Design of Airborne Large Aperture Infrared Optical System Based on Monocentric Lens

Abstract

:1. Introduction

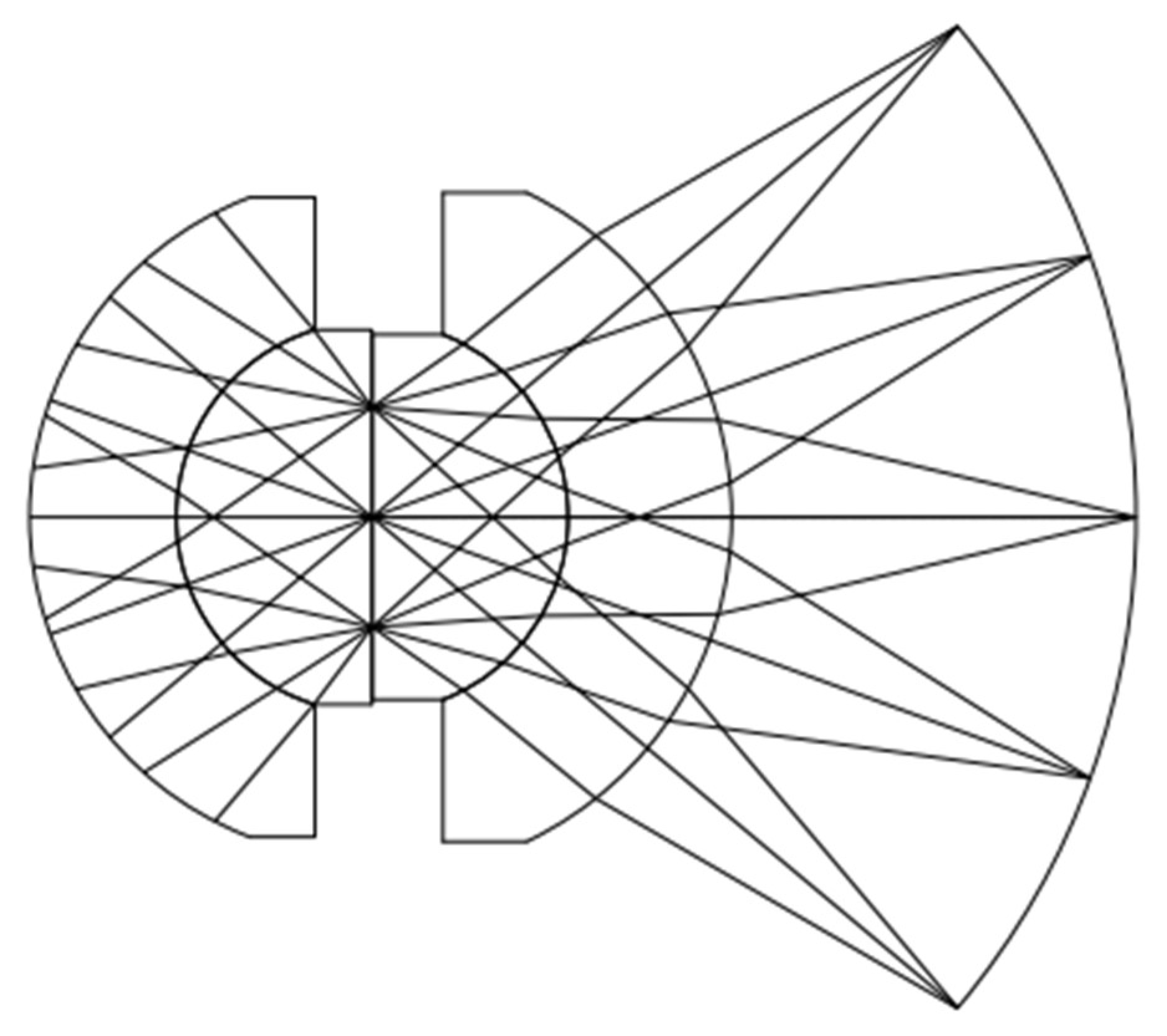

2. Optical System Design

2.1. Monocentric Lenses

2.2. Lens Structure Selection and Design

2.3. Sensor Selection

3. System Optimization and Results Analysis

3.1. System Optimization Design

- (1)

- Modify the initial structure and make the structural parameters variables.

- (2)

- Set restrictions on the lenses’ thickness, total system length, focal length, back focal length, F number, and wavelength. The thickness of the lens is set to be more than 10 mm and less than 50 mm, due to the restrictions of the airborne large-aperture infrared system size and optical processing. The back focal length is set to be greater than 5 mm.

- (3)

- Use the operands to control the incidence angles to reduce vignetting. The total system length of the lens also needs to be controlled with corresponding operands.

- (4)

- Set the aperture stop at the center of the lens. The matching mold should be made in accordance with the location of the aperture stop during actual manufacture and processing.

- (5)

- A glued surface is added to facilitate processing, assembly, and adjustment. The two hemispherical surfaces should then be joined using the adhesive NOA 61, which can avoid absorption on the surfaces. NOA 61 can withstand temperatures from −15 °C to 60 °C before aging when used for glass bonding. After aging, it can withstand temperatures from −150 °C to 125 °C. The transmissivity of the adhesive reaches 85% in the mid-wave infrared.

- (6)

- Compute and minimize the wavefront deformation to find an approximate surface radii for a valid glass combination to correct for axis chromatism and spherical aberrations.

3.2. System Optimization Results

4. Heatless Processing and Tolerance Analysis

4.1. Non-Thermalization Treatment

4.2. Tolerance Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, L.; Liu, L.; Jiang, L.; Zhang, T. Automatic mapping of thermokarst landforms from remote sensing images using deep learning: A case study in the northeastern Tibetan Plateau. Remote Sens. 2018, 10, 2067. [Google Scholar] [CrossRef] [Green Version]

- Česnulevičius, A.; Bautrėnas, A.; Bevainis, L.; Ovodas, D. A comparison of the influence of vegetation cover on the precision of an UAV 3D model and ground measurement data for archaeological investigations: A case study of the Lepelionys Mound, Middle Lithuania. Sensors 2019, 19, 5303. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rodriguez-Padilla, I.; Castelle, B.; Marieu, V.; Morichon, D. A simple and efficient image stabilization method for coastal monitoring video systems. Remote Sens. 2019, 12, 70. [Google Scholar] [CrossRef] [Green Version]

- Qin, H.; Zhou, W.; Yao, Y.; Wang, W. Estimating aboveground carbon stock at the scale of individual trees in subtropical forests using UAV LiDAR and hyperspectral data. Remote Sens. 2021, 13, 4969. [Google Scholar] [CrossRef]

- Velusamy, P.; Rajendran, S.; Mahendran, R.K.; Naseer, S.; Shafiq, M.; Choi, J.G. Unmanned aerial vehicles (UAV) in precision agriculture: Applications and challenges. Energies 2021, 15, 217. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, Q.; Yi, X.; Ma, L.; Zhang, L.; Huang, C.; Zhang, Z.; Lv, X. Estimation of cotton leaf area index (LAI) based on spectral transformation and vegetation index. Remote Sens. 2021, 14, 136. [Google Scholar] [CrossRef]

- Tuśnio, N.; Wróblewski, W. The efficiency of drones usage for safety and rescue operations in an open area: A case from Poland. Sustainability 2021, 14, 327. [Google Scholar] [CrossRef]

- Fedele, A.; Somma, R.; Troise, C.; Holmberg, K.; De Natale, G.; Matano, F. Time-lapse landform monitoring in the Pisciarelli (Campi Flegrei-Italy) fumarole field using UAV photogrammetry. Remote Sens. 2020, 13, 118. [Google Scholar] [CrossRef]

- Hall, A.R.; Coyne, C.J. The political economy of drones. Def. Peace Econ. 2014, 25, 445–460. [Google Scholar] [CrossRef]

- Elish, M.C. Remote Split: A history of US drone operations and the distributed labor of war. Sci. Technol. Hum. Values 2017, 42, 1100–1131. [Google Scholar] [CrossRef]

- Ahn, N.; Kim, S. Optimal and heuristic algorithms for the multi-objective vehicle routing problem with drones for military surveillance operations. J. Ind. Manag. Optim. 2022, 18, 1651. [Google Scholar] [CrossRef]

- Dong, K.; Wang, J.; Sun, Q.; Wang, H.; Li, Q.; Jiang, H. Design of an airborne dual field-of-view middle wave infrared optical system. Chin. Opt. 2012, 5, 596–601. [Google Scholar]

- Wang, L.; Cai, Y. Recent progress and perspectives of infrared optical systems. Infrared Technol. 2019, 41, 1–12. [Google Scholar]

- Mannila, R.; Holmlund, C.; Ojanen, H.J.; Näsilä, A.; Saari, H. Short-wave infrared (SWIR) spectral imager based on Fabry-Perot interferometer for remote sensing. SPIE Remote Sens. 2014, 9241, 92411M. [Google Scholar]

- Evers, R.; Masters, P. The application of low-altitude near-infrared aerial photography for detecting clandestine burials using a UAV and low-cost unmodified digital camera. Forensic Sci. Int. 2018, 289, 408–418. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Luo, X.; Wu, H. Design of airborne infrared optical system based on refraction/diffraction hybrid. Laser Infrared 2020, 50, 215–223. [Google Scholar]

- Wu, H.; Wang, W. Design of airborne miniaturized medium wave infrared continuous zoom optical system. Infrared Technol. 2021, 43, 1177–1182. [Google Scholar]

- Zheng, N.; Schmidler, S.C.; Marks, D.; Brady, D. Computer experiment and global optimization of layered monocentric lens systems. Optik 2012, 123, 1249–1259. [Google Scholar] [CrossRef]

- Stamenov, I.; Arianpour, A.; Olivas, S.J.; Agurok, I.P.; Johnson, A.R.; Stack, R.A.; Morrison, R.L.; Ford, J.E. Panoramic monocentric imaging using fiber-coupled focal planes. Opt. Express 2014, 22, 31708–31721. [Google Scholar] [CrossRef] [Green Version]

- Schuster, G.M.; Mellette, W.M.; Ford, J.E. Folded monocentric imager with deformable mirror focus. Appl. Opt. 2017, 56, 3435–3444. [Google Scholar] [CrossRef] [Green Version]

- Pang, W.; Brady, D.J. Field of view in monocentric multiscale cameras. Appl. Opt. 2018, 57, 6999–7005. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Meng, X.; Zhang, L.; Fu, Y.; Gu, Z. Design of super-wide-angle mobile phone camera based on concentric lens. Acta Opt. Sin. 2018, 38, 1022001. [Google Scholar] [CrossRef]

- Elagha, H.A. Ray tracing in monocentric and ball lenses by a general exact formula. JOSA A 2019, 36, 1117–1125. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Fu, Y.; Zhang, G.; Liu, Z. Modeling and analysis of a monocentric multi-scale optical system. Opt. Express 2020, 28, 32657–32675. [Google Scholar] [CrossRef] [PubMed]

- Meng, X.; Wang, Y.; Zhang, L.; Fu, Y.; Gu, Z. Design of miniaturization and super wide angle monitor lens based on monocentric lens. Infrared Laser Eng. 2018, 47, 1218002. [Google Scholar] [CrossRef]

- Yang, W.; Liu, J.; Han, P.; Shao, X.; Zhao, X. Design of an infrared zoom imaging system based on concentric spherical lens with wide FOV and high resolution. Infrared Millim. Waves 2019, 38, 805–812. [Google Scholar]

- Wang, Y.; Wang, N.; Gu, Z.; Zhang, L.; Fu, Y. Design of miniaturization concentric reflective mobile phone lens. Infrared Laser Eng. 2021, 50, 20210129. [Google Scholar]

- Li, J.; Tan, F.; Zeng, C.; Ji, Y. Design of optical system for UAV-borne ultra-low altitude and wide coverage remote sensing camera. Acta Opt. Sin. 2021, 41, 1422001. [Google Scholar]

- Stamenov, I.; Agurok, I.P.; Ford, J.E. Optimization of two-glass monocentric lenses for compact panoramic imagers: General aberration analysis and specific designs. Appl. Opt. 2012, 51, 7648–7661. [Google Scholar] [CrossRef] [Green Version]

- Kingslake, R.; Johnson, B. Lens Design Fundamentals, 2nd ed.; Academic Press: Pittsburgh, PA, USA; SPIE: Bellingham, WA, USA, 2010; p. 355. [Google Scholar]

- Li, X.; Jia, H.; Zhang, R.; Guo, H. Engineering Optics, 2nd ed.; Science Press: Beijing, China, 2010; pp. 35–48. [Google Scholar]

- Sasián, J. Theory of sixth-order wave aberrations. Appl. Opt. 2010, 49, D69–D95. [Google Scholar] [CrossRef]

- Stamenov, I.; Agurok, I.; Ford, J.E. Optimization of high-performance monocentric lenses. Appl. Opt. 2013, 52, 8287–8304. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gao, W.; Xu, Z.; Han, X.; Pan, C. Recent advances in curved image sensor arrays for bioinspired vision system. Nano Today 2022, 42, 101366. [Google Scholar] [CrossRef]

- Feng, L.; Meng, J.; Dun, X.; Tao, Y. Wavefront coding for athermalization of infrared imaging system. Infrared Laser Eng. 2011, 40, 83–86. [Google Scholar]

- Wang, Y.; Chou, R.; Li, Q.; Kan, J.; Bai, J. Low-cost athermalization of infrared optical system based on wavefront coding. Flight Control Detect. 2020, 3, 84–94. [Google Scholar]

- Hao, S.; Xie, J.; Wen, M.; Wang, Y.; Yuan, L. Design and realization of light and small long-wave infrared optical system. Infrared Laser Eng. 2020, 49, 293–300. [Google Scholar]

- Pham, K.L.; Leuchter, J.; Bystricky, R.; Andrle, M.; Pham, N.N.; Pham, V.T. The study of electrical energy power supply system for UAVs based on the energy storage technology. Aerospace 2022, 9, 500. [Google Scholar] [CrossRef]

- Torky, M.; El-Dosuky, M.; Goda, E.; Snášel, V.; Hassanien, A.E. Scheduling and securing drone charging system using particle swarm optimization and blockchain technology. Drones 2022, 6, 237. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Wave/μm | 3–5 |

| Focal length/mm | 63.5 |

| Total length/mm | 100–150 |

| FOV/(°) | 100 |

| F number | 1 |

| Surface Type | Radius/mm | Thickness/mm | Glass Type |

|---|---|---|---|

| OBJ (0) | Infinity | Infinity | |

| 1 | 61.445 | 43.764 | GERMANIUM |

| 2 | 17.681 | 17.681 | AMTIR1 |

| STO (3) | Infinity | 23.159 | AMTIR1 |

| 4 | −20.158 | 18.253 | ZNS_BROAD |

| 5 | −41.411 | 2.459 | |

| 6 | −47.872 | 13.717 | IG2 |

| 7 | −53.657 | 5.102 | |

| IMA (8) | −63.473 |

| Item | Value |

|---|---|

| Refractive index Radius/mm Thickness/mm | 0.0005 0.002 0.002 |

| Element tilt/(′) | ±5 |

| Element decenter/mm | 0.002 |

| Irregularity | 0.05 fringe |

| Abbe number | 0.5% |

| Sampling Probability | 90% | 80% | 50% | 20% | 10% |

| MTF Value | 0.316 | 0.337 | 0.399 | 0.453 | 0.483 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Qin, T.; Xie, Z.; Sun, L.; Lin, Z.; Cao, T.; Zhang, C. Design of Airborne Large Aperture Infrared Optical System Based on Monocentric Lens. Sensors 2022, 22, 9907. https://doi.org/10.3390/s22249907

Zhang J, Qin T, Xie Z, Sun L, Lin Z, Cao T, Zhang C. Design of Airborne Large Aperture Infrared Optical System Based on Monocentric Lens. Sensors. 2022; 22(24):9907. https://doi.org/10.3390/s22249907

Chicago/Turabian StyleZhang, Jiyan, Teng Qin, Zhexin Xie, Liting Sun, Zhengyu Lin, Tianhao Cao, and Chentao Zhang. 2022. "Design of Airborne Large Aperture Infrared Optical System Based on Monocentric Lens" Sensors 22, no. 24: 9907. https://doi.org/10.3390/s22249907