Microbial Fuel Cell Biosensor with Capillary Carbon Source Delivery for Real-Time Toxicity Detection

Abstract

:1. Introduction

2. Materials and Methods

2.1. Stock Solutions and Analytical Methods

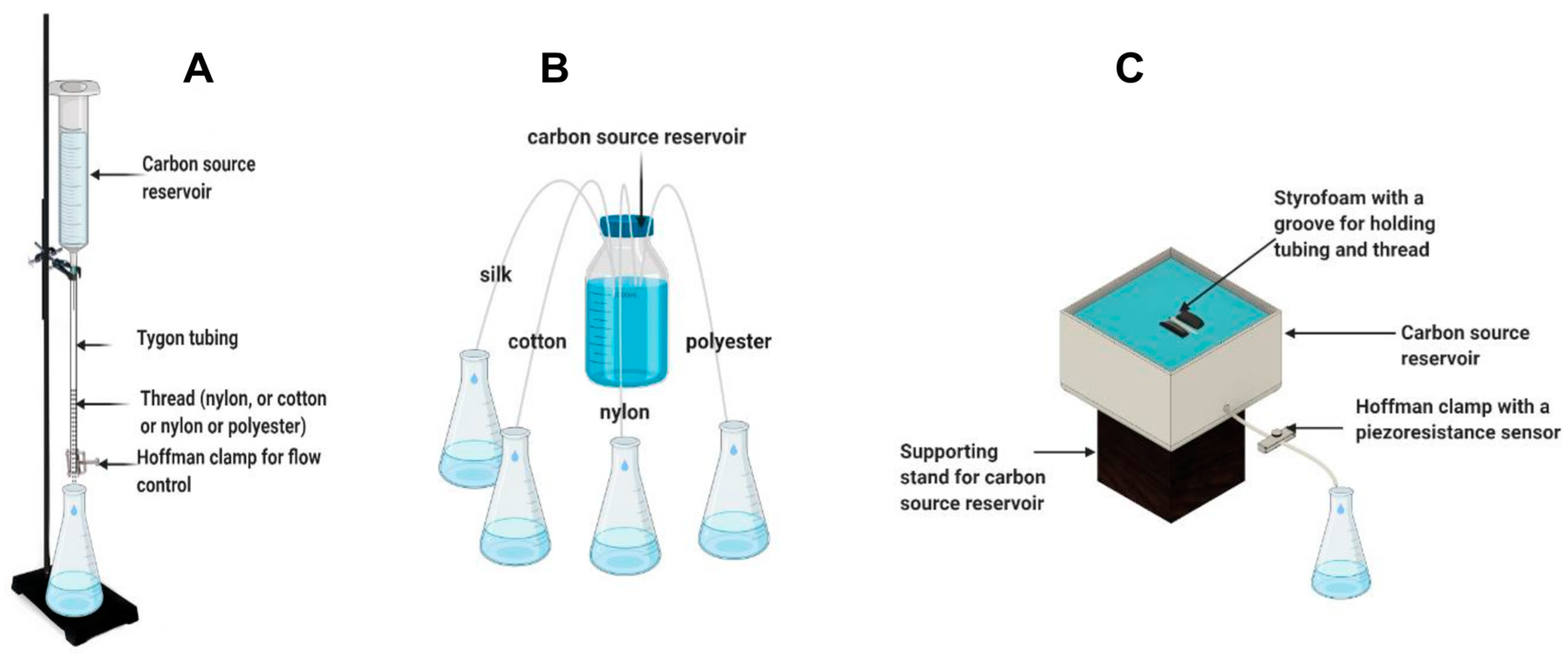

2.2. Capillary Carbon Source Delivery Systems

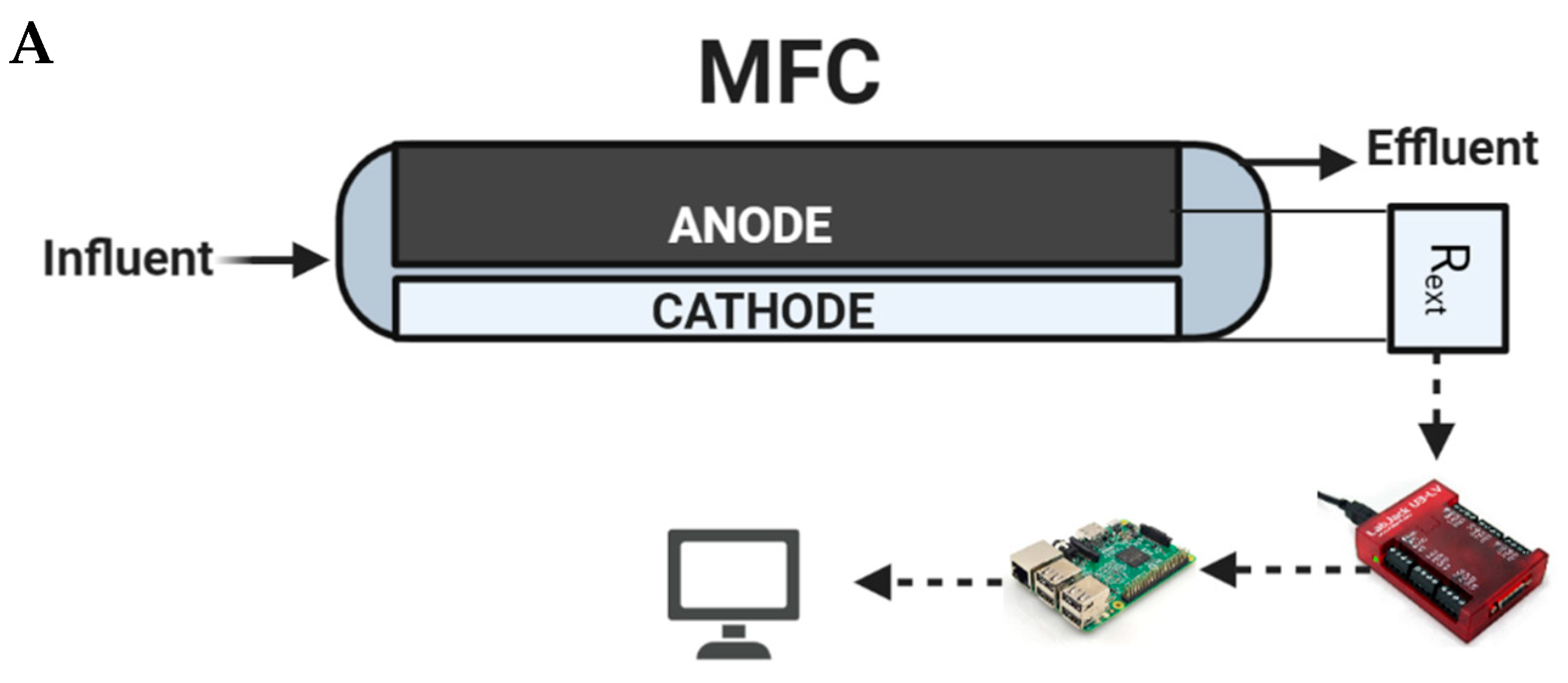

2.3. Biosensor Design and Operation

2.4. Microbial Community Analysis

3. Results and Discussion

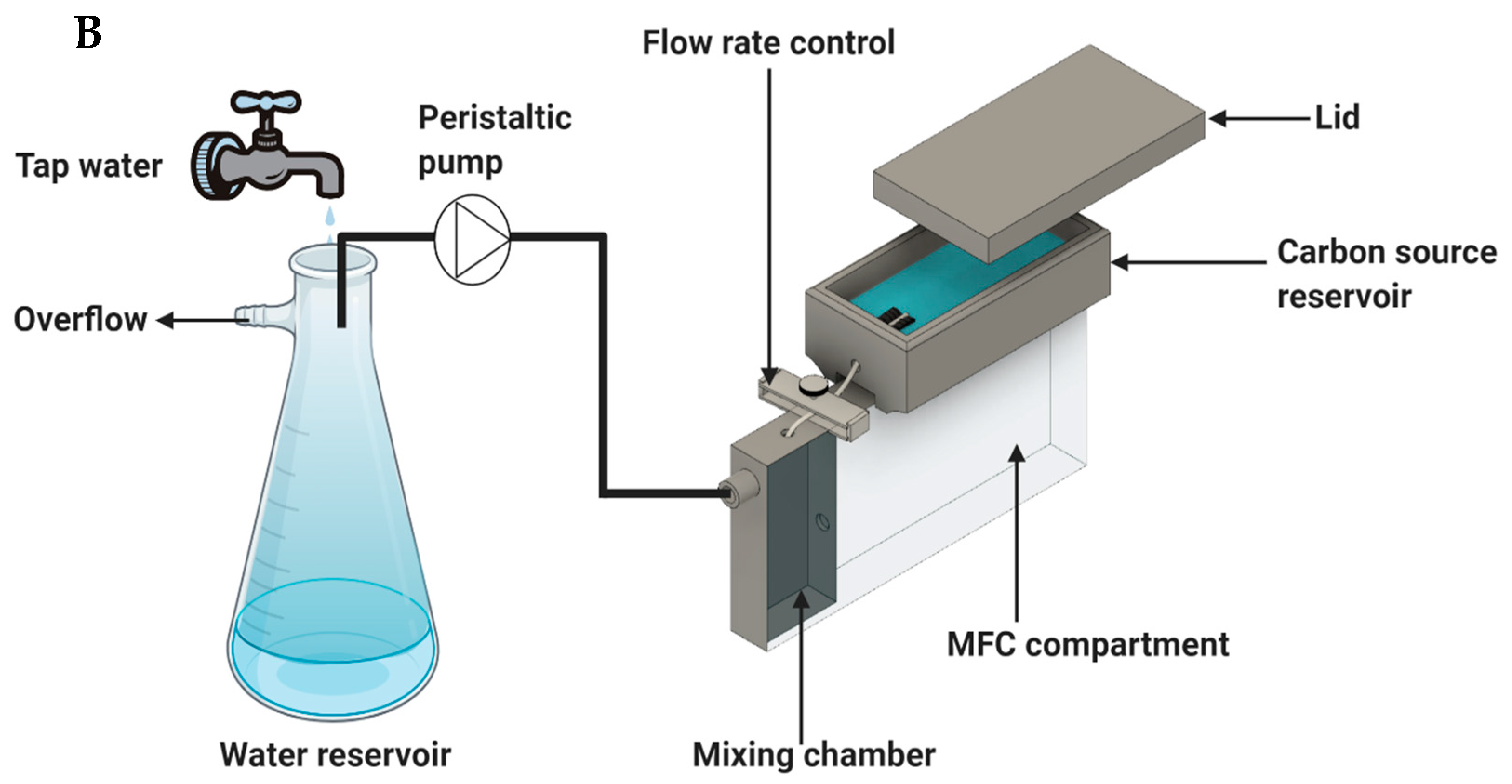

3.1. Evaluation of Water and Carbon Source Flow Rates in the Passive Delivery System

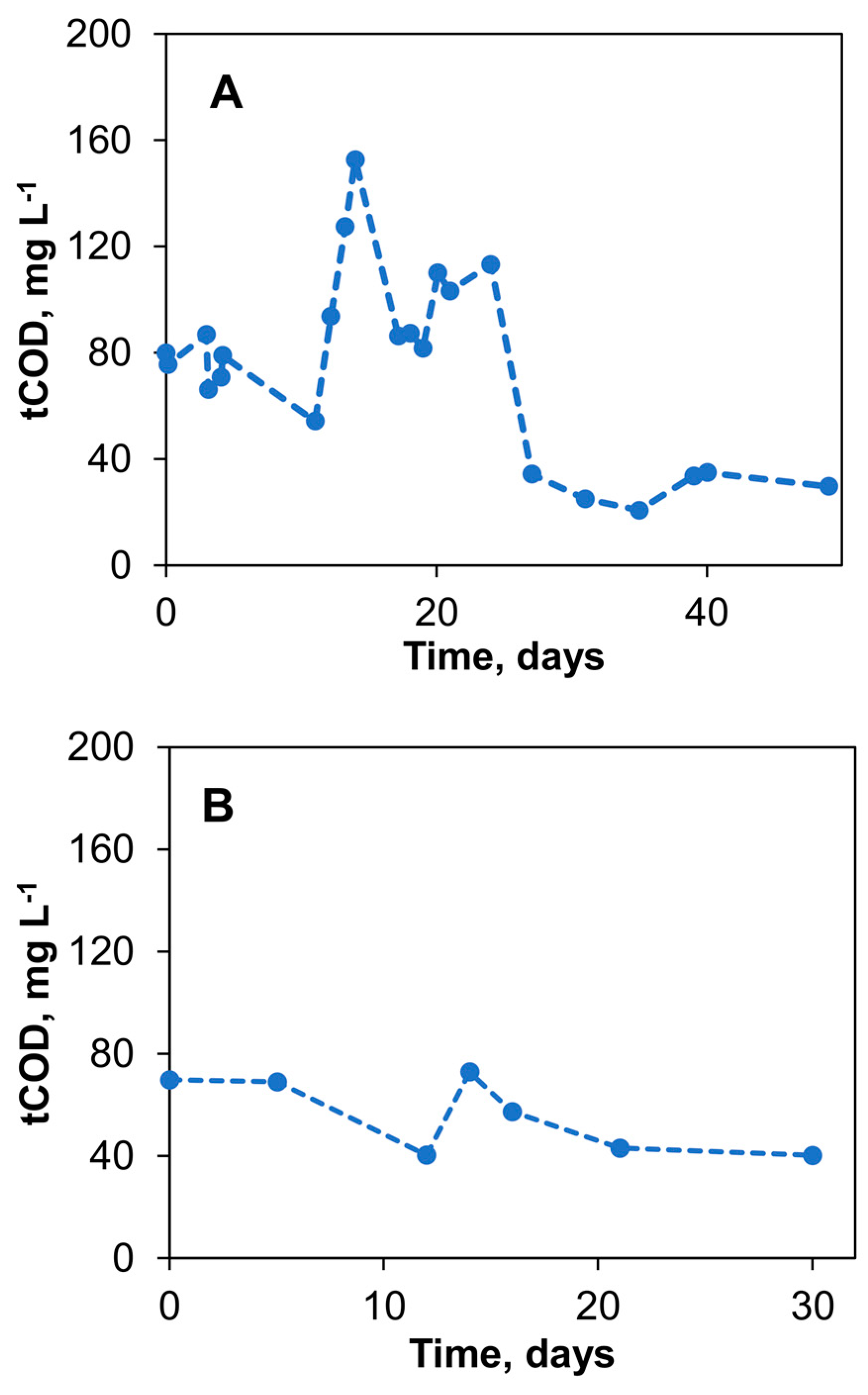

3.2. Passive Carbon Source Delivery to Biosensors

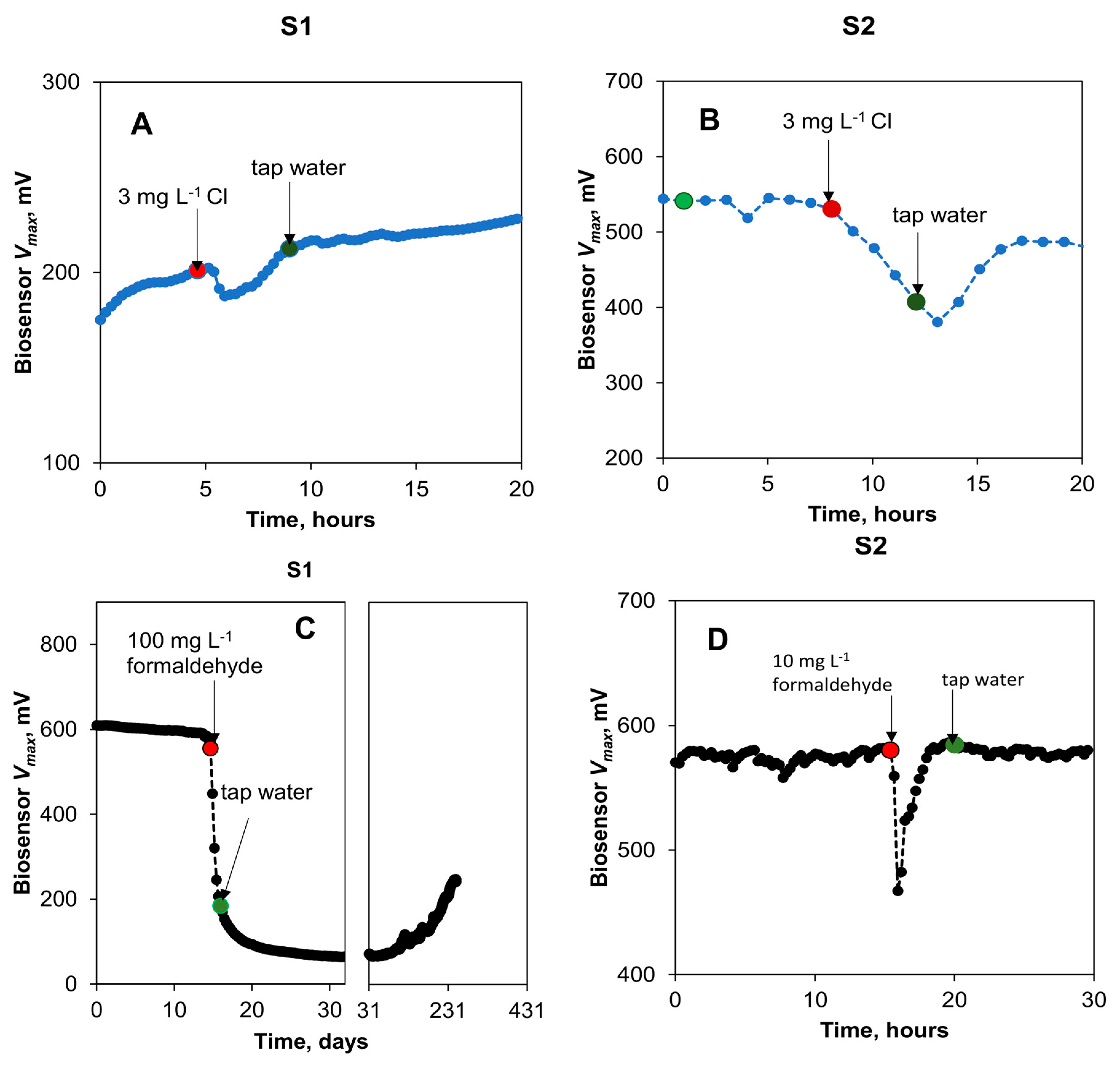

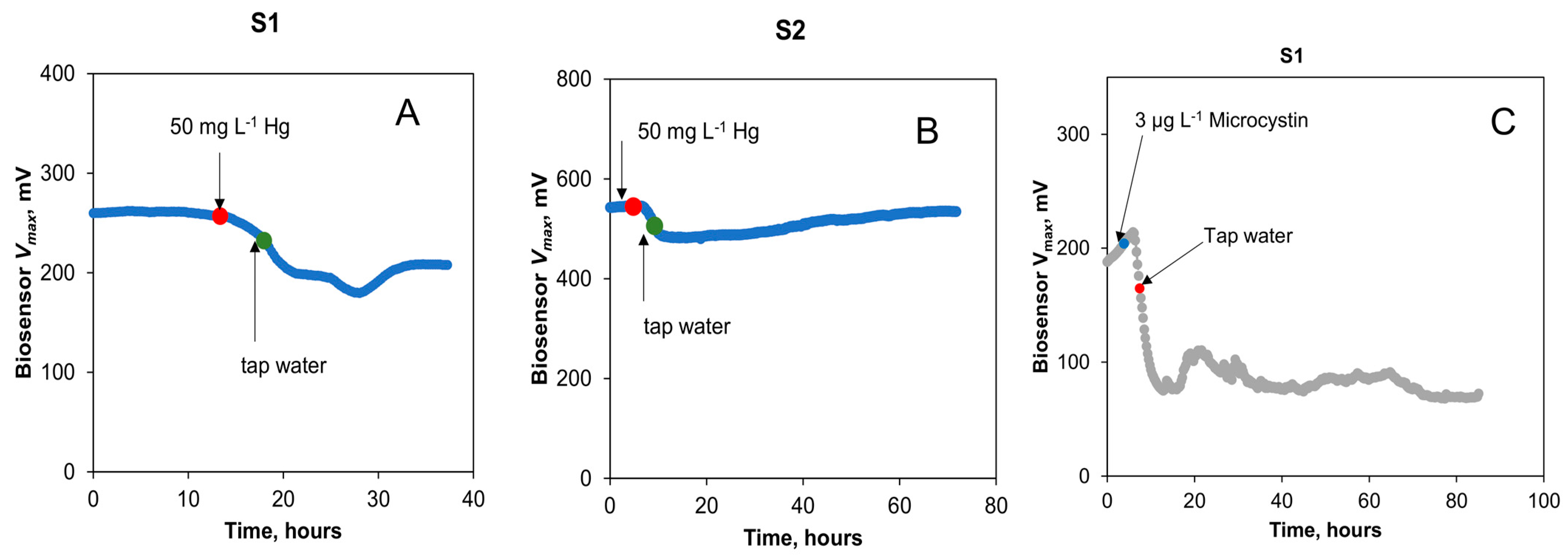

3.3. Detection of Toxicity Spikes in Tap Water

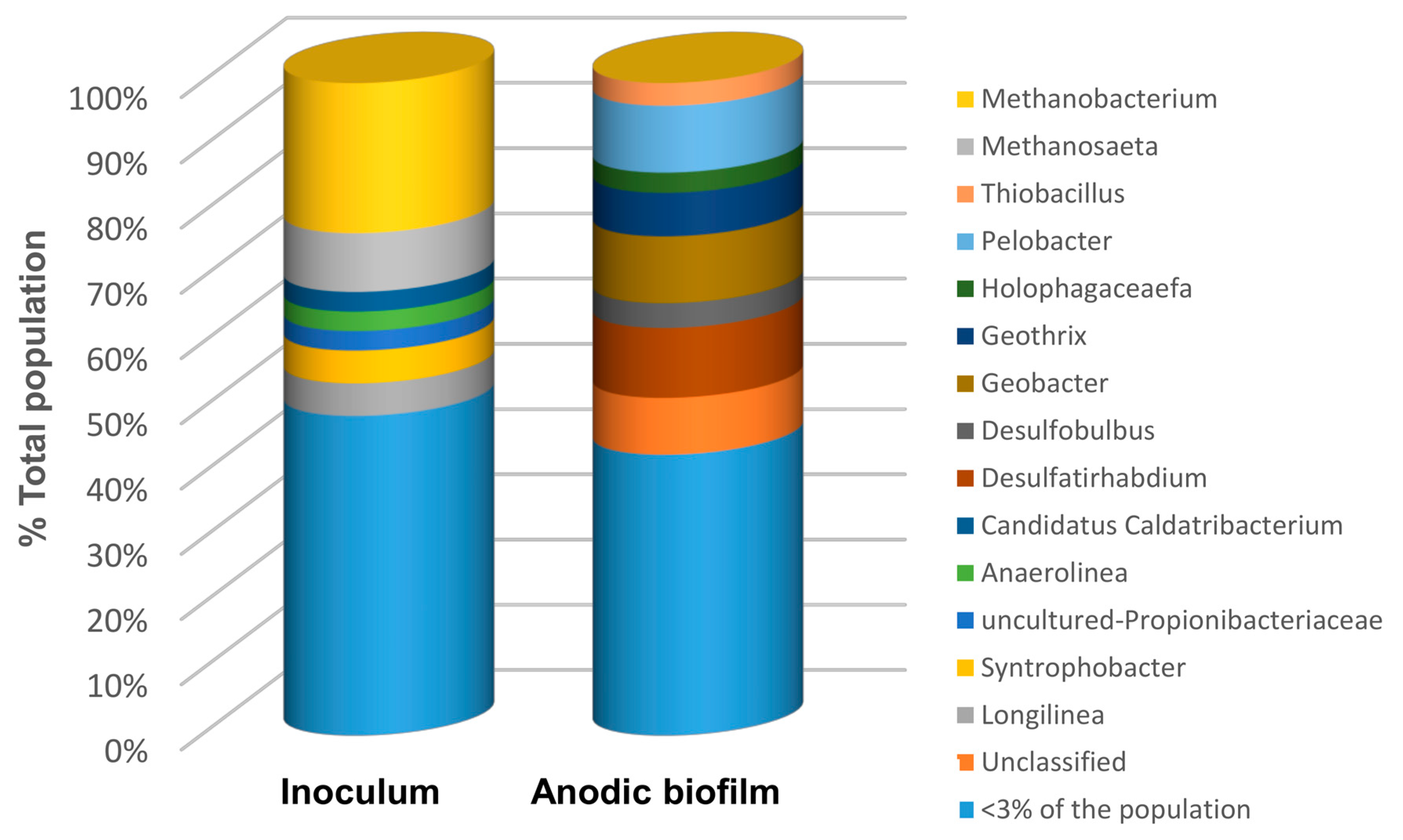

3.4. The 16S Analysis of Microbial Community

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Olias, L.G.; Di Lorenzo, M. Microbial fuel cells for in-field water quality monitoring. RSC Adv. 2021, 11, 16307–16317. [Google Scholar] [CrossRef] [PubMed]

- Adekunle, A.; Rickwood, C.; Tartakovsky, B. On-line monitoring of water quality with a floating microbial fuel cell biosensor: Field test results. Ecotoxicology 2021, 30, 851–862. [Google Scholar] [CrossRef] [PubMed]

- Adekunle, A.; Rickwood, C.; Tartakovsky, B. Online monitoring of heavy metal–related toxicity using flow-through and floating microbial fuel cell biosensors. Environ. Monit. Assess. 2019, 192, 52. [Google Scholar] [CrossRef]

- Chouler, J.; Cruz-Izquierdo, Á.; Rengaraj, S.; Scott, J.L.; Di Lorenzo, M. A screen-printed paper microbial fuel cell biosensor for detection of toxic compounds in water. Biosens. Bioelectron. 2018, 102, 49–56. [Google Scholar] [CrossRef] [PubMed]

- Di Lorenzo, M.; Thomson, A.R.; Schneider, K.; Cameron, P.J.; Ieropoulos, I. A small-scale air-cathode microbial fuel cell for on-line monitoring of water quality. Biosens. Bioelectron. 2014, 62, 182–188. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Do, M.H.; Ngo, H.H.; Guo, W.; Chang, S.W.; Nguyen, D.D.; Liu, Y.; Varjani, S.; Kumar, M. Microbial fuel cell-based biosensor for online monitoring wastewater quality: A critical review. Sci. Total. Environ. 2019, 712, 135612. [Google Scholar] [CrossRef]

- Jiang, Y.; Liang, P.; Liu, P.; Wang, D.; Miao, B.; Huang, X. A novel microbial fuel cell sensor with biocathode sensing element. Biosens. Bioelectron. 2017, 94, 344–350. [Google Scholar] [CrossRef] [Green Version]

- Bennetto, H.P.; Stirling, J.L.; Tanaka, K.; Vega, C.A. Anodic reactions in microbial fuel cells. Biotechnol. Bioeng. 1983, 25, 559–568. [Google Scholar] [CrossRef]

- Liu, H.; Cheng, S.; Logan, B.E. Production of Electricity from Acetate or Butyrate Using a Single-Chamber Microbial Fuel Cell. Environ. Sci. Technol. 2004, 39, 658–662. [Google Scholar] [CrossRef]

- Di Lorenzo, M.; Curtis, T.P.; Head, I.M.; Scott, K. A single-chamber microbial fuel cell as a biosensor for wastewaters. Water Res. 2009, 43, 3145–3154. [Google Scholar] [CrossRef]

- Ucar, D.; Zhang, Y.; Angelidaki, I. An Overview of Electron Acceptors in Microbial Fuel Cells. Front. Microbiol. 2017, 8, 643. [Google Scholar] [CrossRef] [Green Version]

- Logan, B.E.; Hamelers, B.; Rozendal, R.; Schröder, U.; Keller, J.; Freguia, S.; Aelterman, P.; Verstraete, W.; Rabaey, K. Microbial Fuel Cells: Methodology and Technology. Environ. Sci. Technol. 2006, 40, 5181–5192. [Google Scholar] [CrossRef] [PubMed]

- Stein, N.E.; Hamelers, H.V.; Buisman, C.N. The effect of different control mechanisms on the sensitivity and recovery time of a microbial fuel cell based biosensor. Sensors Actuators B Chem. 2012, 171–172, 816–821. [Google Scholar] [CrossRef]

- Cui, Y.; Lai, B.; Tang, X. Microbial Fuel Cell-Based Biosensors. Biosensors 2019, 9, 92. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Do, M.H.; Ngo, H.H.; Guo, W.; Chang, S.W.; Nguyen, D.D.; Pandey, A.; Sharma, P.; Varjani, S.; Nguyen, T.A.H.; Hoang, N.B. A dual chamber microbial fuel cell based biosensor for monitoring copper and arsenic in municipal wastewater. Sci. Total Environ. 2021, 811, 152261. [Google Scholar] [CrossRef] [PubMed]

- Martin, E.; Savadogo, O.; Guiot, S.; Tartakovsky, B. The influence of operational conditions on the performance of a microbial fuel cell seeded with mesophilic anaerobic sludge. Biochem. Eng. J. 2010, 51, 132–139. [Google Scholar] [CrossRef]

- Peixoto, L.; Min, B.; Martins, G.; Brito, A.G.; Kroff, P.; Parpot, P.; Angelidaki, I.; Nogueira, R. In situ microbial fuel cell-based biosensor for organic carbon. Bioelectrochemistry 2011, 81, 99–103. [Google Scholar] [CrossRef]

- Lóránt, B.; Gyalai-Korpos, M.; Goryanin, I.; Tardy, G.M. Single chamber air–cathode microbial fuel cells as biosensors for determination of biodegradable organics. Biotechnol. Lett. 2019, 41, 555–563. [Google Scholar] [CrossRef] [Green Version]

- Tardy, G.M.; Lóránt, B.; Gyalai-Korpos, M.; Bakos, V.; Simpson, D.; Goryanin, I. Microbial fuel cell biosensor for the determination of biochemical oxygen demand of wastewater samples containing readily and slowly biodegradable organics. Biotechnol. Lett. 2021, 43, 445–454. [Google Scholar] [CrossRef]

- Adekunle, A.; Raghavan, V.; Tartakovsky, B. Carbon source and energy harvesting optimization in solid anolyte microbial fuel cells. J. Power Sources 2017, 356, 324–330. [Google Scholar] [CrossRef]

- Tommasi, T.; Salvador, G.P.; Quaglio, M. New insights in Microbial Fuel Cells: Novel solid phase anolyte. Sci. Rep. 2016, 6, 29091. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Adekunle, A.; Tartakovsky, B.; Raghavan, V. Synthesizing developments in the usage of solid organic matter in microbial fuel cells: A review. Chem. Eng. J. Adv. 2021, 8, 100140. [Google Scholar] [CrossRef]

- Jiang, Y.; Liang, P.; Huang, X.; Ren, Z.J. A novel microbial fuel cell sensor with a gas diffusion biocathode sensing element for water and air quality monitoring. Chemosphere 2018, 203, 21–25. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Naik, S.; Jujjavarapu, S.E. Self-powered and reusable microbial fuel cell biosensor for toxicity detection in heavy metal polluted water. J. Environ. Chem. Eng. 2021, 9, 105318. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, J.; Yang, S.; Li, H.; Li, X. Electrode Modification and Optimization in Air-Cathode Single-Chamber Microbial Fuel Cells. Int. J. Environ. Res. Public Health 2018, 15, 1349. [Google Scholar] [CrossRef] [Green Version]

- Zhou, T.; Han, H.; Liu, P.; Xiong, J.; Tian, F.; Li, X. Microbial Fuels Cell-Based Biosensor for Toxicity Detection: A Review. Sensors 2017, 17, 2230. [Google Scholar] [CrossRef]

- Kharat, S. Density, viscosity and ultrasonic velocity studies of aqueous solutions of sodium acetate at different temperatures. J. Mol. Liq. 2008, 140, 10–14. [Google Scholar] [CrossRef]

- Grondin, F.; Perrier, M.; Tartakovsky, B. Microbial fuel cell operation with periodic connection of the external resistance. IFAC Proc. Vol. 2012, 45, 120–124. [Google Scholar] [CrossRef]

- Grondin, F.; Perrier, M.; Tartakovsky, B. Microbial fuel cell operation with intermittent connection of the electrical load. J. Power Sources 2012, 208, 18–23. [Google Scholar] [CrossRef]

- Adekunle, A.; Raghavan, V.; Tartakovsky, B. On-line monitoring of heavy metals-related toxicity with a microbial fuel cell biosensor. Biosens. Bioelectron. 2019, 132, 382–390. [Google Scholar] [CrossRef]

- Tremblay, J.; Singh, K.; Fern, A.; Kirton, E.S.; He, S.; Woyke, T.; Lee, J.; Chen, F.; Dangl, J.L.; Tringe, S.G. Primer and platform effects on 16S rRNA tag sequencing. Front. Microbiol. 2015, 6, 771. [Google Scholar] [CrossRef] [Green Version]

- Prévoteau, A.; Carvajal-Arroyo, J.M.; Ganigué, R.; Rabaey, K. Microbial electrosynthesis from CO2: Forever a promise? Curr. Opin. Biotechnol. 2019, 62, 48–57. [Google Scholar] [CrossRef]

- Chouler, J.; Monti, M.D.; Morgan, W.J.; Cameron, P.; Di Lorenzo, M. A photosynthetic toxicity biosensor for water. Electrochimica Acta 2019, 309, 392–401. [Google Scholar] [CrossRef]

- Lisha, K.P.; Anshup; Pradeep, T. Towards a practical solution for removing inorganic mercury from drinking water using gold nanoparticles. Gold Bull. 2009, 42, 144–152. [Google Scholar] [CrossRef] [Green Version]

- WHO. Guidelines for Drinking-Water Quality: Fourth Edition Incorporating the First Addendum; World Health Organization: Geneva, Switzerland, 2017; p. 631. [Google Scholar]

- Lun, Z.; Hai, Y.U.; Kun, C. Relationship Between Microcystin in Drinking Water and Colorectal Cancer. Biomed. Environ. Sci. 2002, 15, 166–171. [Google Scholar]

- Taylor, J.B.; Wohlers, D.W. Toxicological Profile for Chlorine Dioxide and Chlorite; U.S. Environmental Protection Agency: Washingthon, DC, USA, 2004.

- Dávila, D.; Esquivel, J.; Sabaté, N.; Mas, J. Silicon-based microfabricated microbial fuel cell toxicity sensor. Biosens. Bioelectron. 2011, 26, 2426–2430. [Google Scholar] [CrossRef]

- Lu, H.; Yu, Y.; Zhou, Y.; Xing, F. A quantitative evaluation method for wastewater toxicity based on a microbial fuel cell. Ecotoxicol. Environ. Saf. 2019, 183, 109589. [Google Scholar] [CrossRef]

- Fei, S.; Ren, H. Determining the Dose–Response Curve of Exoelectrogens: A Microscale Microbial Fuel Cell Biosensor for Water Toxicity Monitoring. Micromachines 2022, 13, 1560. [Google Scholar] [CrossRef]

- Gai, R.; Liu, Y.; Liu, J.; Yan, C.; Jiao, Y.; Cai, L.; Zhang, L. Behavior of Copper, Nickel, Cadmium and Mercury Ions in Anode Chamber of Microbial Fuel Cells. Int. J. Electrochem. Sci. 2018, 13, 3050–3062. [Google Scholar] [CrossRef]

- Zheng, Y.; Xiao, Y.; Yang, Z.-H.; Wu, S.; Xu, H.-J.; Liang, F.-Y.; Zhao, F. The bacterial communities of bioelectrochemical systems associated with the sulfate removal under different pHs. Process. Biochem. 2014, 49, 1345–1351. [Google Scholar] [CrossRef]

- Lovley, D.R.; Ueki, T.; Zhang, T.; Malvankar, N.S.; Shrestha, P.M.; Flanagan, K.A.; Aklujkar, M.; Butler, J.E.; Giloteaux, L.; Rotaru, A.-E.; et al. Geobacter: The Microbe Electric’s Physiology, Ecology, and Practical Applications. Adv. Microb. Physiol. 2011, 59, 1–100. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adekunle, A.; Bambace, S.; Tanguay-Rioux, F.; Tartakovsky, B. Microbial Fuel Cell Biosensor with Capillary Carbon Source Delivery for Real-Time Toxicity Detection. Sensors 2023, 23, 7065. https://doi.org/10.3390/s23167065

Adekunle A, Bambace S, Tanguay-Rioux F, Tartakovsky B. Microbial Fuel Cell Biosensor with Capillary Carbon Source Delivery for Real-Time Toxicity Detection. Sensors. 2023; 23(16):7065. https://doi.org/10.3390/s23167065

Chicago/Turabian StyleAdekunle, Ademola, Stefano Bambace, Fabrice Tanguay-Rioux, and Boris Tartakovsky. 2023. "Microbial Fuel Cell Biosensor with Capillary Carbon Source Delivery for Real-Time Toxicity Detection" Sensors 23, no. 16: 7065. https://doi.org/10.3390/s23167065