Evaluation Methods and Measurement Challenges for Industrial Exoskeletons

Abstract

:1. Introduction

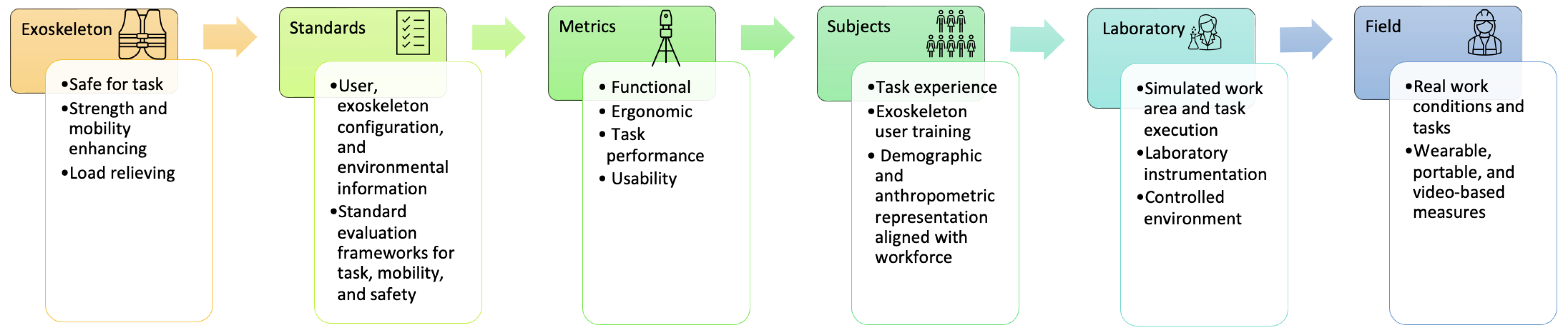

2. Materials and Methods

3. Towards Exoskeleton Test Methods and Standards

3.1. Information Standards

3.2. Evaluation Standards

4. Discussion

4.1. Evaluation Challenges

4.2. Measurement Challenges

4.3. Future Research Directions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Injuries, Illnesses and Fatalities. Occupational Injuries and Illnesses Resulting in Musculoskeletal Disorders (MSDs), U.S. Bureau of Labor Statistics. Available online: https://www.bls.gov/iif/factsheets/msds.htm (accessed on 22 December 2022).

- Vergrift, J.L.; Gold, J.E.; Hanlon, A.; Punnett, L. Physical and psychosocial ergonomic risk factors for low back pain in automobile manufacturing workers. Occup. Environ. Med. 2012, 69, 29–34. [Google Scholar] [CrossRef] [PubMed]

- Yale Environmental Health and Safety. Ergonomics: Awkward Posture. 2018. Available online: https://ehs.yale.edu/sites/default/files/files/ergo-awkward-posture.pdf (accessed on 22 December 2022).

- Liberty Mutual Insurance. 2022 Workplace Safety Index. June 2022. Available online: https://business.libertymutual.com/insights/2022-workplace-safety-index/ (accessed on 22 December 2022).

- Howard, J.; Murashov, V.V.; Lowe, B.D.; Lu, M.L. Industrial exoskeletons: Need for intervention effec-tiveness research. Am. J. Ind. Med. 2020, 63, 201–208. [Google Scholar] [CrossRef] [PubMed]

- Gillette, J.C.; Stephenson, M.L. Electromyographic assessment of a shoulder support exoskeleton during on-site job tasks. IISE Trans. Occup. Ergon. Hum. Factors 2019, 7, 302–310. [Google Scholar] [CrossRef] [Green Version]

- Butler, T.; Gillette, J.C. Exoskeletons used as PPE for injury prevention. Prof. Saf. 2019, 64, 32–37. [Google Scholar]

- Crea, S.; Beckerle, P.; De Looze, M.; De Pauw, K.; Grazi, L.; Kermavnar, T.; Masood, J.; O’Sullivan, L.W.; Pacifico, I.; Rodriguez-Guerrero, C.; et al. Occupational exoskeletons: A roadmap toward large-scale adoption. Methodology and challenges of bringing exoskeletons to workplaces. Wearable Technol. 2021, 2, e11. [Google Scholar] [CrossRef]

- Yu, H.; Choi, I.S.; Han, K.L.; Choi, J.Y.; Chung, G.; Suh, J. Development of a stand-alone powered exoskeleton robot suit in steel manufacturing. ISIJ Int. 2015, 55, 2609–2617. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.; Nussbaum, M.A.; Esfahani, M.I.M.; Alemi, M.M.; Alabdulkarim, S.; Rashedi, E. Assessing the influence of a passive, upper extremity exoskeletal vest for tasks requiring arm elevation: Part I—”Expected” effects on discomfort, shoulder muscle activity, and work task performance. Appl. Ergon. 2018, 70, 315–322. [Google Scholar] [CrossRef]

- Baltrusch, S.J.; Krause, F.; de Vries, A.W.; van Dijk, W.; de Looze, M.P. What about the Human in Human Robot Collaboration? A literature review on HRC’s effects on aspects of job quality. Ergonomics 2022, 65, 719–740. [Google Scholar] [CrossRef]

- Zheng, L.; Lowe, B.; Hawke, A.L.; Wu, J.Z. Evaluation and Test Methods of Industrial Exoskeletons In Vitro, In Vivo, and In Silico: A Critical Review. Crit. Rev. Biomed. Eng. 2021, 49, 1–13. [Google Scholar] [CrossRef]

- ISO/TC 299 Robotics. Available online: https://www.iso.org/committee/5915511.html (accessed on 5 March 2023).

- Lowe, B.D.; Billotte, W.G.; Peterson, D.R. ASTM F48 Formation and Standards for Industrial Exoskeletons and Exosuits. IISE Trans. Occup. Erg. Hum. Factors 2019, 7, 230–236. [Google Scholar] [CrossRef]

- ASTM Committee F48 on Exoskeletons and Exosuits. Available online: https://www.astm.org/get-involved/technical-committees/committee-f48 (accessed on 7 March 2023).

- Bostelman, R.; Li-Baboud, Y.; Virts, A.; Yoon, S.; Shah, M. Towards Standard Exoskeleton Test Methods for Load Handling; WearRACon: Scottsdale, AZ, USA, 2019. Available online: https://tsapps.nist.gov/publication/get_pdf.cfm?pub_id=927164 (accessed on 21 May 2023).

- Virts, A.; Bostelman, R.; Yoon, S.; Li-Baboud, Y.; Shah, M. A Peg-in-Hole Test and Analysis Method for Exoskeleton Evaluation, Technical Note (NIST TN); National Institute of Standards and Technology: Gaithersburg, MD, USA, 2022. Available online: https://tsapps.nist.gov/publication/get_pdf.cfm?pub_id=932548 (accessed on 21 May 2023). [CrossRef]

- Bostelman, R.; Virts, A.; Shah, M.; Yoon, S.; Li-Baboud, Y. Towards Standard Test Artefacts for Synchronous Tracking of Human-Exoskeleton Knee Kinematics. Int. J. Hum. Factors Model. Simul. 2022, 7, 171–203. [Google Scholar] [CrossRef]

- NIST Exoskeletons and Exosuits Research and Test Methods Development. July 2021. Available online: https://www.nist.gov/el/intelligent-systems-division-73500/exoskeletons-and-exosuits-research-and-standard-test-methods-1 (accessed on 5 March 2023).

- Rahman, A. Towards a Markerless 3D Pose Estimation Tool. In Proceedings of the Extended Abstracts of the 2023 CHI Conference on Human Factors in Computing Systems, Hamburg, Germany, 23–28 April 2023. [Google Scholar]

- Chen, B.; Ma, H.; Qin, L.Y.; Gao, F.; Chan, K.M.; Law, S.W.; Qin, L.; Liao, W.H. Recent developments and challenges of lower extremity exoskeletons. J. Orthop. Transl. 2016, 5, 26–37. [Google Scholar] [CrossRef] [Green Version]

- Jackson, R.W.; Collins, S.H. An experimental comparison of the relative benefits of work and torque assistance in ankle exoskeletons. J. Appl. Physiol. 2015, 119, 541–557. [Google Scholar] [CrossRef] [Green Version]

- ASTM F3614-22; Standard Practice for Recording the Exoskeleton User Information. Available online: https://www.astm.org/f3614-22.html (accessed on 21 May 2023).

- ASTM F3613-22; Standard Practice for Recording the Exoskeleton Fit to the User. Available online: https://www.astm.org/f3613-22.html (accessed on 21 May 2023).

- ASTM F3576-22; Standard Practice for Recording the Exoskeleton Test Configuration. Available online: https://www.astm.org/f3576-22.html (accessed on 21 May 2023).

- ASTMF3427-20; Standard Practice for Documenting Environmental Conditions for Utilization with Exoskeleton Test Methods. Available online: https://www.astm.org/f3427-20.html (accessed on 21 May 2023).

- ASTM F3527-21; Standard Guide for Assessing Risks Related to Implementation of Exoskeletons in Task-Specific Environments. Available online: https://www.astm.org/f3527-21.html (accessed on 21 May 2023).

- ASTM F3444-20; Standard Practice for Training Exoskeleton Users. Available online: https://www.astm.org/f3444_f3444m-20.html (accessed on 21 May 2023).

- ASTM F3474-20; Standard Practice for Establishing Exoskeleton Functional Ergonomic Parameters and Test Metrics. Available online: https://www.astm.org/f3474-20.html (accessed on 21 May 2023).

- ASTM F3518-21; Standard Guide for Quantitative Measures for Establishing Exoskeleton Functional Ergonomic Parameters and Test Metrics. 2021. Available online: https://www.astm.org/f3518-21.html (accessed on 21 May 2023).

- ASTM F3443-20; Standard Practice for Load Handling When Using an Exoskeleton. Available online: https://www.astm.org/f3443-20.html (accessed on 21 May 2023).

- ASTM 3517-21; Standard Practice for Movement Tests When Using an Exoskeleton. Available online: https://www.astm.org/f3517-21.html (accessed on 11 March 2023).

- ASTM F3528-21; Standard Test Method for Exoskeleton Use: Gait. Available online: https://www.astm.org/f3528-21.html (accessed on 21 May 2023).

- ASTM F3523-21; Standard Test Method for Exoskeleton Use: Confined Space: Horizontal Movement. Available online: https://www.astm.org/f3523-21.html (accessed on 21 May 2023).

- ASTM F3583-22; Standard Test Method for Exoskeleton Use: Beams. Available online: https://www.astm.org/f3583-22.html (accessed on 17 March 2023).

- ASTM F3582-22; Standard Test Method for Exoskeleton Use: Gaps. Available online: https://www.astm.org/f3582-22.html (accessed on 17 March 2023).

- ASTM F3581-22; Standard Test Method for Exoskeleton Use: Hurdles. Available online: https://www.astm.org/f3581-22.html (accessed on 17 March 2023).

- ASTM WK75742; New Test Methods for Exoskeleton Use: Mobility over Variable Terrains. Available online: https://www.astm.org/workitem-wk75742 (accessed on 11 March 2023).

- ASTM WK84258; New Test Method for Exoskeleton Use: Inclined Planes. Available online: https://www.astm.org/workitem-wk84258 (accessed on 11 March 2023).

- ASTM WK76431; New Test Method for Exoskeleton Use: Stairs. Available online: https://www.astm.org/workitem-wk76431 (accessed on 11 March 2023).

- ASTM WK83509; New Test Method for Exoskeleton Use: Crawling. Available online: https://www.astm.org/workitem-wk83509 (accessed on 11 March 2023).

- ASTM WK76543; New Practice for Lower Extremity Exoskeleton Locomotion Transitions. Available online: https://www.astm.org/workitem-wk76543 (accessed on 11 March 2023).

- ASTM WK84262; New Test Method for Exoskeleton Use: Ladders. Available online: https://www.astm.org/workitem-wk84262 (accessed on 11 March 2023).

- ASTM WK81267; New Test Method for Exoskeleton Use: Confined Space: Vertical Movement. Available online: https://www.astm.org/workitem-wk81267 (accessed on 11 March 2023).

- ASTM F3584-22; Standard Test Method for Exoskeleton Use: Obstacle Avoidance: Walking. Available online: https://www.astm.org/f3584-22.html (accessed on 17 March 2023).

- ASTM F3578-22; Standard Test Method for Evaluating Exoskeleton Fall Risk Due to Stumbling. Available online: https://www.astm.org/f3578-22.html (accessed on 21 May 2023).

- Koopman, A.S.; Kingma, I.; de Looze, M.P.; van Dieën, J.H. Effects of a passive back exoskeleton on the mechanical loading of the low-back during symmetric lifting. J. Biomech. 2020, 102, 109486. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Looze, M.P.; Bosch, T.; Krause, F.; Stadler, K.S.; O’sullivan, L.W. Exoskeletons for industrial application and their potential effects on physical work load. Ergonomics 2016, 59, 671–681. [Google Scholar] [CrossRef] [Green Version]

- Basmajian, J.V. Muscles alive. Their functions revealed by electromyography. Acad. Med. 1962, 37, 802. [Google Scholar]

- Hummel, A.; Läubli, T.; Pozzo, M.; Schenk, P.; Spillmann, S.; Klipstein, A. Relationship between perceived exertion and mean power frequency of the EMG signal from the upper trapezius muscle during isometric shoulder elevation. Eur. J. Appl. Physiol. 2005, 95, 321–326. [Google Scholar] [CrossRef]

- Arendt-Nielsen, L.; Mills, K.R. Muscle fibre conduction velocity, mean power frequency, mean EMG voltage and force during submaximal fatiguing contractions of human quadriceps. Eur. J. Appl. Physiol. Occup. Physiol. 1988, 58, 20–25. [Google Scholar] [CrossRef]

- Baltrusch, S.J.; van Dieën, J.H.; Koopman, A.S.; Näf, M.B.; Rodriguez-Guerrero, C.; Babič, J.; Houdijk, H. SPEXOR Passive Spinal Exoskeleton Decreases Metabolic Cost during Symmetric Repetitive Lifting. Eur. J. Appl. Physiol. 2020, 120, 401–412. [Google Scholar] [CrossRef] [Green Version]

- Skeleton Marker Sets. Optitrack Version 3.0 Documentation. Available online: https://docs.optitrack.com/markersets (accessed on 12 May 2023).

- Mooney, L.M.; Herr, H.M. Biomechanical walking mechanisms underlying the metabolic reduction caused by an autonomous exoskeleton. J. Neuroeng. Rehabil. 2016, 13, 4. [Google Scholar] [CrossRef] [Green Version]

- Yoon, S.; Li-Baboud, Y.-S.; Virts, A.; Bostelman, R.; Shah, M. Feasibility of using depth cameras for evaluating human-exoskeleton interaction. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting, Atlanta, GA, USA, 10–14 October 2022; Volume 66, pp. 1892–1896. [Google Scholar] [CrossRef]

- Cappozzo, A.; Della Croce, U.; Leardini, A.; Chiari, L. Human movement analysis using stereophotogrammetry: Part 1: Theoretical background. Gait Posture 2005, 21, 186–196. [Google Scholar] [PubMed]

- Chiari, L.; Della Croce, U.; Leardini, A.; Cappozzo, A. Human movement analysis using stereophotogrammetry: Part 2: Instrumental errors. Gait Posture 2005, 21, 197–211. [Google Scholar] [CrossRef] [PubMed]

- Seel, T.; Raisch, J.; Schauer, T. IMU-based joint angle measurement for gait analysis. Sensors 2014, 14, 6891–6909. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, B.; Lanotte, F.; Grazi, L.; Vitiello, N.; Crea, S. Classification of lifting techniques for application of a robotic hip exoskeleton. Sensors 2019, 19, 963. [Google Scholar] [CrossRef] [Green Version]

- Carlson, B.; Norton, A.; Yanco, H. Preliminary development of test methods to evaluate lower body wearable robots for human performance augmentation. In Advances in Cooperative Robotics; World Scientific: Singapore, 2017; pp. 143–157. [Google Scholar]

- Pesenti, M.; Antonietti, A.; Golla, M.; Pedrocchi, A. Towards a functional performance validation standard for industrial low-back exoskeletons: State of the art review. Sensors 2021, 21, 808. [Google Scholar] [CrossRef]

- Walsh, C.J.; Endo, K.; Herr, H. A quasi-passive leg exoskeleton for load-carrying augmentation. Int. J. Humanoid Robot. 2007, 4, 487–506. [Google Scholar] [CrossRef]

- Sawicki, G.S.; Ferris, D.P. Mechanics and energetics of level walking with powered ankle exoskeletons. J. Exp. Biol. 2008, 211, 1402–1413. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.; Norton, A.; Zielinski, M.R.; Kao, P.; Stanwicks, A.; Pang, P.; Cring, C.H.; Flynn, B.; Yanco, H.A. Characterizing the Effects of Explosive Ordnance Disposal Operations on the Human Body While Wearing Heavy Personal Protective Equipment. Hum. Factors 2022, 64, 1137–1153. [Google Scholar] [CrossRef]

- Mooney, L.M.; Rouse, E.J.; Herr, H.M. Autonomous exoskeleton reduces metabolic cost of human walking during load carriage. J. Neuroeng. Rehabil. 2014, 11, 80. [Google Scholar] [CrossRef] [Green Version]

- Massardi, S.; Rodriguez-Cianca, D.; Pinto-Fernandez, D.; Moreno, J.C.; Lancini, M.; Torricelli, D. Characterization and evaluation of human–exoskeleton interaction dynamics: A review. Sensors 2022, 22, 3993. [Google Scholar] [CrossRef]

- Sposito, M.; Di Natali, C.; Toxiri, S.; Caldwell, D.G.; De Momi, E.; Ortiz, J. Exoskeleton kinematic design robustness: An assessment method to account for human variability. Wearable Technol. 2020, 1, e7. [Google Scholar] [CrossRef]

- Porges, O.; Lampariello, R.; Artigas, J.; Wedler, A.; Borst, C.; Roa, M.A. Reachability and dexterity: Analysis and applications for space robotics. In Proceedings of the Workshop on Advanced Space Technologies for Robotics and Automation-ASTRA, Noordwijk, The Netherlands, 11–13 May 2015. [Google Scholar]

- Waters, T.R.; Putz-Anderson, V.; Garg, A.; Fine, L.J. Applications Manual for the Revised NIOSH Lifting Equation; U.S. Department of Health and Human Services, National Institute for Occupational Safety and Health: Cincinnati, OH, USA, 1994; pp. 94–110.

- Fritzsche, L.; Galibarov, P.E.; Gärtner, C.; Bornmann, J.; Damsgaard, M.; Wall, R.; Schirrmeister, B.; Gonzalez-Vargas, J.; Pucci, D.; Maurice, P.; et al. Assessing the efficiency of exoskeletons in physical strain reduction by biomechanical simulation with AnyBody Modeling System. Wearable Technol. 2021, 2, e6. [Google Scholar] [CrossRef]

- Kermavnar, T.; O’Sullivan, K.J.; de Eyto, A.; O’Sullivan, L.W. Discomfort/pain and tissue oxygenation at the lower limb during circumferential compression: Application to soft exoskeleton design. Hum. Factors 2020, 62, 475–488. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kermavnar, T.; Power, V.; de Eyto, A.; O’Sullivan, L.W. Computerized cuff pressure algometry as guidance for circumferential tissue compression for wearable soft robotic applications: A systematic review. Soft Robot. 2018, 5, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Huysamen, K.; de Looze, M.; Bosch, T.; Ortiz, J.; Toxiri, S.; O’Sullivan, L.W. Assessment of an Active Industrial Exoskeleton to Aid Dynamic Lifting and Lowering Manual Handling Tasks. Appl. Ergon. 2018, 68, 125–131. [Google Scholar] [CrossRef]

- Kozinc, Ž.; Babič, J.; Šarabon, N. Human pressure tolerance and effects of different padding materials with implications for development of exoskeletons and similar devices. Appl. Ergon. 2021, 93, 103379. [Google Scholar] [CrossRef]

- Kim, S.; Nussbaum, M.A.; Esfahani, M.I.M.; Alemi, M.M.; Jia, B.; Rashedi, E. Assessing the influence of a passive, upper extremity exoskeletal vest for tasks requiring arm elevation: Part II—“Unexpected” effects on shoulder motion, balance, and spine loading. Appl. Ergon. 2018, 70, 323–330. [Google Scholar] [CrossRef]

- Centers for Disease Control. Perceived Exertion (Borg Rating of Perceived Exertion Scale). Available online: https://www.cdc.gov/physicalactivity/basics/measuring/exertion.htm (accessed on 17 March 2023).

- Göb, R.; McCollin, C.; Ramalhoto, M.F. Ordinal methodology in the analysis of Likert scales. Qual. Quant. 2007, 41, 601–626. [Google Scholar] [CrossRef]

- Bostelman, R.; Hong, T. Test methods for exoskeletons—Lessons learned from industrial and response robotics. In Wearable Exoskeleton Systems: Design, Control and Applications; Bai, S., Virk, G.S., Sugar, T., Eds.; The Institution of Engineering and Technology: Michael Faraday House: Stevenage, UK, 2018; pp. 335–361. [Google Scholar]

- Bosch, T.; van Eck, J.; Knitel, K.; de Looze, M. The effects of a passive exoskeleton on muscle activity, discomfort and endurance time in forward bending work. Appl. Ergon. 2016, 54, 212–217. [Google Scholar] [CrossRef]

- Otten, B.M.; Weidner, R.; Argubi-Wollesen, A. Evaluation of a novel active exoskeleton for tasks at or above head level. IEEE Robot. Autom. Lett. 2018, 3, 2408–2415. [Google Scholar] [CrossRef]

- Baltrusch, S.J.; van Dieën, J.H.; Bruijn, S.M.; Koopman, A.S.; van Bennekom, C.A.M.; Houdijk, H. The effect of a passive trunk exoskeleton on metabolic costs during lifting and walking. Ergonomics 2019, 62, 903–916. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, Y.; Weston, E.B.; Mehta, R.K.; Marras, W.S. Neural and biomechanical tradeoffs associated with human-exoskeleton interactions. Appl. Ergon. 2021, 96, 103494. [Google Scholar] [CrossRef] [PubMed]

- Hart, S.G. NASA-Task Load Index (NASA-TLX); 20 Years Later. In Proceedings of the Human Factors and Ergonomics Society 50th Annual Meeting, San Francisco, CA, USA, 16–20 October 2006; pp. 904–908. [Google Scholar]

- Bequette, B.; Norton, A.; Jones, E.; Stirling, L. Physical and Cognitive Load Effects Due to a Powered Lower-Body Exoskeleton. Hum. Factors 2020, 62, 411–423. [Google Scholar] [CrossRef] [PubMed]

- Elstub, L.J.; Fine, S.J.; Zelik, K.E. Exoskeletons and Exosuits Could Benefit from Mode-Switching Body Interfaces That Loosen/Tighten to Improve Thermal Comfort. Int. J. Environ. Res. Public Health 2021, 18, 13115. [Google Scholar] [CrossRef]

- Han, D.; Park, M.; Choi, J.; Shin, H.; Kim, D.; Rhim, S. Assessment of Pain Onset and Maximum Bearable Pain Thresholds in Physical Contact Situations. Sensors 2022, 22, 2996. [Google Scholar] [CrossRef]

- DeRossi, R.; Marco, M.S.; Nicola, V.; Tommaso, L.; Renaud, R.; Bram, K.; Alessandro, P.; Fabrizio, V.; Jan, I.A.; Herman, V.K.; et al. Sensing pressure distribution on a lower-limb exoskeleton physical human-machine interface. Sensors 2010, 11, 207–227. [Google Scholar] [CrossRef]

- Theurel, J.; Desbrosses, K. Occupational exoskeletons: Overview of their benefits and limitations in preventing work-related musculoskeletal disorders. IISE Trans. Occup. Ergon. Hum. Factors 2019, 7, 264–280. [Google Scholar] [CrossRef]

- Kao, P.C.; Lewis, C.L.; Ferris, D.P. Invariant ankle moment patterns when walking with and without a robotic ankle exoskeleton. J. Biomech. 2010, 43, 203–209. [Google Scholar] [CrossRef] [Green Version]

- Poggensee, K.L.; Collins, S.H. How adaptation, training, and customization contribute to benefits from exoskeleton assistance. Sci. Robot. 2021, 6, eabf1078. [Google Scholar] [CrossRef]

- Luger, T.; Seibt, R.; Cobb, T.J.; Rieger, M.A.; Steinhilber, B. Influence of a passive lower-limb exoskeleton during simulated industrial work tasks on physical load, upper body posture, postural control and discomfort. Appl. Ergon. 2019, 80, 152–160. [Google Scholar] [CrossRef]

- Poliero, T.; Mancini, L.; Caldwell, D.G.; Ortiz, J. Enhancing back-support exoskeleton versatility based on human activity recognition. In Proceedings of the 2019 Wearable Robotics Association Conference (WearRAcon), Scottsdale, AZ, USA, 25–27 March 2019; pp. 86–91. [Google Scholar]

- Slade, P.; Kochenderfer, M.J.; Delp, S.L.; Collins, S.H. Personalizing exoskeleton assistance while walking in the real world. Nature 2022, 610, 277–282. [Google Scholar] [CrossRef] [PubMed]

- Rashedi, E.; Kim, S.; Nussbaum, M.A.; Agnew, M.J. Ergonomic evaluation of a wearable assistive device for overhead work. Ergonomics 2014, 57, 1864–1874. [Google Scholar] [CrossRef] [PubMed]

- Hoffmann, N.; Prokop, G.; Weidner, R. Methodologies for evaluating exoskeletons with industrial applications. Ergonomics 2022, 65, 276–295. [Google Scholar] [CrossRef] [PubMed]

- Kranenborg, S.E.; Greve, C.; Reneman, M.F.; Roossien, C.C. Side-effects and adverse events of a shoulder- and back-support exoskeleton in workers: A systematic review. Appl. Ergon. 2023, 111, 104042. [Google Scholar] [CrossRef] [PubMed]

- Lund, M.E.; de Zee, M.; Andersen, M.S.; Rasmussen, J. On validation of multibody musculoskeletal models. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2012, 226, 82–94. [Google Scholar] [CrossRef] [Green Version]

| Area | Parameter | Reference |

|---|---|---|

| User | Healthy | ASTM F3614 User [23] |

| Musculoskeletal Disorders | ||

| Injuries | ||

| Occupation | ||

| Demographic | ||

| Age | ||

| Height | ||

| Weight | ||

| Profession | ||

| Exo fit to user | User anthropometry | ASTMF3613 Fit [24] |

| Configuration | ||

| Don and doff | ||

| Range of motion | ||

| Exo configuration | Hardware | ASTM F3576-22 Config [25] |

| Hardware settings | ||

| Control settings | ||

| User controlled | ||

| Non-user controlled | ||

| Power | ||

| Environmental conditions | Indoor or outdoor | ASTM F3427-20 Env Cond [26] |

| Humidity | ||

| Temperature | ||

| Sanitization | ||

| Risks | ASTM F3527-21 Env Risks [27] | |

| Training exoskeleton users | Don and doff | ASTM F3444-20 Train Exo [28] |

| Fitting | ||

| Intended use | ||

| Maintenance and operations | ||

| Metrics | Ergonomic parameters and test metrics | ASTM F3474-20 [29] |

| ASTM F3518-21 [30] | ||

| Load/material handling | Lifting | ASTM F3443-20 Load handling [31] |

| Static holding | ||

| Carrying | ||

| Dragging | ||

| Endurance | ||

| Symmetric | ||

| Asymmetric | ||

| Alignment |

| Area | Function | Type | Location | Standard |

|---|---|---|---|---|

| Task | Load/material handling | Lifting | Overhead | ASTM F3443-20 Load handling [31] |

| Static holding | Back | |||

| Carrying | Shoulder | |||

| Dragging | Side(s) | |||

| Endurance | Front | |||

| Symmetric | Pull/push | |||

| Asymmetric | ||||

| Alignment | ||||

| Assembly | Kneeling | Forward low | ||

| Stooping | Forward middle | |||

| Peg-in-hole | Drill/fasten | Forward high | ||

| Down | ||||

| Applied force | Sanding | Hands | ||

| Overhead painting | Shoulder | |||

| Mobility | Movement | Sit to stand | Full body | ASTM F3517-21 Movement [32] |

| (loaded/unloaded) | Gait | ASTM F3528-21 Gait [33] | ||

| Variable terrain | ASTM WK75742 Terrains [38] | |||

| Inclined plane | ASTM WK84258 Incl Plane [39] | |||

| Stairs | ASTM WK76431 Stairs [40] | |||

| Crawling | ASTM WK83509 Crawling [41] | |||

| Transitions | ASTM WK76543 Transitions [42] | |||

| Ingress/egress | ||||

| Climbing | Ladders | ASTM WK84262 Ladders [43] | ||

| Trees | ||||

| Agility | Confined spaces: vertical | ASTM WK81267 Vertical [44] | ||

| Confined spaces: horizontal | ASTM F3523-21 Horizontal [34] | |||

| Obstacle avoidance | ASTM F3584-22 Obst avoid [45] | |||

| Gaps | ASTM F3582-22 Gaps [36] | |||

| Beams | ASTM F3583-22 Beams [35] | |||

| Hurdles | ASTM F3581-22 Hurdles [37] | |||

| Dexterity | Hand dexterity | Hands | ||

| Safety | Fall risk | Stumbling | ASTM F3578-22 Fall risk [46] |

| Functional Measure | Metric | Sensors | References |

|---|---|---|---|

| Degrees of freedom (DoF) | A-DOF (assisted DOF) | Pesenti 2021 [61] | |

| N-DOF (non-actuated DOF) | |||

| Kinematic structure | Rigid | Crea 2021 [8] | |

| Anthropomorphic | |||

| Non-anthropomorphic | |||

| Exosuit (soft) | |||

| Actuation type | Passive | Lowe 2019 [14] | |

| Quasi-passive | |||

| Quasi-active | |||

| Active | |||

| Metabolic cost | Locomotory economy | Walsh 2007 [62] | |

| Walking metabolic power | |||

| Carbon-dioxide production | Walsh 2007 [62] | ||

| Oxygen consumption | Oxygen mask | Sawicki and Ferris 2008 [63] | |

| Heart rate | Heart-rate monitor (HRM) | ||

| Respiratory rate | Pulse oximeter | Wu 2022 [64] | |

| Skin temperature | Skin temperature sensor | ||

| Performance index | |||

| Augmentation factor | Mooney et al., 2014 [65] | ||

| Support | Intended and perceived areas | Bostelman et al., 2019 [16] | |

| Back | |||

| Hand | |||

| Shoulder | |||

| Legs | |||

| Interaction torque | Torque sensor | Massardi 2022 [66] | |

| Reachability | Joint angle | IMU | Sposito 2020 [67] |

| Capability and dexterity | Joint angle, speed | IMU | Porges 2015 [68] |

| Ergonomic Measure | Metric | Sensors | References |

|---|---|---|---|

| Hand position | Horizontal location of hands | Video | Waters et al., 1994 [69] |

| Vertical location of hands | Video | ||

| OTS | |||

| Type of grasp (coupling classification) | Video | ||

| Muscle activity | Reduction | EMG | De Looze et al., 2016 [48] |

| Augmentation | ASTM 3518-21 [30] | ||

| Fatigue | Theurel and Desbrosses 2019 [22] | ||

| Strain | Fritzsche et al., 2021 [70] | ||

| Joint angle | Knee flexion | OTS | Bostelman et al., 2022 [18] |

| Back rotation | IMU | ||

| Back flexion | Depth perception camera | Yoon et al., 2022 [55] | |

| Trunk flexion | Monocular video | Rahman 2023 [20] | |

| Arm/shoulder flexion | Stereo video | ||

| Interaction force | Force between user and exoskeleton | Force Plates | Howard et al., 2020 [5] |

| Deep-tissue oxygenation | Kermavnar 2020 [71] | ||

| Pressure sensors | Kermavnar et al., 2018 [72] | ||

| Huysamen et al., 2018 [73] | |||

| Algometry: first-discomfort threshold (FDT), first-pain threshold (FPT), time to FDT | Kozinc et al. 2021 [74] | ||

| Normal, shear | |||

| Posture | Postural control | Force plates | Kim et al., 2018 [75] |

| Asymmetry | OTS, video (pose estimation) | Waters et al., 1994 [69] | |

| CoP displacement | Pressure walkway | Wu et al., 2022 [64] | |

| Balance | CoP displacement | Pressure insoles | |

| Anterior–posterior (AP) | |||

| Mediolateral | |||

| Kinematics | Human–exo alignment | OTS | Bostelman et al., 2022 [18] |

| Task Measure | Metric | Method | References |

|---|---|---|---|

| Productivity | Perceived exhaustion | Borg scale | CDC [76] |

| Likert scale | Gob 2007 [77] | ||

| Task rate | Video (pose estimation) | Bostelman 2022 [18] | |

| Task completion time | Video (manual counting) | Kim et al., 2018 [10] | |

| Number of errors | |||

| Task duration | Bostelman, et al., 2018 [78] | ||

| Bosch 2016 [79] | |||

| Load | Lifting index | Waters 1994 [69] | |

| Composite lifting index | |||

| Lift duration | Video | ||

| Lift frequency | Video | ||

| Travel distance | Video | ||

| Load weight | |||

| Mobility | Movement velocity | IMU, OTS | Otten 2018 [80] |

| Video (pose estimation) | |||

| Quality | Task precision | Video (pose estimation) | Howard 2020 [5] |

| Bostelman 2018 [78] | |||

| Range of motion | Task angle | OTS | Kim et al., 2018 [10] |

| Task height | Kim et al., 2018 [75] | ||

| Video (pose estimation) | Yoon et al., 2022 [55] | ||

| Mobility | Gait speed | Pressure walkway | Kim et al., 2018 [75] |

| Stride length | Video (pose estimation) | Yoon et al., 2022 [55] | |

| Baltrusch et al., 2019 [81] |

| Task Measure | Metric | Method | References |

|---|---|---|---|

| Complexity | Cognitive load | fNIRS-based brain connectivity | Zhu 2021 [82] |

| Mental demand | TLX scale | NASA-TLX 2006 [83] | |

| Physical demand | |||

| Temporal demand | |||

| Performance | |||

| Effort | |||

| Frustration | |||

| Visual misses | Number missed (visual) | Bequette 2020 [84] | |

| Visual reaction time | Time: visual cue and reaction | ||

| Audio misses | Number missed (audio) | ||

| Audio reaction time | Time: audio cue and reaction | ||

| Lag time | |||

| Don/doff time | Time to wear and to remove without aid | ||

| Don/doff ease | Likert scale | ||

| Comfort | Perceived | Likert scale | De Looze et al., 2016 [48] |

| Thermal comfort | Thermal ratings (comfort, acceptability, sensation) | Elstub et al., 2021 [85] | |

| Skin temperature sensor | |||

| Pain, pressure, discomfort | Body location and severity | Bostelman et al., 2019 [16] | |

| Han et al., 2022 [86] | |||

| Deep-tissue oxygenation | Kermavnar 2020 [71] | ||

| Pressure sensors | Huysamen et al., 2018 [73] | ||

| Algometry: first-discomfort threshold (FDT), first-pain threshold (FPT), time to FDT | Kozinc et al. 2021 [74] | ||

| Chafing | Pressure sensor | DeRossi 2010 [87] | |

| Exertion | Subjective effort | Likert scale | Theurel and Desbrosses 2019 [22] |

| Borg CR10 | Otten et al., 2018 [80] | ||

| Fit | Human–exo alignment | OTS | Bostelman 2022 [18] |

| Comfort | Likert scale | ||

| Pressure | Pressure measurement over contact area | DeRossi 2010 [87] | |

| Drift | IMU | Sposito et al., 2020 [67] | |

| Task difficulty | Subjective effort | Likert scale | Theurel and Desbrosses 2019 [88] |

| Acceptance | Satisfaction | Likert scale | Bostelman, et al., 2019 [16] |

| Fluency | Joint moment similarity | Kao 2010 [89] | |

| Human–exo concurrency | Baltrusch 2022 [11] | ||

| Idle time | |||

| Training and use hours | Poggensee 2022 [90] | ||

| Fall risk | Force plates | Kim et al., 2018 [75] | |

| Luger et al., 2019 [91] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li-Baboud, Y.-S.; Virts, A.; Bostelman, R.; Yoon, S.; Rahman, A.; Rhode, L.; Ahmed, N.; Shah, M. Evaluation Methods and Measurement Challenges for Industrial Exoskeletons. Sensors 2023, 23, 5604. https://doi.org/10.3390/s23125604

Li-Baboud Y-S, Virts A, Bostelman R, Yoon S, Rahman A, Rhode L, Ahmed N, Shah M. Evaluation Methods and Measurement Challenges for Industrial Exoskeletons. Sensors. 2023; 23(12):5604. https://doi.org/10.3390/s23125604

Chicago/Turabian StyleLi-Baboud, Ya-Shian, Ann Virts, Roger Bostelman, Soocheol Yoon, Amaan Rahman, Lucia Rhode, Nishat Ahmed, and Mili Shah. 2023. "Evaluation Methods and Measurement Challenges for Industrial Exoskeletons" Sensors 23, no. 12: 5604. https://doi.org/10.3390/s23125604

APA StyleLi-Baboud, Y.-S., Virts, A., Bostelman, R., Yoon, S., Rahman, A., Rhode, L., Ahmed, N., & Shah, M. (2023). Evaluation Methods and Measurement Challenges for Industrial Exoskeletons. Sensors, 23(12), 5604. https://doi.org/10.3390/s23125604