A Novel Prescribed-Performance-Tracking Control System with Finite-Time Convergence Stability for Uncertain Robotic Manipulators

Abstract

:1. Introduction

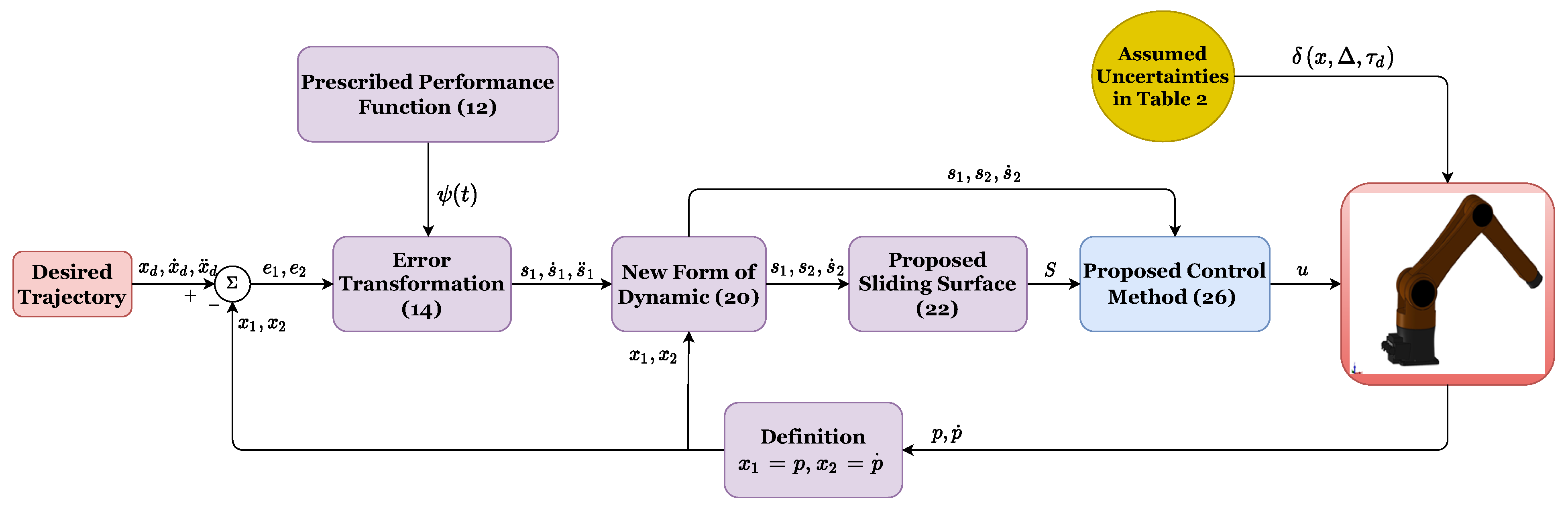

- We avoid any singularity problems by providing a modified integral nonlinear sliding-mode hyperplane.

- The improved control scheme is built on a combination of the STM [21], the designed nonlinear sliding-mode surface, and a performance function concept [24]. As a result, the desirable transient state is maintained, the maximum allowable size of the control errors at the steady-state can be predefined, and these errors will inevitably converge to origin within a finite time.

- With a PPF, one can manage the convergence rate and the maximum overshoot of the state error variables during the transient response process; furthermore, a modified integral nonlinear sliding-mode hyperplane combined with the STM allows for substantially reducing all chattering effects and finally achieving high tracking accuracy for state error variables in a steady-state response.

- The rigorous investigation provides sufficient evidence of stability and convergence in a finite time.

- A full evaluation of the effectiveness of the proposed control algorithm and a comparison of its performance to that of other control methods have already been conducted via simulation of an industrial robot manipulator.

2. Basic Definitions, Lemmas, and Problem Statement

2.1. Basic Definitions and Lemmas

- ;

- is decreasing and positive;

2.2. Dynamic Modeling of Robotic Manipulators

3. Design of the Proposed Control Method

3.1. Prescribed Performance Function

3.2. Change of Coordinates

3.3. Proposing of a Modified Integral Nonlinear Sliding-Mode Hyperplane

3.4. Proposed Controller Design

4. Simulation Results and Discussion

4.1. Configuration of the Testing System and Selection of Control Parameters

4.2. Simulation Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SM | Sliding Mode |

| SMC | Sliding-Mode Control |

| TSM | Terminal Sliding Mode |

| TSMC | Terminal Sliding-Mode Control |

| FTSMC | Fast Terminal Sliding-Mode Control |

| INTSM | Integral Non-Singular Terminal Sliding Mode |

| FOSMC | First-Order Sliding-Mode Control |

| SOSM | Second-Order Sliding Mode |

| SOSMC | Second-Order Sliding-Mode Control |

| HOSMC | Higher-Order Sliding-Mode Control |

| FnTC | Finite-Time Control |

| FxTC | Fixed-Time Control |

| STM | Super-Twisting Method |

| PFC | Prescribed Performance Control |

| PPF | Prescribed Performance Function |

| DoF | Degrees of Freedom |

| BsCM | Back-Stepping Control Method |

| RMS | Root Mean Square |

| URM | Uncertain Robotic Manipulator |

| CAD | Computer-Aided Design |

References

- Niku, S.B. Introduction to Robotics: Analysis, Control, Applications; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- Edwards, C.; Colet, E.F.; Fridman, L.; Colet, E.F.; Fridman, L.M. Advances in Variable Structure and Sliding Mode Control; Springer: Berlin/Heidelberg, Germany, 2006; Volume 334. [Google Scholar]

- Zhang, H.; Xu, N.; Zong, G.; Alkhateeb, A.F. Adaptive fuzzy hierarchical sliding mode control of uncertain under-actuated switched nonlinear systems with actuator faults. Int. J. Syst. Sci. 2021, 52, 1499–1514. [Google Scholar] [CrossRef]

- Utkin, V.; Lee, H. Chattering problem in sliding mode control systems. In Proceedings of the International Workshop on Variable Structure Systems—VSS’06, Alghero, Italy, 5–7 June 2006; IEEE: Piscataway, NJ, USA, 2006; pp. 346–350. [Google Scholar]

- Levant, A. Higher-order sliding modes, differentiation and output-feedback control. Int. J. Control 2003, 76, 924–941. [Google Scholar] [CrossRef]

- Galicki, M. Finite-time control of robotic manipulators. Automatica 2015, 51, 49–54. [Google Scholar] [CrossRef]

- Bartolini, G.; Pisano, A.; Punta, E.; Usai, E. A survey of applications of second-order sliding mode control to mechanical systems. Int. J. Control 2003, 76, 875–892. [Google Scholar] [CrossRef]

- Chang, X.h.; Jing, Y.w.; Gao, X.y.; Liu, X.p. Hinf tracking control design of TS fuzzy systems. Control Decis. 2008, 23, 329–332. [Google Scholar]

- Li, Z.M.; Chang, X.H.; Park, J.H. Quantized static output feedback fuzzy tracking control for discrete-time nonlinear networked systems with asynchronous event-triggered constraints. IEEE Trans. Syst. Man Cybern. Syst. 2019, 51, 3820–3831. [Google Scholar] [CrossRef]

- Ma, L.; Xu, N.; Zhao, X.; Zong, G.; Huo, X. Small-gain technique-based adaptive neural output-feedback fault-tolerant control of switched nonlinear systems with unmodeled dynamics. IEEE Trans. Syst. Man Cybern. Syst. 2020, 51, 7051–7062. [Google Scholar] [CrossRef]

- Tang, Y. Terminal sliding mode control for rigid robots. Automatica 1998, 34, 51–56. [Google Scholar] [CrossRef]

- Parra-Vega, V.; Rodríguez-Angeles, A.; Hirzinger, G. Perfect position/force tracking of robots with dynamical terminal sliding mode control. J. Robot. Syst. 2001, 18, 517–532. [Google Scholar] [CrossRef]

- Bhat, S.P.; Bernstein, D.S. Geometric homogeneity with applications to finite-time stability. Math. Control Signals Syst. 2005, 17, 101–127. [Google Scholar] [CrossRef] [Green Version]

- Bhat, S.P.; Bernstein, D.S. Finite-time stability of continuous autonomous systems. SIAM J. Control Optim. 2000, 38, 751–766. [Google Scholar] [CrossRef]

- Su, Y.; Zheng, C. Global finite-time inverse tracking control of robot manipulators. Robot. Comput.-Integr. Manuf. 2011, 27, 550–557. [Google Scholar] [CrossRef]

- Li, Y.; Niu, B.; Zong, G.; Zhao, J.; Zhao, X. Command filter-based adaptive neural finite-time control for stochastic nonlinear systems with time-varying full-state constraints and asymmetric input saturation. Int. J. Syst. Sci. 2022, 53, 199–221. [Google Scholar] [CrossRef]

- Tuan, V.A.; Kang, H.J. A New Finite-time Control Solution to The Robotic Manipulators Based on The Nonsingular Fast Terminal Sliding Variables and Adaptive Super-Twisting Scheme. J. Comput. Nonlinear Dyn. 2019, 14, 031002. [Google Scholar] [CrossRef]

- Truong, T.N.; Vo, A.T.; Kang, H.J. A backstepping global fast terminal sliding mode control for trajectory tracking control of industrial robotic manipulators. IEEE Access 2021, 9, 31921–31931. [Google Scholar] [CrossRef]

- Vo, A.T.; Kang, H.J. An Adaptive Terminal Sliding Mode Control for Robot Manipulators With Non-Singular Terminal Sliding Surface Variables. IEEE Access 2019, 7, 8701–8712. [Google Scholar] [CrossRef]

- Edwards, C.; Spurgeon, S. Sliding Mode Control: Theory and Applications; CRC Press: Bristol, PA, USA, 1998. [Google Scholar]

- Laghrouche, S.; Liu, J.; Ahmed, F.S.; Harmouche, M.; Wack, M. Adaptive second-order sliding mode observer-based fault reconstruction for PEM fuel cell air-feed system. IEEE Trans. Control Syst. Technol. 2014, 23, 1098–1109. [Google Scholar] [CrossRef]

- Nagesh, I.; Edwards, C. A multivariable super-twisting sliding mode approach. Automatica 2014, 50, 984–988. [Google Scholar] [CrossRef] [Green Version]

- Rivera, J.; Garcia, L.; Mora, C.; Raygoza, J.J.; Ortega, S. Super-twisting sliding mode in motion control systems. Sliding Mode Control 2011, 1, 237–254. [Google Scholar]

- Bechlioulis, C.P.; Rovithakis, G.A. Robust adaptive control of feedback linearizable MIMO nonlinear systems with prescribed performance. IEEE Trans. Autom. Control 2008, 53, 2090–2099. [Google Scholar] [CrossRef]

- Zhu, Y.; Qiao, J.; Guo, L. Adaptive sliding mode disturbance observer-based composite control with prescribed performance of space manipulators for target capturing. IEEE Trans. Ind. Electron. 2018, 66, 1973–1983. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, X.; Jing, Y. Adaptive neural networks finite-time tracking control for non-strict feedback systems via prescribed performance. Inf. Sci. 2018, 468, 29–46. [Google Scholar] [CrossRef]

- Jing, Y.; Liu, Y.; Zhou, S. Prescribed performance finite-time tracking control for uncertain nonlinear systems. J. Syst. Sci. Complex. 2019, 32, 803–817. [Google Scholar] [CrossRef]

- Zhou, Z.G.; Zhou, D.; Shi, X.N.; Li, R.F.; Kan, B.Q. Prescribed performance fixed-time tracking control for a class of second-order nonlinear systems with disturbances and actuator saturation. Int. J. Control 2021, 94, 223–234. [Google Scholar] [CrossRef]

- Zuo, Z. Non-singular fixed-time terminal sliding mode control of non-linear systems. IET Control Theory Appl. 2015, 9, 545–552. [Google Scholar] [CrossRef]

- Ding, S.; Levant, A.; Li, S. Simple homogeneous sliding-mode controller. Automatica 2016, 67, 22–32. [Google Scholar] [CrossRef]

- Craig, J.J. Introduction to Robotics: Mechanics and Control; Pearson Educacion: Upper Saddle River, NJ, USA, 2005. [Google Scholar]

- Jiang, B.; Staroswiecki, M.; Cocquempot, V. Fault accommodation for nonlinear dynamic systems. IEEE Trans. Autom. Control 2006, 51, 1578–1583. [Google Scholar] [CrossRef]

- Yu, S.; Yu, X.; Shirinzadeh, B.; Man, Z. Continuous finite-time control for robotic manipulators with terminal sliding mode. Automatica 2005, 41, 1957–1964. [Google Scholar] [CrossRef]

- Armstrong, B.; Khatib, O.; Burdick, J. The explicit dynamic model and inertial parameters of the PUMA 560 arm. In Proceedings of the 1986 IEEE International Conference on Robotics and Automation, San Francisco, CA, USA, 7–10 April 1986; Volume 3, pp. 510–518. [Google Scholar]

- Vo, A.T.; Truong, T.N.; Kang, H.J. A novel tracking control algorithm with finite-time disturbance observer for a class of second-order nonlinear systems and its applications. IEEE Access 2021, 9, 31373–31389. [Google Scholar] [CrossRef]

| Description | Link 1 | Link 2 | Link 3 |

|---|---|---|---|

| Link Length (m) | |||

| Link Weight (kg) | |||

| Center of Mass (mm) | |||

| Inertia (kg.m) |

| Assumed Uncertainty Type | Functions |

|---|---|

| Assumed Dynamic Uncertainties | |

| Assumed Frictions | |

| Assumed Disturbances | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vo, A.T.; Truong, T.N.; Kang, H.-J. A Novel Prescribed-Performance-Tracking Control System with Finite-Time Convergence Stability for Uncertain Robotic Manipulators. Sensors 2022, 22, 2615. https://doi.org/10.3390/s22072615

Vo AT, Truong TN, Kang H-J. A Novel Prescribed-Performance-Tracking Control System with Finite-Time Convergence Stability for Uncertain Robotic Manipulators. Sensors. 2022; 22(7):2615. https://doi.org/10.3390/s22072615

Chicago/Turabian StyleVo, Anh Tuan, Thanh Nguyen Truong, and Hee-Jun Kang. 2022. "A Novel Prescribed-Performance-Tracking Control System with Finite-Time Convergence Stability for Uncertain Robotic Manipulators" Sensors 22, no. 7: 2615. https://doi.org/10.3390/s22072615