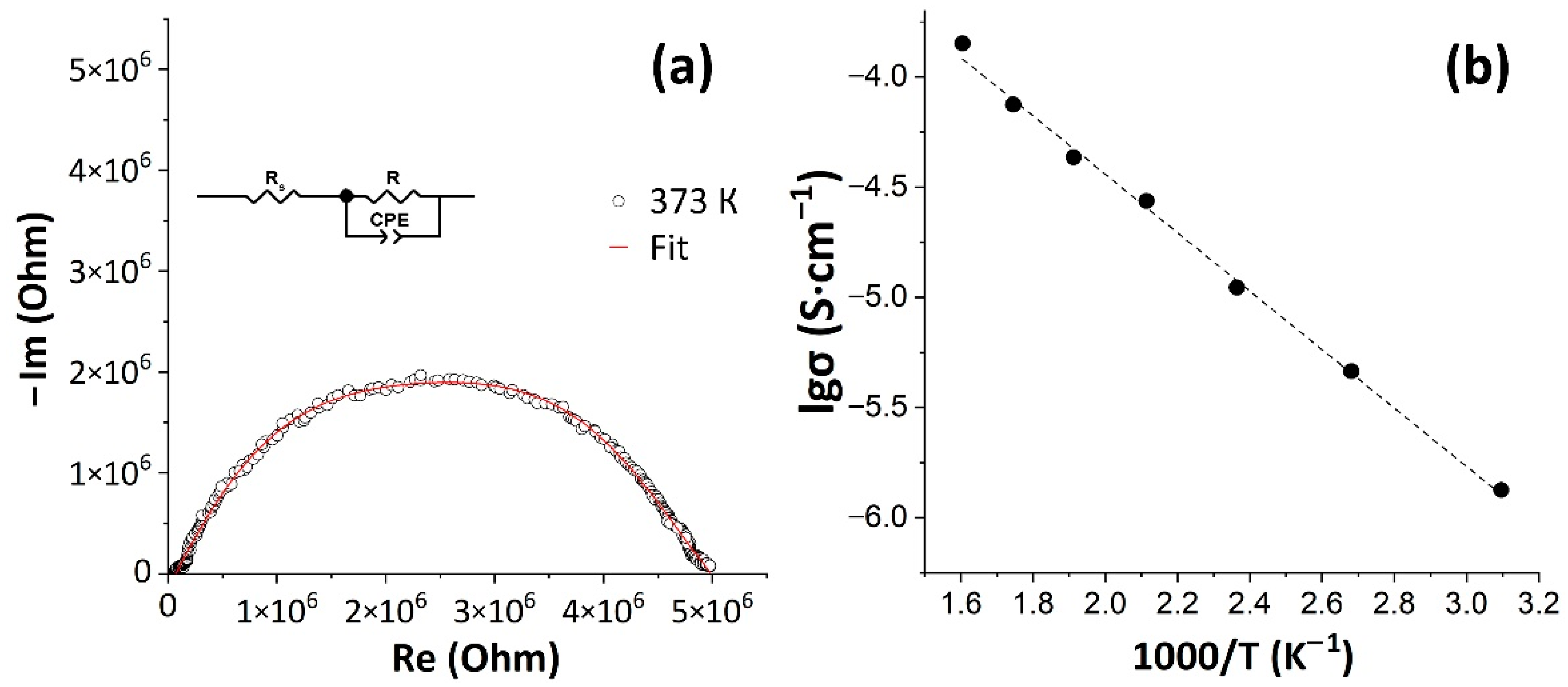

3.4. Electrical Conductivity of the Printed Oxide Film

3.5. Chemosensory Properties of SnO2 Film

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mai, L.; Zanders, D.; Subaşl, E.; Ciftyurek, E.; Hoppe, C.; Rogalla, D.; Gilbert, W.; Arcos, T.D.L.; Schierbaum, K.; Grundmeier, G.; et al. Low-Temperature Plasma-Enhanced Atomic Layer Deposition of Tin (IV) Oxide from a Functionalized Alkyl Precursor: Fabrication and Evaluation of SnO2-Based Thin-Film Transistor Devices. ACS Appl. Mater. Interfaces 2019, 11, 3169–3180. [Google Scholar] [CrossRef] [PubMed]

- Jang, B.; Kim, T.; Lee, S.; Lee, W.Y.; Kang, H.; Cho, C.S.; Jang, J. High Performance Ultrathin SnO2 Thin-Film Transistors by Sol-Gel Method. IEEE Electron Device Lett. 2018, 39, 1179–1182. [Google Scholar] [CrossRef]

- Liang, D.; Chen, B.J.; Feng, B.; Ikuhara, Y.; Cho, H.J.; Ohta, H. Optimization of Two-Dimensional Channel Thickness in Nanometer-Thick SnO2-Based Top-Gated Thin-Film Transistors Using Electric Field Thermopower Modulation: Implications for Flat-Panel Displays. ACS Appl. Nano Mater. 2020, 3, 12427–12432. [Google Scholar] [CrossRef]

- Liang, D.D.; Zhang, Y.Q.; Cho, H.J.; Ohta, H. Electric field thermopower modulation analyses of the operation mechanism of transparent amorphous SnO2 thin-film transistor. Appl. Phys. Lett. 2020, 116, 143503. [Google Scholar] [CrossRef] [Green Version]

- Gorobtsov, P.Y.; Fisenko, N.A.; Solovey, V.R.; Simonenko, N.P.; Simonenko, E.P.; Volkov, I.A.; Sevastyanov, V.G.; Kuznetsov, N.T. Microstructure and local electrophysical properties of sol-gel derived (In2O3-10%SnO2)/V2O5 films. Colloid Interface Sci. Commun. 2021, 43, 100452. [Google Scholar] [CrossRef]

- Mokrushin, A.S.; Fisenko, N.A.; Gorobtsov, P.Y.; Simonenko, T.L.; Glumov, O.V.; Melnikova, N.A.; Simonenko, N.P.; Bukunov, K.A.; Simonenko, E.P.; Sevastyanov, V.G.; et al. Pen plotter printing of ITO thin film as a highly CO sensitive component of a resistive gas sensor. Talanta 2021, 221, 121455. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zheng, J.; Li, M.; Wu, Q.; Huang, B.; Chen, C.; Wu, J.; Liu, C. Solution-based SnGaO thin-film transistors for Zn- and In-free oxide electronic devices. Appl. Phys. Lett. 2018, 113, 122101. [Google Scholar] [CrossRef]

- Zhang, Q.; Ruan, C.; Gong, H.; Xia, G.; Wang, S. Low-temperature and high-performance ZnSnO thin film transistor activated by lightwave irradiation. Ceram. Int. 2021, 47, 20413–20421. [Google Scholar] [CrossRef]

- Satoh, K.; Murakami, S.; Kanaoka, Y.; Yamada, Y.; Kakehi, Y.; Sakurai, Y. Effect of postannealing on properties of ZnO-SnO2 thin film transistors. J. Vac. Sci. Technol. A 2018, 36, 02C105. [Google Scholar] [CrossRef]

- Zhu, B.L.; Zhao, X.; Hu, W.C.; Li, T.T.; Wu, J.; Gan, Z.H.; Liu, J.; Zeng, D.W.; Xie, C.S. Structural, electrical, and optical properties of F-doped SnO or SnO2 films prepared by RF reactive magnetron sputtering at different substrate temperatures and O2 fluxes. J. Alloy. Compd. 2017, 719, 429–437. [Google Scholar] [CrossRef]

- Cong, Y.; Han, D.; Zhou, X.; Huang, L.; Shi, P.; Yu, W.; Zhang, Y.; Zhang, S.; Zhang, X.; Wang, Y. High-Performance Al-Sn-Zn-O Thin-Film Transistor with a Quasi-Double-Channel Structure. IEEE Electron Device Lett. 2016, 37, 53–56. [Google Scholar] [CrossRef]

- Yue, J.; Wang, W.; Wang, N.; Yang, X.; Feng, J.; Yang, J.; Qian, Y. Triple-walled SnO2 at N-doped carbon at SnO2 nanotubes as an advanced anode material for lithium and sodium storage. J. Mater. Chem. A 2015, 3, 23194–23200. [Google Scholar] [CrossRef]

- Heo, J.; Kim, S.B.; Gordon, R.G. Atomic layer deposition of tin oxide with nitric oxide as an oxidant gas. J. Mater. Chem. 2012, 22, 4599–4602. [Google Scholar] [CrossRef] [Green Version]

- Zhitomirsky, V.N.; Boxman, R.L.; Goldsmith, S. Plasma distribution and SnO2 coating deposition using a rectangular filtered vacuum arc plasma source. Surf. Coat. Technol. 2004, 185, 1–11. [Google Scholar] [CrossRef]

- Xu, H.Y.; Chen, Z.R.; Liu, C.Y.; Ye, Q.; Yang, X.P.; Wang, J.Q.; Cao, B.Q. Preparation of {200} crystal faced SnO2 nanorods with extremely high gas sensitivity at lower temperature. Rare Met. 2021, 40, 2004–2016. [Google Scholar] [CrossRef]

- He, Y.; Sun, B.; Jiang, L.; Li, X.; Ma, Y.; Wang, K.; Han, P.; Jin, S. Effect of Ag doping on SnO2 sensing for detecting H2S: A first-principles study. Vacuum 2021, 194, 110587. [Google Scholar] [CrossRef]

- Onkar, S.G.; Raghuwanshi, F.C.; Patil, D.R.; Krishnakumar, T. Synthesis, Characterization and Gas Sensing Study of SnO2 Thick Film Sensor towards H2S, NH3, LPG and CO2. Mater. Today Proc. 2020, 23, 190–201. [Google Scholar] [CrossRef]

- Mahalingappa, K.; Pranesh, G.M.; Manjunath, G.B.; Mundinamani, S.; Molakkalu Padre, S.; Mishra, N.N.; Chandrasekhar, G.S. Low-Temperature Operating Black SnO2-Based VOC Sensor Setup. ACS Omega 2021, 6, 22900–22908. [Google Scholar] [CrossRef]

- Ge, W.; Zhang, G.; Wang, P.; Li, Z.; Deng, Y. Highly selective detection of ethanol based on hierarchical three-dimensional SnO2: Combining experiment with first-principles calculation. Sens. Actuators A Phys. 2021, 331, 112994. [Google Scholar] [CrossRef]

- Xu, X.; Liu, W.; Wang, S.; Wang, X.; Chen, Y.; Zhang, G.; Ma, S.; Pei, S. Design of high-sensitivity ethanol sensor based on Pr-doped SnO2 hollow beaded tubular nanostructure. Vacuum 2021, 189, 110244. [Google Scholar] [CrossRef]

- Wu, P.; Li, Y.; Xiao, S.; Chen, J.; Tang, J.; Chen, D.; Zhang, X. SnO2 nanoparticles based highly sensitive gas sensor for detection of C4F7N: A new eco-friendly gas insulating medium. J. Hazard. Mater. 2022, 422, 126882. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Yang, M.; Cheng, X.; Zhang, X.; Guo, C.; Xu, Y.; Gao, S.; Major, Z.; Zhao, H.; Huo, L. Fast detection of NO2 by porous SnO2 nanotoast sensor at low temperature. J. Hazard. Mater. 2021, 419, 126414. [Google Scholar] [CrossRef] [PubMed]

- Inaba, M.; Oda, T.; Kono, M.; Phansiri, N.; Morita, T.; Nakahara, S.; Nakano, M.; Suehiro, J. Effect of mixing ratio on NO2 gas sensor response with SnO2-decorated carbon nanotube channels fabricated by one-step dielectrophoretic assembly. Sens. Actuators B Chem. 2021, 344, 130257. [Google Scholar] [CrossRef]

- Lu, S.; Zhang, Y.; Liu, J.; Li, H.Y.; Hu, Z.; Luo, X.; Gao, N.; Zhang, B.; Jiang, J.; Zhong, A.; et al. Sensitive H2 gas sensors based on SnO2 nanowires. Sens. Actuators B Chem. 2021, 345, 130334. [Google Scholar] [CrossRef]

- Eslamian, M.; Salehi, A.; Nadimi, E. The role of oxygen vacancies on SnO2 surface in reducing cross-sensitivity between ambient humidity and CO: A first principles investigation. Surf. Sci. 2021, 708, 121817. [Google Scholar] [CrossRef]

- Abokifa, A.A.; Haddad, K.; Raman, B.; Fortner, J.; Biswas, P. Room temperature gas sensing mechanism of SnO2 towards chloroform: Comparing first principles calculations with sensing experiments. Appl. Surf. Sci. 2021, 554, 149603. [Google Scholar] [CrossRef]

- Suda, A.; Yamamura, K.; Morikawa, A.; Nagai, Y.; Sobukawa, H.; Ukyo, Y.; Shinjo, H. Atmospheric pressure solvothermal synthesis of ceria–zirconia solid solutions and their large oxygen storage capacity. J. Mater. Sci. 2008, 43, 2258–2262. [Google Scholar] [CrossRef]

- Sotelo, J.G.; Bonilla-Ríos, J.; García-Escobar, F.; Gordillo, J.L. Film growth of tetragonal SnO2 on glass substrate by dip-coating technique for ethanol sensing applications. Coatings 2021, 11, 303. [Google Scholar] [CrossRef]

- Jasim, A.M.; Al-Zubaydi, A.S.J.; Zamel, R.S. Influence of Heat Treatment on the Characteristic of SnO2 Thin Films for Gas Sensor Application. J. Phys. Conf. Ser. 2021, 1795, 012034. [Google Scholar] [CrossRef]

- Ganchev, M.; Katerski, A.; Stankova, S.; Eensalu, J.S.; Terziyska, P.; Gergova, R.; Popkirov, G.; Vitanov, P. Spin—Coating of SnO2 thin films. J. Phys. Conf. Ser. 2019, 1186, 012027. [Google Scholar] [CrossRef]

- Gu, F.; Wang, S.F.; Lü, M.K.; Cheng, X.F.; Liu, S.W.; Zhou, G.J.; Xu, D.; Yuan, D.R. Luminescence of SnO2 thin films prepared by spin-coating method. J. Cryst. Growth 2004, 262, 182–185. [Google Scholar] [CrossRef]

- Ahmad, K.S.; Siraj, H.; Jaffri, S.B.; Alamgir, M.K.; Sohail, M.; Mehmood, R.F.; Rehman, M.U.; Ali, D. Physical Vapor Deposited [Co:Cd-(dtc)2]/SnO2 Dual Semiconductor Systems: Synthesis, Characterization and Photo-Electrochemistry. J. Inorg. Organomet. Polym. Mater. 2021, 31, 2579–2593. [Google Scholar] [CrossRef]

- Naeem, R.; Mansoor, M.A.; Munawar, K.; Adnan, A.; Zaharinie, T.; Mohd Zubir, M.N. Versatile Fabrication of Binary Composite SnO2-Mn2O3 Thin Films by AACVD for Synergistic Photocatalytic Effect. J. Electron. Mater. 2021, 50, 3897–3906. [Google Scholar] [CrossRef]

- Rieu, M.; Camara, M.; Tournier, G.; Viricelle, J.P.; Pijolat, C.; De Rooij, N.F.; Briand, D. Inkjet printed SnO2 gas sensor on plastic substrate. Procedia Eng. 2015, 120, 75–78. [Google Scholar] [CrossRef]

- Kassem, O.; Saadaoui, M.; Rieu, M.; Viricelle, J.-P. Synthesis and Inkjet Printing of SnO2 Ink on a Flexible Substrate for Gas Sensor Application. Proceedings 2017, 3, 622. [Google Scholar] [CrossRef] [Green Version]

- Kassem, O.; Saadaoui, M.; Rieu, M.; Viricelle, J.P. A novel approach to a fully inkjet printed SnO2-based gas sensor on a flexible foil. J. Mater. Chem. C 2019, 7, 12343–12353. [Google Scholar] [CrossRef]

- Devabharathi, N.; Umarji, A.M.; Dasgupta, S. Fully Inkjet-Printed Mesoporous SnO2-Based Ultrasensitive Gas Sensors for Trace Amount NO2Detection. ACS Appl. Mater. Interfaces 2020, 12, 57207–57217. [Google Scholar] [CrossRef]

- Yang, R.; Gao, T.; Li, D.; Chen, Y.; Jin, G.; Liang, H.; Niu, F. Transparent and flexible force sensor based on microextrusion 3D printing. Micro Nano Lett. 2018, 13, 1460–1464. [Google Scholar] [CrossRef]

- Seo, H.; Nishi, T.; Kishimoto, M.; Ding, C.; Iwai, H.; Saito, M.; Yoshida, H. Study of Microextrusion Printing for Enlarging Electrode–Electrolyte Interfacial Area in Anode-Supported SOFCs. ECS Trans. 2019, 91, 1923–1931. [Google Scholar] [CrossRef]

- Seo, H.; Iwai, H.; Kishimoto, M.; Ding, C.; Saito, M.; Yoshida, H. Microextrusion printing for increasing electrode–electrolyte interface in anode-supported solid oxide fuel cells. J. Power Sources 2020, 450, 227682. [Google Scholar] [CrossRef]

- Olate-Moya, F.; Arens, L.; Wilhelm, M.; Mateos-Timoneda, M.A.; Engel, E.; Palza, H. Chondroinductive Alginate-Based Hydrogels Having Graphene Oxide for 3D Printed Scaffold Fabrication. ACS Appl. Mater. Interfaces 2020, 12, 4343–4357. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Huang, Z.; Liang, Y.; Yuan, W.; Bian, L.; Duan, L.; Rong, Z.; Xiong, J.; Wang, D.; Xia, J. 3D printed gelatin/hydroxyapatite scaffolds for stem cell chondrogenic differentiation and articular cartilage repair. Biomater. Sci. 2021, 9, 2620–2630. [Google Scholar] [CrossRef] [PubMed]

- Mokrushin, A.S.; Simonenko, T.L.; Simonenko, N.P.; Gorobtsov, P.Y.; Bocharova, V.A.; Kozodaev, M.G.; Markeev, A.M.; Lizunova, A.A.; Volkov, I.A.; Simonenko, E.P.; et al. Microextrusion printing of gas-sensitive planar anisotropic NiO nanostructures and their surface modification in an H2S atmosphere. Appl. Surf. Sci. 2022, 578, 151984. [Google Scholar] [CrossRef]

- Simonenko, T.L.; Simonenko, N.P.; Gorobtsov, P.Y.; Klyuev, A.L.; Grafov, O.Y.; Ivanova, T.M.; Simonenko, E.P.; Sevastyanov, V.G.; Kuznetsov, N.T. Hydrothermally synthesized hierarchical Ce1-xSmxO2-δ oxides for additive manufacturing of planar solid electrolytes. Ceram. Int. 2022, 48, 22401–22410. [Google Scholar] [CrossRef]

- Simonenko, N.P.; Kadyrov, N.S.; Simonenko, T.L.; Simonenko, E.P.; Sevastyanov, V.G.; Kuznetsov, N.T. Preparation of ZnS Nanopowders and Their Use in the Additive Production of Thick-Film Structures. Russ. J. Inorg. Chem. 2021, 66, 1283–1288. [Google Scholar] [CrossRef]

- Simonenko, N.P.; Fisenko, N.A.; Fedorov, F.S.; Simonenko, T.L.; Mokrushin, A.S.; Simonenko, E.P.; Korotcenkov, G.; Sysoev, V.V.; Sevastyanov, V.G.; Kuznetsov, N.T. Printing Technologies as an Emerging Approach in Gas Sensors: Survey of Literature. Sensors 2022, 22, 3473. [Google Scholar] [CrossRef]

- Tong, A.; Pham, Q.L.; Abatemarco, P.; Mathew, A.; Gupta, D.; Iyer, S.; Voronov, R. Review of Low-Cost 3D Bioprinters: State of the Market and Observed Future Trends. SLAS Technol. 2021, 26, 333–366. [Google Scholar] [CrossRef] [PubMed]

- Mokrushin, A.S.; Nagornov, I.A.; Simonenko, T.L.; Simonenko, N.P.; Gorobtsov, P.Y.; Khamova, T.V.; Kopitsa, G.P.; Evzrezov, A.N.; Simonenko, E.P.; Sevastyanov, V.G.; et al. Chemoresistive gas-sensitive ZnO/Pt nanocomposites films applied by microplotter printing with increased sensitivity to benzene and hydrogen. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2021, 271, 115233. [Google Scholar] [CrossRef]

- Mohan Rao, U.; Fofana, I.; Kartheek, R.; Yapi, K.M.L.; Jaya, T. Mineral Oil and Ester Based Oil/Paper Insulation Decaying Assessment by FTIR Measurements. In Proceedings of the 21st International Symposium on High Voltage Engineering, Budapest, Hungary, 26–30 August 2019; pp. 615–624. [Google Scholar]

- Wang, Q.; Peng, C.; Du, L.; Li, H.; Zhang, W.; Xie, J.; Qi, H.; Li, Y.; Tian, L.; Huang, Y. Enhanced Performance of Perovskite Solar Cells via Low-Temperature-Processed Mesoporous SnO 2. Adv. Mater. Interfaces 2020, 7, 1901866. [Google Scholar] [CrossRef]

- Gubbala, S.; Russell, H.B.; Shah, H.; Deb, B.; Jasinski, J.; Rypkema, H.; Sunkara, M.K. Surface properties of SnO2 nanowires for enhanced performance with dye-sensitized solar cells. Energy Environ. Sci. 2009, 2, 1302. [Google Scholar] [CrossRef]

- Fang, X.; Yan, J.; Hu, L.; Liu, H.; Lee, P.S. Thin SnO2 Nanowires with Uniform Diameter as Excellent Field Emitters: A Stability of More Than 2400 Minutes. Adv. Funct. Mater. 2012, 22, 1613–1622. [Google Scholar] [CrossRef]

- Babu, B.; Neelakanta Reddy, I.; Yoo, K.; Kim, D.; Shim, J. Bandgap tuning and XPS study of SnO2 quantum dots. Mater. Lett. 2018, 221, 211–215. [Google Scholar] [CrossRef]

- Tran, V.-H.; Park, H.; Eom, S.H.; Yoon, S.C.; Lee, S.-H. Modified SnO2 with Alkali Carbonates as Robust Electron-Transport Layers for Inverted Organic Solar Cells. ACS Omega 2018, 3, 18398–18410. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yakuphanoglu, F. Electrical conductivity, Seebeck coefficient and optical properties of SnO2 film deposited on ITO by dip coating. J. Alloys Compd. 2009, 470, 55–59. [Google Scholar] [CrossRef]

- Ambardekar, V.; Bandyopadhyay, P.P.; Majumder, S.B. Understanding on the ethanol sensing mechanism of atmospheric plasma sprayed 25 wt.% WO3-75 wt.% SnO2 coating. Sens. Actuators B Chem. 2019, 290, 414–425. [Google Scholar] [CrossRef]

- McConnell, C.; Kanakaraj, S.N.; Dugre, J.; Malik, R.; Zhang, G.; Haase, M.R.; Hsieh, Y.Y.; Fang, Y.; Mast, D.; Shanov, V. Hydrogen Sensors Based on Flexible Carbon Nanotube-Palladium Composite Sheets Integrated with Ripstop Fabric. ACS Omega 2020, 5, 487–497. [Google Scholar] [CrossRef]

- Sadhanala, H.K.; Nandan, R.; Nanda, K.K. Understanding the ammonia sensing behavior of filter coffee powder derived N-doped carbon nanoparticles using the Freundlich-like isotherm. J. Mater. Chem. A 2016, 4, 8860–8865. [Google Scholar] [CrossRef]

- Ji, H.; Zeng, W.; Li, Y. Gas sensing mechanisms of metal oxide semiconductors: A focus review. Nanoscale 2019, 11, 22664–22684. [Google Scholar] [CrossRef]

- Kim, H.J.; Lee, J.H. Highly sensitive and selective gas sensors using p-type oxide semiconductors: Overview. Sens. Actuators B Chem. 2014, 192, 607–627. [Google Scholar] [CrossRef]

- Gulevich, D.; Rumyantseva, M.; Gerasimov, E.; Khmelevsky, N.; Tsvetkova, E.; Gaskov, A. Synergy effect of Au and SiO2 modification on SnO2 sensor properties in vocs detection in humid air. Nanomaterials 2020, 10, 813. [Google Scholar] [CrossRef] [Green Version]

- Motsoeneng, R.G.; Kortidis, I.; Ray, S.S.; Motaung, D.E. Designing SnO2 Nanostructure-Based Sensors with Tailored Selectivity toward Propanol and Ethanol Vapors. ACS Omega 2019, 4, 13696–13709. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zito, C.A.; Perfecto, T.M.; Volanti, D.P. Palladium-Loaded Hierarchical Flower-like Tin Dioxide Structure as Chemosensor Exhibiting High Ethanol Response in Humid Conditions. Adv. Mater. Interfaces 2017, 4, 1700847. [Google Scholar] [CrossRef]

- Großmann, K.; Wicker, S.; Weimar, U.; Barsan, N. Impact of Pt additives on the surface reactions between SnO2, water vapour, CO and H2; an operando investigation. Phys. Chem. Chem. Phys. 2013, 15, 19151–19158. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Yao, S.; Yang, Q.; Sun, P.; Gao, Y.; Liang, X.; Liu, F.; Lu, G. Highly sensitive and humidity-independent ethanol sensors based on In2O3 nanoflower/SnO2 nanoparticle composites. RSC Adv. 2015, 5, 52252–52258. [Google Scholar] [CrossRef]

- Zhu, H.; Li, Q.; Ren, Y.; Gao, Q.; Chen, J.; Wang, N.; Deng, J.; Xing, X. A New Insight into Cross-Sensitivity to Humidity of SnO2 Sensor. Small 2018, 14, 1703974. [Google Scholar] [CrossRef]

- Li, M.; Qiao, L.J.; Chu, W.Y.; Volinsky, A.A. Water pre-adsorption effect on room temperature SnO2 nanobelt ethanol sensitivity in oxygen-deficient conditions. Sens. Actuators B Chem. 2011, 158, 340–344. [Google Scholar] [CrossRef]

- Yue, J.; Jiang, X.; Yu, A. Adsorption of the OH Group on SnO2 (110) Oxygen Bridges: A Molecular Dynamics and Density Functional Theory Study. J. Phys. Chem. C 2013, 117, 9962–9969. [Google Scholar] [CrossRef]

- Kaneti, Y.V.; Yue, J.; Moriceau, J.; Chen, C.; Liu, M.; Yuan, Y.; Jiang, X.; Yu, A. Experimental and theoretical studies on noble metal decorated tin oxide flower-like nanorods with high ethanol sensing performance. Sens. Actuators B Chem. 2015, 219, 83–93. [Google Scholar] [CrossRef]

- Song, L.; Dou, K.; Wang, R.; Leng, P.; Luo, L.; Xi, Y.; Kaun, C.-C.; Han, N.; Wang, F.; Chen, Y. Sr-Doped Cubic In2O3/Rhombohedral In2O3 Homojunction Nanowires for Highly Sensitive and Selective Breath Ethanol Sensing: Experiment and DFT Simulation Studies. ACS Appl. Mater. Interfaces 2020, 12, 1270–1279. [Google Scholar] [CrossRef]

- Xia, Y.; Wu, C.; Zhao, N.; Zhang, H. Spongy MoO3 hierarchical nanostructures for excellent performance ethanol sensor. Mater. Lett. 2016, 171, 117–120. [Google Scholar] [CrossRef]

- Goikhman, B.V.; Fedorov, F.S.; Simonenko, N.P.; Simonenko, T.L.; Fisenko, N.A.; Dubinina, T.S.; Ovchinnikov, G.; Lantsberg, A.V.; Lipatov, A.; Simonenko, E.P.; et al. Quantum of selectivity testing: Detection of isomers and close homologs using an AZO based e-nose without a prior training. J. Mater. Chem. A 2022, 10, 8413–8423. [Google Scholar] [CrossRef]

- Jiang, Q.; Wu, C.; Feng, L.; Gong, L.; Ye, Z.; Lu, J. High-response of amorphous ZnSnO sensors for ultraviolet and ethanol detections. Appl. Surf. Sci. 2015, 357, 1536–1540. [Google Scholar] [CrossRef]

- Su, C.; Zhang, L.; Han, Y.; Ren, C.; Chen, X.; Hu, J.; Zeng, M.; Hu, N.; Su, Y.; Zhou, Z.; et al. Controllable synthesis of crescent-shaped porous NiO nanoplates for conductometric ethanol gas sensors. Sens. Actuators B Chem. 2019, 296, 126642. [Google Scholar] [CrossRef]

- Li, X.Q.; Li, D.P.; Xu, J.C.; Han, Y.B.; Jin, H.X.; Hong, B.; Ge, H.L.; Wang, X.Q. Calcination-temperature-dependent gas-sensing properties of mesoporous α-Fe2O3 nanowires as ethanol sensors. Solid State Sci. 2017, 69, 38–43. [Google Scholar] [CrossRef]

- Umar, A.; Lee, J.-H.; Kumar, R.; Al-Dossary, O.; Ibrahim, A.A.; Baskoutas, S. Development of highly sensitive and selective ethanol sensor based on lance-shaped CuO nanostructures. Mater. Des. 2016, 105, 16–24. [Google Scholar] [CrossRef]

- Beniwal, A.; Sahu, P.K.; Sharma, S. Sol–gel spin coating assisted room temperature operated nanostructured ZnO ethanol sensor with behavior transformation. J. Sol-Gel Sci. Technol. 2018, 88, 322–333. [Google Scholar] [CrossRef]

- Qin, W.; Yuan, Z.; Gao, H.; Meng, F. Ethanol Sensors Based on Porous In2O3 Nanosheet-Assembled Micro-Flowers. Sensors 2020, 20, 3353. [Google Scholar] [CrossRef]

- De Pascali, C.; Signore, M.A.; Taurino, A.; Francioso, L.; Macagnano, A.; Avossa, J.; Siciliano, P.; Capone, S. Investigation of the Gas-Sensing Performance of Electrospun TiO2 Nanofiber-Based Sensors for Ethanol Sensing. IEEE Sens. J. 2018, 18, 7365–7374. [Google Scholar] [CrossRef]

- Jin, W.; Yan, S.; An, L.; Chen, W.; Yang, S.; Zhao, C.; Dai, Y. Enhancement of ethanol gas sensing response based on ordered V2O5 nanowire microyarns. Sens. Actuators B Chem. 2015, 206, 284–290. [Google Scholar] [CrossRef]

- Zeng, Q.; Cui, Y.; Zhu, L.; Yao, Y. Increasing oxygen vacancies at room temperature in SnO2 for enhancing ethanol gas sensing. Mater. Sci. Semicond. Process. 2020, 111, 104962. [Google Scholar] [CrossRef]

- He, Y.; Tang, P.; Li, J.; Zhang, J.; Fan, F.; Li, D. Ultrafast response and recovery ethanol sensor based on SnO2 quantum dots. Mater. Lett. 2016, 165, 50–54. [Google Scholar] [CrossRef]

- Zhang, B.; Fu, W.; Li, H.; Fu, X.; Wang, Y.; Bala, H.; Wang, X.; Sun, G.; Cao, J.; Zhang, Z. Synthesis and characterization of hierarchical porous SnO2 for enhancing ethanol sensing properties. Appl. Surf. Sci. 2016, 363, 560–565. [Google Scholar] [CrossRef]

- Palla Papavlu, A.; Mattle, T.; Temmel, S.; Lehmann, U.; Hintennach, A.; Grisel, A.; Wokaun, A.; Lippert, T. Highly sensitive SnO2 sensor via reactive laser-induced transfer. Sci. Rep. 2016, 6, 25144. [Google Scholar] [CrossRef] [Green Version]

- Jiang, X.H.; Ma, S.Y.; Sun, A.M.; Xu, X.L.; Li, W.Q.; Wang, T.T.; Jin, W.X.; Luo, J.; Cheng, L.; Mao, Y.Z. 3D porous flower-like SnO2 microstructure and its gas sensing properties for ethanol. Mater. Lett. 2015, 159, 5–8. [Google Scholar] [CrossRef]

- Ngoc, T.M.; Van Duy, N.; Hung, C.M.; Hoa, N.D.; Trung, N.N.; Nguyen, H.; Van Hieu, N. Ultralow power consumption gas sensor based on a self-heated nanojunction of SnO2 nanowires. RSC Adv. 2018, 8, 36323–36330. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, L.; Tong, R.; Ge, W.; Guo, R.; Shirsath, S.E.; Zhu, J. Facile one-step hydrothermal synthesis of SnO2 microspheres with oxygen vacancies for superior ethanol sensor. J. Alloys Compd. 2020, 814, 152266. [Google Scholar] [CrossRef]

- Lu, C.L.; Chang, S.J.; Weng, T.C.; Hsueh, T.J. A Bifacial SnO2 Thin-Film Ethanol Gas Sensor. IEEE Electron Device Lett. 2018, 39, 1223–1225. [Google Scholar] [CrossRef]

- Qiang, Z.; Ma, S.Y.; Jiao, H.Y.; Wang, T.T.; Jiang, X.H.; Jin, W.X.; Yang, H.M.; Chen, H. Highly sensitive and selective ethanol sensors using porous SnO2 hollow spheres. Ceram. Int. 2016, 42, 18983–18990. [Google Scholar] [CrossRef]

- Tan, W.; Yu, Q.; Ruan, X.; Huang, X. Design of SnO2-based highly sensitive ethanol gas sensor based on quasi molecular-cluster imprinting mechanism. Sens. Actuators B Chem. 2015, 212, 47–54. [Google Scholar] [CrossRef]

| Material | Temperature, °C | Concentration, ppm | Response (S) | S Calculation Formula | Relative Humidity, % | Reference |

|---|---|---|---|---|---|---|

| MoO3 | 250 | 100 | 19.8 | Rair/Rg | 0 | [71] |

| Al2O3-ZnO | 300 | 1 | 53 | (ΔR/Rair) × 100 | [72] | |

| ZnSnO | 450 | 20–500 | 3.21–31.18 | Rair/Rg | [73] | |

| NiO | 130 | 100 | 1.68 | 12 | [74] | |

| α-Fe2O3 | 300 | 100 | 29.64–37.57 | ~65 | [75] | |

| CuO | 300–450 | 100 | 2.30–9.10 | 0 | [76] | |

| ZnO | RT/175 °C | 2–100 | 22.9–59.6/90.5–321.7 | (ΔR/Rair) × 100 | ~55 | [77] |

| In2O3 | 270 | 0.5–100 | 1.6–66 | Rair/Rg | 0 | [78] |

| TiO2 | 350–450 | 50–150 | 1.8–6.5 | [79] | ||

| V2O5 | 330 | 50–1000 | 1.19–9.09 | [80] | ||

| SnO2 | 190 | 20–1000 | 35.6–120 | 50–70 | [81] | |

| SnO2 | 100–300 | 50 | 9–31 | 35 ± 5 | [82] | |

| SnO2 | 160–340 | 20–1000 | 21–50 | 0 | [83] | |

| SnO2 | 350 | 10–30 | 0.7–1 | (ΔR/Rair) × 100 | [84] | |

| SnO2 | 200–400 | 10–500 | 21.96–207.68 | Rair/Rg | [85] | |

| SnO2 | 150–300 | 2000 | 1.25–1.6 | Rair/Rg | [86] | |

| SnO2 | 230 | 200 | 24.9 | 30–90 | [87] | |

| SnO2 | 200 | 56–446 | 62–86 | (ΔR/Rair) × 100 | 0 | [88] |

| SnO2 | 260 | 50–1000 | 274.5 | Rair/Rg | [89] | |

| SnO2 | 200–400 | 19.4–100 | 1–20 | [90] | ||

| SnO2 | 150–300 | 100–500 | 40–157 | [66] | ||

| SnO2 | 200 | 4–100 | 1.4–63.5 | 25–70 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fisenko, N.A.; Solomatov, I.A.; Simonenko, N.P.; Mokrushin, A.S.; Gorobtsov, P.Y.; Simonenko, T.L.; Volkov, I.A.; Simonenko, E.P.; Kuznetsov, N.T. Atmospheric Pressure Solvothermal Synthesis of Nanoscale SnO2 and Its Application in Microextrusion Printing of a Thick-Film Chemosensor Material for Effective Ethanol Detection. Sensors 2022, 22, 9800. https://doi.org/10.3390/s22249800

Fisenko NA, Solomatov IA, Simonenko NP, Mokrushin AS, Gorobtsov PY, Simonenko TL, Volkov IA, Simonenko EP, Kuznetsov NT. Atmospheric Pressure Solvothermal Synthesis of Nanoscale SnO2 and Its Application in Microextrusion Printing of a Thick-Film Chemosensor Material for Effective Ethanol Detection. Sensors. 2022; 22(24):9800. https://doi.org/10.3390/s22249800

Chicago/Turabian StyleFisenko, Nikita A., Ivan A. Solomatov, Nikolay P. Simonenko, Artem S. Mokrushin, Philipp Yu. Gorobtsov, Tatiana L. Simonenko, Ivan A. Volkov, Elizaveta P. Simonenko, and Nikolay T. Kuznetsov. 2022. "Atmospheric Pressure Solvothermal Synthesis of Nanoscale SnO2 and Its Application in Microextrusion Printing of a Thick-Film Chemosensor Material for Effective Ethanol Detection" Sensors 22, no. 24: 9800. https://doi.org/10.3390/s22249800

APA StyleFisenko, N. A., Solomatov, I. A., Simonenko, N. P., Mokrushin, A. S., Gorobtsov, P. Y., Simonenko, T. L., Volkov, I. A., Simonenko, E. P., & Kuznetsov, N. T. (2022). Atmospheric Pressure Solvothermal Synthesis of Nanoscale SnO2 and Its Application in Microextrusion Printing of a Thick-Film Chemosensor Material for Effective Ethanol Detection. Sensors, 22(24), 9800. https://doi.org/10.3390/s22249800