Various Types of Light Guides for Use in Lossy Mode Resonance-Based Sensors

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Socorro, A.B.; Del Villar, I.; Corres, J.M.; Arregui, F.J.; Matias, I.R. Tapered single-mode optical fiber pH sensor based on lossy mode resonances generated by a polymeric thin-film. IEEE Sens. J. 2012, 12, 2598–2603. [Google Scholar] [CrossRef]

- Cheng, X.; Bonefacino, J.; Guan, B.O.; Tam, H.Y. All-polymer fiber-optic pH sensor. Opt. Express 2018, 26, 14610–14616. [Google Scholar] [CrossRef]

- Gu, B.; Yin, M.-J.; Zhang, A.P.; Qian, J.-W.; He, S. Low-cost high-performance fiber-optic pH sensor based on thin-core fiber modal interferometer. Opt. Express 2009, 17, 22296–22302. [Google Scholar] [CrossRef]

- Socorro, A.B.; Corres, J.M.; Del Villar, I.; Arregui, F.J.; Matias, I.R. Fiber-optic biosensor based on lossy mode resonance. Sens. Actuators B 2012, 174, 263–269. [Google Scholar] [CrossRef]

- Zeni, L.; Perri, C.; Cennamo, N.; Arcadio, F.; D’Agostino, G.; Salmona, M.; Beeg, M.; Gobbi, M. A portable optical-fibre-based surface plasmon resonance biosensor for the detection of therapeutic antibodies in human serum. Sci. Rep. 2020, 10, 11154. [Google Scholar] [CrossRef]

- Leitão, C.; Pereira, S.O.; Marques, C.; Cennamo, N.; Zeni, L.; Shaimerdenova, M.; Ayupova, T.; Tosi, D. Cost-effective fiber optic solutions for biosensing. Biosensors 2022, 12, 575. [Google Scholar] [CrossRef]

- Wang, Y.; Shen, C.; Lou, W.; Shentu, F.; Zhong, C.; Dong, X.; Tong, L. Fiber optic relative humidity sensor based on the tilted fiber Bragg grating coated with graphene oxide. Appl. Phys. Lett. 2016, 109, 031107. [Google Scholar] [CrossRef]

- Zhang, E.; Lu, D.; Zhang, S.; Gui, X.; Guan, H.; Zhang, Z.; Lin, Y.; Ming, J.; Hong, J.; Dong, J.; et al. High-sensitivity fiber-optic humidity sensor based on microfiber overlaid with niobium disulfide. J. Mater. Sci. 2020, 55, 16576–16587. [Google Scholar] [CrossRef]

- Limodehi, H.E.; Légaré, F. Fiber optic humidity sensor using water vapor condensation. Opt. Express 2017, 25, 15313–15321. [Google Scholar] [CrossRef]

- Sanchez, P.; Mendizabal, D.; Zamarreño, C.R.; Matias, I.R.; Arregui, F.J. Indium-Tin-Oxide-Coated optical fibers for temperature- viscosity sensing applications in synthetic lubricant oil. Proc. SPIE 2015, 9634, 1024–1027. [Google Scholar] [CrossRef]

- Hu, T.; Zhao, Y.; Song, A. Fiber optic SPR sensor for refractive index and temperature measurement based on MMF-FBG-MMF structure. Sens. Actuators B Chem. 2016, 237, 521–525. [Google Scholar] [CrossRef]

- Gao, S.; Ji, C.; Ning, Q.; Chen, W.; Li, J. High-sensitive Mach-Zehnder interferometric temperature fiber-optic sensor based on core-offset splicing technique. Opt. Fiber Technol. 2020, 56, 102202. [Google Scholar] [CrossRef]

- Yin, M.-J.; Gu, B.; An, Q.-F.; Yang, C.; Guan, Y.L.; Yong, K.-T. Recent development of fiber-optic chemical sensors and biosensors: Mechanisms, materials, micro/nano-fabrications and applications. Coord. Chem. Rev. 2018, 376, 348–392. [Google Scholar] [CrossRef]

- Devendiran, S.; Priya, A.K.; Sastikumar, D. Design of aluminium oxide (Al2O3) fiber optic gas sensor based on detection of refracted light in evanescent mode from the side-polished modified clad region. Sens. Actuators B Chem. 2022, 361, 131738. [Google Scholar] [CrossRef]

- Vitoria, I.; Ruiz Zamarreño, C.; Ozcariz, A.; Matias, I.R. Fiber optic gas sensors based on lossy mode resonances and sensing materials used therefor: A comprehensive review. Sensors 2021, 21, 731. [Google Scholar] [CrossRef] [PubMed]

- Yan, A.; Huang, S.; Li, S.; Chen, R.; Ohodnicki, P.; Chen, K. Fiber optical methane sensors using functional metal oxide nanomaterials. In Proceedings of the Asia-Pacific Optical Sensors Conference, Shanghai, China, 11–14 October 2016; p. W4A.12. [Google Scholar] [CrossRef]

- Gordon, J.D.; Lowder, T.L.; Selfridge, R.H.; Schultz, S.M. Optical D-fiber-based volatile organic compound sensor. Appl. Opt. 2007, 46, 7805–7810. [Google Scholar] [CrossRef]

- Naku, W.; Nambisan, A.K.; Roman, M.; Zhu, C.; Gerald, R.E., II; Huang, J. Identification of volatile organic liquids by combining an array of fiber-optic sensors and machine learning. ACS Omega 2023, 8, 4597–4607. [Google Scholar] [CrossRef]

- Ascorbe, J.; Corres, J.M.; Matias, I.R.; Arregui, F.J. High sensitivity humidity sensor based on cladding-etched optical fiber and lossy mode resonances. Sens. Actuators B 2016, 233, 7–16. [Google Scholar] [CrossRef]

- Zhu, S.; Pang, F.; Huang, S.; Zou, F.; Dong, Y.; Wang, T. High sensitivity refractive index sensor based on adiabatic tapered optical fiber deposited with nanofilm by ALD. Opt. Express 2015, 23, 13880–13888. [Google Scholar] [CrossRef]

- Ozcariz, A.; Dominik, M.; Smietana, M.; Zamarreño, C.R.; Del Villar, I.; Arregui, F.J. Lossy mode resonance optical sensors based on indium-gallium-zinc oxide thin film. Sens. Actuators A 2019, 290, 20–27. [Google Scholar] [CrossRef]

- Rees, N.D.; James, S.W.; Tatam, R.P.; Ashwell, G.J. Optical fiber long-period gratings with Langmuir Blodgett thin-film overlays. Opt. Lett. 2002, 27, 686–688. [Google Scholar] [CrossRef]

- Del Villar, I.; Matías, I.; Arregui, F.; Lalanne, P. Optimization of sensitivity in Long Period Fiber Gratings with overlay deposition. Opt. Express 2005, 13, 56–69. [Google Scholar] [CrossRef] [PubMed]

- Zou, F.; Liu, Y.; Deng, C.; Dong, Y.; Zhu, S.; Wang, T. Refractive index sensitivity of nano-film coated longperiod fiber gratings. Opt. Express 2015, 23, 1114–1124. [Google Scholar] [CrossRef]

- Zheltikov, A.M. Ray-optic analysis of the (bio)sensing ability of ring-cladding hollow waveguides. Appl. Opt. 2008, 47, 474–479. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Pang, F.; Dong, Y.; Wen, J.; Chen, Z.; Wang, T. Refractive index sensitivity enhancement of optical fiber cladding mode by depositing nanofilm via ALD technology. Opt. Express 2013, 21, 26136–26143. [Google Scholar] [CrossRef] [PubMed]

- Del Villar, I.; Zamarreño, C.R.; Hernáez, M.; Arregui, F.J.; Matías, I.R. Lossy mode resonance generation with Indium Tin Oxide coated optical fibers for sensing applications. J. Light. Technol. 2010, 28, 111–117. [Google Scholar] [CrossRef]

- Paliwal, N.; John, J. Lossy Mode Resonance (LMR) Based Fiber Optic Sensors: A Review. IEEE Sens. J. 2015, 15, 5361–5371. [Google Scholar] [CrossRef]

- Del Villar, I.; Arregui, F.J.; Zamarreño, C.R.; Corres, J.M.; Bariain, C.; Goicoechea, J.; Elosua, C.; Hernaez, M.; Rivero, P.J.; Socorro, A.B.; et al. Optical sensors based on lossy-mode resonances. Sens. Actuators B 2017, 240, 174–185. [Google Scholar] [CrossRef]

- Wang, Q.; Zhao, W.-M. A comprehensive review of lossy mode resonance-based fber optic sensors. Opt. Lasers Eng. 2018, 100, 47–60. [Google Scholar] [CrossRef]

- Savelyev, E. Sensitivity of lossy mode resonance-based optical fiber sensors as a function of the coating material refractive index. Eur. Phys. J. D 2021, 75, 285. [Google Scholar] [CrossRef]

- Zamarreno, C.R.; Sanchez, P.; Hernaez, M.; Del Villar, I.; Fernandez-Valdivielso, C.; Matias, I.R.; Arregui, F.J. Sensing properties of indium oxide coated optical fiber devices based on lossy mode resonances. IEEE Sens. J. 2012, 12, 151–155. [Google Scholar] [CrossRef]

- Del Villar, I.; Socorro, A.B.; Hernaez, M.; Corres, J.M.; Zamarreño, C.R.; Sanchez, P.; Arregui, F.J.; Matias, I.R. Sensors based on thin-film coated cladding removed multimode optical Fiber and single-mode multimode single-mode Fiber: A comparative study. J. Sens. 2015, 2015, 763762. [Google Scholar] [CrossRef]

- Prasanth, A.; Meher, S.R.; Alex, Z.C. Experimental analysis of SnO2 coated LMR based fiber optic sensor for ethanol detection. Opt. Fiber Technol. 2021, 65, 102618. [Google Scholar] [CrossRef]

- Zubiate, P.; Zamarreño, C.R.; Del Villar, I.; Matias, I.R.; Arregui, F.J. High sensitive refractometers based on lossy mode resonances (LMRs) supported by ITO coated D-shaped optical fibers. Opt. Express 2015, 23, 8045–8050. [Google Scholar] [CrossRef]

- Śmietana, M.; Sobaszek, M.; Michalak, B.; Niedziałkowski, P.; Białobrzeska, W.; Koba, M.; Sezemsky, P.; Stranak, V.; Karczewski, J.; Ossowski, T.; et al. Optical monitoring of electrochemical processes with ITO-based lossy-mode resonance optical fiber sensor applied as an electrode. J. Lightwave Technol. 2018, 36, 954–960. [Google Scholar] [CrossRef]

- Sanchez, P.; Zamarreño, C.R.; Hernaez, M.; Matias, I.R.; Arregui, F.J. Optical fiber refractometers based on Lossy Mode Resonances by means of SnO2 sputtered coatings. Sens. Actuators B 2014, 202, 154–159. [Google Scholar] [CrossRef]

- Kuznetsov, P.I.; Sudas, D.P.; Savelyev, E.A. Fiber optic lossy mode resonance based sensor for aggressive liquids. Sens. Actuators A Phys. 2021, 321, 112576. [Google Scholar] [CrossRef]

- Sudas, D.P.; Zakharov, L.Y.; Jitov, V.A.; Golant, K.M. Silicon oxynitride thin film coating to lossy mode resonance fiber-optic refractometer. Sensors 2022, 22, 3665. [Google Scholar] [CrossRef]

- Pezzotti, G.; Marin, E.; Adachi, T.; Lerussi, F.; Rondinella, A.; Boschetto, F.; Zhu, W.; Kitajima, T.; Inada, K.; McEntire, B.J.; et al. Incorporating Si3N4 into PEEK to Produce Antibacterial, Osteocondutive, and Radiolucent Spinal Implants. Macromol. Biosci. 2018, 18, e1800033. [Google Scholar] [CrossRef]

- Pezzotti, G.; McEntire, B.J.; Bock, R.; Boffelli, M.; Zhu, W.; Vitale, E.; Puppulin, L.; Adachi, T.; Yamamoto, T.; Kanamura, N.; et al. Silicon Nitride: A synthetic mineral for vertebrate biology. Sci. Rep. 2016, 6, 31717. [Google Scholar] [CrossRef]

- Doering, R.; Nishi, Y. (Eds.) Handbook of Semiconductor Manufacturing Technology, 2nd ed.; CRC Press, Inc.: Boca Raton, FL, USA, 2008. [Google Scholar] [CrossRef]

- Ko, S.; Lee, J.; Koo, J.; Joo, B.S.; Gu, M.; Lee, J.H. Chemical wet etching of an optical fiber using a hydrogen fluoride-free solution for a saturable absorber based on the evanescent field interaction. J. Light. Technol. 2016, 34, 3776. [Google Scholar] [CrossRef]

- Kuznetsov, P.I.; Sudas, D.P.; Yapaskurt, V.O.; Savelyev, E.A. Lossy mode resonance fiber-optic sensors based on niobium pentoxide thin film. Opt. Mater. Express 2021, 11, 2650–2664. [Google Scholar] [CrossRef]

- Kovalev, V.; Kuznetzov, P.; Zhitov, V.; Zakharov, L.; Rukovishnikov, A.; Khomich, A.; Yakushcheva, G.; Gaponenko, S. Spectral ellipsometry of multilayer ZnS/ZnSe heterostructures. J. Appl. Spectrosc. 2002, 69, 298–304. [Google Scholar] [CrossRef]

- Savelyev, E.A.; Sudas, D.P.; Kuztestov, P.I. Using lossy mode resonance for in situ measurement of the refractive index of a layer deposited on an optical fiber lateral surface. Opt. Lett. 2022, 47, 361–364. [Google Scholar] [CrossRef] [PubMed]

- Marciniak, M.; Grzegorzewski, J.; Szustakowski, M. Analysis of lossy mode cut-off conditions in planar waveguides with semiconductor guiding layer. IEE Proc. J. Optoelectron. 1993, 140, 247. [Google Scholar] [CrossRef]

- Golant, E.I.; Pashkovskii, A.B.; Golant, K.M. Lossy mode resonance in an etched-out optical fiber taper covered by a thin ITO layer. Appl. Opt. 2020, 59, 9254. [Google Scholar] [CrossRef]

- Roussey, M.; Descrovi, E.; Häyrinen, M.; Angelini, A.; Kuittinen, M.; Honkanen, S. One-dimensional photonic crystals with cylindrical geometry. Opt. Express 2014, 22, 27236–27241. [Google Scholar] [CrossRef]

- Villatoro, J.; Monzón-Hernández, D.; Mejía, E. Fabrication and modeling of uniform-waist single-mode tapered optical fiber sensors. Appl. Opt. 2003, 42, 2278–2283. [Google Scholar] [CrossRef]

- Yariv, A.; Yeh, P. Photonics: Optical Electronics in Modern Communications. In The Oxford Series in Electrical and Computer Engineering, 6th ed.; Oxford University Press: Oxford, UK, 2006; ISBN 978-0195179460. [Google Scholar]

- Kokubun, Y. Lightwave Engineering (Optical Science and Engineering), 1st ed.; CRC Press, Inc.: Boca Raton, FL, USA, 2012; ISBN 978-1420046489. [Google Scholar]

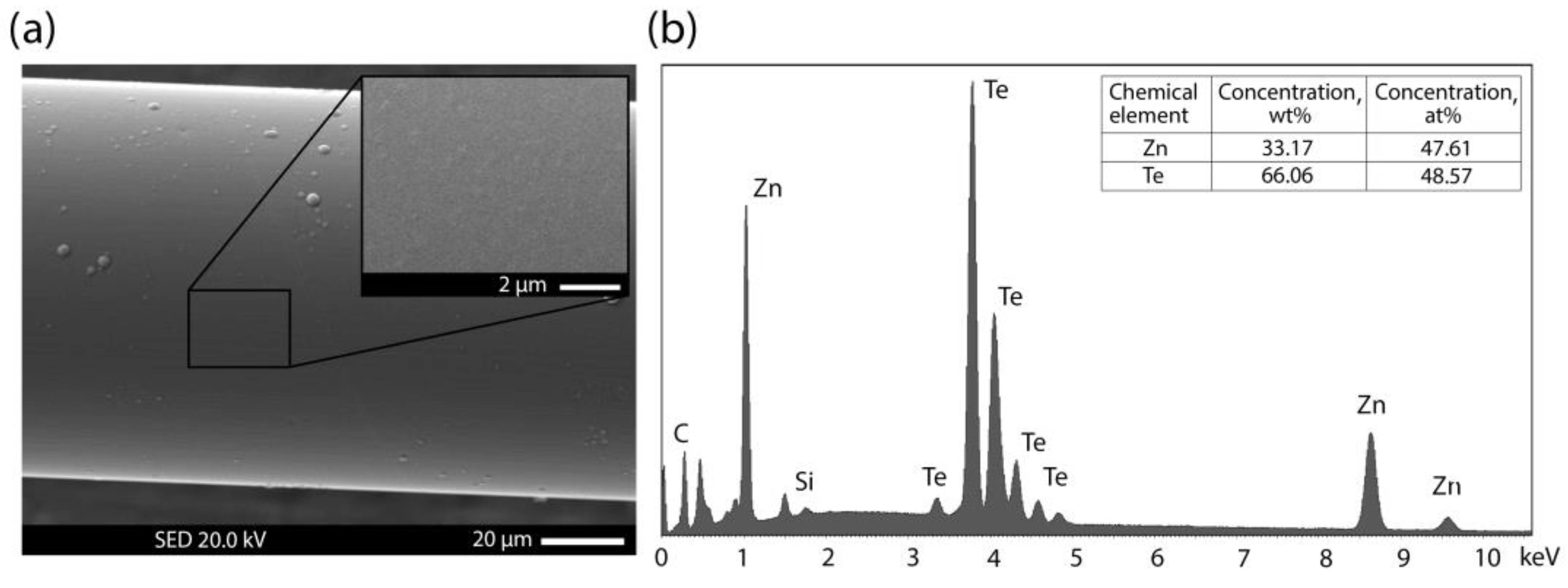

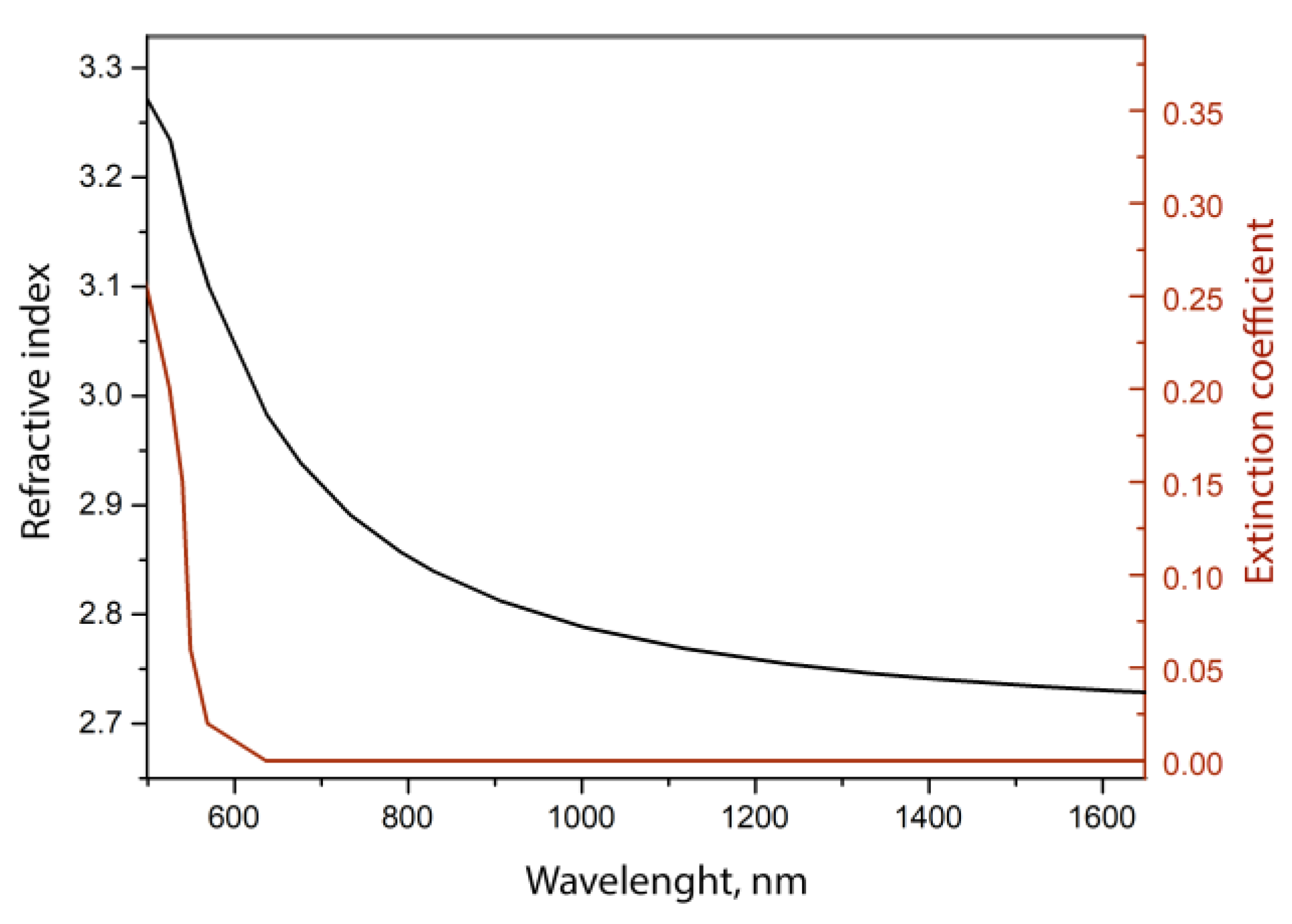

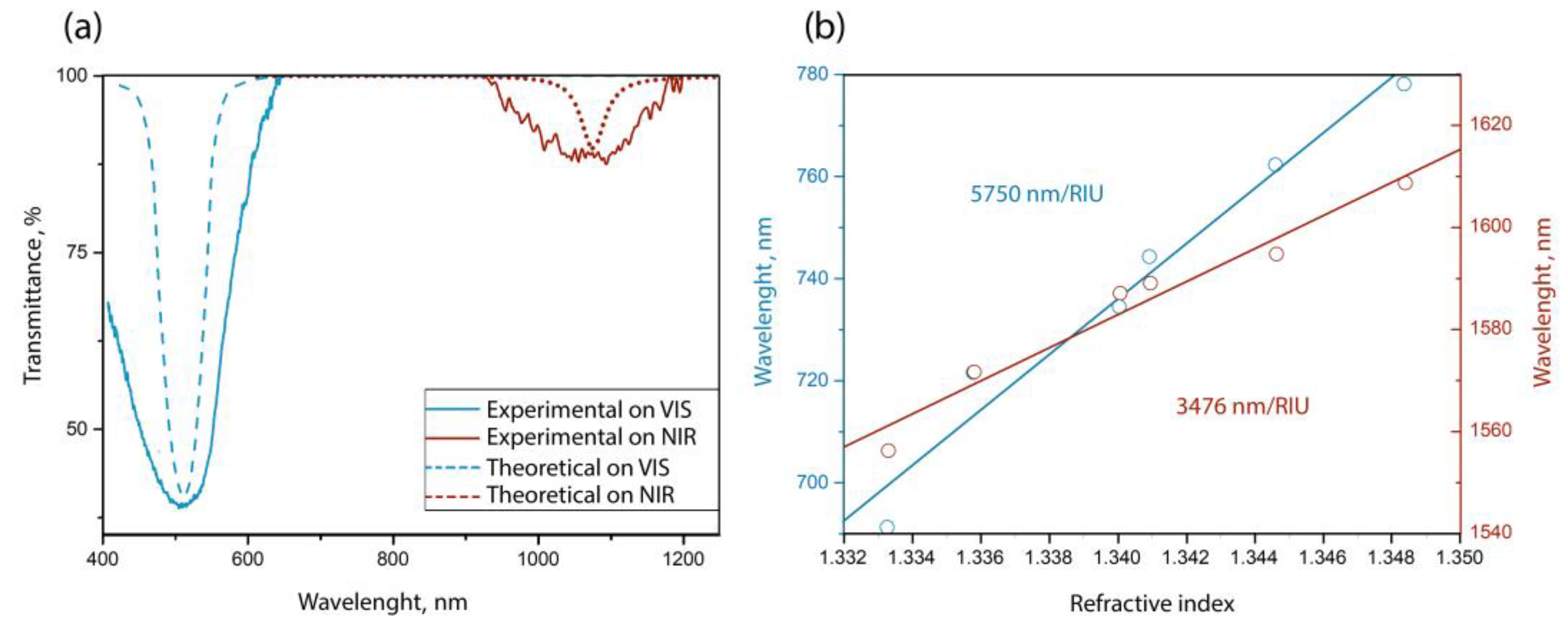

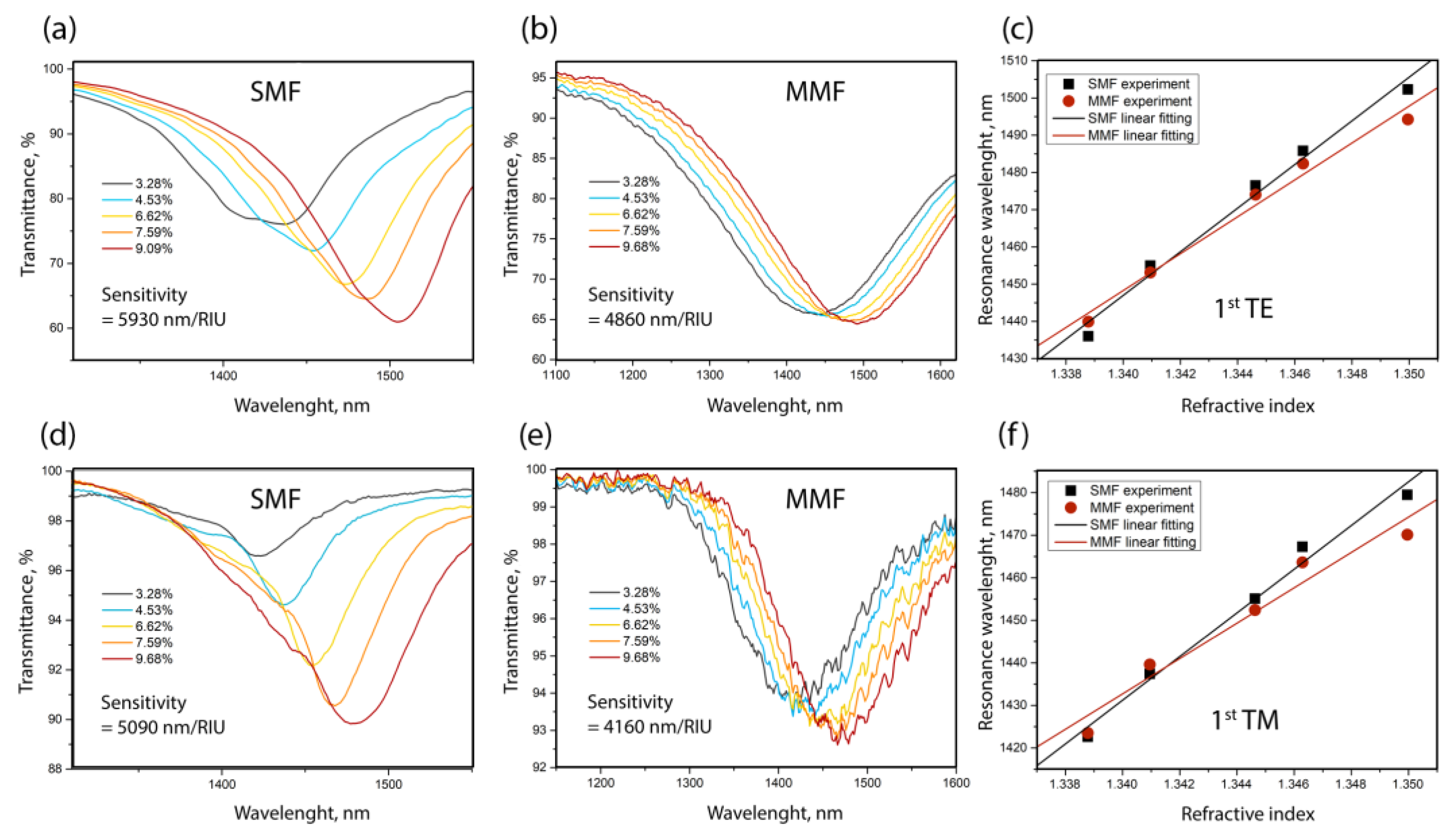

- Kuznetsov, P.I.; Sudas, D.P.; Savelyev, E.A. A study of the lossy mode resonances during the synthesis process of zinc telluride films. Sensors 2022, 22, 8108. [Google Scholar] [CrossRef] [PubMed]

| Fiber Type | Etched Diameter (µm) | Etched Fiber | Coated Fiber | ||

|---|---|---|---|---|---|

| RMS (nm) | Roughness (nm) | RMS (nm) | Roughness (nm) | ||

| SMF | 26.3 | 10.514 | 7.651 | 19.597 | 11.557 |

| MMF | 99.5 | 3.410 | 2.521 | 4.936 | 3.035 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sudas, D.P.; Jitov, V.A.; Kuznetsov, P.I. Various Types of Light Guides for Use in Lossy Mode Resonance-Based Sensors. Sensors 2023, 23, 6049. https://doi.org/10.3390/s23136049

Sudas DP, Jitov VA, Kuznetsov PI. Various Types of Light Guides for Use in Lossy Mode Resonance-Based Sensors. Sensors. 2023; 23(13):6049. https://doi.org/10.3390/s23136049

Chicago/Turabian StyleSudas, Dmitriy P., Viktor A. Jitov, and Petr I. Kuznetsov. 2023. "Various Types of Light Guides for Use in Lossy Mode Resonance-Based Sensors" Sensors 23, no. 13: 6049. https://doi.org/10.3390/s23136049

APA StyleSudas, D. P., Jitov, V. A., & Kuznetsov, P. I. (2023). Various Types of Light Guides for Use in Lossy Mode Resonance-Based Sensors. Sensors, 23(13), 6049. https://doi.org/10.3390/s23136049