Multi-Gas Detection System Based on Non-Dispersive Infrared (NDIR) Spectral Technology

Abstract

:1. Introduction

2. Theory

2.1. Non-Dispersive Infrared

2.2. Algorithm Design

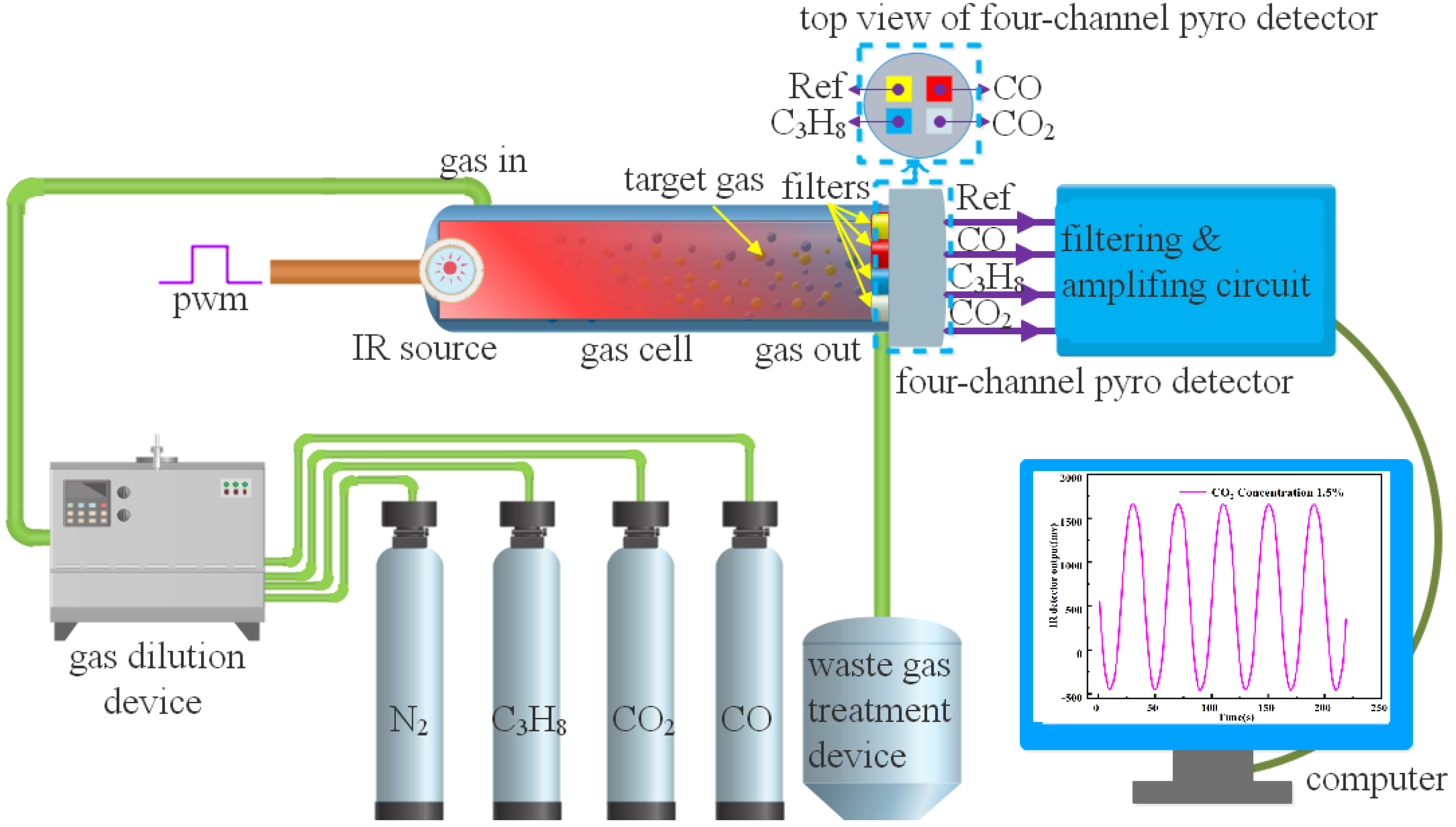

3. Experimental System Setup

4. Experimental Results and Discussion

4.1. Calibration and Data-Fitting

4.2. Cross Interference

4.3. Relative Error

4.4. Interference Test

4.5. Repeatability

4.6. Stability

4.7. Response Time

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Beaton, S.P.; Bishop, G.A.; Zhang, Y.; Stedman, D.H.; Ashbaugh, L.L.; Lawson, D.R. On-road vehicle emissions: Regulations, costs, and benefits. Science 1995, 268, 991–993. [Google Scholar] [CrossRef]

- Cadle, S.H. Real-world vehicle emissions: A summary of the third annual CRC-APRAC on-road vehicle emissions workshop. Air Waste 1993, 43, 1084–1090. [Google Scholar] [CrossRef]

- Zahniser, M.S.; Jimenez, J.L. A tunable diode laser system for the remote sensing of on-road vehicle emissions. Appl. Phys. B 1998, 67, 433–441. [Google Scholar]

- Chen, C.; Ren, Q.; Wang, Y. Review on multi gas detector using infrared spectral absorption technology. Appl. Spectrosc. Rev. 2019, 54, 425–444. [Google Scholar] [CrossRef]

- Besson, J.P.; Schilt, S.; Thévenaz, L. Sub-ppm multi-gas photoacoustic sensor. Spectrochim. Acta A 2006, 63, 899–904. [Google Scholar] [CrossRef] [Green Version]

- Peng, B.; Zhou, Y.; Liu, G.; He, Y.; Gao, C.; Guo, Y. An ultra-sensitive detectionsystem for sulfur dioxide and nitric oxide based on improved differential optical absorption spectroscopy method. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2020, 233, 118169. [Google Scholar] [CrossRef]

- Peng, B.; Gao, C.; Zhou, Y.; Guo, Y. Temperature-compensated ppb-level sulfur dioxide detection system based on fourier transform ultraviolet differential optical absorption spectrum method. Sens. Actuators B. Chem. 2020, 312, 127988. [Google Scholar] [CrossRef]

- Betty, C.A.; Choudhury, S.; Girija, K.G. Reliability studies of highly sensitive and specific multi-gas sensor based on nanocrystalline SnO2 film. Sensors 2014, 193, 484–491. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, X.; Wang, Y.; Tai, H.; Guo, Y. UV illumination-enhanced molecular ammonia detection based on a ternary-reduced graphene oxidetitanium dioxide-Au composite film at room temperature. Anal. Chem. 2019, 91, 3311–3318. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Gao, C.; Guo, Y. UV assisted ultrasensitive trace NO2 gas sensing based on few-layer MoS2 nanosheet-ZnO nanowire heterojunctions at room temperature. J. Mater. Chem. A 2018, 6, 10286–10296. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, G.; Zhu, X.; Guo, Y. Ultrasensitive NO2 gas sensing based on rGO/MoS2 nanocomposite film at low temperature. Sens. Actuators B Chem. 2017, 251, 280–290. [Google Scholar] [CrossRef]

- Ma, Y.; Lewicki, R.; Razeghi, M.; Tittel, F.K. QEPAS based ppb-level detection of CO and N2O using a high power CW DFB-QCL. Opt. Express 2013, 21, 1008–1019. [Google Scholar] [CrossRef] [Green Version]

- Yuanyuan, T.; Wenqing, L.; Ruifeng, K.; Jianguo, L.; Yabai, H.; Yujun, Z.; Zhenyu, X.; Jun, R.; Hui, G. Measurements of NO and CO in Shanghai urban atmosphere by using quantum cascade lasers. Opt. Express 2011, 19, 20224–20232. [Google Scholar] [CrossRef]

- Qiao, S.; Ma, Y.; He, Y.; Patimisco, P.; Sampaolo, A.; Spagnolo, V. Ppt level carbon monoxide detection based on light-induced thermoelastic spectroscopy exploring custom quartz tuning forks and a mid-infrared QCL. Opt. Express 2021, 29, 25100–25108. [Google Scholar] [CrossRef]

- Castro, J.; Meneses, J.; Briz, S.; Lopez, F. Nondispersive infrared monitoring of NO emissions in exhaust gases of vehicles. Rev. Sci. Instrum. 1999, 70, 3156. [Google Scholar] [CrossRef]

- Biasio, M.D.; Leitner, R.; Krall, C.; Krivec, M.; Maier, D. Ethylene gas sensing using non-dispersive infrared spectroscopy. In Proceedings of the 2016 IEEE SENSORS, Orlando, FL, USA, 30 October–3 November 2016. [Google Scholar]

- Rubio, R.; Santander, J.; Fonseca, L.; Sabate, N.; Gracia, I.; Cane, C.; Udina, S.; Marco, S. Non-selective NDIR array for gas detection. Sens. Actuators B 2007, 127, 69. [Google Scholar] [CrossRef]

- Dinh, T.-V.; Ahn, J.-W.; Choi, I.-Y.; Song, K.-Y.; Chung, C.-H.; Kim, J.-C. A review on non-dispersive infrared gas sensors: Improvement of sensor detection limit and interference correction. Sens. Actuators B 2017, 243, 684. [Google Scholar] [CrossRef]

- Hodgkinson, J.; Tatam, R.P. Optical gas sensing: A review. Meas. Sci. Technol. 2013, 24, 012004. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.G.; Liu, W.Q.; Dong, F.Z.; Xie, P.H.; Zhang, Y.J.; Wei, Q.N. Optical Technologies for Atmospheric, Ocean, and Environmental Studies; SPIE: Bellingham, WA, USA, 2005. [Google Scholar]

- Wang, H.; Wang, J.; Ma, X.; Chen, W.; Chen, D.; Li, Q. Note: A NDIR instrument for multicomponent gas detection using the galvanometer modulation. Rev. Sci. Instrum. 2017, 88, 116103. [Google Scholar] [CrossRef]

- Xie, J.; Zhang, Y.; Yuan, Y. Research of Weak Signal Processing Circuit Based on Non-dispersive Infrared Automobile Exhaust Sensor. Appl. Mech. Mater. 2013, 336–338, 163–167. [Google Scholar] [CrossRef]

- Tan, Q.; Tang, L.; Yang, M.; Xue, C.; Zhang, W.; Liu, J.; Xiong, J. Three-gas detection system with IR optical sensor based on NDIR technology. Opt. Lasers Eng. 2015, 74, 103–108. [Google Scholar] [CrossRef]

- Guohua, L.; Yujun, Z.; Chen, C.; Yibing, L.; Chungui, H.; Yanwei, G.; Kun, Y.; Ying, H.; Kai, Z.; Wenqing, L. Design of Non-dispersion Infrared Detector’s Data Processor on Measurement of Automobile Emission CO and CO2. In Proceedings of the Infrared Technology and Applications, and Robot Sensing and Advanced Control, Beijing, China, 9–11 May 2016; Volume 10157, p. 101572Z. [Google Scholar]

- Dong, M.; Zheng, C.; Miao, S. Development and Measurements of a Mid-Infrared Multi-Gas Sensor System for CO, CO2 and CH4 Detection. Sensors 2017, 17, 2221. [Google Scholar] [CrossRef] [Green Version]

- Villar, M.S.; Thurmond, K.; Urso, J.; Parupalli, A.; Ninnemann, E.; Terracciano, V.S. High-Altitude Balloon Flight Demonstration of LED-Based NDIR Multi-Gas Sensor for Space Applications. In Proceedings of the AIAA SPACE and Astronautics Forum and Exposition, Orlando, FL, USA, 12–14 September 2017. [Google Scholar]

| Target Gas | Absorption Peak (µm) | Central Wavelength (CWL) (µm) | Half-Power Bandwidth (HPB) (nm) |

|---|---|---|---|

| C3H8 | 3.39 | 3.33 | 160 |

| CO | 4.70 | 4.74 | 140 |

| CO2 | 4.25 | 4.26 | 180 |

| Ref gas | no | 3.95 | 90 |

| Method | TARGET GAS | The Range of Concentration | Reference |

|---|---|---|---|

| NDIR | CO2 | 0–4.8% | [20] |

| CO | 0–4.45% | ||

| CH4 | 0–5% | ||

| NDIR | CO, CO2, CH4, H2CO, NH3, NO | 0–4% | [24] |

| NDIR | CO, CO2, CH4 | 0–0.25% | [22] |

| NDIR | CO2 | 0–20% | This work |

| CO | 0–14% | ||

| C3H8 | 0–0.5% |

| Gas Composition | True Concentration | Measurement Concentration | Deviation (%) |

|---|---|---|---|

| C3H8(ppm) | 500 | 644 | 2.88 |

| CO2(%) | 1 | 0.89 | −0.55 |

| CO(%) | 1 | 0.95 | −0.36 |

| C3H8(ppm) | 980 | 1033 | 1.06 |

| CO2(%) | 6 | 5.69 | −1.55 |

| CO(%) | 2 | 1.68 | −2.29 |

| C3H8(ppm) | 1000 | 1098 | 1.96 |

| CO2(%) | 1.2 | 1.12 | −0.40 |

| CO(%) | 1 | 0.90 | −0.71 |

| C3H8(ppm) | 1500 | 1584 | 1.68 |

| CO2(%) | 1 | 0.95 | −0.25 |

| CO(%) | 2 | 1.70 | −2.14 |

| C3H8(ppm) | 2000 | 2084 | 1.68 |

| CO2(%) | 2 | 1.93 | −0.35 |

| CO(%) | 2 | 1.81 | −1.36 |

| C3H8(ppm) | 2500 | 2653 | 3.06 |

| CO2(%) | 0.70 | 0.67 | −0.15 |

| CO(%) | 1 | 0.81 | −1.36 |

| C3H8(ppm) | 3000 | 3024 | 0.48 |

| CO2(%) | 0.70 | 0.60 | −0.50 |

| CO(%) | 2 | 1.89 | −0.79 |

| C3H8(ppm)/NO(ppm)/NO2(ppm) | 500/100/100 | 1000/100/100 | 1500/100/100 | 2000/100/100 | 2500/100/100 |

|---|---|---|---|---|---|

| Measurements (C3H8) | 638 | 1065 | 1567 | 2068 | 2598 |

| Deviation (%) | 2.76 | 1.30 | 1.34 | 1.36 | 1.96 |

| CO2(%)/NO(ppm)/NO2(ppm) | 0.7/100/100 | 1/100/100 | 1.2/100/100 | 2/100/100 | 6/100/100 |

| Measurements (CO2) | 0.65 | 0.98 | 1.18 | 1.65 | 5.54 |

| Deviation (%) | −0.25 | −0.10 | −0.10 | −1.75 | −2.30 |

| CO(%)/NO(ppm)/NO2(ppm) | 1/100/100 | 2/100/100 | 1/100/100 | 2/100/100 | 1/100/100 |

| Measurements (CO) | 0.79 | 1.84 | 0.91 | 1.83 | 0.85 |

| Deviation (%) | −1.50 | −1.14 | −0.64 | −1.21 | −1.07 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, M.; Peng, B.; Zhu, X.; Guo, Y. Multi-Gas Detection System Based on Non-Dispersive Infrared (NDIR) Spectral Technology. Sensors 2022, 22, 836. https://doi.org/10.3390/s22030836

Xu M, Peng B, Zhu X, Guo Y. Multi-Gas Detection System Based on Non-Dispersive Infrared (NDIR) Spectral Technology. Sensors. 2022; 22(3):836. https://doi.org/10.3390/s22030836

Chicago/Turabian StyleXu, Manlin, Bo Peng, Xiangyi Zhu, and Yongcai Guo. 2022. "Multi-Gas Detection System Based on Non-Dispersive Infrared (NDIR) Spectral Technology" Sensors 22, no. 3: 836. https://doi.org/10.3390/s22030836

APA StyleXu, M., Peng, B., Zhu, X., & Guo, Y. (2022). Multi-Gas Detection System Based on Non-Dispersive Infrared (NDIR) Spectral Technology. Sensors, 22(3), 836. https://doi.org/10.3390/s22030836