Flexible Pressure Sensors for Integration into Karate Body Protector

Abstract

:1. Introduction and Objectives

2. Materials and Methods

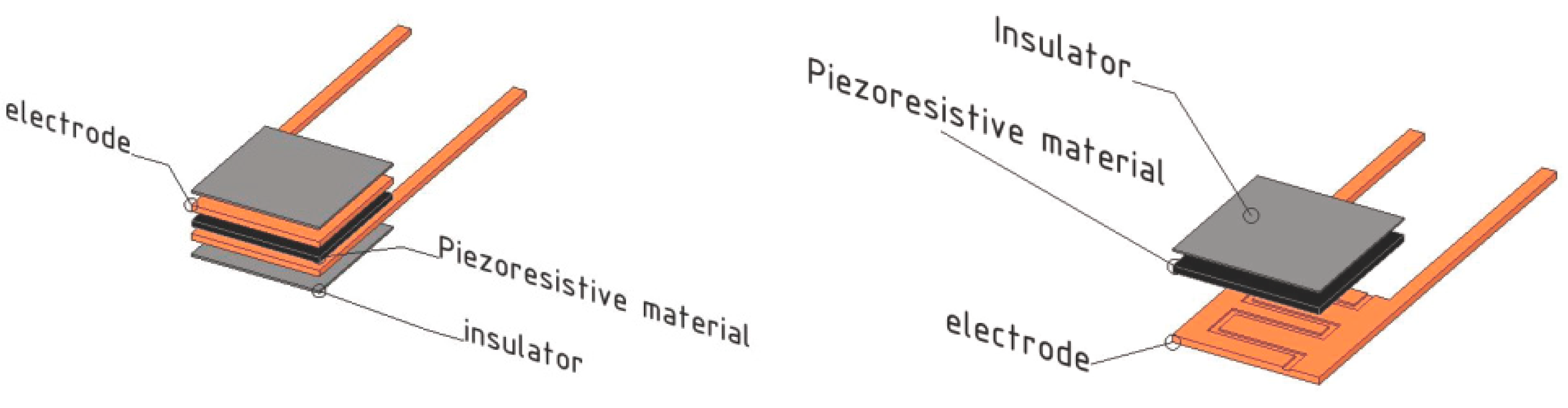

2.1. Small-Scale Pressure Sensor Preparation

2.1.1. Manufacture of the Pressure Sensors Using Ultrasonic Welding

2.1.2. Manufacture of the Pressure Sensors Using a Hot Press

2.1.3. Building Pressure Sensors Using Bonding Materials

2.2. Large-Scale Pressure Sensor Preparation for Integrating into Body Protector

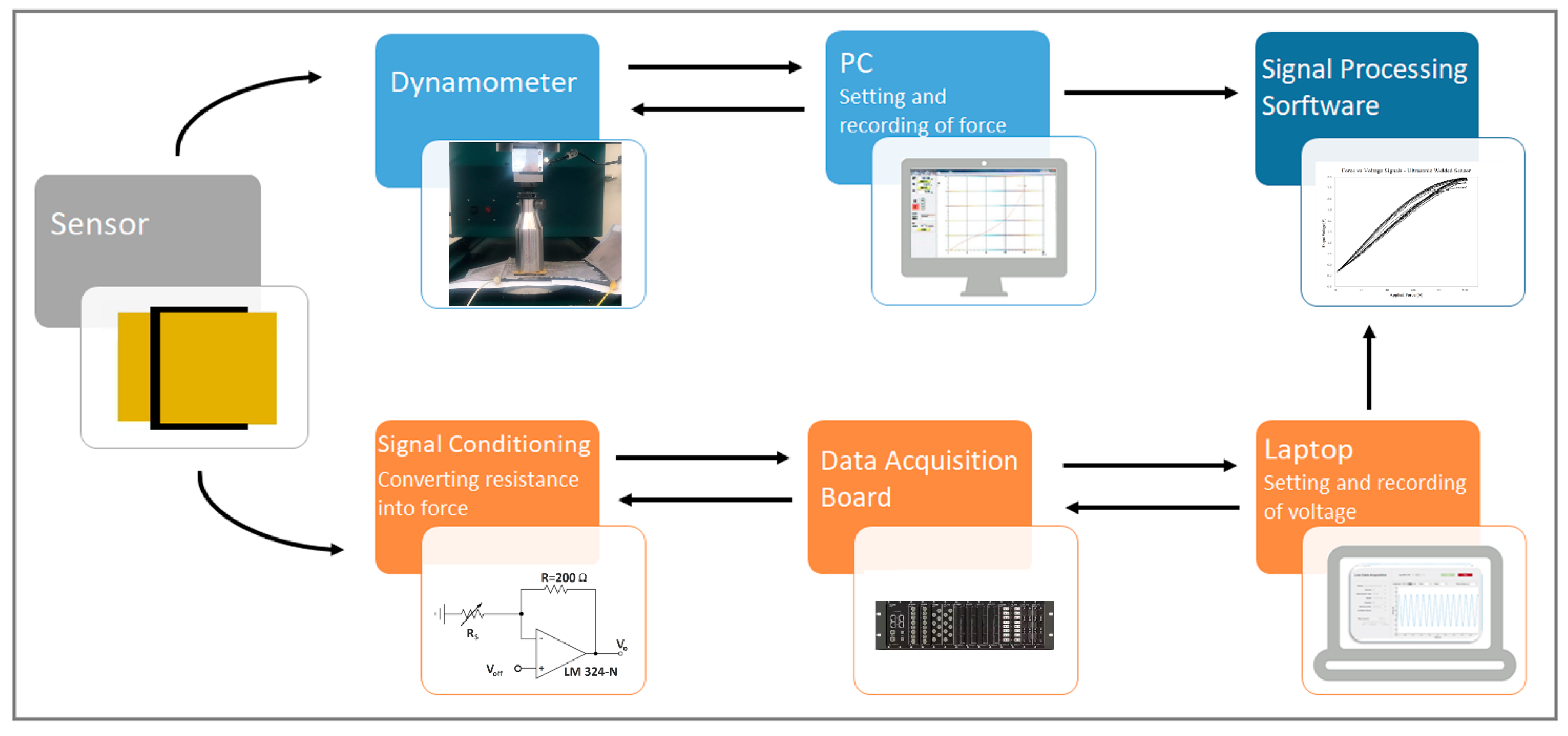

2.3. Pressure Sensors Testing

3. Results and Discussion

3.1. Small-Scale Sensor Results

3.1.1. Sensor Assembled Using Ultrasonic Welding

3.1.2. Sensors Welded Directly in the Hot Press

3.1.3. Sensors Assembled Using Bonding Materials

3.2. The Large-Scale Sensor Results

4. Conclusions

- The sensors developed using the hot press welding technique were nonfunctional due to the possibility of silver nanoparticles being embedded into the piezoresistive film;

- Functional sensors were obtained by joining the layers at four sides using the ultrasonic welding technique as well as by using thermoplastic net (TN) and thermoplastic web (TW) materials. Due to the bonding materials’ uniform surface structure, TN gave the best results as a pressure sensor.

- The sensor prepared using TN showed nonuniform pressure sensing ability, from which it can be concluded that, at large dimensions, nonuniform bonding may occur in the curing process.

- The sensor prepared using the double-sided film that was laser-cut to create adjacent circles of 15 mm in diameter also showed variations in output voltage in different measurement positions (po1 to po5) in the cyclic tests.

- Similar voltage outputs were obtained in the tests of the sensor produced using 2 mm diameters of adjacent circles cut into double-sided film in different measurement positions.

- The variability of the sensor responses at different positions may be explained by construction issues, but also by nonuniform resistances of the piezoelectric film used.

- Regarding the data obtained, it was clear that the sensor was able to detect every punch, even the light punches, and, as a result, it can be used in sport karate.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schwartz, M. Encyclopedia of Materials, Parts and Finishes, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2002; p. 936. [Google Scholar]

- Bosowski, P.; Hoerr, M.; Mecnika, V.; Gries, T.; Jockenhövel, S. Design and manufacture of textile-based sensors. In Electronic Textiles; Dias, T., Ed.; Woodhead Publishing: Cambridge, UK, 2015; pp. 75–107. [Google Scholar]

- Grancarić, A.M.; Jerković, I.; Koncar, V.; Cochrane, C.; Kelly, F.M.; Soulat, D.; Legrand, X. Conductive polymers for smart textile applications. J. Ind. Text. 2018, 48, 612–642. [Google Scholar] [CrossRef]

- Shi, J.; Liu, S.; Zhang, L.; Yang, B.; Shu, L.; Yang, Y.; Ren, M.; Wang, Y.; Chen, J.; Chen, W.; et al. Smart textile-integrated microelectronic systems for wearable applications. Adv. Mater. 2020, 32, 1901958. [Google Scholar] [CrossRef] [PubMed]

- Simegnaw, A.A.; Malengier, B.; Rotich, G.; Tadesse, M.G.; Van Langenhove, L. Review on the Integration of Microelectronics for E-Textile. Materials 2021, 14, 5113. [Google Scholar] [CrossRef] [PubMed]

- Cochrane, C.; Koncar, V.; Lewandowski, M.; Dufour, C. Design and development of a flexible strain sensor for textile structures based on a conductive polymer composite. Sensors 2007, 7, 473–492. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Liu, J.; Zhuang, R.; Mäder, E.; Heinrich, G.; Gao, S. Single MWNT-glass fiber as strain sensor and switch. Adv. Mater. 2011, 23, 3392–3397. [Google Scholar] [CrossRef] [PubMed]

- Yamada, T.; Hayamizu, Y.; Yamamoto, Y.; Yomogida, Y.; Izadi-Najafabadi, A.; Futaba, D.N.; Hata, K. A stretchable carbon nanotube strain sensor for human-motion detection. Nat. Nanotechnol. 2011, 6, 296–301. [Google Scholar] [CrossRef]

- Wang, J.; Lu, C.; Zhang, K. Textile-based strain sensor for human motion detection. Energy Environ. Mater. 2020, 3, 80–100. [Google Scholar] [CrossRef] [Green Version]

- Meyer, J.; Lukowicz, P.; Troster, G. Textile pressure sensor for muscle activity and motion detection. In Proceedings of the 10th IEEE International Symposium on Wearable Computers, Montreux, Switzerland, 11 October 2006. [Google Scholar]

- Rothmaier, M.; Luong, M.P.; Clemens, F. Textile pressure sensor made of flexible plastic optical fibers. Sensors 2008, 8, 4318–4329. [Google Scholar] [CrossRef] [Green Version]

- Carvalho, H.; Yao, Y.; Gonçalves, L.M. Flexible force sensors for e-textiles. IOP Conf. Ser. Mater. Sci. Eng. 2017, 254, 072007. [Google Scholar] [CrossRef]

- Gomes, P.; Tama, D.; Yao, Y.; Abreu, M.J.; Souto, A.P.; Carvalho, H. Development of pressure sensors for smart textiles. IOP Conf. Ser. Mater. Sci. Eng. 2018, 460, 012024. [Google Scholar] [CrossRef] [Green Version]

- Carvalho, H.; Tama, D.; Gomes, P.; Abreu, M.J.; Yao, Y.; Souto, A.P. Flexible piezoresistive pressure sensors for smart textiles. IOP Conf. Ser. Mater. Sci. Eng. 2018, 459, 012035. [Google Scholar] [CrossRef]

- Carbonaro, N.; Laurino, M.; Arcarisi, L.; Menicucci, D.; Gemignani, A.; Tognetti, A. Textile-based pressure sensing matrix for in-bed monitoring of subject sleeping posture and breathing activity. Appl. Sci. 2021, 11, 2552. [Google Scholar] [CrossRef]

- Husain, M.D.; Kennon, R. Preliminary investigations into the development of textile based temperature sensor for healthcare applications. Fibers 2013, 1, 2–10. [Google Scholar] [CrossRef] [Green Version]

- Ataman, C.; Kinkeldei, T.; Vasquez-Quintero, A.; Molina-Lopez, F.; Courbat, J.; Cherenack, K.; Briand, D.; Tröster, G.; De Rooij, N.F. Humidity and temperature sensors on plastic foil for textile integration. Procedia Eng. 2011, 25, 136–139. [Google Scholar] [CrossRef]

- Soukup, R.; Hamacek, A.; Mracek, L.; Reboun, J. Textile based temperature and humidity sensor elements for healthcare applications. In Proceedings of the 37th International Spring Seminar on Electronics Technology, Dresden, Germany, 7–11 May 2014. [Google Scholar]

- Weremczuk, J.; Tarapata, G.; Jachowicz, R. Humidity sensor printed on textile with use of ink-jet technology. Procedia Eng. 2012, 47, 1366–1369. [Google Scholar] [CrossRef] [Green Version]

- Tama, D.; Gomes, P.; Abreu, M.J.; Souto, A.P.; Carvalho, H. Developing Smart Body Protector for Sports Karate. In Proceedings of the 14th International Izmir Textile and Apparel Symposium, Izmir, Türkiye, 25–28 October 2017. [Google Scholar]

- Valle-Lopera, D.A.; Castaño-Franco, A.F.; Gallego-Londoño, J.; Hernández-Valdivieso, A.M. Test and fabrication of piezoresistive sensors for contact pressure measurement. Rev. Fac. Ing. Univ. Antioq. 2017, 82, 47–52. [Google Scholar] [CrossRef] [Green Version]

- Edmison, J.; Jones, M.; Nakad, Z.; Martin, T. Using piezoelectric materials for wearable electronic textiles. In Proceedings of the Sixth International Symposium on Wearable Computers, Seattle, WA, USA, 7–10 October 2002. [Google Scholar]

- Rendl, C.; Greindl, P.; Haller, M.; Zirkl, M.; Stadlober, B.; Hartmann, P. PyzoFlex: Printed piezoelectric pressure sensing foil. In Proceedings of the 25th Annual ACM symposium on User interface software and technology, Cambridge, MA, USA, 7–10 October 2012. [Google Scholar]

- Chen, J.J.; Lin, G.Q.; Wang, Y.; Sowade, E.; Baumann, R.R.; Feng, Z.S. Fabrication of conductive copper patterns using reactive inkjet printing followed by two-step electroless plating. Appl. Surf. Sci. 2017, 396, 202–207. [Google Scholar] [CrossRef]

- Ahn, S.; Cho, Y.; Park, S.; Kim, J.; Sun, J.; Ahn, D.; Lee, M.; Kim, D.; Kim, T.; Shin, H.; et al. Wearable multimode sensors with amplified piezoelectricity due to the multi local strain using 3D textile structure for detecting human body signals. Nano Energy 2020, 74, 104932. [Google Scholar] [CrossRef]

- Ullrich, J.; Eisenreich, M.; Zimmermann, Y.; Mayer, D.; Koehne, N.; Tschannett, J.F.; Mahmud-Ali, A.; Bechtold, T. Piezo-Sensitive Fabrics from Carbon Black Containing Conductive Cellulose Fibres for Flexible Pressure Sensors. Materials 2020, 13, 5150. [Google Scholar] [CrossRef]

- Sergio, M.; Manaresi, N.; Nicolini, M.; Gennaretti, D.; Tartagni, M.; Guerrieri, R. A textile-based capacitive pressure sensor. Sens. Lett. 2004, 2, 153–160. [Google Scholar] [CrossRef]

- Masihi, S.; Panahi, M.; Maddipatla, D.; Bose, A.K.; Zhang, X.; Hanson, A.J.; Palaniappan, V.; Narakathu, B.B.; Bazuin, B.J.; Atashbar, M.Z. A novel printed fabric based porous capacitive pressure sensor for flexible electronic applications. In Proceedings of the 2019 IEEE SENSORS, Montreal, QC, Canada, 27–30 October 2019; pp. 1–4. [Google Scholar]

- Meyer, J.; Arnrich, B.; Schumm, J.; Troster, G. Design and modeling of a textile pressure sensor for sitting posture classification. IEEE Sens. J. 2010, 10, 1391–1398. [Google Scholar] [CrossRef]

- Holleczek, T.; Rüegg, A.; Harms, H.; Tröster, G. Textile pressure sensors for sports applications. In Proceedings of the SENSORS, 2010 IEEE, Waikoloa, HI, USA, 1–4 November 2010; pp. 732–737. [Google Scholar]

- Zhou, Z.; Li, Y.; Cheng, J.; Chen, S.; Hu, R.; Yan, X.; Liao, X.; Xu, C.; Yu, J.; Li, L. Supersensitive all-fabric pressure sensors using printed textile electrode arrays for human motion monitoring and human–machine interaction. J. Mater. Chem. 2018, 6, 13120–13127. [Google Scholar] [CrossRef]

- Donati, M.; Cecchi, F.; Bonaccorso, F.; Branciforte, M.; Dario, P.; Vitiello, N. A modular sensorized mat for monitoring infant posture. Sensors 2013, 14, 510–531. [Google Scholar] [CrossRef]

- He, J.; Zhang, Y.; Zhou, R.; Meng, L.; Chen, T.; Mai, W.; Pan, C. Recent advances of wearable and flexible piezoresistivity pressure sensor devices and its future prospects. J. Mater. 2020, 6, 86–101. [Google Scholar] [CrossRef]

- Gong, S.; Schwalb, W.; Wang, Y.; Chen, Y.; Tang, Y.; Si, J.; Shirinzadeh, B.; Cheng, W. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires. Nat. Commun. 2014, 5, 3132. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, Z.; Yan, C.; Liu, Z.; Fu, X.; Peng, L.M.; Hu, Y.; Zheng, Z. Machine-washable textile triboelectric nanogenerators for effective human respiratory monitoring through loom weaving of metallic yarns. Adv. Mater. 2016, 28, 10267–10274. [Google Scholar] [CrossRef]

- Cao, R.; Pu, X.; Du, X.; Yang, W.; Wang, J.; Guo, H.; Zhao, S.; Yuan, Z.; Zhang, C.; Li, C.; et al. Screen-printed washable electronic textiles as self-powered touch/gesture tribo-sensors for intelligent human–machine interaction. ACS Nano 2018, 12, 5190–5196. [Google Scholar] [CrossRef]

- Gomes, P.; Tama, D.; Carvalho, H.; Souto, A.P. Resistance variation of conductive ink applied by the screen printing technique on different substrates. Color. Technol. 2020, 136, 130–136. [Google Scholar] [CrossRef]

- Luo, S.; Liu, T. Structure–property–processing relationships of single-wall carbon nanotube thin film piezoresistive sensors. Carbon 2013, 59, 315–324. [Google Scholar] [CrossRef]

- Müller, S.; Schröter, C.; Gross, H.M. Smart fur tactile sensor for a socially assistive mobile robot. In International Conference on Intelligent Robotics and Applications; Springer: Cham, Switzerland, 2015; pp. 49–60. [Google Scholar]

- Zhu, Y.; Jiang, S.; Xiao, Y.; Yu, J.; Sun, L.; Zhang, W. A flexible three-dimensional force sensor based on PI piezoresistive film. J. Mater. Sci. Mater. Electron. 2018, 29, 19830–19839. [Google Scholar] [CrossRef]

- Binelli, M.R.; van Dommelen, R.; Nagel, Y.; Kim, J.; Haque, R.I.; Coulter, F.B.; Siqueira, G.; Studart, A.R.; Briand, D. Digital manufacturing of personalised footwear with embedded sensors. Sci. Rep. 2023, 13, 1962. [Google Scholar] [CrossRef] [PubMed]

- Duan, Z.; Yuan, Z.; Jiang, Y.; Liu, Y.; Tai, H. Amorphous carbon material of daily carbon ink: Emerging applications in pressure, strain, and humidity sensors. J. Mater. Chem. C 2023, 11, 5585. [Google Scholar] [CrossRef]

- Gilanizadehdizaj, G.; Aw, K.C.; Stringer, J.; Bhattacharyya, D. Facile fabrication of flexible piezo-resistive pressure sensor array using reduced graphene oxide foam and silicone elastomer. Sens. Actuators A Phys. 2022, 340, 113549. [Google Scholar] [CrossRef]

- Zhu, Y.; Hartel, M.C.; Yu, N.; Garrido, P.R.; Kim, S.; Lee, J.; Bandary, P.; Guan, S.; Lin, H.; Emaminejad, S.; et al. Epidermis-inspired wearable piezoresistive pressure sensors using reduced graphene oxide self-wrapped copper nanowire networks. Small Methods 2022, 6, 2100900. [Google Scholar] [CrossRef] [PubMed]

- Duan, Y.; He, S.; Wu, J.; Su, B.; Wang, Y. Recent progress in flexible pressure sensor arrays. Nanomaterials 2022, 12, 2495. [Google Scholar] [CrossRef] [PubMed]

- Gilanizadehdizaj, G.; Bhattacharyya, D.; Stringer, J.; Aw, K. Elucidating the Conducting Mechanisms in a Flexible Piezoresistive Pressure Sensor Using Reduced Graphene Oxide Film in Silicone Elastomer. Sensors 2023, 23, 2443. [Google Scholar] [CrossRef]

- Arruda, L.M.; Moreira, I.P.; Sanivada, U.K.; Carvalho, H.; Fangueiro, R. Development of piezoresistive sensors based on graphene nanoplatelets screen-printed on woven and knitted fabrics: Optimisation of active layer formulation and transversal/longitudinal textile direction. Materials 2022, 15, 5185. [Google Scholar] [CrossRef]

- TDS. Capling. Available online: https://www.caplinq.com/index.php?option=com_filecabinet&cid[0]=106&lang=en&task=download&tmpl=component#product=1232 (accessed on 8 September 2018).

- Shieldex Bremen, R.S. Available online: https://www.shieldex.de/en/products/shieldex-bremen-rs/ (accessed on 10 May 2018).

- Demir, A.; Bozaci, E.; Gülümser, T.; Sarikanat, M. An ecological approach for the surface modification of aramid fibers. Tekst. Konfeksiyon 2016, 26, 256–261. [Google Scholar]

- Souto, A.P.; Carneiro, N.; Mendes, F.; Dias, P. Development of a new vat dyeing process for cellulose materials pre-treated with corona. In Textiles for Sustainable Development; Nova Science Publisher, Inc.: Hauppauge, NY, USA, 2007; pp. 276–283. [Google Scholar]

- Özgüney, A.T.; Bozacι, E.; Demir, A.; Özdoğan, E. Inkjet printing of linen fabrics pretreated with atmospheric plasma and various print pastes. AATCC J. Res. 2017, 4, 22–27. [Google Scholar] [CrossRef]

- Pedro, A.; Ribeiro, F.; Carneiro, N. Polyamide 6.6 Modified by DBD Plasma Treatment for Anionic Dyeing Processes. In Textile Dyeing; InTech: London, UK, 2010; pp. 241–260. [Google Scholar]

- Kalantari, M.; Dargahi, J.; Kövecses, J.; Mardasi, M.G.; Nouri, S. A new approach for modeling piezoresistive force sensors based on semiconductive polymer composites. IEEE/ASME Trans. Mechatron. 2011, 17, 572–581. [Google Scholar] [CrossRef] [Green Version]

- Perabo, C. Tighter Specifications on Linqstat Volume Conductive Plastic. Available online: https://www.caplinq.com/blog/tighter-specifications-on-linqstat-volume-conductive-plastic_881/ (accessed on 14 April 2023).

- Perabo, C. Which Linqstat Product Is Right for Pressure Sensors? Available online: https://www.caplinq.com/blog/which-linqstat-product-is-right-for-pressure-sensors_890/ (accessed on 14 April 2023).

| Specification | Conductive Polyethylene Film | Conductive Fabric |

|---|---|---|

| Description | Carbon-loaded PE | Silver-plated polyamide fabric (RS) |

| Plating | - | 99% Pure silver |

| Surface Resistivity | ±50,000 Ω/sq | Average < 0.3 Ω/sq |

| Total Thickness | 0.1 mm | 0.090 mm ± 12% |

| Weight | - | 43 g/m² ± 10% |

| Temperature Range | up to 115 °C | −30 °C to 90 °C |

| Density | 1 g/cm3 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tama Birkocak, D.; Gomes, P.; Carvalho, H. Flexible Pressure Sensors for Integration into Karate Body Protector. Sensors 2023, 23, 6524. https://doi.org/10.3390/s23146524

Tama Birkocak D, Gomes P, Carvalho H. Flexible Pressure Sensors for Integration into Karate Body Protector. Sensors. 2023; 23(14):6524. https://doi.org/10.3390/s23146524

Chicago/Turabian StyleTama Birkocak, Derya, Pedro Gomes, and Helder Carvalho. 2023. "Flexible Pressure Sensors for Integration into Karate Body Protector" Sensors 23, no. 14: 6524. https://doi.org/10.3390/s23146524

APA StyleTama Birkocak, D., Gomes, P., & Carvalho, H. (2023). Flexible Pressure Sensors for Integration into Karate Body Protector. Sensors, 23(14), 6524. https://doi.org/10.3390/s23146524