Paintable Silicone-Based Corrugated Soft Elastomeric Capacitor for Area Strain Sensing

Abstract

:1. Introduction

2. Background

2.1. Fabrication Process

- PDMS-coated titania (−OSI(CH)) (TPL, Inc., Albuquerque, NM) particles with an average diameter of 100 nm are added in 3 wt% to 5 mL of the liquid silicone WACKER Elastosil P 7670 A (Polydimethyl siloxane (63148-62-9), Polydimethylsiloxane vinyl terminated (68083-19-2), (TSRN 38673700-5112 P)) for a concentration of 30 g/L.

- Rutile titania particles are uniformly dispersed in the silicone matrix using a low-speed homogenizer for 600 s at 650 RPM while the solution is cooled in an iced water bath.

- A volume of 5 mL of the liquid silicone WACKER Elastosil P 7670 B (Polydimethyl siloxane (63148-62-9), (TSRN 38673700-5101P), Polydimethylsiloxane vinyl terminated (68083-19-2), Silazanetreated Silica (68909-20-6), Polydimethyl hydrogenmethyl siloxane (69013-23-6)) is added into the stock solution and mixed using a shear mixer for 180 s at 2000 RPM, yielding a dynamic viscosity of approximately 2000 cP.

- The resulting silicone–titania solution is drop-cast onto an 80 mm × 80 mm non-stick square steel mold. The steel mold contains grooves to create a corrugated pattern. The use of surface corrugation is known to improve strain sensing performance by adding the in-plane stiffness and decreasing the transverse Poisson’s ratio [19].

- The drop-casted solution is cured under room temperature over 6 h, and the film is subsequently peeled from the mold. The resulting film has a mean thickness of 0.4 mm over the non-corrugated area and a corrugation height of 0.35 mm. Remark that the thickness of the dielectric layer can be tuned by controlling the volume of the silicone–titania solution drop-casted into the steel mold.

- Carbon black particles are stored in an oven at 50 °C for 24 h to remove moisture, and an anti-static gun (Milty 5036694022153 Zerostat 3) is used to remove the static charge on the surface of the cured dielectric film before brushing electrodes. A dry stacking process through stamping that has no solvent–elastomer interactions [45] can be employed for future studies.

- The dry carbon black particles are brushed onto both sides of the dielectric layer to form conductive soft stretchable electrodes. The painting process is stopped once the electrode has reached a sheet resistance of approximately 3.6 k/Sq (Botron digital surface resistivity meter, SKU: B8563). In prior work on the SEBS version of the sensor, we conducted accelerating ageing tests and found that the use of carbon black conferred the polymer with long-term durability both mechanically and electromechanically [46]. While a similar study on silicone-cSECs is left to future work, it is hypothesized that the use of carbon black would yield similar conclusions.

- Adhesive copper tapes are glued on the brushed conductive electrodes to create electrical connections to the data acquisition system (DAQ). A thin layer of PELCO conductive carbon glue (TED Pella, USA) is added to the exposed parts of copper tapes to enhance mechanical bonding strength and minimize signal noise. The resulting silicone-cSEC has a permittivity of 4.05 at 100 Hz (Equation (1)) with an effective thickness of 0.52 mm for the electrode section of the sensor, which corresponds to an increase of approximately 40% compared to the pure silicone. The Young’s modulus of the cured silicone composite was found to be 305 kPa using a tensile tester under a strain rate of 2.5%/s.

- As an optional step for deployment, a small amount of WACKER Elastosil P 7670 A and B components are mixed with a weight ratio of 1:1 and applied as a protecting layer onto the surface of the electrodes to improve resilience with respect to weathering. The resulting silicone-cSEC has an initial capacitance of approximately 170 to 200 pF under 1 kHz measuring frequency.

2.2. Electromechanical Model

3. Experiments

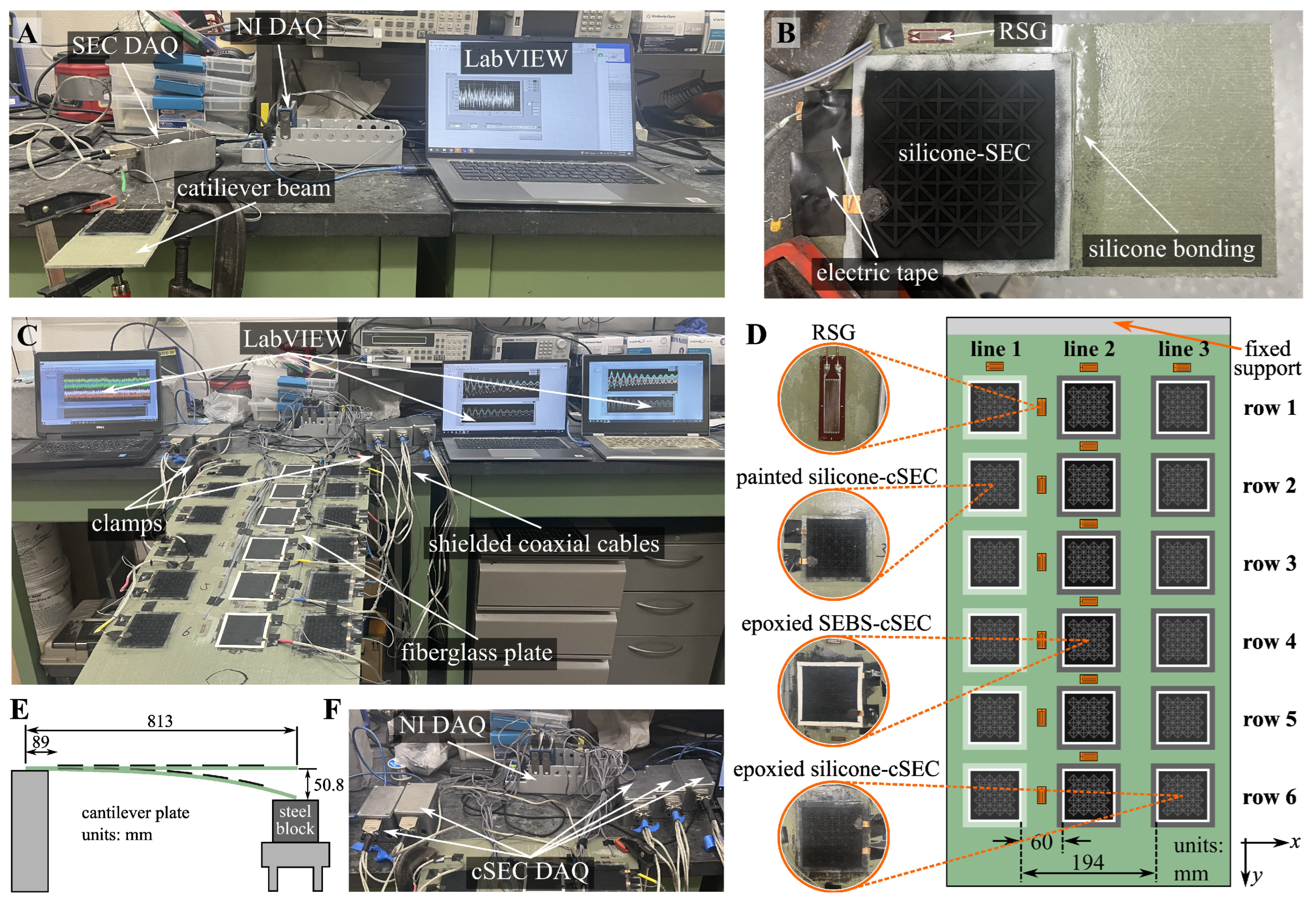

3.1. Cantilever Plate

3.2. Sensor Network Configuration

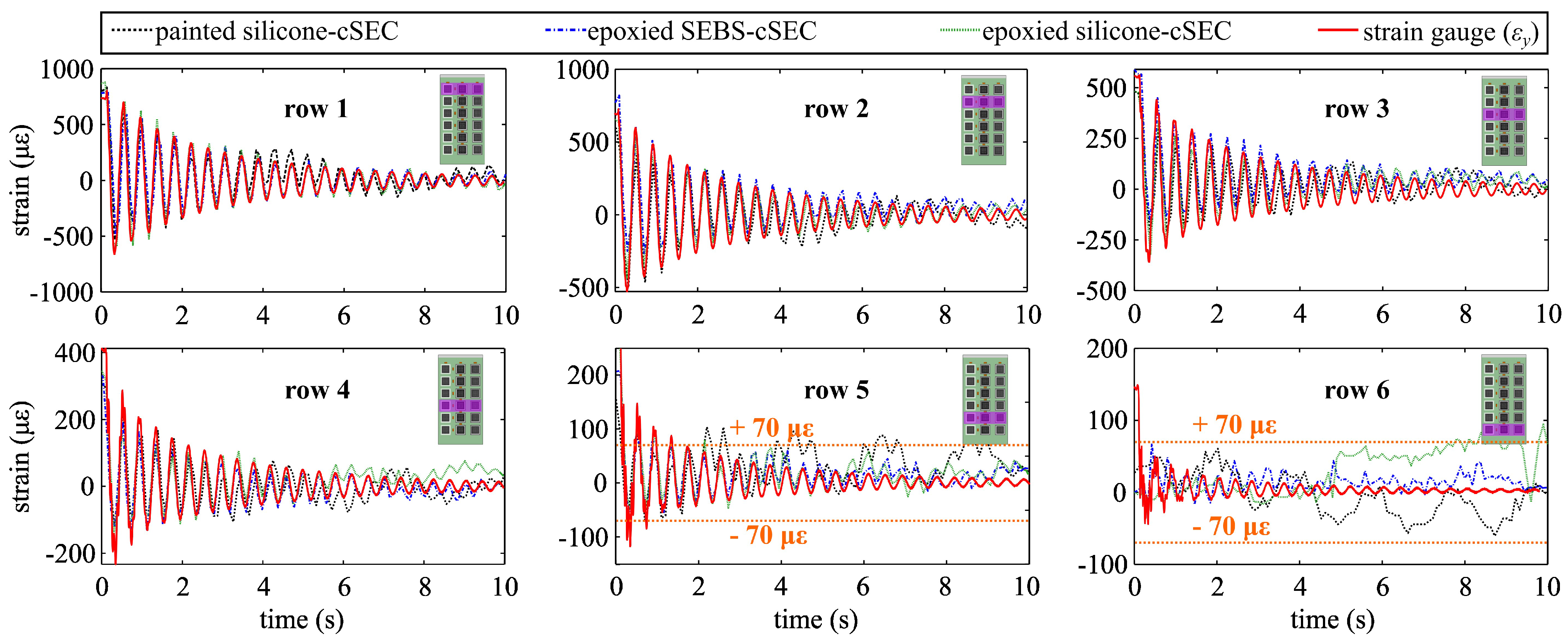

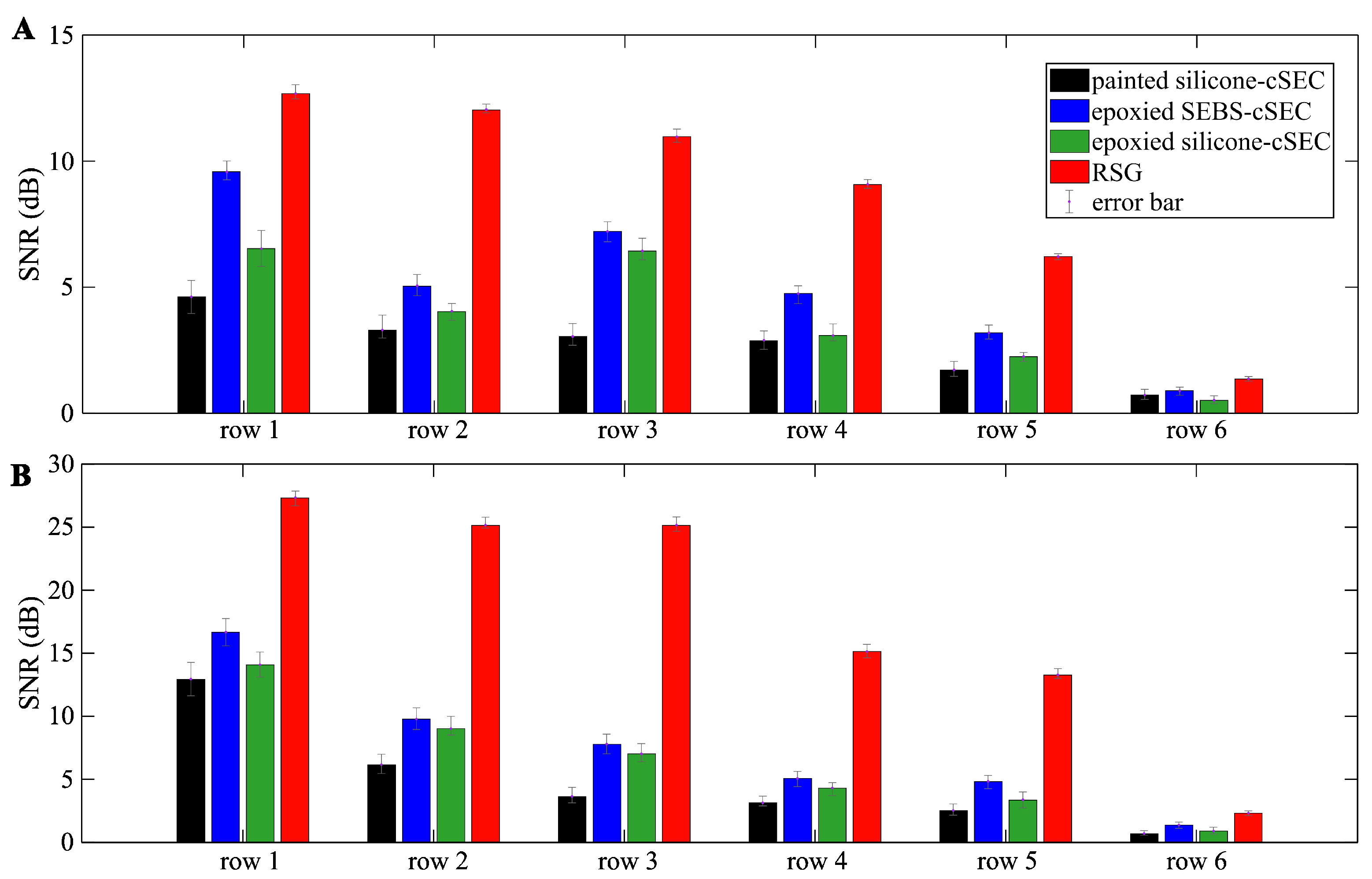

4. Results and Discussion

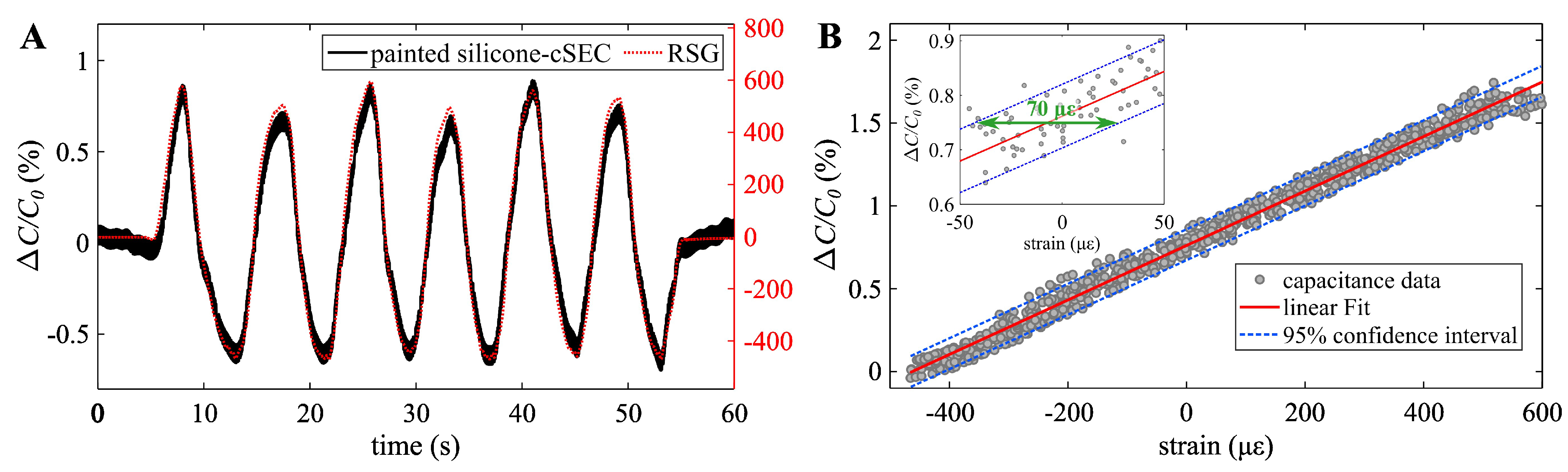

4.1. Electro-Mechanical Behavior

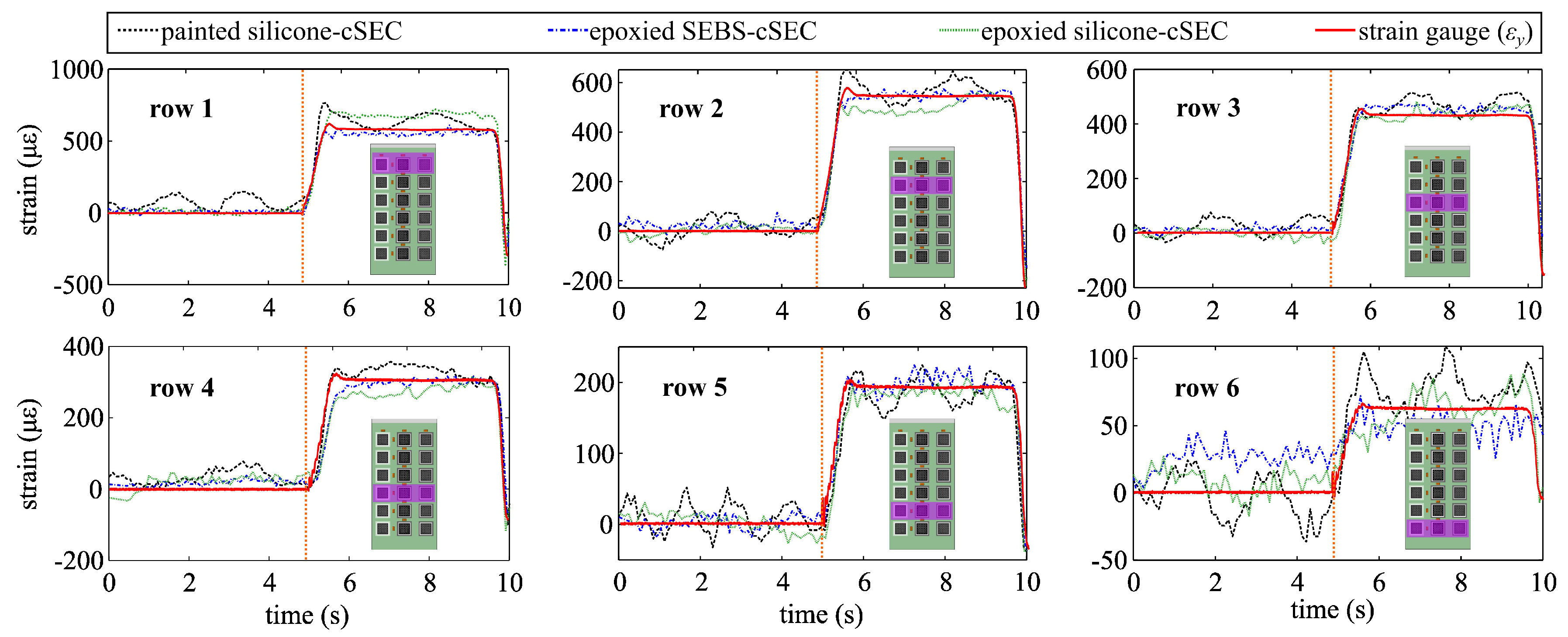

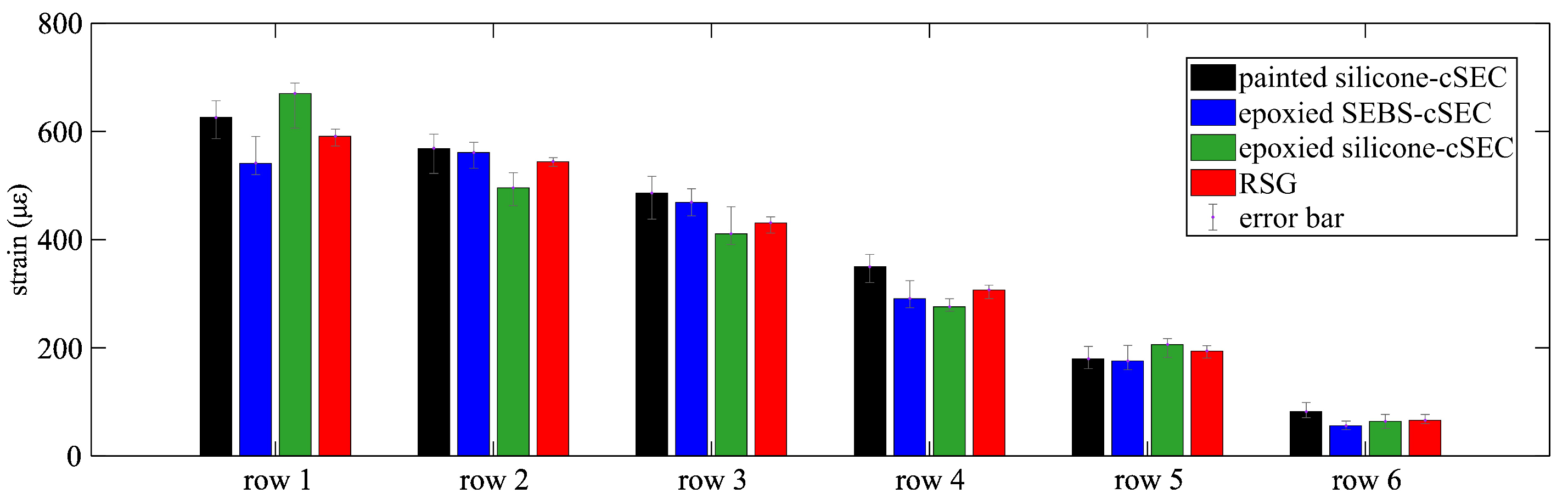

4.2. Network Configuration

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| LAE | Large Area Electronics |

| SHM | Structural Health Monitoring |

| SEBS | Styrene-Ethylene-Butadiene-Styrene |

| cSEC | Corrugated Soft Elastomeric Capacitor |

| DE | Dielectric Elastomer |

| RTV | Room-Temperature-Vulcanizing Silicone |

| RSG | Resistive Strain Gauge |

| CI | Confidence Interval |

| RMSE | Root Mean Square Error |

| MAPE | Mean Absolute Percentage Error |

| FFT | Fast Fourier Transform |

References

- Sony, S.; Laventure, S.; Sadhu, A. A literature review of next-generation smart sensing technology in structural health monitoring. Struct. Control Health Monit. 2019, 26, e2321. [Google Scholar] [CrossRef]

- Liu, Y.; Nayak, S. Structural Health Monitoring: State of the Art and Perspectives. JOM 2012, 64, 789–792. [Google Scholar] [CrossRef]

- Noel, A.B.; Abdaoui, A.; Elfouly, T.; Ahmed, M.H.; Badawy, A.; Shehata, M.S. Structural Health Monitoring Using Wireless Sensor Networks: A Comprehensive Survey. IEEE Commun. Surv. Tutor. 2017, 19, 1403–1423. [Google Scholar] [CrossRef]

- Costa, J.C.; Spina, F.; Lugoda, P.; Garcia-Garcia, L.; Roggen, D.; Münzenrieder, N. Flexible Sensors—From Materials to Applications. Technologies 2019, 7, 35. [Google Scholar] [CrossRef] [Green Version]

- Araromi, O.A.; Graule, M.A.; Dorsey, K.L.; Castellanos, S.; Foster, J.R.; Hsu, W.H.; Passy, A.E.; Vlassak, J.J.; Weaver, J.C.; Walsh, C.J.; et al. Ultra-sensitive and resilient compliant strain gauges for soft machines. Nature 2020, 587, 219–224. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Hu, S.; Xiong, T.; Huang, Y.; Qiu, L. Recent progress in aircraft smart skin for structural health monitoring. Struct. Health Monit. 2021, 21, 2453–2480. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, C.; Pfattner, R.; Yan, H.; Jin, L.; Chen, S.; Molina-Lopez, F.; Lissel, F.; Liu, J.; Rabiah, N.I.; et al. A highly stretchable, transparent, and conductive polymer. Sci. Adv. 2017, 3, e1602076. [Google Scholar] [CrossRef] [Green Version]

- Cheng, X.; Bao, C.; Wang, X.; Dong, W. Stretchable strain sensor based on conductive polymer for structural health monitoring of high-speed train head. Proc. Inst. Mech. Eng. Part J. Mater. Des. Appl. 2019, 234, 496–503. [Google Scholar] [CrossRef]

- Jiang, X.W.; Wang, Z.; Lu, S.W.; Zhang, L.; Wang, X.Q.; Zhang, H.; Lu, J.; Li, B. Vibration monitoring for composite structures using buckypaper sensors arrayed by flexible printed circuit. Int. J. Smart Nano Mater. 2021, 12, 198–217. [Google Scholar] [CrossRef]

- Hu, S.; Wang, Y.; Xiong, T.; Wang, C.; Huang, Y.; Qiu, L. Simulation analysis method of expandable and flexible sensor networks based on the flexible printed circuit process. Struct. Health Monit. 2022, 21, 2670–2687. [Google Scholar] [CrossRef]

- Aygun, L.E.; Kumar, V.; Weaver, C.; Gerber, M.; Wagner, S.; Verma, N.; Glisic, B.; Sturm, J.C. Large-Area Resistive Strain Sensing Sheet for Structural Health Monitoring. Sensors 2020, 20, 1386. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Wang, Y.; Gao, X.; Ji, Y.; Qian, F.; Fan, J.; Wang, H.; Qiu, L.; Li, W.; Yang, H. High-Temperature and Flexible Piezoelectric Sensors for Lamb-Wave-Based Structural Health Monitoring. ACS Appl. Mater. Interfaces 2021, 13, 47764–47772. [Google Scholar] [CrossRef] [PubMed]

- Gao, K.; Zhang, Z.; Weng, S.; Zhu, H.; Yu, H.; Peng, T. Review of Flexible Piezoresistive Strain Sensors in Civil Structural Health Monitoring. Appl. Sci. 2022, 12, 9750. [Google Scholar] [CrossRef]

- Liu, H.; Yan, J.; Kollosche, M.; Bentil, S.A.; Laflamme, S. Surface Textures for Stretchable Capacitive Strain Sensors. Smart Mater. Struct. 2020, 29, 105037. [Google Scholar] [CrossRef]

- Liu, H.; Laflamme, S.; Li, J.; Bennett, C.; Collins, W.N.; Eisenmann, D.J.; Downey, A.R.J.; Ziehl, P.; Jo, H. Investigation of textured sensing skin for monitoring fatigue cracks on fillet welds. Meas. Sci. Technol. 2022, 33, 084001. [Google Scholar] [CrossRef]

- Yan, J.; Downey, A.; Cancelli, A.; Laflamme, S.; Chen, A.; Li, J.; Ubertini, F. Concrete Crack Detection and Monitoring Using a Capacitive Dense Sensor Array. Sensors 2019, 19, 1843. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Laflamme, S.; Li, J.; Bennett, C.; Collins, W.N.; Downey, A.; Ziehl, P.; Jo, H. Soft Elastomeric Capacitor for Angular Rotation Sensing in Steel Components. Sensors 2021, 21, 7017. [Google Scholar] [CrossRef]

- Liu, H.; Laflamme, S.; Zellner, E.M.; Aertsens, A.; Bentil, S.A.; Rivero, I.V.; Secord, T.W. Soft Elastomeric Capacitor for Strain and Stress Monitoring on Sutured Skin Tissues. ACS Sens. 2021, 6, 3706–3714. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Laflamme, S.; Li, J.; Bennett, C.; Collins, W.; Downey, A.; Ziehl, P.; Jo, H. Investigation of surface textured sensing skin for fatigue crack localization and quantification. Smart Mater. Struct. 2021, 30, 105030. [Google Scholar] [CrossRef]

- Davidson, C.J.; Hannigan, J.H.; Bowen, S.E. Effects of inhaled combined Benzene, Toluene, Ethylbenzene, and Xylenes (BTEX): Toward an environmental exposure model. Environ. Toxicol. Pharmacol. 2021, 81, 103518. [Google Scholar] [CrossRef]

- Isah, B.; Mohamad, H.; Ahmad, N. Rock stiffness measurements fibre Bragg grating sensor (FBGs) and the effect of cyanoacrylate and epoxy resin as adhesive materials. Ain Shams Eng. J. 2021, 12, 1677–1691. [Google Scholar] [CrossRef]

- Gong, H.P.; Li, X.R.; Jin, Y.X.; Dong, X.Y. Strain Performance of Fiber Bragg Grating Sensor Fixed by Different Adhesives. Adv. Mater. Res. 2011, 301–303, 415–420. [Google Scholar] [CrossRef]

- Raffler, S.; Bichlmair, S.; Kilian, R. Mounting of sensors on surfaces in historic buildings. Energy Build. 2015, 95, 92–97. [Google Scholar] [CrossRef]

- Liu, X.; Liu, J.; Wang, J.; Wang, T.; Jiang, Y.; Hu, J.; Liu, Z.; Chen, X.; Yu, J. Bioinspired, Microstructured Silk Fibroin Adhesives for Flexible Skin Sensors. ACS Appl. Mater. Interfaces 2020, 12, 5601–5609. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Facchetti, A. Mechanically Flexible Conductors for Stretchable and Wearable E-Skin and E-Textile Devices. Adv. Mater. 2019, 31, 1901408. [Google Scholar] [CrossRef]

- Chen, H.; Song, Y.; Cheng, X.; Zhang, H. Self-powered electronic skin based on the triboelectric generator. Nano Energy 2019, 56, 252–268. [Google Scholar] [CrossRef]

- Patel, M.; Skinner, A. Thermal ageing studies on room-temperature vulcanised polysiloxane rubbers. Polym. Degrad. Stab. 2001, 73, 399–402. [Google Scholar] [CrossRef]

- Ghanbari-Siahkali, A.; Mitra, S.; Kingshott, P.; Almdal, K.; Bloch, C.; Rehmeier, H.K. Investigation of the hydrothermal stability of cross-linked liquid silicone rubber (LSR). Polym. Degrad. Stab. 2005, 90, 471–480. [Google Scholar] [CrossRef]

- Tan, J.; Chao, Y.; Zee, J.V.; Lee, W. Degradation of elastomeric gasket materials in PEM fuel cells. Mater. Sci. Eng. 2007, 445, 669–675. [Google Scholar] [CrossRef]

- Davoodi, E.; Montazerian, H.; Haghniaz, R.; Rashidi, A.; Ahadian, S.; Sheikhi, A.; Chen, J.; Khademhosseini, A.; Milani, A.S.; Hoorfar, M.; et al. 3D-Printed Ultra-Robust Surface-Doped Porous Silicone Sensors for Wearable Biomonitoring. ACS Nano 2020, 14, 1520–1532. [Google Scholar] [CrossRef]

- Mirzanejad, H.; Agheli, M. Soft force sensor made of magnetic powder blended with silicone rubber. Sens. Actuators Phys. 2019, 293, 108–118. [Google Scholar] [CrossRef]

- Taherkhani, B.; Azizkhani, M.B.; Kadkhodapour, J.; Anaraki, A.P.; Rastgordani, S. Highly sensitive, piezoresistive, silicone/carbon fiber-based auxetic sensor for low strain values. Sens. Actuators Phys. 2020, 305, 111939. [Google Scholar] [CrossRef]

- Lee, J.; Kim, J.; Shin, Y.; Jung, I. Ultra-robust wide-range pressure sensor with fast response based on polyurethane foam doubly coated with conformal silicone rubber and CNT/TPU nanocomposites islands. Compos. Part Eng. 2019, 177, 107364. [Google Scholar] [CrossRef]

- Sheng, F.; Zhang, B.; Zhang, Y.; Li, Y.; Cheng, R.; Wei, C.; Ning, C.; Dong, K.; Wang, Z.L. Ultrastretchable Organogel/Silicone Fiber-Helical Sensors for Self-Powered Implantable Ligament Strain Monitoring. ACS Nano 2022, 16, 10958–10967. [Google Scholar] [CrossRef]

- Schweitzer, J.; Merad, S.; Schrodj, G.; Gall, F.B.L.; Vonna, L. Determination of the Crosslinking Density of a Silicone Elastomer. J. Chem. Educ. 2019, 96, 1472–1478. [Google Scholar] [CrossRef]

- Stoyanov, H.; Kollosche, M.; Risse, S.; McCarthy, D.N.; Kofod, G. Elastic block copolymer nanocomposites with controlled interfacial interactions for artificial muscles with direct voltage control. Soft Matter 2011, 7, 194–202. [Google Scholar] [CrossRef]

- Cazacu, M.; Ignat, M.; Racles, C.; Cristea, M.; Musteata, V.; Ovezea, D.; Lipcinski, D. Well-defined silicone–titania composites with good performances in actuation and energy harvesting. J. Compos. Mater. 2013, 48, 1533–1545. [Google Scholar] [CrossRef]

- Yang, D.; Zhang, L.; Liu, H.; Dong, Y.; Yu, Y.; Tian, M. Lead magnesium niobate-filled silicone dielectric elastomer with large actuated strain. J. Appl. Polym. Sci. 2012, 125, 2196–2201. [Google Scholar] [CrossRef]

- Razzaghi-Kashani, M.; Gharavi, N.; Javadi, S. The effect of organo-clay on the dielectric properties of silicone rubber. Smart Mater. Struct. 2008, 17, 065035. [Google Scholar] [CrossRef] [Green Version]

- Wåhlander, M.; Nilsson, F.; Andersson, R.L.; Sanchez, C.C.; Taylor, N.; Carlmark, A.; Hillborg, H.; Malmström, E. Tailoring dielectric properties using designed polymer-grafted ZnO nanoparticles in silicone rubber. J. Mater. Chem. 2017, 5, 14241–14258. [Google Scholar] [CrossRef] [Green Version]

- Guan, S.; Tang, Y.; Song, S.; Liu, H.; Zhao, S. Influence of inter structure of BaTiO3-carbon nanotube hybrid particles on the dielectric properties of PDMS nanocomposites. Mater. Sci. Eng. 2021, 271, 115280. [Google Scholar] [CrossRef]

- Brown, H.R. The Adhesion of Polymers: Relations Between Properties of Polymer Chains and Interface Toughness. J. Adhes. 2006, 82, 1013–1032. [Google Scholar] [CrossRef]

- Skov, A.L.; Yu, L. Optimization Techniques for Improving the Performance of Silicone-Based Dielectric Elastomers. Adv. Eng. Mater. 2017, 20, 1700762. [Google Scholar] [CrossRef]

- Matysek, M.; Lotz, P.; Flittner, K.; Schlaak, H.F. High-Precision Characterization of Dielectric Elastomer Stack Actuators and Their Material Parameters. In Proceedings of the Electroactive Polymer Actuators and Devices (EAPAD), San Diego, CA, USA, 10 April 2008; Bar-Cohen, Y., Ed.; SPIE: Washington, DC, USA, 2008. [Google Scholar] [CrossRef]

- Cohen, A.J.; Kollosche, M.; Yuen, M.C.; Lee, D.Y.; Clarke, D.R.; Wood, R.J. Batch-Sprayed and Stamp-Transferred Electrodes: A New Paradigm for Scalable Fabrication of Multilayer Dielectric Elastomer Actuators. Adv. Funct. Mater. 2022, 32, 2205394. [Google Scholar] [CrossRef]

- Downey, A.; Pisello, A.L.; Fortunati, E.; Fabiani, C.; Luzi, F.; Torre, L.; Ubertini, F.; Laflamme, S. Durability and weatherability of a styrene-ethylene-butylene-styrene (SEBS) block copolymer-based sensing skin for civil infrastructure applications. Sens. Actuators Phys. 2019, 293, 269–280. [Google Scholar] [CrossRef]

- Kong, X.; Li, J.; Collins, W.; Bennett, C.; Laflamme, S.; Jo, H. Sensing distortion-induced fatigue cracks in steel bridges with capacitive skin sensor arrays. Smart Mater. Struct. 2018, 27, 115008. [Google Scholar] [CrossRef] [Green Version]

- Seitz, V.; Arzt, K.; Mahnel, S.; Rapp, C.; Schwaminger, S.; Hoffstetter, M.; Wintermantel, E. Improvement of adhesion strength of self-adhesive silicone rubber on thermoplastic substrates Comparison of an atmospheric pressure plasma jet (APPJ) and a Pyrosil® flame. Int. J. Adhes. Adhes. 2016, 66, 65–72. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Laflamme, S.; Kollosche, M. Paintable Silicone-Based Corrugated Soft Elastomeric Capacitor for Area Strain Sensing. Sensors 2023, 23, 6146. https://doi.org/10.3390/s23136146

Liu H, Laflamme S, Kollosche M. Paintable Silicone-Based Corrugated Soft Elastomeric Capacitor for Area Strain Sensing. Sensors. 2023; 23(13):6146. https://doi.org/10.3390/s23136146

Chicago/Turabian StyleLiu, Han, Simon Laflamme, and Matthias Kollosche. 2023. "Paintable Silicone-Based Corrugated Soft Elastomeric Capacitor for Area Strain Sensing" Sensors 23, no. 13: 6146. https://doi.org/10.3390/s23136146

APA StyleLiu, H., Laflamme, S., & Kollosche, M. (2023). Paintable Silicone-Based Corrugated Soft Elastomeric Capacitor for Area Strain Sensing. Sensors, 23(13), 6146. https://doi.org/10.3390/s23136146