Zero-Padding and Spatial Augmentation-Based Gas Sensor Node Optimization Approach in Resource-Constrained 6G-IoT Paradigm

Abstract

:1. Introduction

1.1. Motivation and Contributions

- A novel approach for gas sensor node power optimization without significant compromise in performance while classifying and/or quantifying the gases.

- The power-efficient sensor node is a key enabler for “Computation on the edge” for resource-constrained 6G-IoT applications.

- The especially used data pre-processing (zero-padded virtual sensors and spatial augmentation) and CNN-based sensor node optimization can reduce the cost of hardware and effective power consumption without significant deviation in the sensor node’s performance.

- The proposed simpler CNN when used with the zero-padded virtual sensors and spatial augmentation is computationally less complex and is well-suited for “computations on edge” in resource-constrained 6G-IoT environments.

1.2. Paper Structure

2. Materials and Methods

2.1. The Dataset

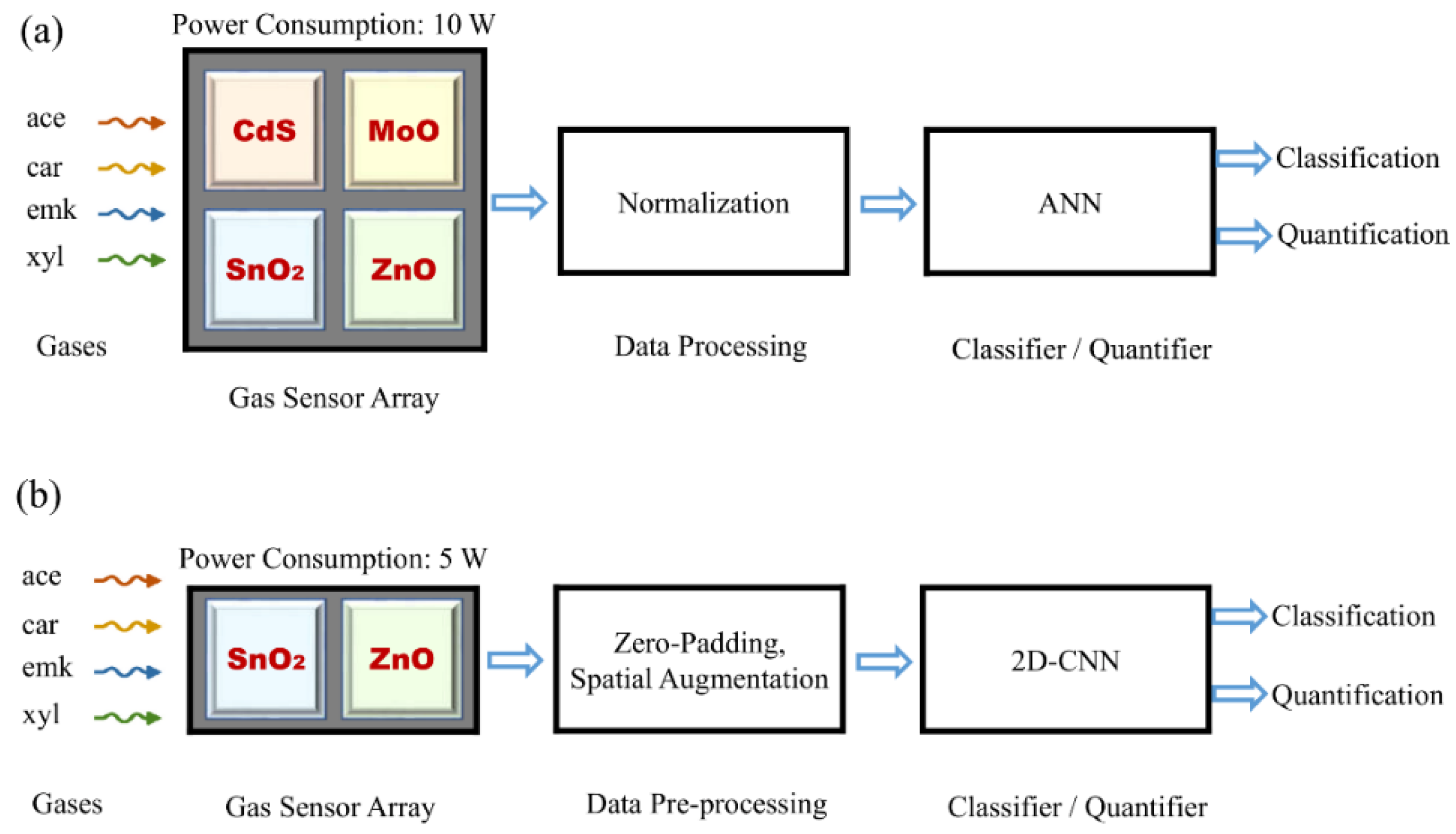

2.2. Gas Sensor System in Resource-Constrained 6G-IoT Scenarios

2.3. A 2D Convolutional Neural Network (2D-CNN)

2.4. Contextual Outline of Virtual Gas Sensors and Zero-Padding

2.5. Contextual Outline of Spatial Augmentation

2.6. Case-Based Experiments (Baseline and Possible Scenarios)

| Algorithm 1 Spatial Augmentation Procedure for Data Up-Scaling | |

| 1 | function Spatial Augmentation (S) |

| Input: Number of sensor elements S in the sensing unit OR Length of raw data vectors | |

| Output: The spatially augmented data vectors compatible with the input to the 2D-CNN | |

| 2 | BEGIN |

| 3 | IF S is a perfect square number: |

| 4 | Represent the data vector in the squared array of size: [√(S) × √(S)] |

| 5 | Following stage 2 as discussed, data vector spatially augmented to the size: [(3 × √(S)) × (3 × √(S))] |

| 6 | ELSE |

| 7 | Find the number of required virtual sensors to make the total number of sensor elements equal to the nearest perfect square number, say α |

| 8 | Following stage 1 virtual sensors were included to make the total number of sensor elements in the sensing unit, [(S + α)] |

| 9 | Represent the obtained data vectors in the squared array of size: [√(S + α) × √(S + α)] |

| 10 | Following stage 2 as discussed, data vector spatially augmented to the size [(3×√(S + α)) × (3×√(S + α))] |

| 11 | STOP |

3. Results

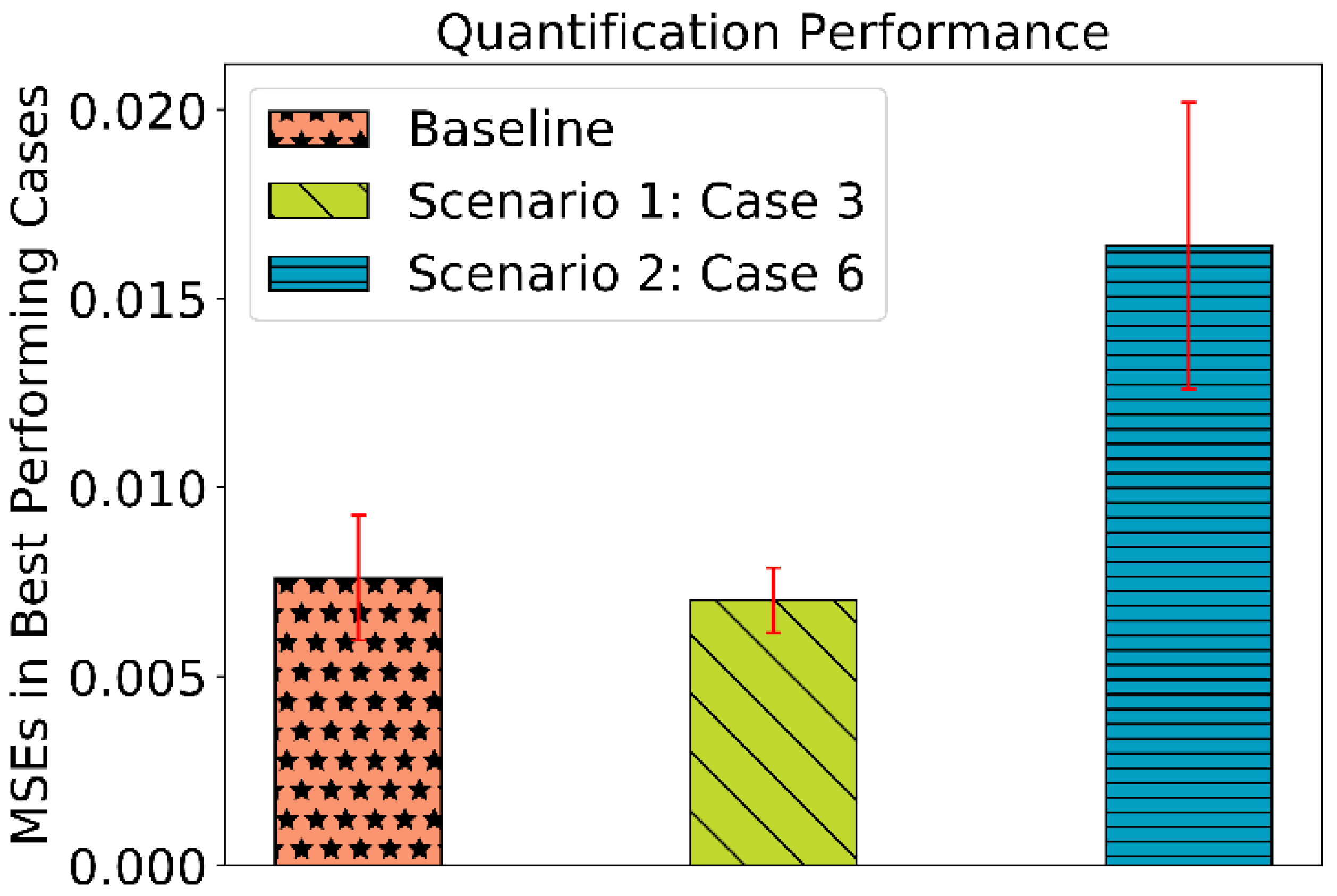

3.1. Experiment 1: Baseline (Four Physical Sensor Elements)

3.2. Experiment 2: Scenario 1 (Three Physical and One Zero-Padded Sensor Element)

3.3. Experiment 3: Scenario 2 (Two Physical and Two Zero-Padded Sensor Elements)

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 6G | Sixth Generation (of wireless communication) |

| IoT | Internet of Things |

| CNN | Convolutional Neural Network |

| MSE | Mean Squared Error |

| CO | Carbon Monoxide |

| QoS | Quality of Service |

| MOX | Metal Oxide |

| AI | Artificial Intelligence |

| DCNN | Deep Convolutional Neural Network |

| 2D | Two Dimensional |

| ace | Acetone |

| car | Carbon Tetrachloride |

| emk | Ethyl Methyl Ketone |

| xyl | Xylene |

| CdS | Cadmium Sulfide |

| MoO | Molybdenum Oxide |

| SnO2 | Tin Oxide |

| ZnO | Zinc Oxide |

| ANN | Artificial Neural Network |

| SGD | Stochastic Gradient Descent |

| VGS | Virtual Gas Sensor |

| QNT_MSE | Quantification-Mean Squared Error |

References

- Galkin, P.; Golovkina, L.; Klyuchnyk, I. Analysis of Single-Board Computers for IoT and IIoT Solutions in Embedded Control Systems. In Proceedings of the International Scientific-Practical Conference Problems of Infocommunications. Science and Technology (PIC S&T), Kharkiv, Ukraine, 9–12 October 2018; pp. 297–302. [Google Scholar] [CrossRef]

- Henkel, J.; Pagani, S.; Amrouch, H.; Bauer, L.; Samie, F. Ultra-low power and dependability for IoT devices (Invited paper for IoT technologies). In Proceedings of the Design, Automation & Test in Europe Conference & Exhibition (DATE), Lausanne, Switzerland, 27–31 March 2017; pp. 954–959. [Google Scholar] [CrossRef]

- Nguyen, D.C.; Ding, M.; Pathirana, P.N.; Seneviratne, A.; Li, J.; Niyato, D.; Dobre, O.; Poor, H.V. 6G Internet of Things: A Comprehensive Survey. IEEE Internet Things J. 2021, 9, 359–383. [Google Scholar] [CrossRef]

- Deshmukh, S.; Bandyopadhyay, R.; Bhattacharyya, N.; Pandey, R.A.; Jana, A. Application of electronic nose for industrial odors and gaseous emissions measurement and monitoring—An overview. Talanta 2015, 144, 329–340. [Google Scholar] [CrossRef] [PubMed]

- Wilson, A.D. Application of Electronic-Nose Technologies and VOC-Biomarkers for the Noninvasive Early Diagnosis of Gastrointestinal Diseases. Sensors 2018, 18, 2613. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wilson, A.D. Diverse Applications of Electronic-Nose Technologies in Agriculture and Forestry. Sensors 2013, 13, 2295–2348. [Google Scholar] [CrossRef] [Green Version]

- Shi, H.; Zhang, M.; Adhikari, B. Advances of electronic nose and its application in fresh foods: A review. Crit. Rev. Food Sci. Nutr. 2018, 58, 2700–2710. [Google Scholar] [CrossRef]

- Mamat, M.; Samad, S.A.; Hannan, M.A. An Electronic Nose for Reliable Measurement and Correct Classification of Beverages. Sensors 2011, 11, 6435–6453. [Google Scholar] [CrossRef] [Green Version]

- Somov, A.; Baranov, A.; Spirjakin, D.; Passerone, R. Circuit Design and Power Consumption Analysis of Wireless Gas Sensor Nodes: One-Sensor Versus Two-Sensor Approach. IEEE Sens. J. 2014, 14, 2056–2063. [Google Scholar] [CrossRef]

- Amarlingam, M.; Durga Prasad, K.V.V.; Rajalakshmi, P.; Channappayya, S.S.; Sastry, C.S. A Novel Low-Complexity Compressed Data Aggregation Method for Energy-Constrained IoT Networks. IEEE Trans. Green Commun. Netw. 2020, 4, 717–730. [Google Scholar] [CrossRef]

- Alsamhi, S.H.; Almalki, F.A.; Afghah, F.; Hawbani, A.; Shvetsov, A.V.; Lee, B.; Song, H. Drones’ Edge Intelligence Over Smart Environments in B5G: Blockchain and Federated Learning Synergy. IEEE Trans. Green Commun. Netw. 2021, 6, 295–312. [Google Scholar] [CrossRef]

- Alsamhi, S.H.; Almalki, F.A.; Al-Dois, H.; Othman, S.B.; Hassan, J.; Hawbani, A.; Sahal, R.; Lee, B.; Saleh, H. Machine Learning for Smart Environments in B5G Networks: Connectivity and QoS. Comput. Intell. Neurosci. 2021, 2021, 6805151. [Google Scholar] [CrossRef]

- Sodhro, A.H.; Pirbhulal, S.; Luo, Z.; Muhammad, K.; Zahid, N.Z. Toward 6G Architecture for Energy-Efficient Communication in IoT-Enabled Smart Automation Systems. IEEE Internet Things J. 2021, 8, 5141–5148. [Google Scholar] [CrossRef]

- Jeyabharathi, D.; Kesavaraja, D.; Sasireka, D. Gas Leakage Detection from Drainage to Offer Safety for Sanitary Workers. In Design and Development of Efficient Energy Systems; Scrivener Publishing: Austin, TX, USA, 2021; pp. 31–42. [Google Scholar]

- Baek, S.-O.; Suvarapu, L.N.; Seo, Y.-K. Occurrence and Concentrations of Toxic Gases in the Ambient Air of Gumi, an Electronics-Industrial City in Korea. Sensors 2015, 15, 19102–19123. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wilson, A.D. Review of electronic-nose technologies and algorithms to detect hazardous chemicals in the environment. Procedia Technol. 2012, 1, 453–463. [Google Scholar] [CrossRef] [Green Version]

- Fan, H.; Bennetts, V.H.; Schaffernicht, E.; Lilienthal, A.J. Towards gas discrimination and mapping in emergency response scenarios using a mobile robot with an electronic nose. Sensors 2019, 19, 685. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Xue, Y.; Sun, Q.; Zhang, T.; Chen, Y.; Yu, W.; Xiong, Y.; Wei, X.; Yu, G.; Wan, H.; et al. A miniaturized electronic nose with artificial neural network for anti-interference detection of mixed indoor hazardous gases. Sens. Actuators B Chem. 2021, 326, 128822. [Google Scholar] [CrossRef]

- Li, H.; Ota, K.; Dong, M. Learning IoT in Edge: Deep Learning for the Internet of Things with Edge Computing. IEEE Netw. 2018, 32, 96–101. [Google Scholar] [CrossRef] [Green Version]

- Merenda, M.; Porcaro, C.; Iero, D. Edge machine learning for AI-enabled IoT devices: A review. Sensors 2020, 20, 2533. [Google Scholar] [CrossRef]

- Peng, P.; Zhao, X.; Pan, X.; Ye, W. Gas Classification Using Deep Convolutional Neural Networks. Sensors 2018, 18, 157. [Google Scholar] [CrossRef] [Green Version]

- Zhao, X.; Wen, Z.; Pan, X.; Ye, W.; Bermak, A. Mixture Gases Classification Based on Multi-Label One-Dimensional Deep Convolutional Neural Network. IEEE Access 2019, 7, 12630–12637. [Google Scholar] [CrossRef]

- Wei, G.; Li, G.; Zhao, J.; He, A. Development of a LeNet-5 gas identification CNN structure for electronic noses. Sensors 2019, 19, 217. [Google Scholar] [CrossRef] [Green Version]

- Lecun, Y.; Bottou, L.; Bengio, Y.; Haffner, P. Gradient-based learning applied to document recognition. Proc. IEEE 1998, 86, 2278–2324. [Google Scholar] [CrossRef] [Green Version]

- Chaudhri, S.N.; Rajput, N.S. Multidimensional Multiconvolution Based Feature Extraction Approach for Drift Tolerant Robust Classifier for Gases/Odors. IEEE Sens. Lett. 2022, 6, 1–4. [Google Scholar] [CrossRef]

- Nayak, M.S.; Dwivedi, R.; Srivastava, S.K. Sensitivity and response times of doped tin oxide integrated gas sensors. Microelectron. J. 1994, 25, 17–25. [Google Scholar] [CrossRef]

- Rajput, N.S.; Das, R.R.; Mishra, V.N.; Singh, K.P.; Dwivedi, R. A neural net implementation of SPCA pre-processor for gas/odor classification using the responses of thick film gas sensor array. Sens. Actuators B Chem. 2010, 148, 550–558. [Google Scholar] [CrossRef]

- Mishra, A.; Rajput, N.S.; Han, G. NDSRT: An efficient virtual multi-sensor response transformation for classification of gases/odors. IEEE Sens. J. 2017, 17, 3416–3421. [Google Scholar] [CrossRef]

- Chaudhri, S.N.; Rajput, N.S. Mirror Mosaicking: A Novel Approach to Achieve High-performance Classification of Gases Leveraging Convolutional Neural Network. In Proceedings of the 10th International Conference on Sensor Networks, SENSORNETS, Online, 9–10 February 2021; Volume 1, pp. 86–91. [Google Scholar] [CrossRef]

- Chatterjee, B.; Cao, N.; Raychowdhury, A.; Sen, S. Context-Aware Intelligence in Resource-Constrained IoT Nodes: Opportunities and Challenges. IEEE Des. Test 2019, 36, 7–40. [Google Scholar] [CrossRef]

- Chaudhri, S.N.; Rajput, N.S.; Mishra, A. A novel principal component-based virtual sensor approach for efficient classification of gases/odors. J. Electr. Eng. 2022, accepted. [Google Scholar]

- Wang, T.; Sun, M.; Hu, K. Dilated Deep Residual Network for Image Denoising. In Proceedings of the IEEE 29th International Conference on Tools with Artificial Intelligence (ICTAI), Boston, MA, USA, 6–8 November 2017; pp. 1272–1279. [Google Scholar] [CrossRef] [Green Version]

- Lopez-del Rio, A.; Martin, M.; Perera-Lluna, A.; Saidi, R. Effect of sequence padding on the performance of deep learning models in archaeal protein functional prediction. Sci. Rep. 2020, 10, 14634. [Google Scholar] [CrossRef]

- Chaudhri, S.N.; Rajput, N.S.; Singh, K.P.; Singh, D. Mirror Mosaicking Based Reduced Complexity Approach for the Classification of Hyperspectral Images. In Proceedings of the IEEE International Geoscience and Remote Sensing Symposium IGARSS, Brussels, Belgium, 11–16 July 2021; pp. 3657–3660. [Google Scholar] [CrossRef]

| Experiments | Physical Sensors | Zero-Padded Virtual Sensors | Classification Accuracy (%) | Quantification MSE | Effective Power (Consumed) |

|---|---|---|---|---|---|

| Baseline | CdS, MoO, SnO2, ZnO | 0 | 100 | (7.61 ± 1.66) × 10−3 | 10 W |

| Scenario 1: Case 1 | CdS, MoO, SnO2 | 1 | 100 | (1.15 ± 0.35) × 10−2 | 7.5 W |

| Scenario 1: Case 2 | CdS, MoO, ZnO | 1 | 100 | (4.01 ± 0.53) × 10−2 | 7.5 W |

| Scenario 1: Case 3 | CdS, SnO2, ZnO | 1 | 100 | (7.02 ± 0.86) × 10−3 | 7.5 W |

| Scenario 1: Case 4 | MoO, SnO2, ZnO | 1 | 100 | (1.43 ± 0.21) × 10−2 | 7.5 W |

| Scenario 2: Case 1 | CdS, MoO | 2 | 100 | (3.01 ± 0.16) × 10−0 | 5 W |

| Scenario 2: Case 2 | CdS, SnO2 | 2 | 100 | (1.42 ± 0.33) × 10−1 | 5 W |

| Scenario 2: Case 3 | CdS, ZnO | 2 | 100 | (2.43 ± 0.40) × 10−2 | 5 W |

| Scenario 2: Case 4 | MoO, SnO2 | 2 | 100 | (1.68 ± 0.19) × 10−1 | 5 W |

| Scenario 2: Case 5 | MoO, ZnO | 2 | 100 | (3.17 ± 0.91) × 10−1 | 5 W |

| Scenario 2: Case 6 | SnO2, ZnO | 2 | 100 | (1.64 ± 0.38) × 10−2 | 5 W |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chaudhri, S.N.; Rajput, N.S.; Alsamhi, S.H.; Shvetsov, A.V.; Almalki, F.A. Zero-Padding and Spatial Augmentation-Based Gas Sensor Node Optimization Approach in Resource-Constrained 6G-IoT Paradigm. Sensors 2022, 22, 3039. https://doi.org/10.3390/s22083039

Chaudhri SN, Rajput NS, Alsamhi SH, Shvetsov AV, Almalki FA. Zero-Padding and Spatial Augmentation-Based Gas Sensor Node Optimization Approach in Resource-Constrained 6G-IoT Paradigm. Sensors. 2022; 22(8):3039. https://doi.org/10.3390/s22083039

Chicago/Turabian StyleChaudhri, Shiv Nath, Navin Singh Rajput, Saeed Hamood Alsamhi, Alexey V. Shvetsov, and Faris A. Almalki. 2022. "Zero-Padding and Spatial Augmentation-Based Gas Sensor Node Optimization Approach in Resource-Constrained 6G-IoT Paradigm" Sensors 22, no. 8: 3039. https://doi.org/10.3390/s22083039