Development of a Smart Clinical Bluetooth Thermometer Based on an Improved Low-Power Resistive Transducer Circuit

Abstract

:1. Introduction

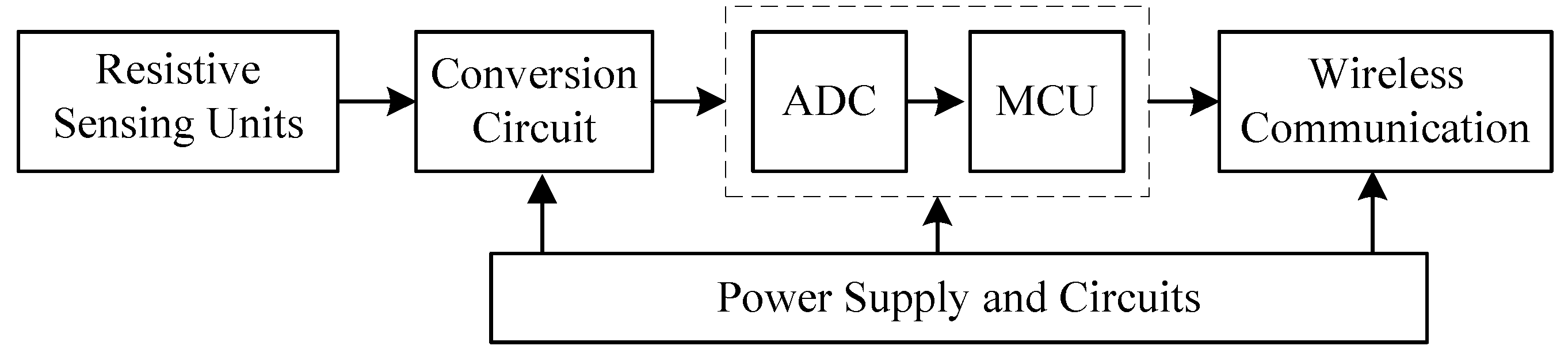

2. The Improved Low-Power Resistive Transducer Circuit

2.1. Bridge Conversion Circuitry

2.2. The Minimal Convention Circuit

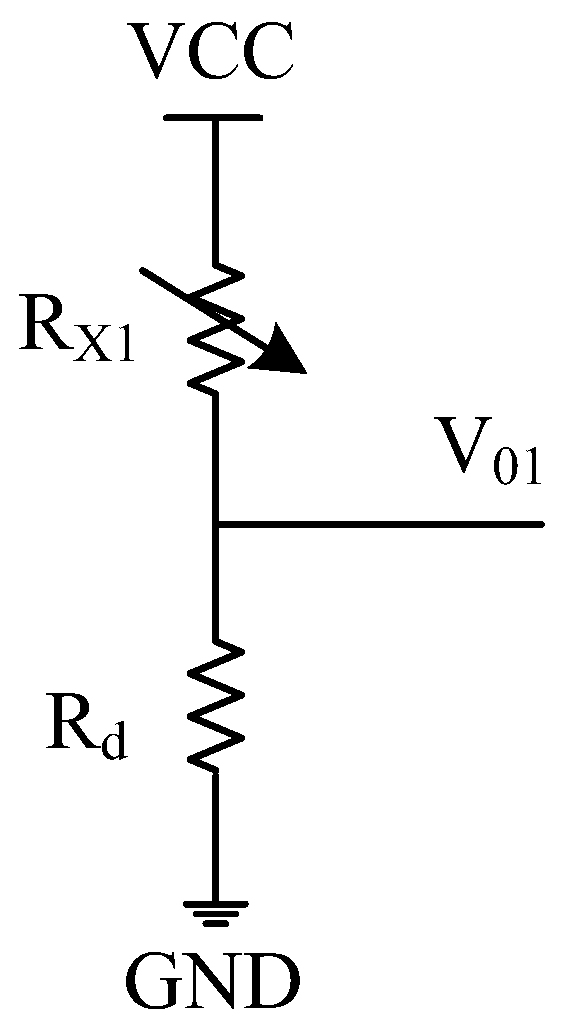

2.2.1. Fixed Resistor Grounding Bleeder Circuit

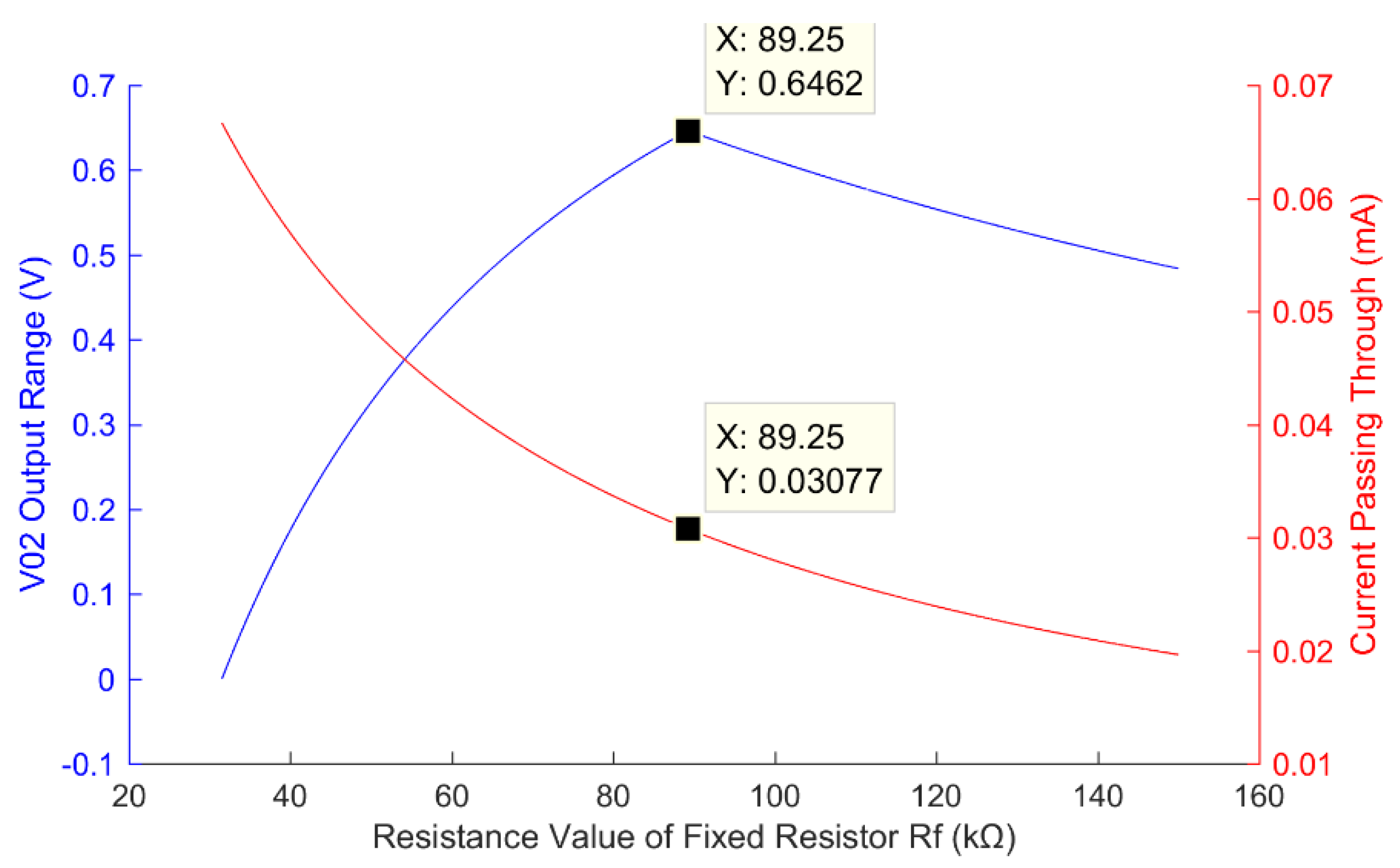

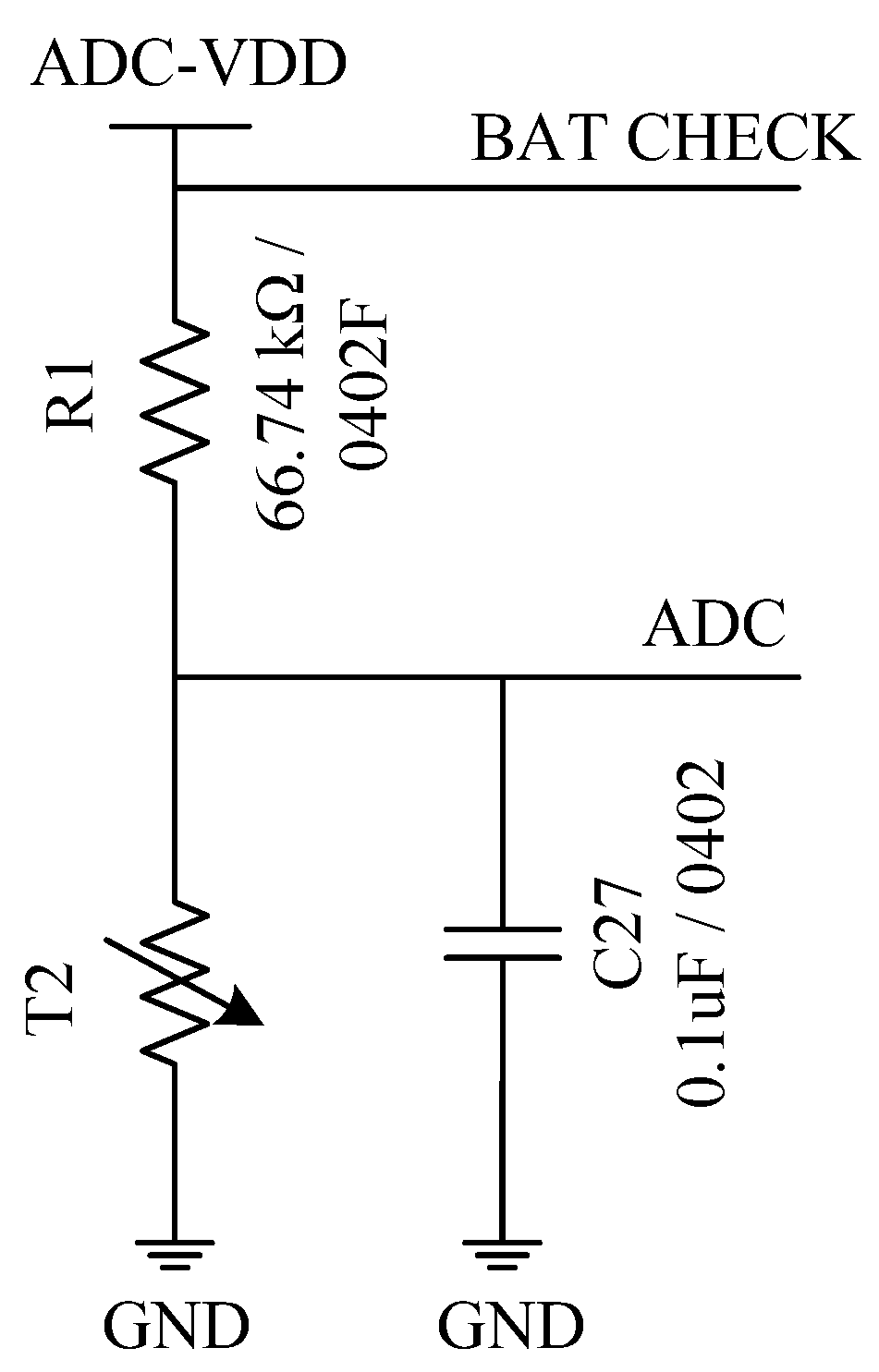

2.2.2. The Proposed Low-Power Circuit

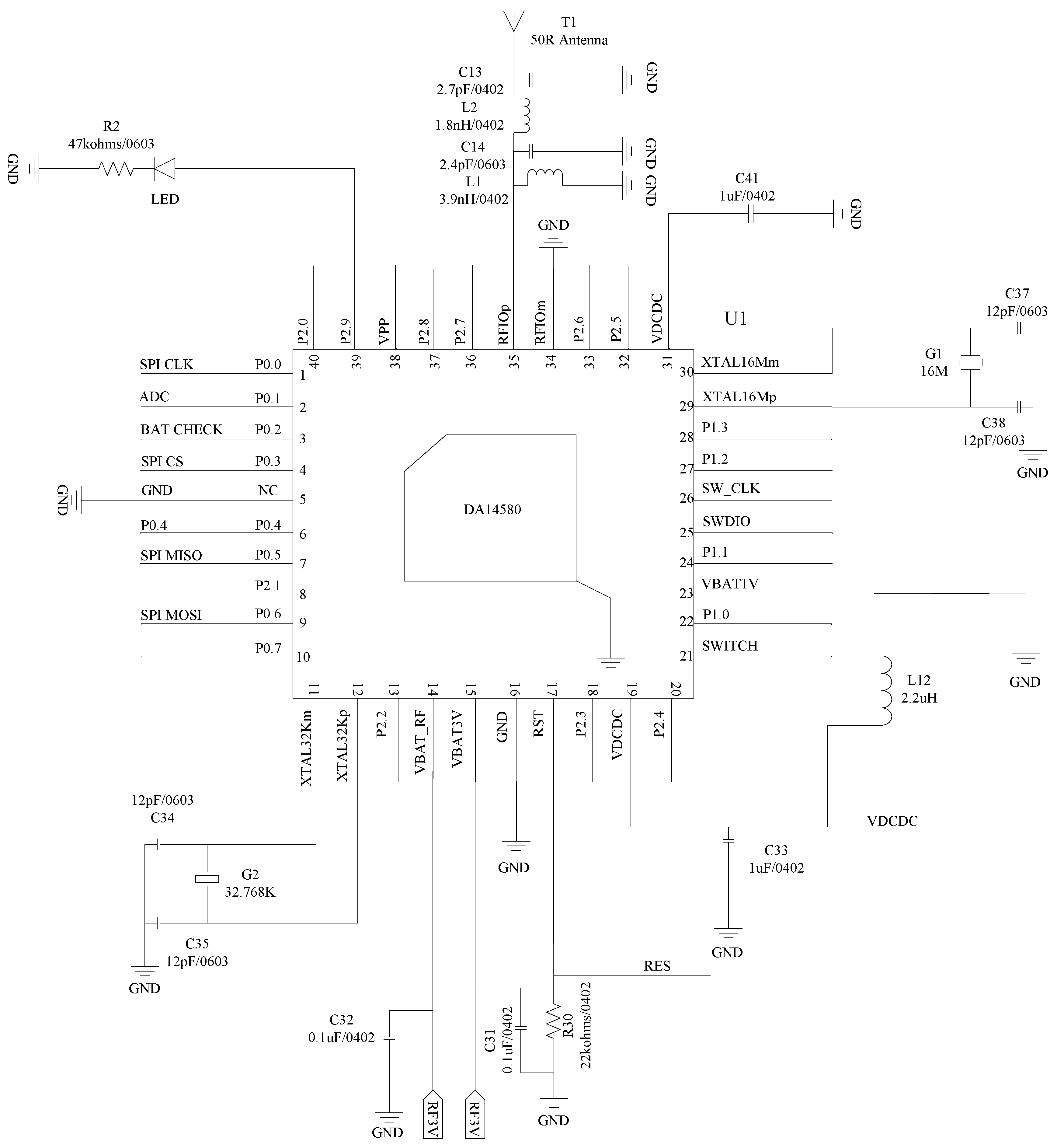

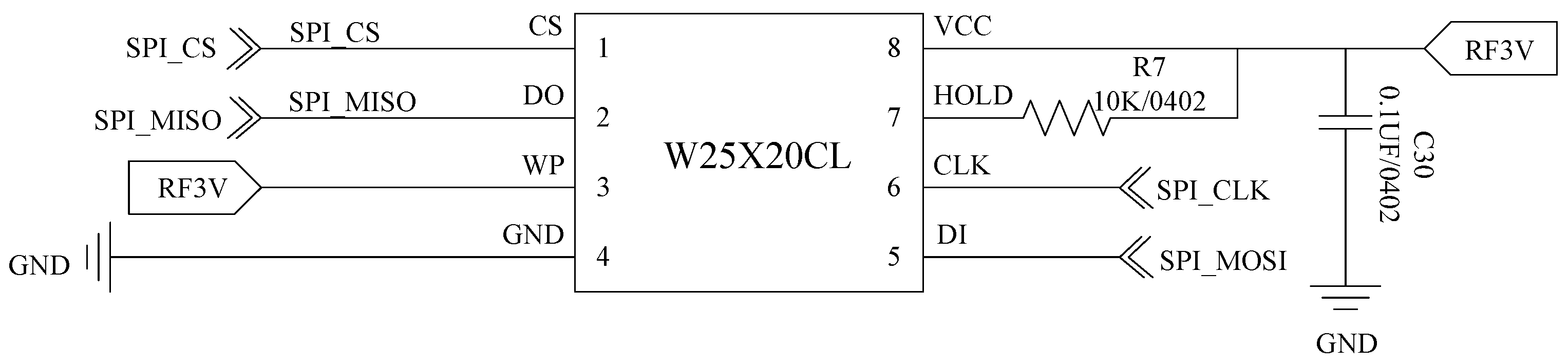

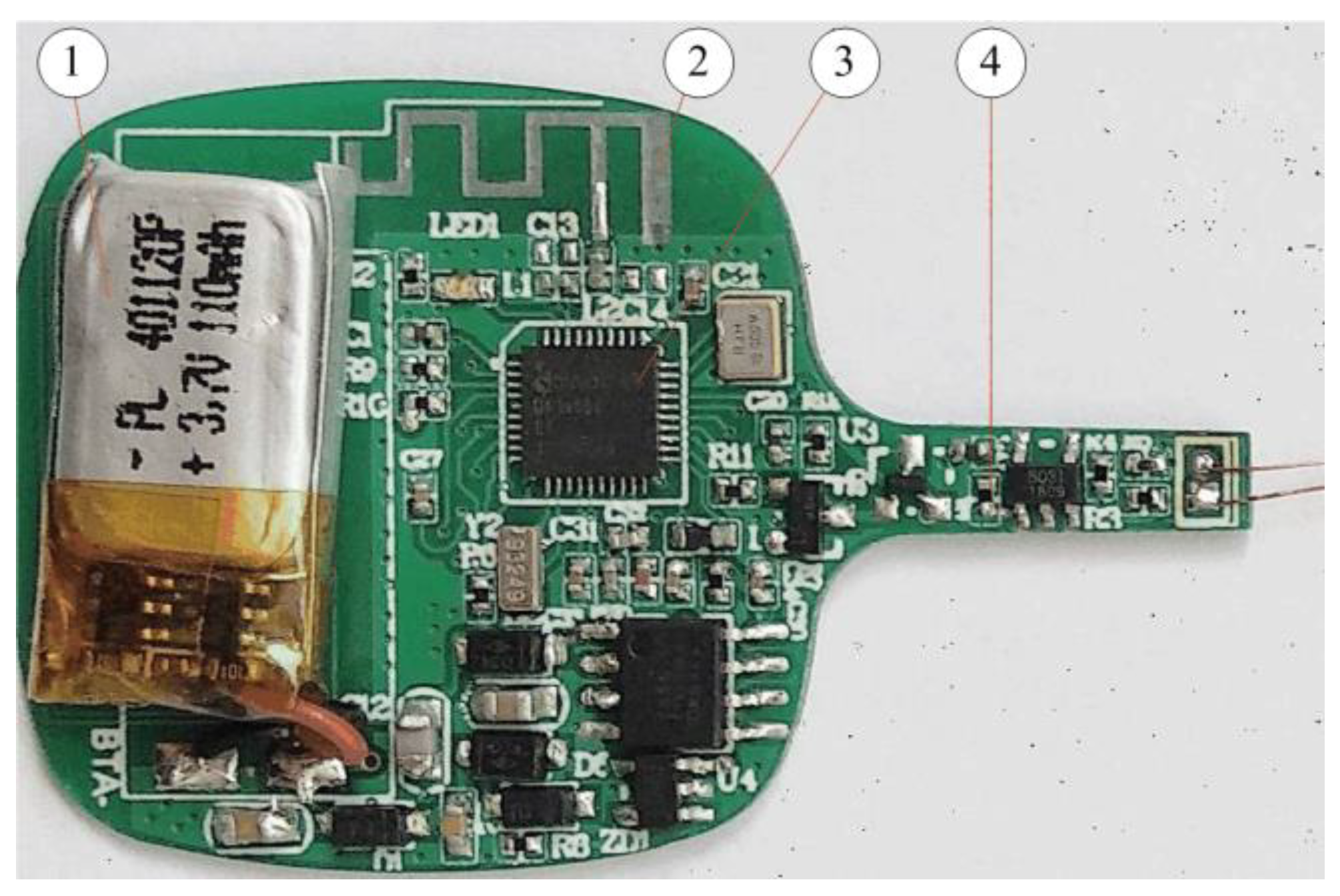

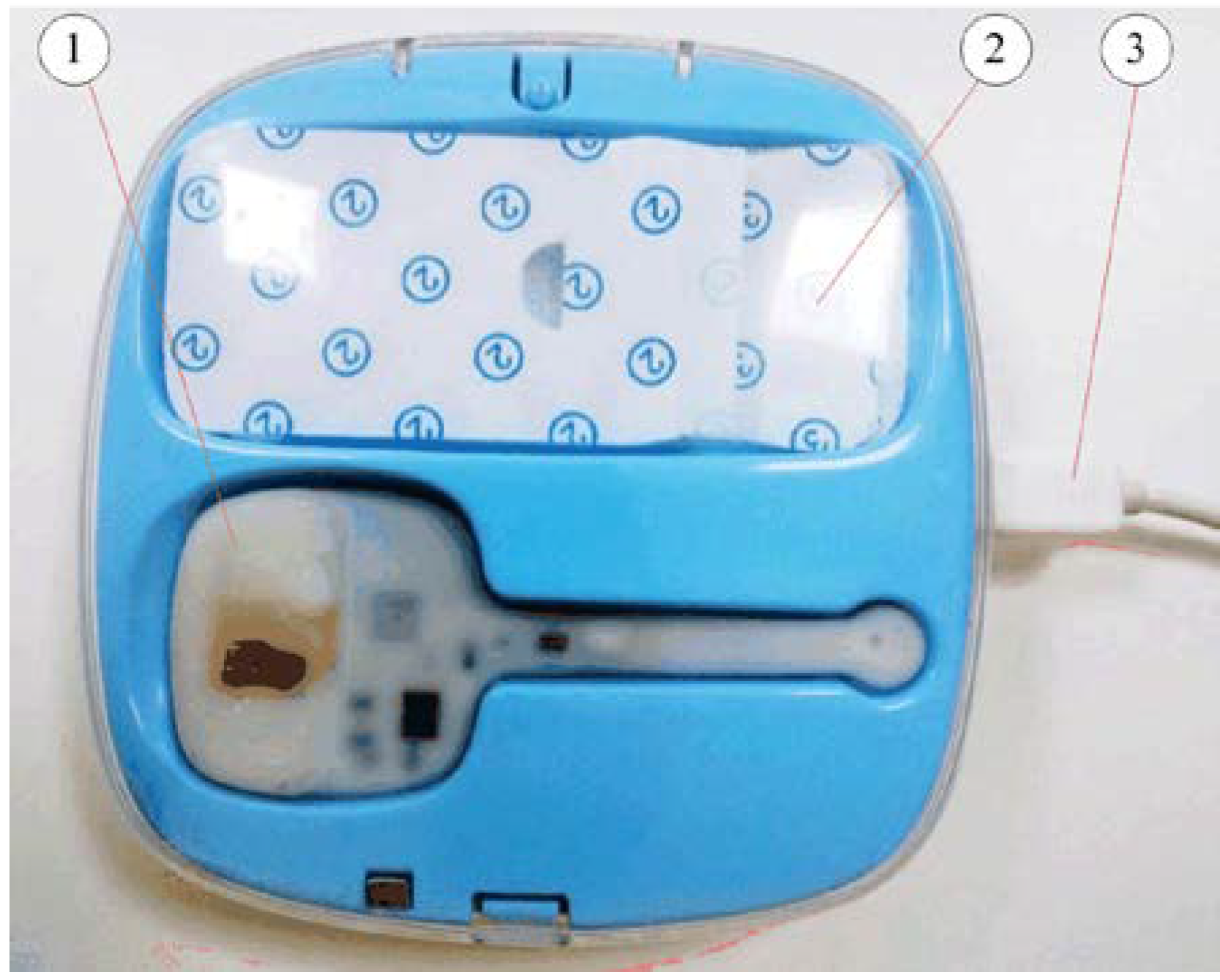

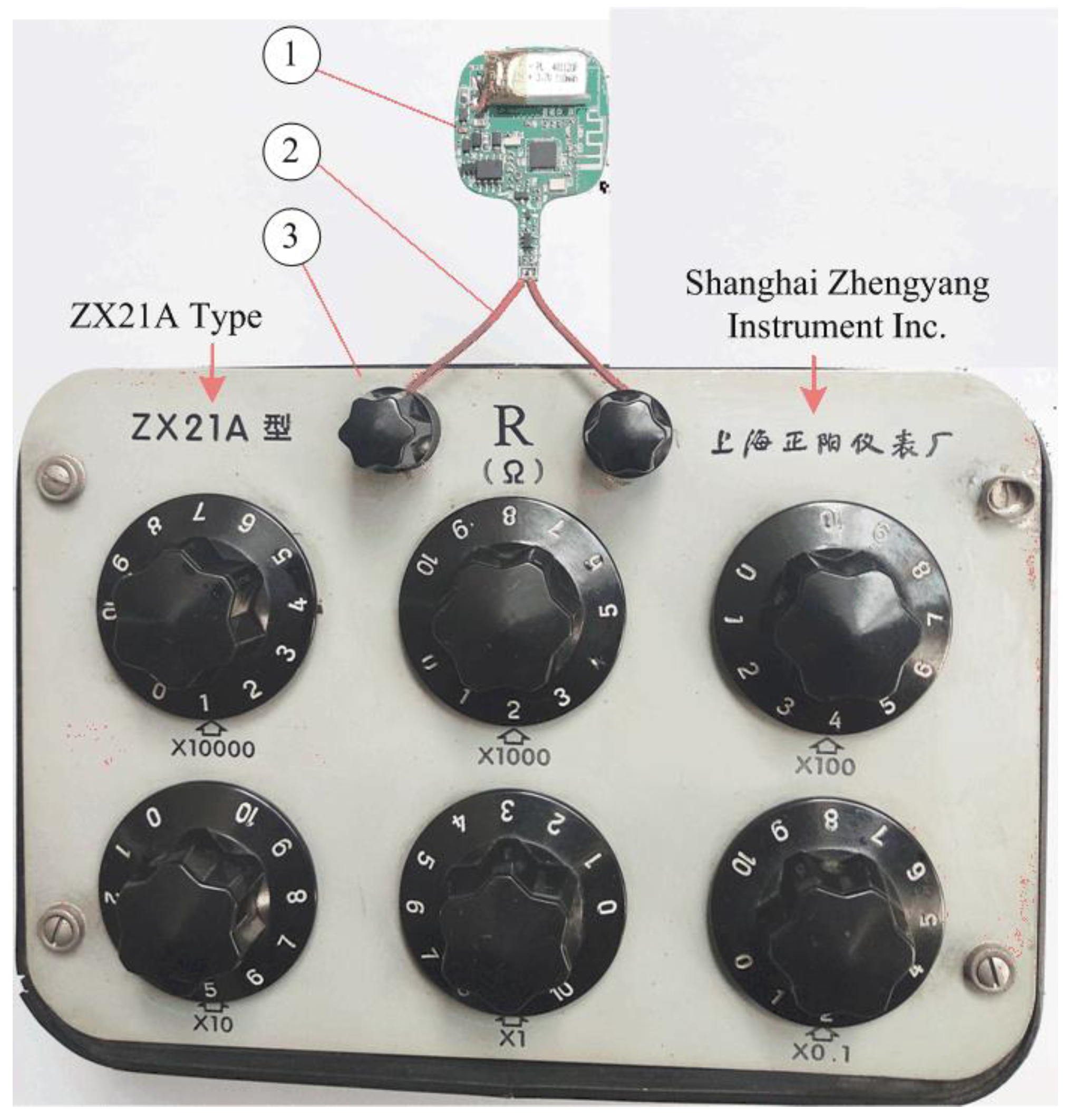

3. Development of a Smart Clinical Thermometer

4. Experimental Tests and Analysis

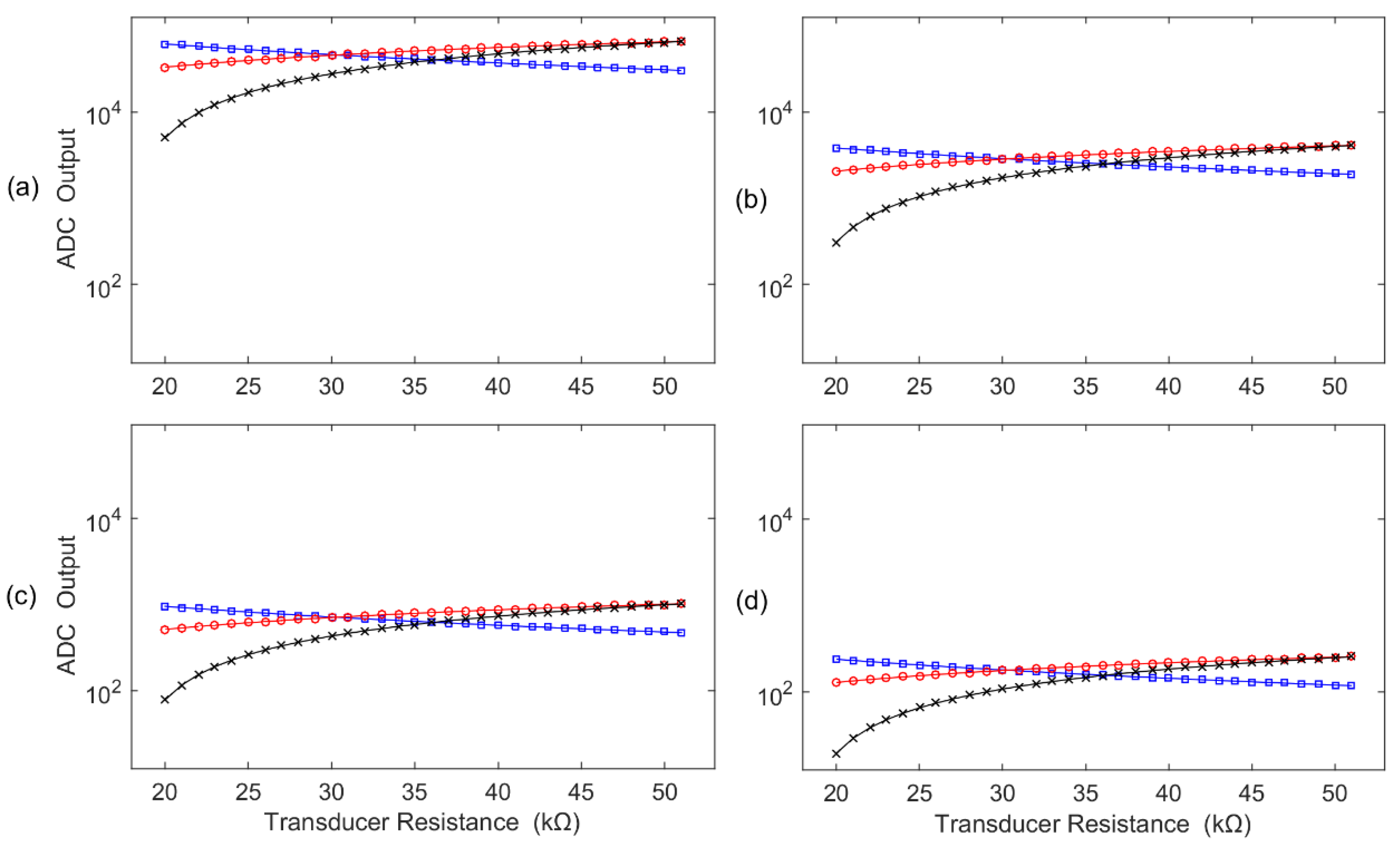

4.1. Testing and Analysis of the Improved Transducer Grounding Bleeder Circuits

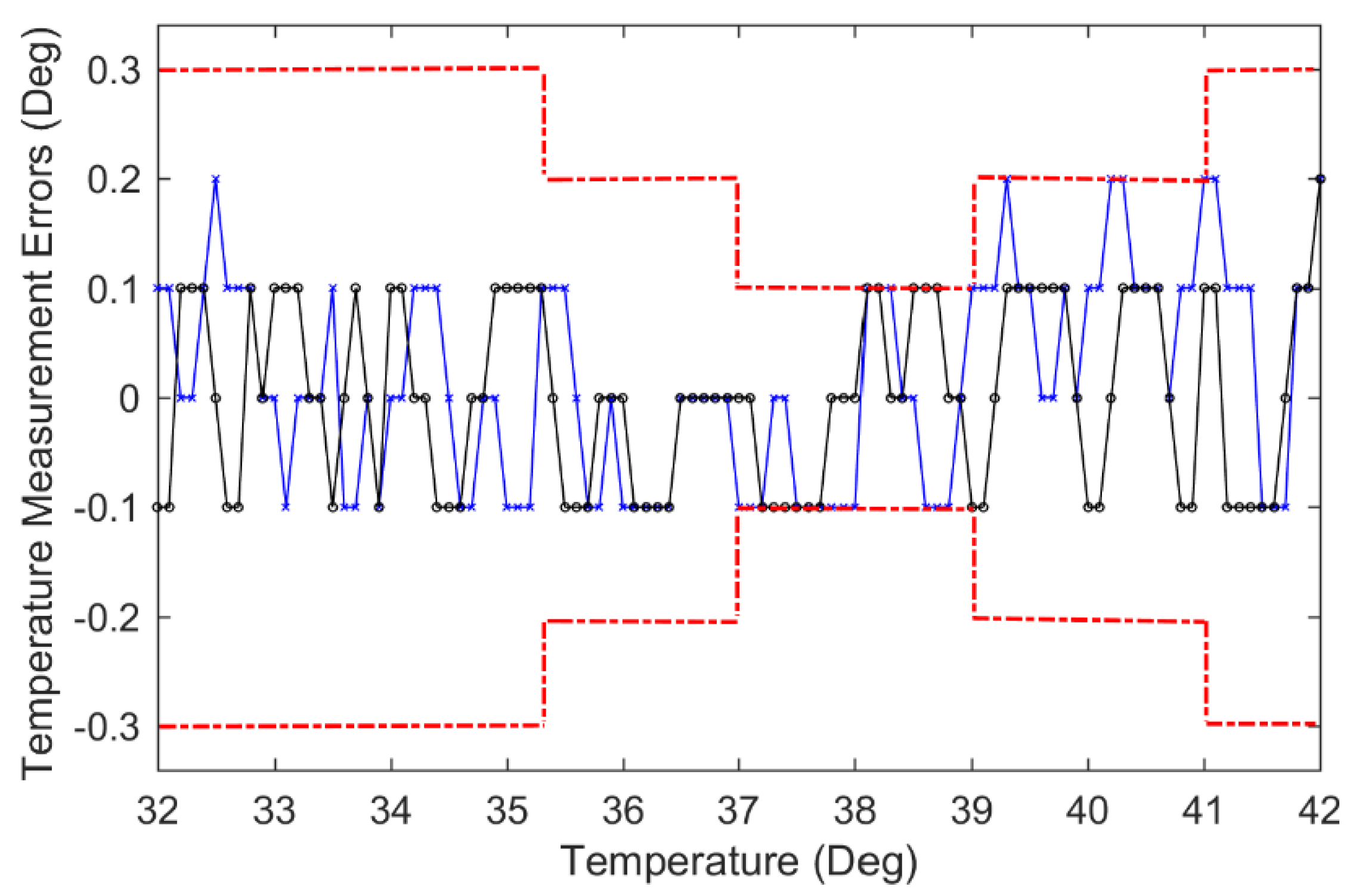

4.2. Test and Analysis of the Smart Thermometer System

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Baldominos, A.; Saez, Y.; Isasi, P. Evolutionary design of convolutional neural networks for human activity recognition in sensor-rich environments. Sensors 2018, 18, 1288. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, S.; Yang, W.; Wang, W. Power-saving design of RFID sensor networks in bus seat belt monitoring systems. Sensors 2020, 20, 5882. [Google Scholar] [CrossRef] [PubMed]

- Erhui, G. A data processing method for resistive strain sensors. Internet Things Technol. 2019, 9, 82–83, 86. [Google Scholar]

- Lin, X.; Seet, B.C. A linear wide-range textile pressure sensor integrally embedded in regular fabric. IEEE Sens. J. 2015, 15, 5384–5385. [Google Scholar] [CrossRef]

- Gesi, W. Virtual simulation of resistive sensor design. Exp. Sci. Technol. 2019, 17, 47–50. [Google Scholar]

- Jiang, J.; Liu, D.; Keke, L. The design of a resistance strain sensor signal conditioning circuit. Ship Electr. Technol. 2013, 33, 12–14. [Google Scholar]

- Erhui, G. A wireless strain sensor node design based on Zigbee. Electron. Technol. Softw. Eng. 2019, 10, 73–74. [Google Scholar]

- Pizarro, F.; Villavicencio, P.; Yunge, D.; Rodríguez, M.; Hermosilla, G.; Leiva, A. Easy-to-build textile pressure sensor. Sensors 2018, 18, 1190. [Google Scholar] [CrossRef] [Green Version]

- Li, P.; Li, X. A single-sided micromachined piezoresistive SiO2 cantilever sensor for ultra-sensitive detection of gaseous chemicals. J. Micromech. Microeng. 2006, 16, 2539–2546. [Google Scholar] [CrossRef]

- Xu, W.; Huang, M.C.; Amini, N.; He, L.; Sarrafzadeh, M. eCushion: A textile pressure sensor array design and calibration for sitting posture analysis. IEEE Sens. J. 2013, 13, 3926–3934. [Google Scholar] [CrossRef]

- Lin, X.; Seet, B.C. Battery-free smart sock for abnormal relative plantar pressure monitoring. IEEE Trans. Biomed. Circuits Syst. 2017, 11, 464–473. [Google Scholar] [CrossRef] [PubMed]

- Lin, F.; Wang, A.; Zhuang, Y.; Tomita, M.R.; Xu, W. Smart Insole: A wearable sensor device for unobtrusive gait monitoring in daily life. IEEE Trans. Ind. Inform. 2016, 12, 2281–2291. [Google Scholar] [CrossRef]

- Sefa Orak, M.; Nasrollahi, A.; Ozturk, T.; Mas, D.; Ferrer, B.; Rizzo, P. Non-contact smartphone-based monitoring of thermally stressed structures. Sensors 2018, 18, 1250. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Texas Instruments, Analog Engineer’s Circuit, Temperature Sensing with PTC Circuit. Available online: https://www.ti.com/lit/an/sboa322b/sboa322b.pdf (accessed on 29 November 2021).

- Texas Instruments, Analog Engineer’s Circuit: Data Converters, Monitoring NTC Thermistor Circuit with Single-Ended ADC. Available online: https://www.ti.com/lit/an/sbaa338/sbaa338.pdf (accessed on 29 November 2021).

- Jeon, H.; Hong, S.K.; Kim, M.S.; Cho, S.J.; Lim, G. Omni-purpose stretchable strain sensor based on a highly dense nanocracking structure for whole-body motion monitoring. ACS Appl. Mater. Interfaces 2017, 9, 41712–41721. [Google Scholar] [CrossRef]

- Ion, M.; Dinulescu, S.; Firtat, B.; Savin, M.; Ionescu, O.N.; Moldovan, C. Design and fabrication of a new wearable pressure sensor for blood pressure monitoring. Sensors 2021, 21, 2075. [Google Scholar] [CrossRef]

- Marcellis, A.D.; Cubells-Beltran, M.D.; Reig, C.; Madrenas, J.; Zadov, B.; Paperno, E.; Cardoso, S.; Freitas, P.P. Quasi-digital front-ends for current measurement in integrated circuits with giant magnetoresistance technology. IET Circuits Devices Syst. 2014, 8, 291–300. [Google Scholar] [CrossRef]

- Gandhi, N.; Shelke, S.D. Sigma delta analog to digital converter: Design and implementation with reduction in power consumption. In Proceedings of the 2017 International Conference on Trends in Electronics and Informatics (ICEI), Tirunelveli, India, 11–12 May 2017; pp. 1035–1039. [Google Scholar] [CrossRef]

- Onohara, K.; Nishioka, J.; Yoshida, T.; Suzuki, N. A study of multi-channel analog-to-digital conversion for beyond-5G mobile fronthaul. In Proceedings of the 2020 Opto-Electronics and Communications Conference (OECC), Taipei, Taiwan, 4–8 October 2020; pp. 1–3. [Google Scholar] [CrossRef]

- Li, Y.; Koay, K.C.; Chan, P.K. A 65nm CMOS ping-pong auto-zero resistance-to-frequency converter for resistive bridge sensors. In Proceedings of the 2016 International Symposium on Integrated Circuits (ISIC), Singapore, 12–14 December 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Qingzhi, Y.; Yunzhi, Z. Design of a simple and fast intelligent thermometer based on NTC thermistor. J. Qujing Norm. Univ. 2020, 39, 58–62. [Google Scholar]

- Libo, D.; Xuehui, W. Design of a web-based temperature and humidity monitoring system. In Proceedings of the 2011 2nd International Conference on Artificial Intelligence, Management Science and Electronic Commerce (AIMSEC), Dengfeng, China, 8–10 August 2011; pp. 2028–2030. [Google Scholar] [CrossRef]

- Qin, Z.; Shenglong, Y.; Heng, Z.; Xuesheng, C.; Shengmao, Z.; Yang, D. Design and implementation of marine temperature measurement system based on LoRa. In Proceedings of the 2018 International Symposium in Sensing and Instrumentation in IoT Era (ISSI), Shanghai, China, 6–7 September 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Guo, J.; Chen, H.; Lei, Y.; Li, X.; Wang, Q.; Xie, C.; Miao, J.; Lv, Y.; Liu, W.; Song, Z. An ultra-low quiescent current resistor-less power on reset circuit. IEEE Trans. Circuits Syst. II Express Briefs 2020, 68, 146–150. [Google Scholar] [CrossRef]

- Junfang, W.; Haibin, W.; Xiaochang, N.; Zhaohui, L.; Fei, Y.; Xu, Y. Design and implementation of electronic scale based on resistance strain gauge sensor. Intell. Comput. Appl. 2016, 6, 121–123. [Google Scholar]

- Analog Semicondutor: Low Energy Bluetooth 4.2 SoC: DA14580. Available online: https://www.mouser.ca/new/dialog-semiconductor/dialog-semi-da14580-soc (accessed on 1 July 2021).

- Lizhi, X.; Lanshen, G.; Lei, Z. Design of flexible sensor array based on piezoresistive effect of strain gauges. Instrum. Technol. Sens. 2017, 7, 4–6. [Google Scholar]

- Kurnyta, A.; Dziendzikowski, M.; Dragan, K. Use of resistive ladder sensors for crack monitoring during full scale fatigue test. In Proceedings of the 2014 IEEE Metrology for Aerospace (MetroAeroSpace), Benevento, Italy, 29–30 May 2014; pp. 196–200. [Google Scholar] [CrossRef]

- Winbond Electronics, Serial Flash Memory, W25X20CL. Available online: https://datasheetspdf.com/datasheet/W25X20CL.html (accessed on 1 July 2021).

- Lee, S.Y.; Wang, C.P.; Chu, Y.S. Low-voltage OTA–C filter with an area and power-efficient OTA for biosignal sensor applications. IEEE Trans. Biomed. Circuits Syst. 2019, 13, 56–67. [Google Scholar] [CrossRef]

- Qxmd, Independent Linear Lithium Battery Charger QX4054. Available online: https://datasheetspdf.com/datasheet/QX4054.html (accessed on 1 July 2021).

- Shenzhen Yongjing Technology Co., Ltd. Available online: https://detail.1688.com/offer/597706833463.html?spm=a2615.7691456.autotrace-offerGeneral.2.705a3ae2GemKu5 (accessed on 29 December 2021).

- Shenzhen Baizhikang Technology Co., Ltd. Available online: http://www.szbzk.com.cn/product/html/?86.html# (accessed on 29 December 2021).

- AMICCOM A8105 Datasheet. Available online: https://atta.szlcsc.com/upload/public/pdf/source/20200107/C479512_446577F0F0BE8BFD6B82FEC96763E88A.pdf (accessed on 29 December 2021).

- TEXAS INSTRUMENTS CC2540 Datasheet. Available online: https://www.ti.com/cn/lit/ds/symlink/cc2540.pdf?ts=1640743388677 (accessed on 29 December 2021).

| ADC Bits | Classical Bridge Conversion Circuit | Fixed Resistor Grounding Bleeder Circuit | Resistive Transducer Grounding Bleeder Circuit | |||

|---|---|---|---|---|---|---|

| Conversion Range | Measurement Resolution | Conversion Range | Measurement Resolution | Conversion Range | Measurement Resolution | |

| 8 | 255 | ±1.02 × 10−1 °C | 138 | ±1.90 × 10−1 °C | 138 | ±1.89 × 10−1 °C |

| 10 | 1021 | ±2.55 × 10−2 °C | 551 | ±4.73 × 10−2 °C | 551 | ±4.72 × 10−2 °C |

| 12 | 4088 | ±6.11 × 10−3 °C | 2205 | ±1.18 × 10−2 °C | 2205 | ±1.17 × 10−2 °C |

| 16 | 65,420 | ±4.22 × 10−4 °C | 35,280 | ±7.38 × 10−4 °C | 35,288 | ±7.36 × 10−4 °C |

| Temperature Display Range (°C) | Maximum Allowable Errors (°C) |

|---|---|

| Lower than 35.3 | ±0.3 |

| 35.3~36.9 | ±0.2 |

| 37.0~39.0 | ±0.1 |

| 39.1~41.0 | ±0.2 |

| Higher than 41.0 | ±0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, S.; Xv, J.; Wang, W.; Wang, C. Development of a Smart Clinical Bluetooth Thermometer Based on an Improved Low-Power Resistive Transducer Circuit. Sensors 2022, 22, 874. https://doi.org/10.3390/s22030874

Sun S, Xv J, Wang W, Wang C. Development of a Smart Clinical Bluetooth Thermometer Based on an Improved Low-Power Resistive Transducer Circuit. Sensors. 2022; 22(3):874. https://doi.org/10.3390/s22030874

Chicago/Turabian StyleSun, Sitong, Jinglun Xv, Wilson Wang, and Chengyuan Wang. 2022. "Development of a Smart Clinical Bluetooth Thermometer Based on an Improved Low-Power Resistive Transducer Circuit" Sensors 22, no. 3: 874. https://doi.org/10.3390/s22030874

APA StyleSun, S., Xv, J., Wang, W., & Wang, C. (2022). Development of a Smart Clinical Bluetooth Thermometer Based on an Improved Low-Power Resistive Transducer Circuit. Sensors, 22(3), 874. https://doi.org/10.3390/s22030874