High-Sensitivity Pressure Sensors Based on a Low Elastic Modulus Adhesive

Abstract

:1. Introduction

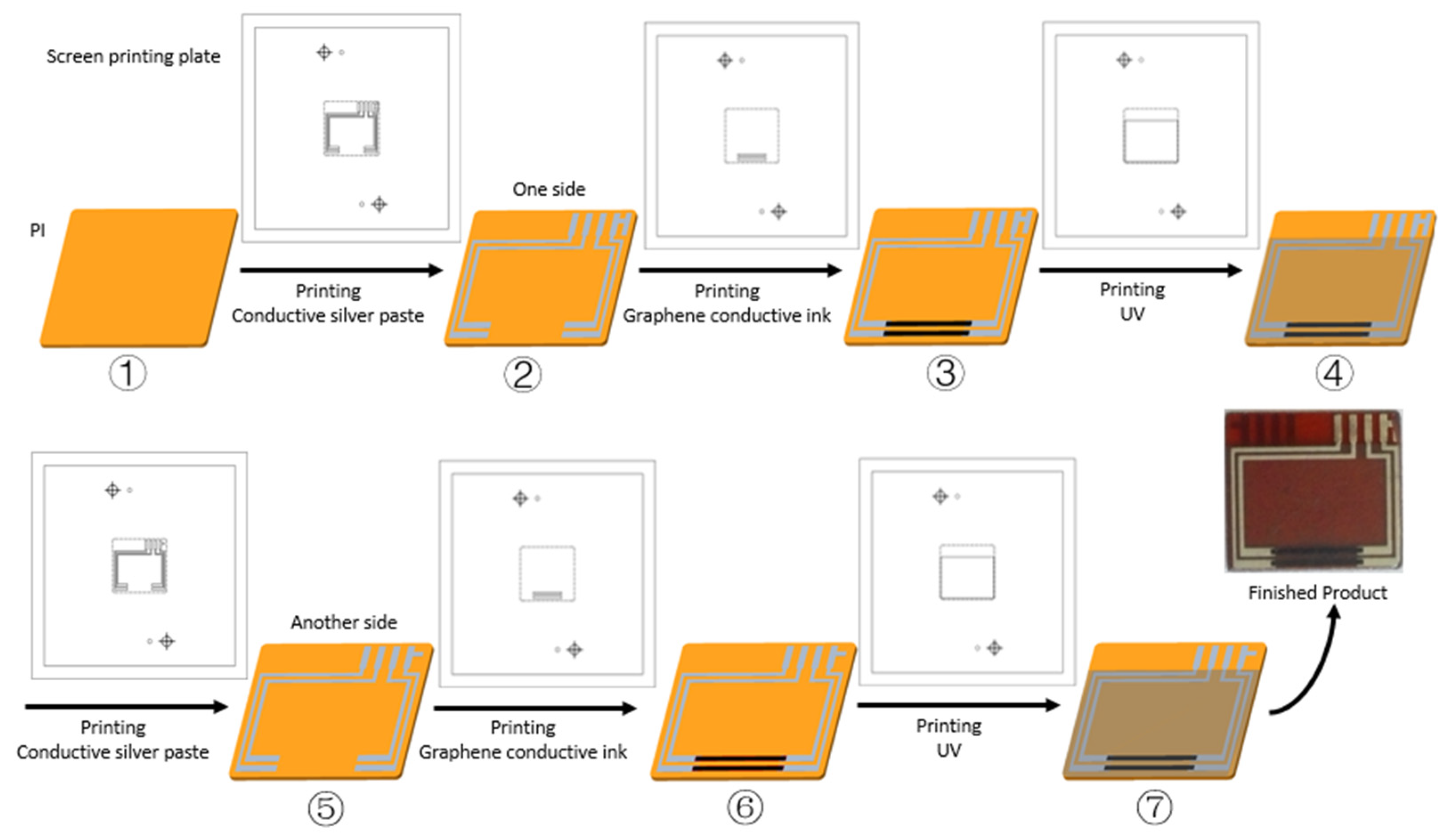

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cai, L.; Song, L.; Luan, P.S.; Zhang, Q.; Zhang, N.; Gao, Q.; Zhao, D.; Zhang, X.; Tu, M.; Yang, F.; et al. Super-stretchable, Transparent Carbon Nanotube-Based Capacitive Strain Sensors for Human Motion Detection. Sci. Rep. 2013, 3, 3048. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Y.; Wang, L.; Yang, T.; Li, X.; Zang, X.; Zhu, M.; Wang, K.; Wu, D.; Zhu, H. Wearable and Highly Sensitive Graphene Strain Sensors for Human Motion Monitoring. Adv. Funct. Mater. 2014, 24, 4666–4670. [Google Scholar] [CrossRef]

- Yogeswaran, N.; Dang, W.; Navaraj, W.T.; Shakthivel, D.; Khan, S.; Polat, E.O.; Gupta, S.; Heidari, H.; Kaboli, M.; Lorenzelli, L.; et al. New materials and advances in making electronic skin for interactive robots. Adv. Robot. 2015, 29, 1359–1373. [Google Scholar] [CrossRef] [Green Version]

- Trung, T.Q.; Lee, N.E. Flexible and Stretchable Physical Sensor Integrated Platforms for Wearable Human-Activity Monitoringand Personal Healthcare. Adv. Mater. 2016, 28, 4338–4372. [Google Scholar] [CrossRef]

- Wang, R.; Xu, W.; Shen, W.; Shi, X.; Huang, J.; Song, W. A highly stretchable and transparent silver nanowire/thermoplastic polyurethane film strain sensor for human motion monitoring. Inorg. Chem. Front. 2019, 6, 3119–3124. [Google Scholar] [CrossRef]

- Lee, J.; Kim, S.; Lee, J.; Yang, D.; Park, B.C.; Ryu, S.; Park, I. A stretchable strain sensor based on a metal nanoparticle thin film for human motion detection. Nanoscale 2014, 6, 11932–11939. [Google Scholar] [CrossRef]

- Xiang, L.; Zeng, X.W.; Xia, F.; Jin, W.L.; Liu, Y.D.; Hu, Y.F. Recent Advances in Flexible and Stretchable Sensing Systems: From the Perspective of System Integration. ACS Nano 2020, 14, 6449–6469. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, M.Y.; Yang, B.; Ding, X.Y.; Tan, J.J.; Song, S.X.; Nie, J.Y. Flexible, Robust, and Durable Aramid Fiber/CNT Composite Paper as a Multifunctional Sensor for Wearable Applications. ACS Appl. Mater. Inter. 2021, 13, 5486–5497. [Google Scholar] [CrossRef]

- Hu, W.; Niu, X.F.; Zhao, R.; Pei, Q.B. Elastomeric transparent capacitive sensors based on an interpenetrating composite of silver nanowires and polyurethane. Appl. Phys. Lett. 2013, 102, 083303. [Google Scholar] [CrossRef]

- Nagatomo, T.; Miki, N. Micromachines, Reduction of Parasitic Capacitance of A PDMS Capacitive Force Sensor. Micromachines 2018, 9, 570. [Google Scholar] [CrossRef] [Green Version]

- Tressler, J.F.; Alkoy, S.; Newnham, R.E. Piezoelectric Sensors and Sensor Materials. J. Electroceram. 1998, 2, 257–272. [Google Scholar] [CrossRef]

- Rödel, J.; Jo, W.; Seifert, K.T.P.; Anton, E.M.; Granzow, T.; Damjanovic, D. Perspective on the Development of Lead-free Piezoceramics. J. Am. Ceram. Soc. 2009, 92, 1153–1177. [Google Scholar] [CrossRef]

- Brace, W.F. Effect of pressure on electric-resistance strain gages. Exp. Mech. 1964, 4, 212–216. [Google Scholar] [CrossRef]

- Cai, G.; Wang, J.; Qian, K.; Chen, J.; Li, S.; Lee, P.S. Extremely Stretchable Strain Sensors Based on Conductive Self-Healing Dynamic Cross-Links Hydrogels for Human-Motion Detection. Adv. Sci. 2017, 4, 1600190. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mohankumar, P.; Ajayan, J.; Yasodharan, R.; Devendran, P.; Sambasivam, R. A review of micromachined sensors for automotive applications. Measurement 2019, 140, 305–322. [Google Scholar] [CrossRef]

- Aslanidis, E.; Skotadis, E.; Moutoulas, E.; Tsoukalas, D. Thin Film Protected Flexible Nanoparticle Strain Sensors: Experiments and Modeling. Sensors 2020, 20, 2584. [Google Scholar] [CrossRef]

- Hu, J.; Yu, J.; Li, Y.; Liao, X.; Yan, X.; Li, L. Nano Carbon Black-Based High Performance Wearable Pressure Sensors. Nanomaterials 2020, 10, 664. [Google Scholar] [CrossRef] [Green Version]

- Yu, R.F.; Zhu, C.Y.; Wan, J.M.; Li, Y.Q.; Hong, X.H. Review of Graphene-Based Textile Strain Sensors, with Emphasis on Structure Activity Relationship. Polymers 2021, 13, 151. [Google Scholar] [CrossRef]

- Han, F.; Li, M.; Ye, H.Y.; Zhang, G.Q. Materials, Electrical Performance, Mechanisms, Applications, and Manufacturing Approaches for Flexible Strain Sensors. Nanomaterials 2021, 11, 1220. [Google Scholar] [CrossRef]

- Kanoun, O.; Bouhamed, A.; Ramalingame, R.; Bautista-Quijano, J.R.; Rajendran, D.; Al-Hamry, A. Review on conductive polymer/cnts nanocomposites based flexible and stretchable strain and pressure sensors. Sensors 2021, 21, 341. [Google Scholar] [CrossRef]

- Abot, J.L.; Kiyono, C.Y.; Thomas, G.P.; Silva, E.C.N. Strain gauge sensors comprised of carbon nanotube yarn: Parametric numerical analysis of their piezoresistive response. Smart Mater. Struct. 2015, 24, 075018. [Google Scholar] [CrossRef]

- Lee, D.; Hong, H.P.; Lee, M.J.; Park, C.W.; Min, N.K. A prototype high sensitivity load cell using single walled carbon nanotube strain Gauges. Sens. Actuators A Phys. 2012, 180, 120–126. [Google Scholar] [CrossRef]

- He, W.; Han, M.; Philippe, G.; Bourhis, E.L.; Renault, P.O.; Wang, S.; Li, L. Strain transfer through film-substrate interface and surface curvature evolution during a tensile test. Appl. Surf. Sci. 2018, 434, 771–780. [Google Scholar] [CrossRef]

- Kang, I.; Schulz, M.J.; Kim, J.H.; Shanov, V.; Shi, D.L. A carbon nanotube strain sensor for structural health monitoring. Smart Mater. Struct. 2006, 15, 737–748. [Google Scholar] [CrossRef]

- Torres, B.; Payá-Zaforteza, I.; Calderón, P.A.; Adam, J.M. Analysis of the strain transfer in a new FBG sensor for Structural Health Monitoring. Eng. Struct. 2011, 33, 539–548. [Google Scholar] [CrossRef] [Green Version]

- Song, H.W.; Qin, L.K.; Zuo, X.Y.; Li, Y. Strain Transfer Analysis of FBG Sensors Bonded on the Surface of Structure. Adv. Mater. Res. 2014, 1065–1069, 1638–1642. [Google Scholar] [CrossRef]

- Wang, B.; Liu, T.; Xu, J.L.; Liu, M.B. Strain transfer analysis of metal paste type resistance strain gauge. China Meas. Test 2016, 42, 1–6. [Google Scholar]

- Xu, Y.Q.; Yang, X.; Wei, T.; Yao, J. Analysis of the factors affecting strain transfer in resistance-strain sensors. China Meas. Test 2018, 44, 136–142. [Google Scholar]

- Wu, R.; Zheng, B.; Liu, Z.; He, P.; Tan, Y. Analysis on strain transfer of a pasted FBG strain sensor. Optik 2014, 125, 4924–4928. [Google Scholar] [CrossRef]

- Ryan, B. MINITAB Handbook; International Edition; Cengage Learning, Inc.: Boston, MA, USA, 2012. [Google Scholar]

- Wolterink, G.; Sanders, R.; Krijnen, G. A flexible, three material, 3D-printed, shear force sensor for use on finger tips. In Proceedings of the 2019 IEEE SENSORS, Montreal, QC, Canada, 27–30 October 2019. [Google Scholar]

- Chimakurthi, S.K.; Reuss, S.; Tooley, M.; Scampoli, S. ANSYS Workbench System Coupling: A state-of-the-art computational framework for analyzing multiphysics problems. Eng. Comput. 2018, 34, 385–411. [Google Scholar] [CrossRef]

- Jiang, D.; Wang, Y.; Li, B.; Sun, C.; Wu, Z.; Yan, H.; Xing, L.; Qi, S.; Li, Y.; Liu, H.; et al. Flexible Sandwich Structural Strain Sensor Based on Silver Nanowires Decorated with Self-Healing Substrate. Macromol. Mater. Eng. 2019, 304, 304. [Google Scholar] [CrossRef]

- Santos, A.; Amorim, L.; Nunes, J.P.; Rocha, L.A.; Silva, F.A.; Viana, J.C. A comparative study between knocked-down aligned carbon nanotubes and buckypaper-based strain sensors. Materials 2019, 12, 2013. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Material Name | Model Name | Company |

|---|---|---|

| Graphene conductive ink | TJ02 | Shanghai Enwang Material Technology Co., Ltd. (Shanghai, China) |

| Conductive silver paste | NT-ST80b | Beijing konaton Electronic Technology Co., Ltd. (Beijing, China) |

| Epoxy conductive adhesive | YC-01 | Nanjing Xiliter Adhesive Co., Ltd. (Nanjing, China) |

| UV | KSM-180 g GH1 | Jiangsu Guangxin New Photosensitive Materials Co., Ltd. (Jiangyin, China) |

| PI film | 0.25 mm | Jiangsu Yabao Insulating Materials Co., Ltd. (Yangzhou, China) |

| Mobile phone glass screen | 152.3 × 72.5 × 0.7 mm | Suzhou Grens Photoelectric Technology Co., Ltd. (Suzhou, China) |

| Screen printing plate | Polyester Screen | Changzhou Pratt Printing Technology Co., Ltd. (Changzhou, China) |

| Equipment Name | Model Name | Company |

|---|---|---|

| Screen-printing machine | PHP-2525 | Shanghai Xuanting Screen-printing Equipment Co., Ltd. (Shanghai, China) |

| Vacuum drying oven | DZF-6020 | Shanghai Bosun Industrial Co., Ltd. (Shanghai, China) |

| UV curing lamp | BHL-1000 L | Philips Lighting Electronics (Xiamen) Co., Ltd. (Xiamen, China) |

| Three-dimensional printer | FLASH DK2 | Guangzhou flash Information Technology Co., Ltd. (Guangzhou, China) |

| Regulated power supply | MS-305d | Dongguan Maihao Electronic Technology Co., Ltd. (Dongguan, China) |

| Voltage resistance equipment meter | Keithley 2400 | Teck Technology (China) Co., Ltd. (Shanghai, China) |

| Resistance metering equipment | TH2829C | Changzhou Tonghui Electronic Co., Ltd. (Changzhou, China) |

| Scanning electron microscope | FESEM S4800 | Hitachi Company (Tokyo, Japan) |

| Model | Simulations | Experiment | ||||

|---|---|---|---|---|---|---|

| Strain on the Backing Surface ε | Strain on the Adhesive Surface με | Total Strain με | Sensitivity mV/V | |||

| Path01 | Path02 | Path03 | Path04 | |||

| M3 | 11.6 | 11.4 | −10.6 | −10.4 | 44.00 | 0.101 |

| L4 | 50.1 | 49.4 | 30.5 | 29.8 | 39.20 | 0.0856 |

| Change | 12.2% | 17.99% | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Zhu, H.; Dai, S.; Sun, T.; Cheng, G.; Ding, J. High-Sensitivity Pressure Sensors Based on a Low Elastic Modulus Adhesive. Sensors 2022, 22, 3425. https://doi.org/10.3390/s22093425

Xu X, Zhu H, Dai S, Sun T, Cheng G, Ding J. High-Sensitivity Pressure Sensors Based on a Low Elastic Modulus Adhesive. Sensors. 2022; 22(9):3425. https://doi.org/10.3390/s22093425

Chicago/Turabian StyleXu, Xiuzhu, Hao Zhu, Shengping Dai, Tao Sun, Guanggui Cheng, and Jianning Ding. 2022. "High-Sensitivity Pressure Sensors Based on a Low Elastic Modulus Adhesive" Sensors 22, no. 9: 3425. https://doi.org/10.3390/s22093425

APA StyleXu, X., Zhu, H., Dai, S., Sun, T., Cheng, G., & Ding, J. (2022). High-Sensitivity Pressure Sensors Based on a Low Elastic Modulus Adhesive. Sensors, 22(9), 3425. https://doi.org/10.3390/s22093425