High-Sensitivity Liquid Dielectric Characterization Differential Sensor by 1-Bit Coding DGS

Abstract

1. Introduction

2. Materials and Methods

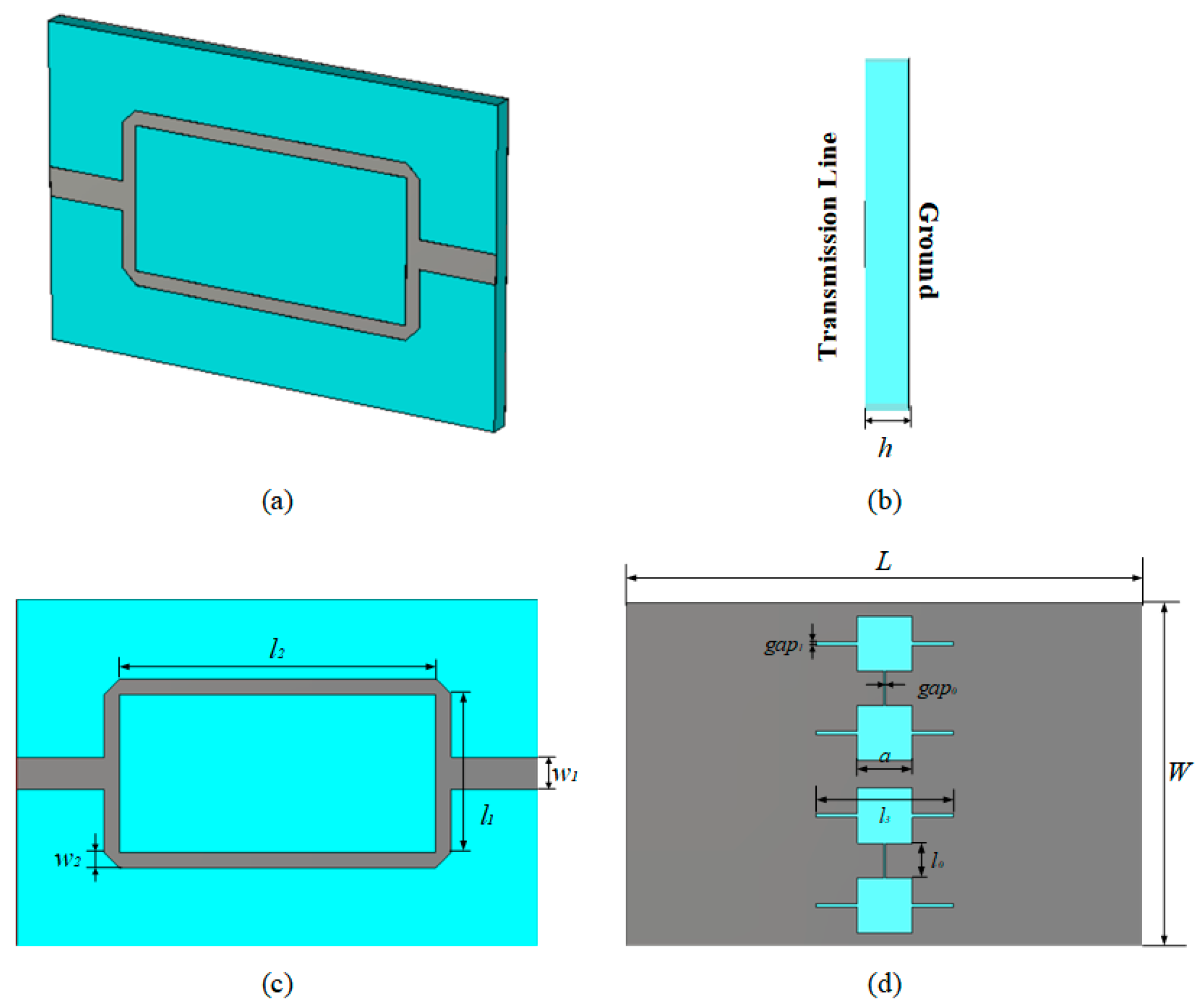

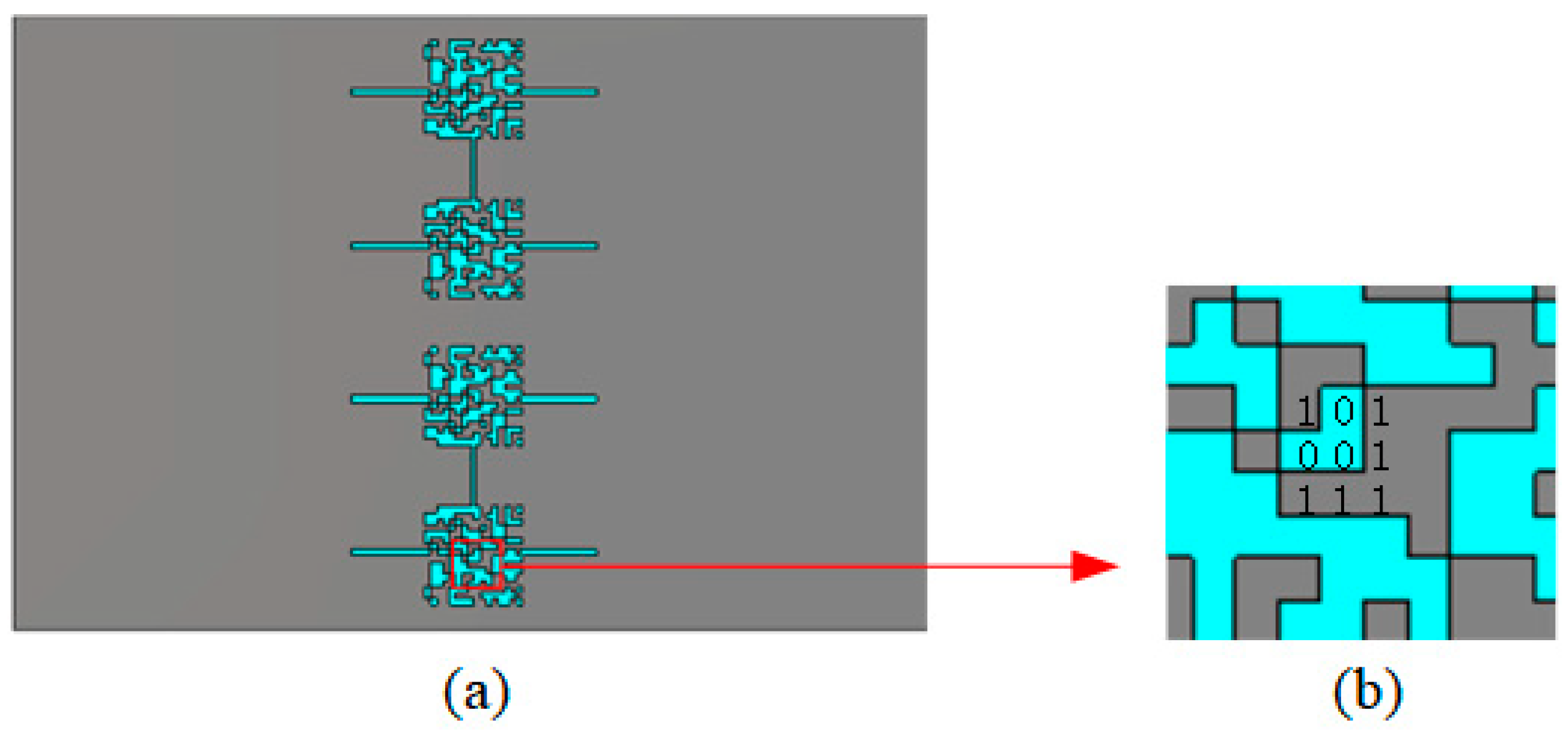

2.1. The Design of the Sensor

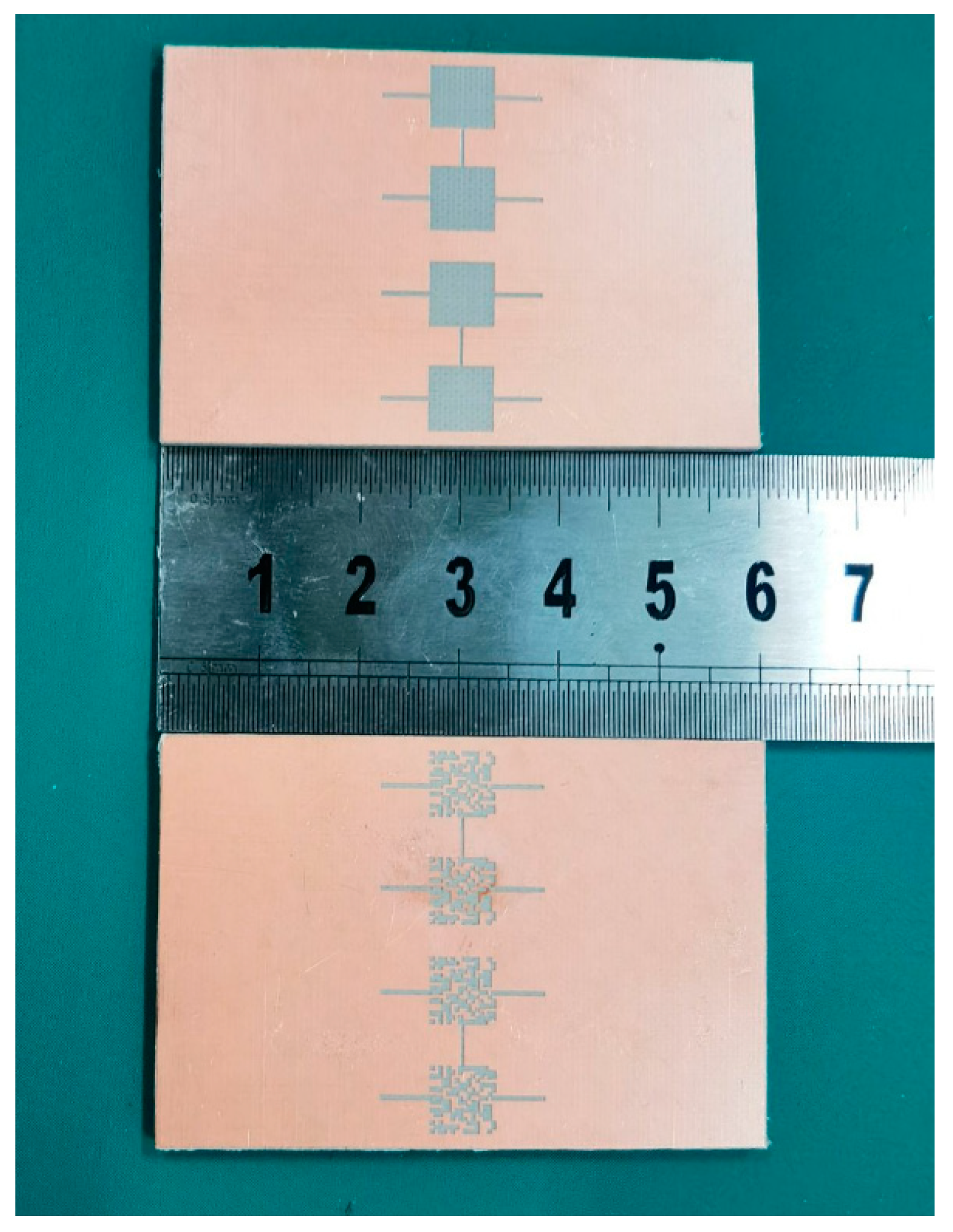

2.2. Method and Material to Measure

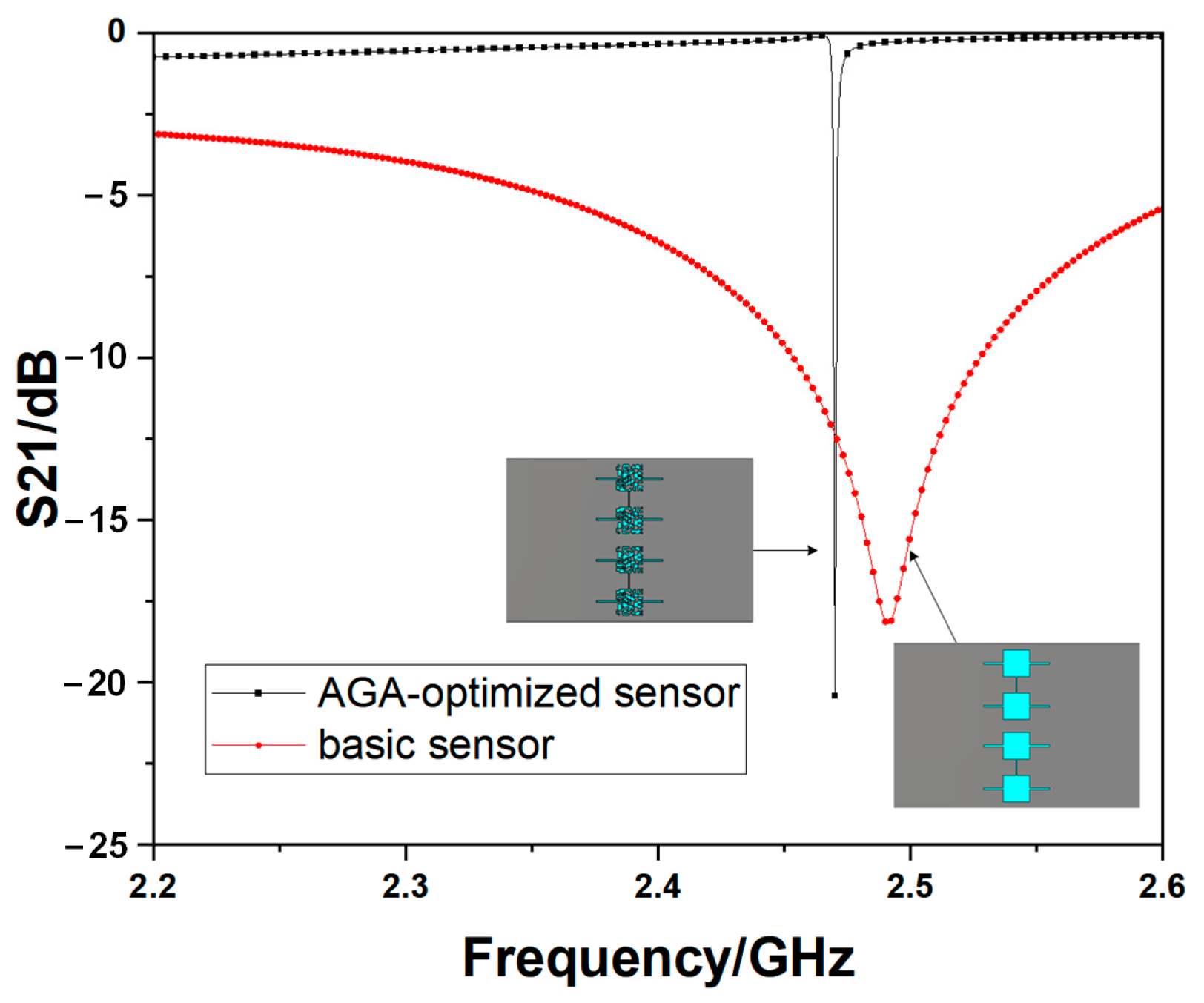

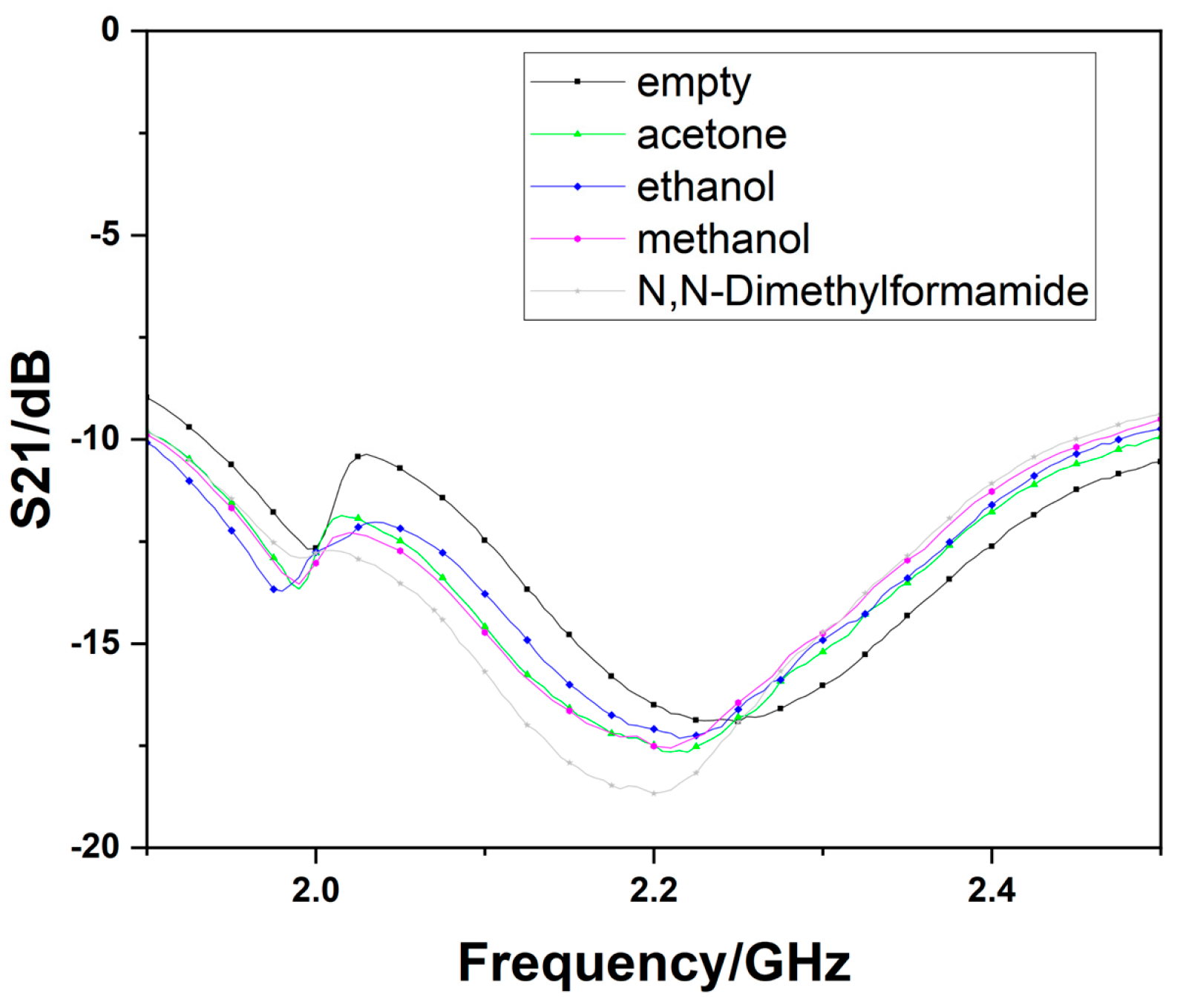

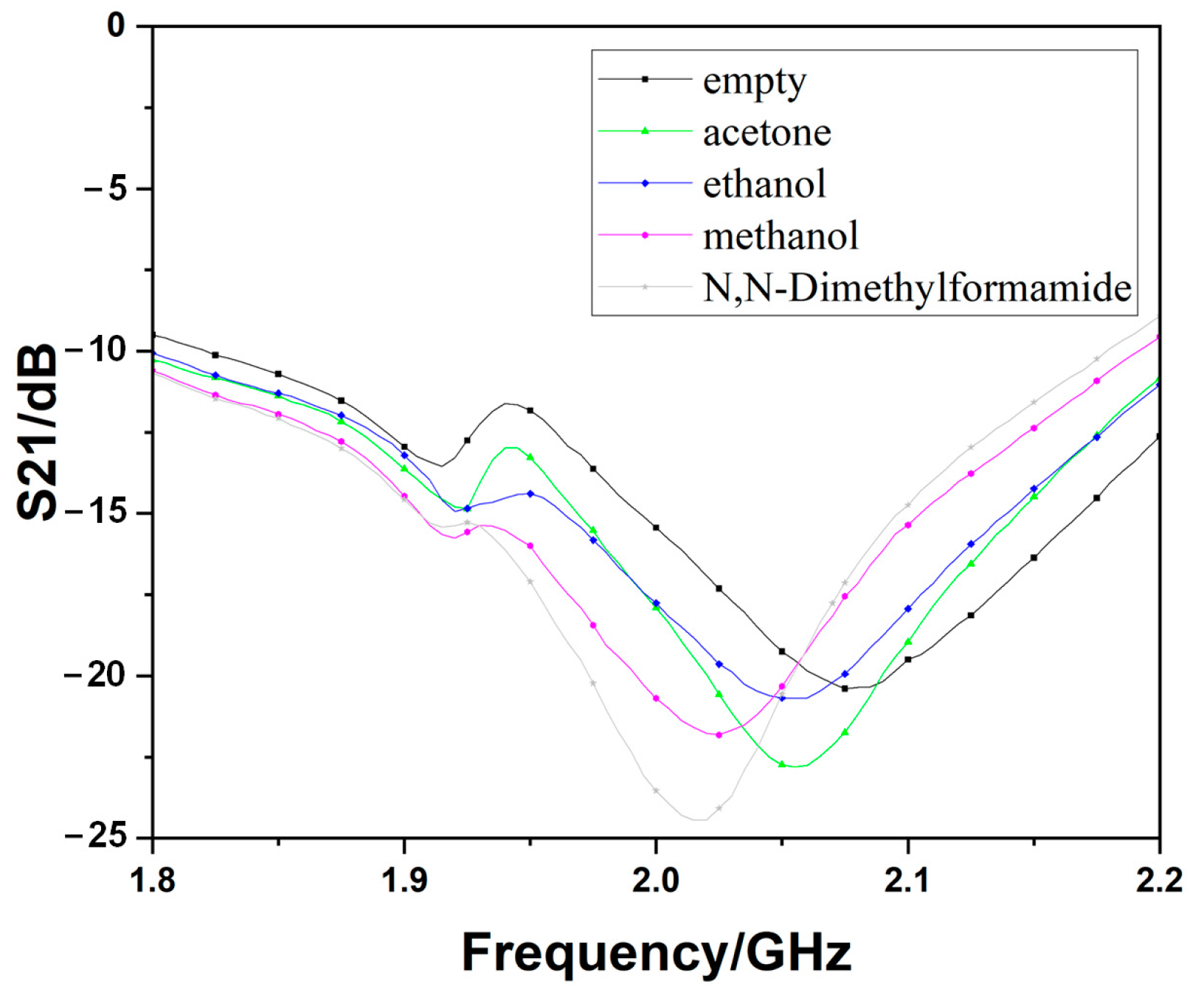

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mondal, D.; Tiwari, N.K.; Akhtar, M.J. Microwave Assisted Non-Invasive Microfluidic Biosensor for Monitoring Glucose Concentration. In Proceedings of the2018 IEEE SENSORS, New Delhi, India, 28–31 October 2018. [Google Scholar]

- Salim, A.; Ghosh, S.; Lim, S. Low-cost and lightweight 3D-printed split-ring resonator for chemical sensing applications. Sensors 2018, 18, 3049. [Google Scholar] [CrossRef] [PubMed]

- Okatani, T.; Sekiguchi, S.; Hane, K.; Kanamori, Y. Surface-plasmon-coupled optical force sensors based on metal-insulator-metal metamaterials with movable air gap. Sci. Rep. 2020, 10, 1–6. [Google Scholar] [CrossRef]

- Ekmekci, E.; Kose, U.; Cinar, A.; Ertan, O.; Ekmekci, Z. The use of metamaterial type double-sided resonator structures in humidity and concentration sensing applications. Sens. Actuators A Phys. 2019, 297, 111559. [Google Scholar] [CrossRef]

- Rocchi, A.; Santecchia, E.; Ciciulla, F.; Mengucci, P.; Barucca, G. Characterization and optimization of level measurement by an ultrasonic sensor system. IEEE Sens. J. 2019, 19, 3077–3084. [Google Scholar] [CrossRef]

- Chuma, E.L.; Iano, Y.; Fontgalland, G.; Roger, L.L. Microwave sensor for liquid dielectric characterization based on metamaterial complementary split ring resonator. IEEE Sens. J. 2018, 18, 9978–9983. [Google Scholar] [CrossRef]

- Jali, M.H.; Rahim, H.R.; Hamid, S.S.; Johari, M.A.; Yusof, H.H.; Thokchom, S.; Harun, S.W.; Khasanah, M.; Yasin, M. Microfiber loop resonator for formaldehyde liquid sensing. Optik 2019, 196, 163174. [Google Scholar] [CrossRef]

- Cai, J.; Zhou, Y.J.; Yang, X.M. A metamaterials-loaded quarter mode SIW microfluidic sensor for microliter liquid characterization. J. Electromagnet Wave 2019, 33, 261–271. [Google Scholar] [CrossRef]

- Abduljabar, A.A.; Hamzah, H.; Porch, A. Multi-resonators, microwave microfluidic sensor for liquid characterization. Microw. Opt. Techn. Lett. 2021, 63, 1042–1047. [Google Scholar] [CrossRef]

- Gulsu, M.S.; Bagci, F.; Can, S.; Yilmaz, A.E.; Akaoglu, B. Minkowski-like fractal resonator-based dielectric sensor for estimating the complex permittivity of binary mixtures of ethanol, methanol and water. Sens. Actuators A Phys. 2021, 330, 112841. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Scott, J.; Ghorbani, K. Ultrahigh-sensitivity microwave sensor for microfluidic complex permittivity measurement. IEEE Trans. Microw. Theory Tech. 2019, 67, 4269–4277. [Google Scholar] [CrossRef]

- Hamzah, H.; Abduljabar, A.A.; Porch, A. High Q microwave microfluidic sensor using a central gap ring resonator. IEEE Trans. Microw. Theory Tech. 2020, 68, 1830–1838. [Google Scholar] [CrossRef]

- Gulsu, M.S.; Bagci, F.; Can, S.; Yilmaz, A.E.; Akaoglu, B. Metamaterial-based sensor with a polycarbonate substrate for sensing the permittivity of alcoholic liquids in a WR-229 waveguide. Sens. Actuators A Phys. 2020, 312, 112139. [Google Scholar] [CrossRef]

- Chretiennot, T.; Dubuc, D.; Grenier, K. A microwave and microfluidic planar resonator for efficient and accurate complex permittivity characterization of aqueous solutions. IEEE Trans. Microw. Theory Tech. 2012, 61, 972–978. [Google Scholar] [CrossRef]

- Wu, W.J.; Zhao, W.S.; Wang, D.W.; Yuan, B.; Wang, G. Ultrahigh-sensitivity microwave microfluidic sensors based on modified complementary electric-LC and split-ring resonator structures. IEEE Sens. J. 2021, 21, 18756–18763. [Google Scholar] [CrossRef]

- Ting, S.W.; Tam, K.W.; Martins, R. Novel defected ground structure element with triple transmission zeros and its application for multispurious suppression of microstrip parallel-coupled-line bandpass filter. Microw. Opt. Techn. Lett. 2007, 49, 1409–1412. [Google Scholar] [CrossRef]

- Abduljabar, A.A.; Rowe, D.J.; Porch, A.; Barrow, D.A. Novel microwave microfluidic sensor using a microstrip split-ring resonator. IEEE Trans. Microw. Theory Tech. 2014, 62, 679–688. [Google Scholar] [CrossRef]

- Vélez, P.; Muñoz-Enano, J.; Gil, M.; Mata-Contreras, J.; Martín, F. Differential microfluidic sensors based on dumbbell-shaped defect ground structures in microstrip technology: Analysis, optimization, and applications. Sensors 2019, 19, 3189. [Google Scholar] [CrossRef]

- Gan, H.Y.; Zhao, W.S.; Liu, Q.; Wang, D.W.; Dong, L.; Wang, G.; Yin, W.Y. Differential microwave microfluidic sensor based on microstrip complementary split-ring resonator (MCSRR) structure. IEEE Sens. J. 2020, 20, 5876–5884. [Google Scholar] [CrossRef]

- Schueler, M.; Mandel, C.; Puentes, M.; Jakoby, R. Metamaterial inspired microwave sensors. IEEE Microw. Mag. 2012, 13, 57–68. [Google Scholar] [CrossRef]

- Camli, B.; Altinagac, E.; Kizil, H.; Torun, H.; Dundar, G.; Yalcinkaya, A.D. Gold-on-glass microwave split-ring resonators with PDMS microchannels for differential measurement in microfluidic sensing. Biomicrofluidics 2020, 14, 054102. [Google Scholar] [CrossRef]

- Gugliandolo, G.; Vermiglio, G.; Cutroneo, G.; Campobello, G.; Crupi, G.; Donato, N. Inkjet-printed capacitive coupled ring resonators aimed at the characterization of cell cultures. In Proceedings of the 2022 IEEE International Symposium on Medical Measurements and Applications (MeMeA), Messina, Italy, 22–24 June 2022. [Google Scholar]

- Ebrahimi, A.; Beziuk, G.; Scott, J.; Ghorbani, K. Microwave differential frequency splitting sensor using magnetic-LC resonators. Sensors 2020, 20, 1066. [Google Scholar] [CrossRef] [PubMed]

- Ebrahimi, A.; Scott, J.; Ghorbani, K. Transmission lines terminated with LC resonators for differential permittivity sensing. IEEE Microw. Wirel. Compon. Lett. 2018, 28, 1149–1151. [Google Scholar] [CrossRef]

- Vélez, P.; Su, L.; Grenier, K.; Mata-Contreras, J.; Dubuc, D.; Martín, F. Microwave microfluidic sensor based on a microstrip splitter/combiner configuration and split ring resonators (SRRs) for dielectric characterization of liquids. IEEE Sens. J. 2017, 17, 6589–6598. [Google Scholar] [CrossRef]

- Velez, P.; Munoz-Enano, J.; Grenier, K.; Mata-Contreras, J.; Dubuc, D.; Martín, F. Split ring resonator-based microwave fluidic sensors for electrolyte concentration measurements. IEEE Sens. J. 2018, 19, 2562–2569. [Google Scholar] [CrossRef]

- Velez, P.; Grenier, K.; Mata-Contreras, J.; Dubuc, D.; Martín, F. Highly-sensitive microwave sensors based on open complementary split ring resonators (OCSRRs) for dielectric characterization and solute concentration measurement in liquids. IEEE Access 2018, 6, 48324–48338. [Google Scholar] [CrossRef]

- Zhou, Z.L.; Wang, C.; Kumar, A.; Zou, D.Q.; Wei, Y.C.; Ali, L.; Zhao, M. Coding DGS resonator sensor for ultra-high Q-factor dielectric thickness detection. J. Electromagnet Wave 2021, 35, 1464–1476. [Google Scholar] [CrossRef]

- Mirjalili, S. Genetic algorithm. In Evolutionary Algorithms and Neural Networks; Springer: Cham, Switzerland, 2019; pp. 43–55. [Google Scholar]

- Polatoğlu, İ.; Aydın, L.; Nevruz, B.Ç.; Özer, S. A novel approach for the optimal design of a biosensor. Anal. Lett. 2020, 53, 1428–1445. [Google Scholar] [CrossRef]

- Shi, P.; Gao, R.; Liu, S.; Yuan, Y. Topology optimization-based design of metamaterial-inspired sensor with improved sensitivity. Sens. Actuators A Phys. 2017, 268, 83–90. [Google Scholar] [CrossRef]

- Zanjani, S.J.; Inampudi, S.; Mosallaei, H. Adaptive genetic algorithm for optical metasurfaces design. Sci. Rep. 2018, 8, 11040. [Google Scholar] [CrossRef]

- Solymar, L.; Walsh, D.; Syms, R.R. Electrical Properties of Material; Oxford University Press: Oxford, UK, 2014. [Google Scholar]

- Gregory, A.P.; Clarke, R.N. Tables of the complex permittivity of dielectric reference liquids at frequencies up to 5 GHz. In NPL Report MAT 23; NPL: Teddington, UK, 2012. [Google Scholar]

- Onimisi, M.Y.; Ikyumbur, J.T.; Abdu, S.G.; Hemba, E.C. Frequency and temperature effect on dielectric properties of acetone and dimethylformamide. Phys. Sci. Int. J. 2016, 11, 1–8. [Google Scholar] [CrossRef]

- Abdolrazzaghi, M.; Daneshmand, M. Exploiting sensitivity enhancement in micro-wave planar sensors using intermodulation products with phase noise analysis. IEEE Trans. Circuits Syst. I Regul. Pap. 2020, 67, 4382–4395. [Google Scholar] [CrossRef]

- Bahar, A.A.; Zakaria, Z.; Ab Rashid, S.R.; Isa, A.A.; Alahnomi, R.A. High-efficiency microwave planar resonator sensor based on bridge split ring topology. IEEE Microw. Wirel. Compon. Lett. 2017, 27, 545–547. [Google Scholar] [CrossRef]

- Fu, L.; Huang, J.; Xiang, Y.; Chen, Y.; Gu, W.; Wu, Y. A miniaturized differential microwave microfluidic sensor with high decoupling. IEEE Microw. Wirel. Compon. Lett. 2021, 31, 909–912. [Google Scholar] [CrossRef]

- Acevedo-Osorio, G.; Reyes-Vera, E.; Lobato-Morales, H. Dual-band microstrip resonant sensor for dielectric measurement of liquid materials. IEEE Sens. J. 2020, 20, 13371–13378. [Google Scholar] [CrossRef]

| Parameters | Values (mm) | Parameters | Values (mm) |

|---|---|---|---|

| L | 60 | l0 | 4.0 |

| W | 40 | l3 | 16 |

| l1 | 18.2 | gap0 | 0.2 |

| l2 | 36.4 | gap1 | 0.4 |

| w1 | 3.7 | a | 6.4 |

| w2 | 1.8 | h | 2.5 |

| Liquid Samples | Complex Permittivity |

|---|---|

| N,N-Dimethylformamide | 36.24 − 3.87j |

| methanol | 24.84 − 12.28j |

| acetone | 19.97 − 5.72j |

| ethanol | 8.26 − 7.91j |

| Liquid Samples | a Mea of ε′ | Ref of ε′ | Error of ε′ | Mea of ε″ | Ref of ε″ | Error of ε″ |

|---|---|---|---|---|---|---|

| N,N-Dimethylformamide | 36.42 | 36.24 | 0.5% | 3.94 | 3.87 | 1.8% |

| methanol | 24.15 | 24.84 | −2.8% | 11.88 | 12.28 | −3.3% |

| acetone | 20.50 | 19.97 | 2.6% | 5.78 | 5.72 | 1.0% |

| ethanol | 8.28 | 8.26 | 0.2% | 7.93 | 7.91 | 0.3% |

| Refs. | Measurement Technique | Operating Frequency (GHz) | Differential | Sensitivity |

|---|---|---|---|---|

| [9] | Planar resonator | 2.500 | No | 0.015 |

| [10] | Minkowski-like fractal resonator | 1.970 | No | 0.026 |

| [37] | Bridge multiple split ring resonator | 2.270 | No | 0.038 |

| [38] | SIW re-entrant cavity resonators | 2.637 | Yes | 0.037 |

| [39] | Single stepped impedance resonator | 2.450 | No | 0.045 |

| This work | AGA optimized DGS differential sensor | 2.180 | Yes | 0.076 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, B.; Gao, Z.; Wang, C.; Ali, L.; Muhammad, A.; Meng, F.; Qian, C.; Ding, X.; Adhikari, K.K.; Wu, Q. High-Sensitivity Liquid Dielectric Characterization Differential Sensor by 1-Bit Coding DGS. Sensors 2023, 23, 372. https://doi.org/10.3390/s23010372

Xie B, Gao Z, Wang C, Ali L, Muhammad A, Meng F, Qian C, Ding X, Adhikari KK, Wu Q. High-Sensitivity Liquid Dielectric Characterization Differential Sensor by 1-Bit Coding DGS. Sensors. 2023; 23(1):372. https://doi.org/10.3390/s23010372

Chicago/Turabian StyleXie, Bingfang, Zhiqiang Gao, Cong Wang, Luqman Ali, Azeem Muhammad, Fanyi Meng, Cheng Qian, Xumin Ding, Kishor Kumar Adhikari, and Qun Wu. 2023. "High-Sensitivity Liquid Dielectric Characterization Differential Sensor by 1-Bit Coding DGS" Sensors 23, no. 1: 372. https://doi.org/10.3390/s23010372

APA StyleXie, B., Gao, Z., Wang, C., Ali, L., Muhammad, A., Meng, F., Qian, C., Ding, X., Adhikari, K. K., & Wu, Q. (2023). High-Sensitivity Liquid Dielectric Characterization Differential Sensor by 1-Bit Coding DGS. Sensors, 23(1), 372. https://doi.org/10.3390/s23010372