Tendon Stress Estimation from Strain Data of a Bridge Girder Using Machine Learning-Based Surrogate Model

Abstract

:1. Introduction

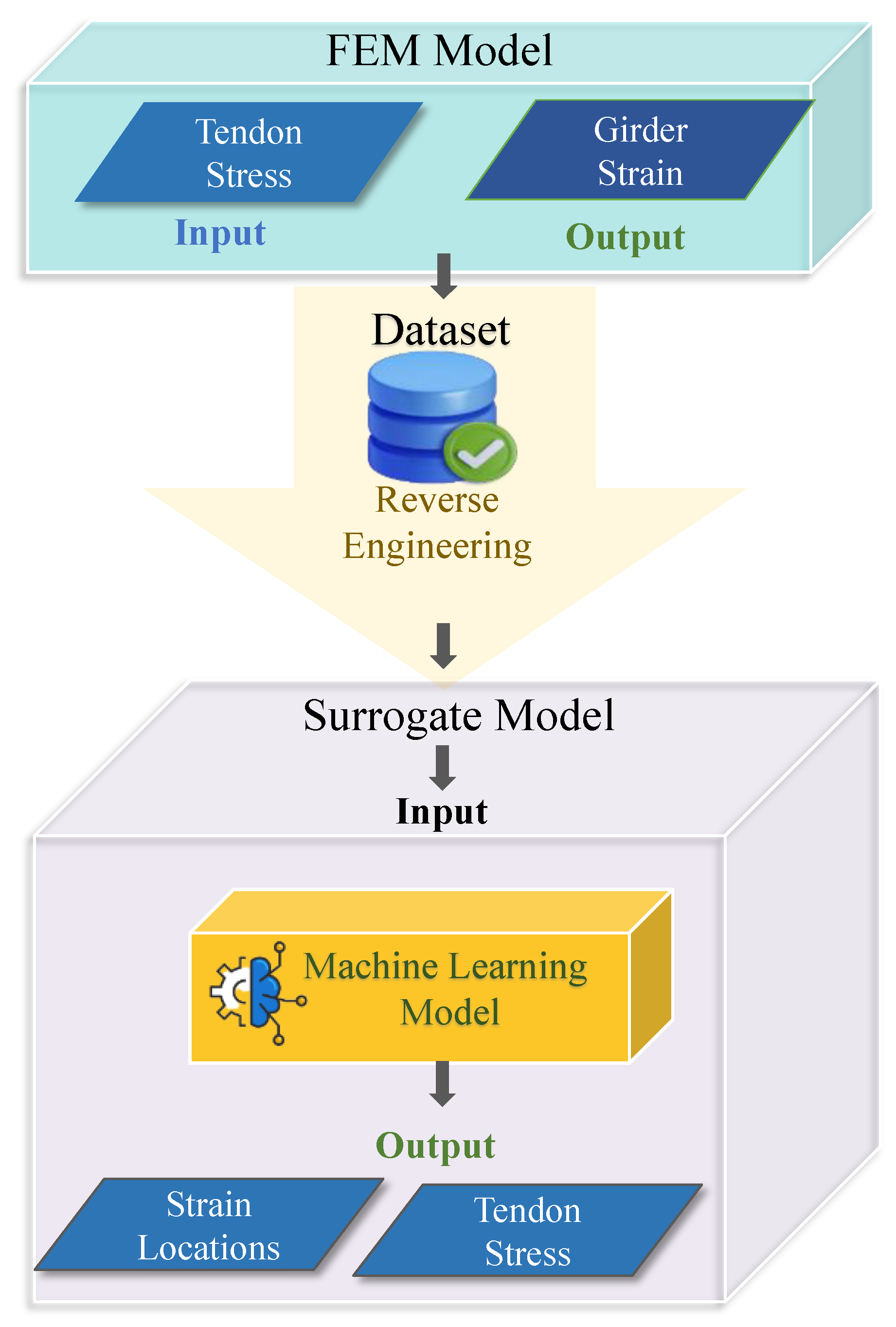

2. Surrogate Model Framework

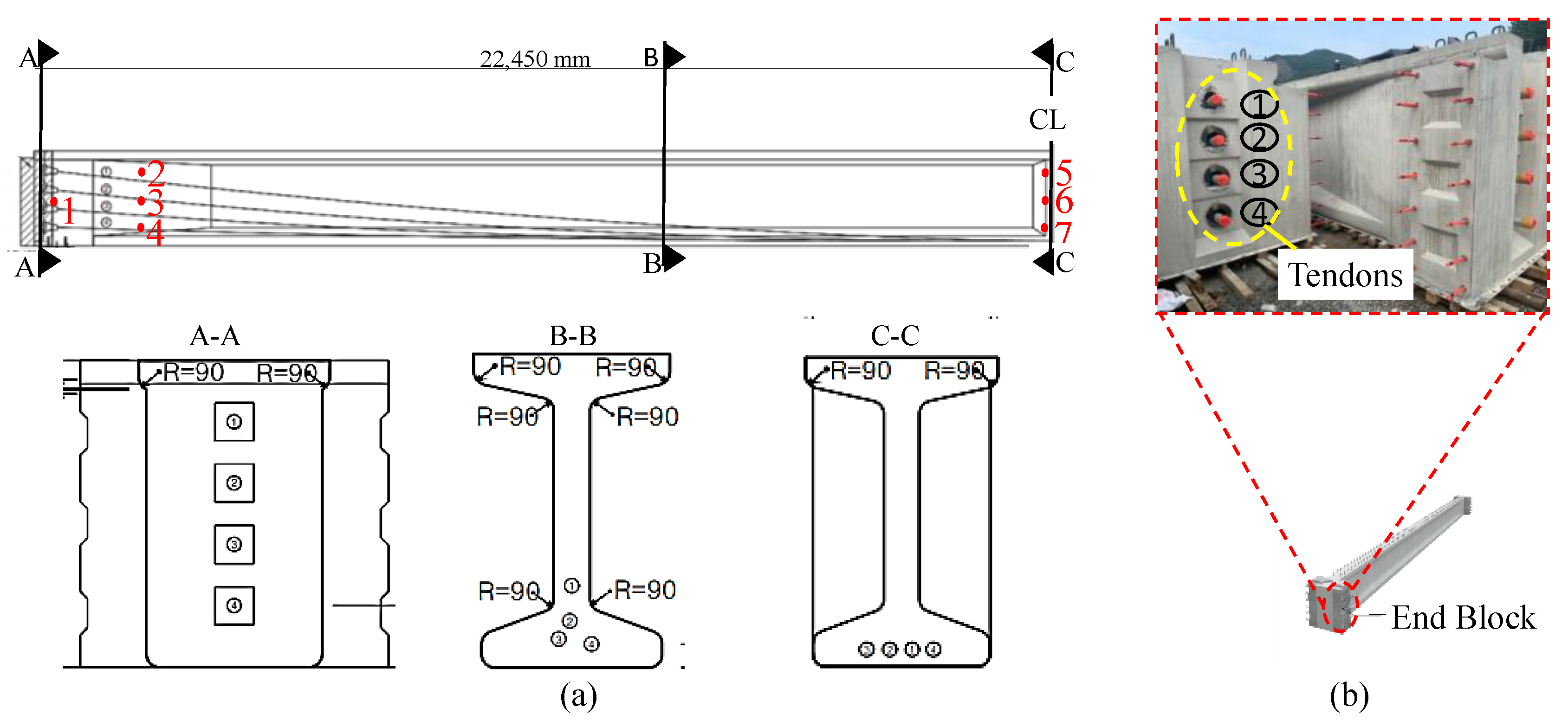

2.1. Girder Specifications

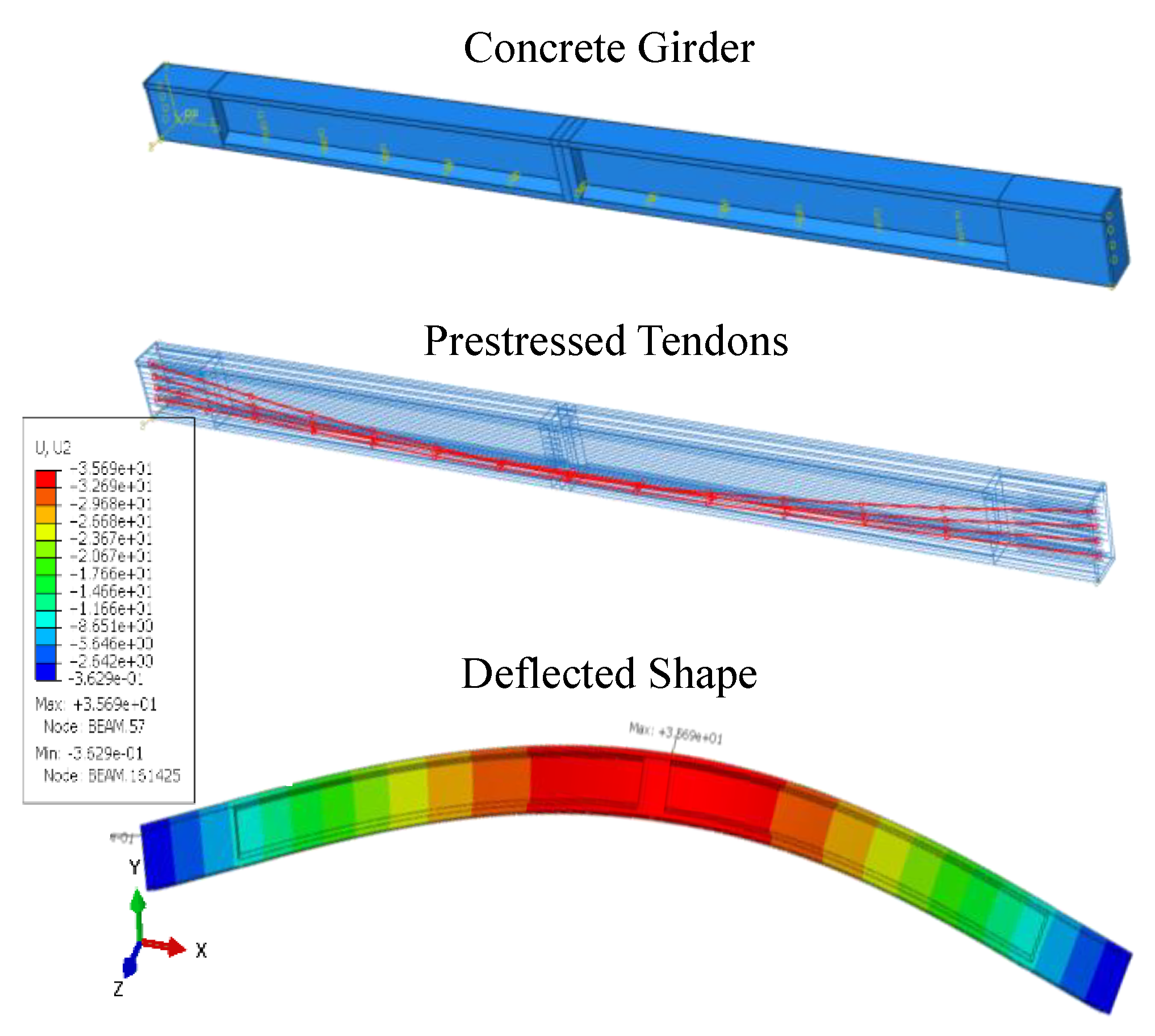

2.2. FEM Modeling

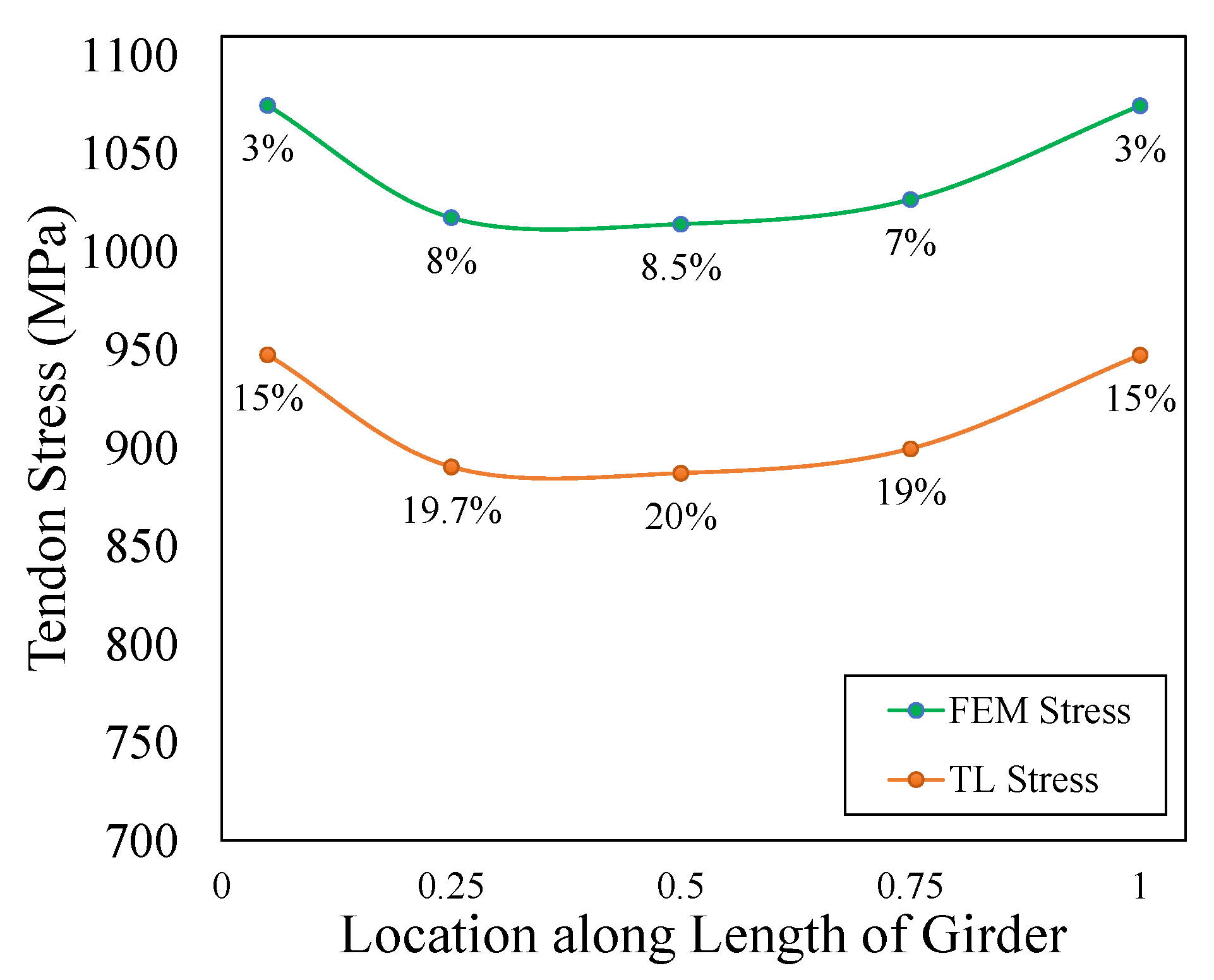

2.3. FEM Validation

2.4. Statistical Background of Parameters

2.5. Data Generation and Preprocessing

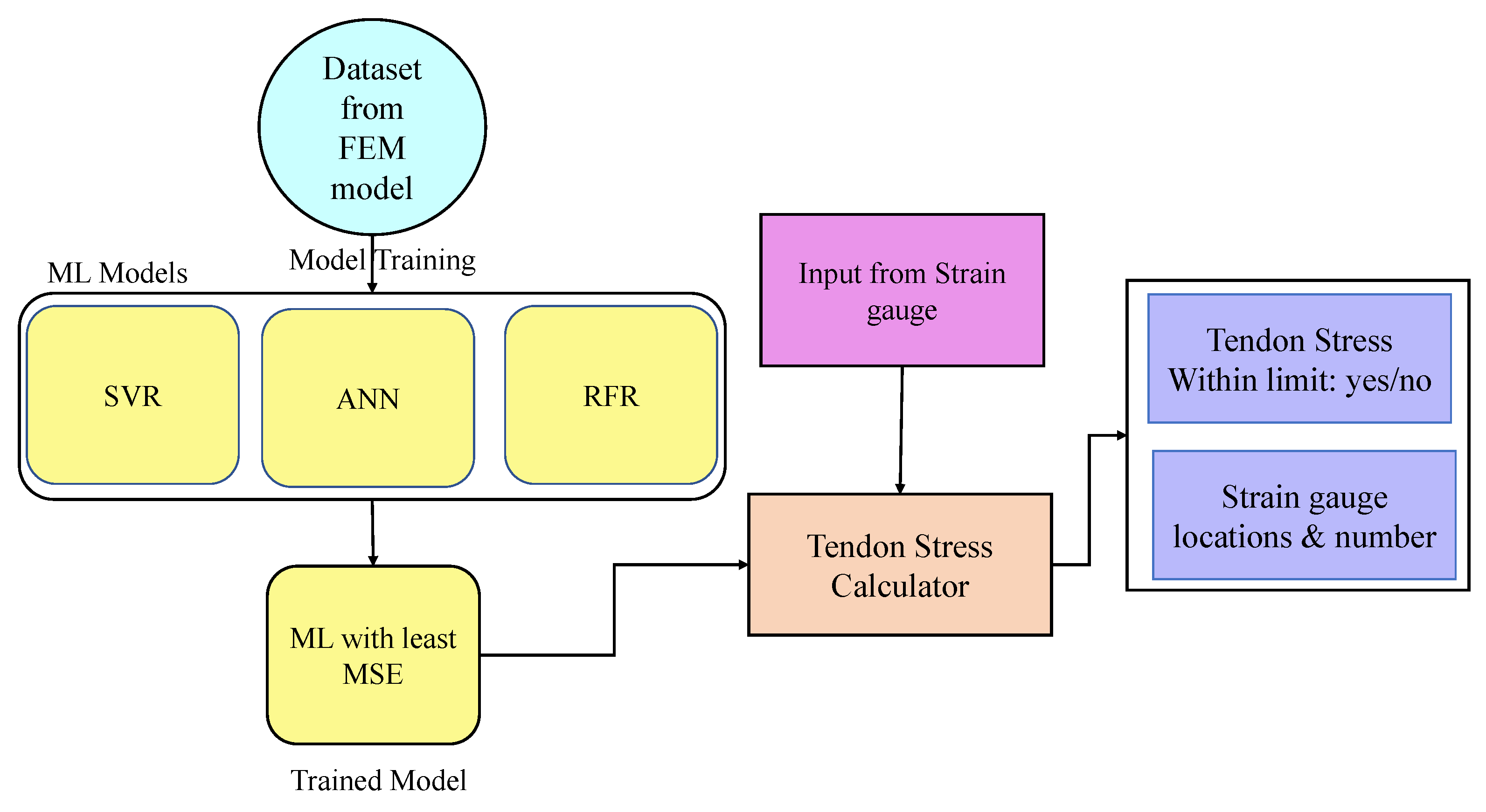

2.6. Machine Learning (ML) Models

3. Results and Discussion

3.1. Prediction Comparison

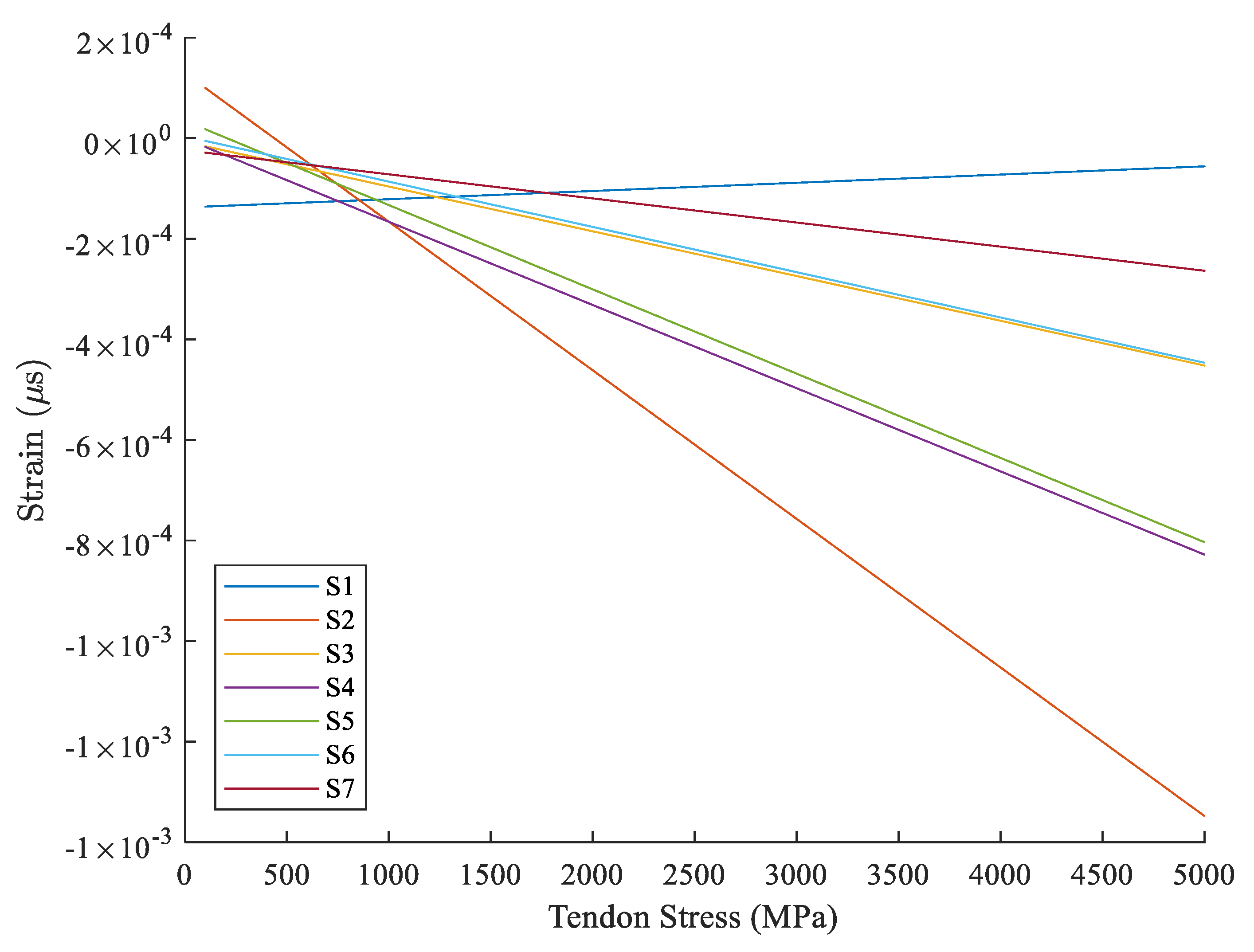

3.2. Strain Gauge Optimization

3.3. Strain Distribution of Girder

3.4. Prestress Losses

4. Practical Considerations

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Parameter | Symbol | Values |

|---|---|---|

| Tendon stress (MPa) | 1109 | |

| Tendon ultimate stress (MPa) | 1860 | |

| Tendon yield stress (MPa) | 1580 | |

| Area of each tendon () | 2635 | |

| Concrete area () | Ac | 1.084 × 106 |

| Total number of tendons | 4 | |

| Eccentricity of prestressing force from Neutral axis () | 935 | |

| Section modulus for top fibers () | 6.159 × 108 | |

| Section modulus for bottom fibers () | 6.135 × 108 | |

| Bending moment at mid-span (Nmm) | 6703.8 × 106 |

References

- Khayam, S.U.; Won, J.; Shin, J.; Park, J.; Park, J.W. Monitoring Precast Structures during Transportation Using a Portable Sensing System. Autom. Constr. 2023, 145, 104–639. [Google Scholar] [CrossRef]

- Gerwick, B.C., Jr. Introduction. In Construction of Prestressed Concrete Structures, 2nd ed.; John Wiley & Sons, Inc.: New York, NY, USA, 1997; pp. 11–52. [Google Scholar]

- Söffker, G.H. Constructing Architecture: Materials, Processes, Structures, 2nd ed.; Deplazes, A., Ed.; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2005; pp. 211–239. [Google Scholar]

- Qingxian, L. Research on Construction Quality Management of Prestress Technology in Road and Bridge Construction. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2021; Volume 236, pp. 5–32. [Google Scholar]

- Reichenbach, S.; Kromoser, B. State of practice of automation in precast concrete production. J. Build. Eng. 2021, 43, 102–527. [Google Scholar] [CrossRef]

- De Domenico, D.; Messina, D.; Recupero, A. Quality control and safety assessment of prestressed concrete bridge decks through combined field tests and numerical simulation. Structures 2022, 39, 1135–1157. [Google Scholar] [CrossRef]

- Jhatial, A.A. Synergic influence of degrading mechanisms and induced loading by prestressing on the concrete: State of the arts. Environ. Sci. Pollut. Res. 2022, 29, 3184–3198. [Google Scholar] [CrossRef]

- Murdock, L.J.; Brook, K.M. Concrete Materials and Practice, 5th ed.; The National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 1979. [Google Scholar]

- Yang, J.; Guo, T.; Li, A. Experimental investigation on long-term behavior of prestressed concrete beams under the coupled effect of sustained load and corrosion. Adv. Struct. Eng. 2020, 23, 2587–2596. [Google Scholar] [CrossRef]

- Guo, T.; Sause, R.; Frangopol, D.M.; Li, A. Time-dependent reliability of PSC box-girder bridge considering creep, shrinkage, and corrosion. J. Bridge Eng. 2011, 16, 29–43. [Google Scholar] [CrossRef]

- Underwood, J.R.; Chiuini, M. Structural Design: A Practical Guide for Architects, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2007; pp. 112–231. [Google Scholar]

- Zhou, W.; Zheng, W. Unbonded Tendon Stresses in Continuous Post-Tensioned Beams. ACI Struct. J. 2014, 111, 525–536. [Google Scholar] [CrossRef]

- Zhang, F.; Zarate Garnica, G.I.; Yang, Y.; Lantsoght, E.; Sliedrecht, H. Monitoring shear behavior of prestressed concrete bridge girders using acoustic emission and digital image correlation. Sensors 2020, 20, 5622. [Google Scholar] [CrossRef]

- Tanchan, P. Flexural Behavior of High-Strength Concrete Beams Prestressed with Unbonded Tendons. Ph.D. Thesis, Rutgers the State University of New Jersey-New Brunswick, New Brunswick, NJ, USA, 2001. [Google Scholar]

- Mahmood, O.I. Camber Control in Simply Supported Prestressed Concrete Bridge Girders. Master’s Thesis, University of Kentucky, Lexington, KY, USA, 2013. [Google Scholar]

- Li, C.; Niu, J.; Zhou, M. Construction-control technique for PC bridge with cantilever casting method. In Proceedings of the 2011 Second International Conference on Mechanic Automation and Control Engineering, IEEE 2011, Inner Mongolia, China, 15–17 July 2011; pp. 5667–5670. [Google Scholar] [CrossRef]

- Tadros, M.K.; Fawzy, F.F.; Hanna, K.E. Precast, prestressed girder camber variability. PCI J. 2011, 56, 123–456. [Google Scholar] [CrossRef]

- Schranz, B.; Czaderski, C.; Vogel, T.; Shahverdi, M. Bond investigations of prestressed, near-surface-mounted, ribbed memory-steel bars with full bond length. Mater. Des. 2020, 196, 109145. [Google Scholar] [CrossRef]

- Abdel-Jaber, H.; Glisic, B. Monitoring of prestressing forces in prestressed concrete structures—An overview. Struct. Control Health Monit. 2019, 26, 23–74. [Google Scholar] [CrossRef]

- Hsiao, J.-K.K.; Jiang, A.Y. Camber in Pretensioned Bridge I-Girder Immediately after Prestress Transfer. Int. J. Bridge Eng. 2018, 6, 61–84. [Google Scholar]

- Ghallab, A. Calculating ultimate tendon stress in externally prestressed continuous concrete beams using simplified formulas. Eng. Struct. 2013, 46, 417–430. [Google Scholar] [CrossRef]

- Cho, K.; Park, S.Y.; Cho, J.R.; Kim, S.T.; Park, Y.H. Estimation of prestress force distribution in the multi-strand system of prestressed concrete structures. Sensors 2015, 15, 14079–14092. [Google Scholar] [CrossRef]

- Kim, Y.-S.; Kim, H.-W. Monitoring of tension force and load transfer of ground anchor by using optical FBG sensors embedded tendon. Smart Struct. Syst. Int. J. 2011, 7, 303–317. [Google Scholar] [CrossRef]

- Tonelli, D.; Luchetta, M.; Rossi, F.; Migliorino, P.; Zonta, D. Structural health monitoring based on acoustic emissions: Validation on a prestressed concrete bridge tested to failure. Sensors 2020, 20, 72. [Google Scholar] [CrossRef]

- Sung, H.J.; Do, T.M.; Kim, J.M.; Kim, Y.S. Long-term monitoring of ground anchor tensile forces by FBG sensors embedded tendon. Smart Struct. Syst. 2017, 19, 269–277. [Google Scholar] [CrossRef]

- Turmo, J.; Ramos, G.; Aparicio, A. FEM study on the structural behavior of segmental concrete bridges with unbonded prestressing and dry joints: Simply supported bridges. Eng. Struct. 2005, 27, 1652–1661. [Google Scholar] [CrossRef]

- Halder, R.; Yuen, T.Y.; Chen, W.W.; Zhou, X.; Deb, T.; Zhang, H.; Wen, T.H. Tendon stress evaluation of unbonded post-tensioned concrete segmental bridges with two-variable response surfaces. Eng. Struct. 2021, 245, 112–984. [Google Scholar] [CrossRef]

- Bu, Z.-Y.; Wu, W.-Y. Inter shear transfer of unbonded prestressing precast segmental bridge column dry joints. Eng. Struct. 2018, 154, 52–65. [Google Scholar] [CrossRef]

- Jeon, S.J.; Shin, H.; Kim, S.H.; Park, S.Y.; Yang, J.M. Transfer lengths in pretensioned concrete measured using various sensing technologies. Int. J. Concr. Struct. Mater. 2019, 13, 43. [Google Scholar] [CrossRef]

- American Concrete Institute. Building Code Requirements for Structural Concrete and Commentary. In American Concrete Institute (ACI) 318-11/ACI 318 R-11; American Concrete Institute: Farmington Hills, MI, USA, 2011. [Google Scholar]

- Qapo, M.; Dirar, S.; Yang, J.; Elshafie, M.Z. Nonlinear finite element modelling and parametric study of CFRP shear-strengthened prestressed concrete girders. Constr. Build. Mater. 2015, 76, 245–255. [Google Scholar] [CrossRef]

- Lee, J.; Lee, Y.J.; Shim, C.S. A multi-scale framework for probabilistic structural analysis of PSC girders considering pit corrosion of prestressing wires. Eng. Struct. 2021, 244, 112–745. [Google Scholar] [CrossRef]

- Kudela, J.; Matousek, R. Recent advances and applications of surrogate models for finite element method computations: A review. Soft Comput. 2022, 26, 13709–13733. [Google Scholar] [CrossRef]

- Wang, G.G.; Shan, S. Review of metamodeling techniques in support of engineering design optimization. J. Mech. Des. 2007, 129, 370–380. [Google Scholar] [CrossRef]

- Cai, L.; Ren, L.; Wang, Y.; Xie, W.; Zhu, G.; Gao, H. Surrogate models based on machine learning methods for parameter estimation of left ventricular myocardium. R. Soc. Open Sci. 2021, 8, 201121. [Google Scholar] [CrossRef]

- Ciccazzo, A.; Pillo, G.D.; Latorre, V. Support vector machines for surrogate modeling of electronic circuits. Neural Comput. Appl. 2014, 24, 69–76. [Google Scholar] [CrossRef]

- Chierichetti, M.; Davoudi, F.; Huang, D.; Vurturbadarinath, P.; Linzmeyer, M. Surrogated finite element models using machine learning. In Proceedings of the AIAA Scitech 2021 Forum, Virtual Event, 11–15 January 2021. [Google Scholar]

- Cunha, B.; Droz, C.; Zine, A.; Foulard, S.; Ichchou, M. A review of machine learning methods applied to structural dynamics and vibroacoustic. arXiv 2022, arXiv:2204.06362. [Google Scholar]

- Qin, S.; Zhou, Y.L.; Cao, H.; Wahab, M.A. Model updating in complex bridge structures using kriging model ensemble with genetic algorithm. KSCE J. Civ. Eng. 2018, 22, 3567–3578. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, G. Seismic vulnerability analysis of RC bridges based on Kriging model. J. Earthq. Eng. 2019, 23, 242–260. [Google Scholar] [CrossRef]

- Slowik, O.; Lehký, D.; Novák, D. Reliability-based optimization of a prestressed concrete roof girder using a surrogate model and the double-loop approach. Struct. Concr. 2021, 22, 2184–2201. [Google Scholar] [CrossRef]

- Kim, J.; Park, S. Field applicability of a machine learning–based tensile force estimation for pre-stressed concrete bridges using an embedded elasto-magnetic sensor. Struct. Health Monit. 2020, 19, 281–292. [Google Scholar] [CrossRef]

- Mariniello, G.; Pastore, T.; Asprone, D.; Cosenza, E. Layout-aware extreme learning machine to detect tendon malfunctions in prestressed concrete bridges using stress data. Autom. Constr. 2021, 132, 103–976. [Google Scholar] [CrossRef]

- Selsøyvold, T.; Samarakoon, S.M.; Nazarko, P. Artificial Neural Network Model for Predicting the Tendon Stress in Unbonded Posttensioned Concrete Members at the Ultimate Limit State. J. Struct. Eng. 2022, 148, 04022151. [Google Scholar] [CrossRef]

- Dassault Systèmes Simulia Corperation. Abaqus Analysis User’s Manual; Dassault Systèmes Simulia Corperation: Dearborn, MI, USA, 2017. [Google Scholar]

- Paik, I.Y.; Shim, C.S.; Chung, Y.S.; Sang, H.J. Statistical properties of material strength of concrete, re-bar and strand used in domestic construction sites. J. Korea Concr. Inst. 2011, 23, 421–430. [Google Scholar] [CrossRef]

- Borisov, V.; Leemann, T.; Seßler, K.; Haug, J.; Pawelczyk, M.; Kasneci, G. Deep neural networks and tabular data: A survey. IEEE Trans. Neural Netw. Learn. Syst. 2022. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, H.R.M.; Ismail, S. Random forest versus support vector machine models’ applicability for predicting beam shear strength. Complexity 2021, 2021, 9978409. [Google Scholar] [CrossRef]

- Liaw, A.; Wiener, M. Classification and regression by random Forest. R News 2002, 2, 18–22. [Google Scholar]

- Muvdi, B.B.; McNabb, J. Engineering Mechanics of Materials; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- ACI Committee. ACI 318-19: Building Code Requirements for Structural Concrete and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2019. [Google Scholar]

- Nawy, E.G. Prestressed Concrete. A Fundamental Approach, 2nd ed.; The National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 1996. [Google Scholar]

- Joint ACI-ASCE Committee 423. Guide to Estimating Prestress Loss; American Concrete Institute: Farmington Hills, MI, USA, 2016. [Google Scholar]

- Garber, D.B.; Gallardo, J.M.; Deschenes, D.J.; Bayrak, O. Prestress loss calculations: Another perspective. PCI J. 2016, 61, 68–85. [Google Scholar] [CrossRef]

| Parameters | Values | Units |

|---|---|---|

| Steel | ||

| Density | 7.8 × 10−6 | kg/mm3 |

| Elastic Modulus | 210,000 | MPa |

| Concrete | ||

| Density | 2.1 × 10−6 | kg/mm3 |

| Elastic Modulus | 30,968 | MPa |

| Girder | ||

| Length | 45,000 | mm |

| Height | 2100 | mm |

| Width | 1300 | mm |

| Beam Midspan Stresses (MPa) | Hand Calculations | FEM Model | Difference (%) |

|---|---|---|---|

| Top fiber stresses | −3.91 | −3.76 | 3.8 |

| Bottom fiber stresses | −17.67 | −17.1 | 3.2 |

| Matric | ANN | SVR | RFR | |

|---|---|---|---|---|

| Train | R2 | 0.9984 | 0.9971 | 0.9717 |

| RMSE | 0.0404 | 0.0532 | 0.1703 | |

| MAE | 0.0313 | 0.0451 | 0.1166 | |

| Test | R2 | 0.9978 | 0.9971 | 0.9746 |

| RMSE | 0.0462 | 0.0540 | 0.1586 | |

| MAE | 0.0312 | 0.0454 | 0.1255 |

| Model | Tendon Stress | Difference (%) |

|---|---|---|

| ANN | 1305 | 0.4 |

| SVR | 1272 | 2.2 |

| RFR | 1339 | 3.0 |

| FEM | 1300 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khayam, S.U.; Ajmal, A.; Park, J.; Kim, I.-H.; Park, J.-W. Tendon Stress Estimation from Strain Data of a Bridge Girder Using Machine Learning-Based Surrogate Model. Sensors 2023, 23, 5040. https://doi.org/10.3390/s23115040

Khayam SU, Ajmal A, Park J, Kim I-H, Park J-W. Tendon Stress Estimation from Strain Data of a Bridge Girder Using Machine Learning-Based Surrogate Model. Sensors. 2023; 23(11):5040. https://doi.org/10.3390/s23115040

Chicago/Turabian StyleKhayam, Sadia Umer, Ammar Ajmal, Junyoung Park, In-Ho Kim, and Jong-Woong Park. 2023. "Tendon Stress Estimation from Strain Data of a Bridge Girder Using Machine Learning-Based Surrogate Model" Sensors 23, no. 11: 5040. https://doi.org/10.3390/s23115040

APA StyleKhayam, S. U., Ajmal, A., Park, J., Kim, I.-H., & Park, J.-W. (2023). Tendon Stress Estimation from Strain Data of a Bridge Girder Using Machine Learning-Based Surrogate Model. Sensors, 23(11), 5040. https://doi.org/10.3390/s23115040