Automated Identification of Hidden Corrosion Based on the D-Sight Technique: A Case Study on a Military Helicopter

Abstract

1. Introduction

2. Inspections and Data Acquisition

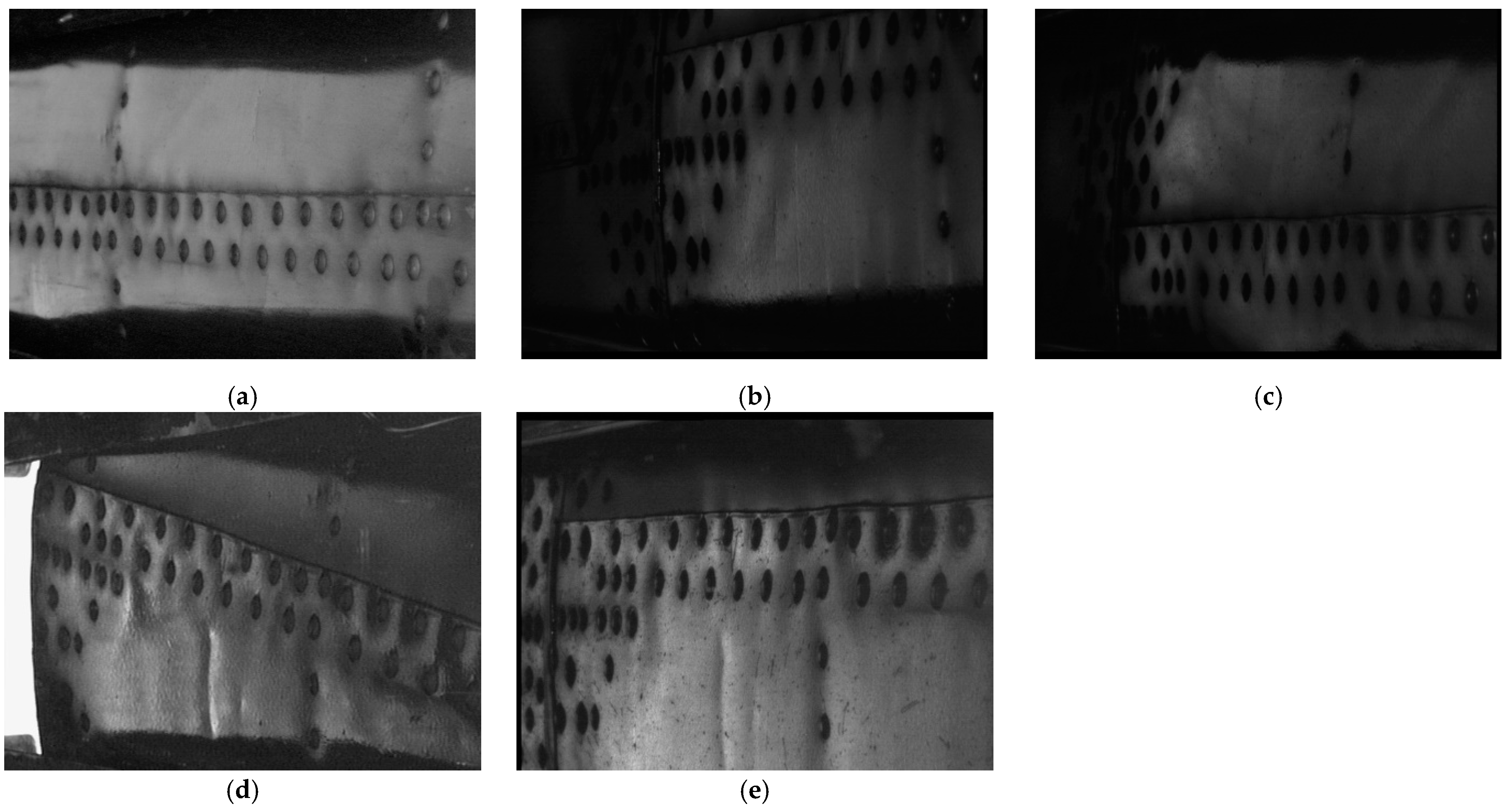

2.1. Pillowing Phenomenon and Challenges of D-Sight Inspections

2.2. Inspections and Acquisition of D-Sight Images

3. Processing and Evaluation of D-Sight Images

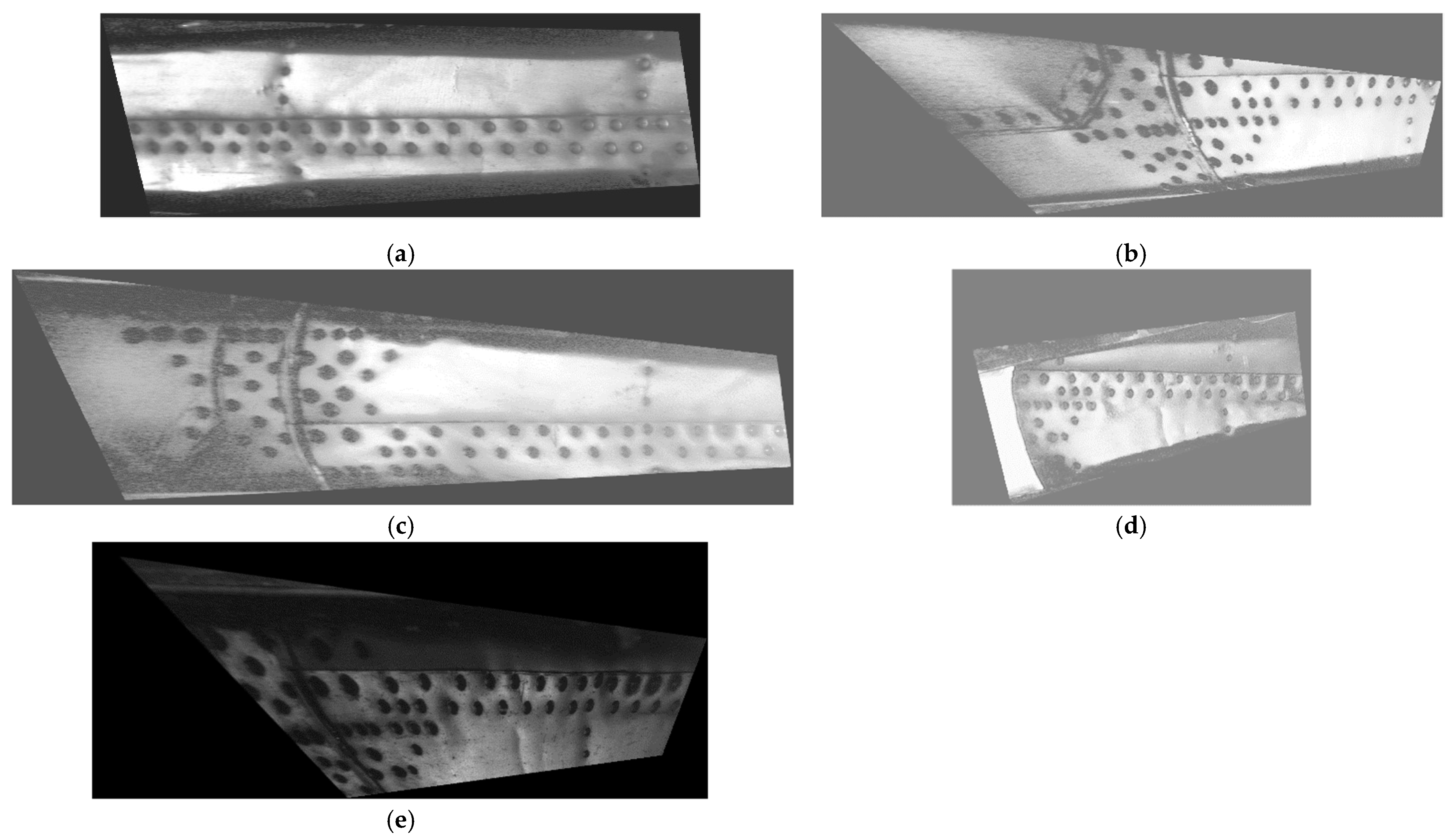

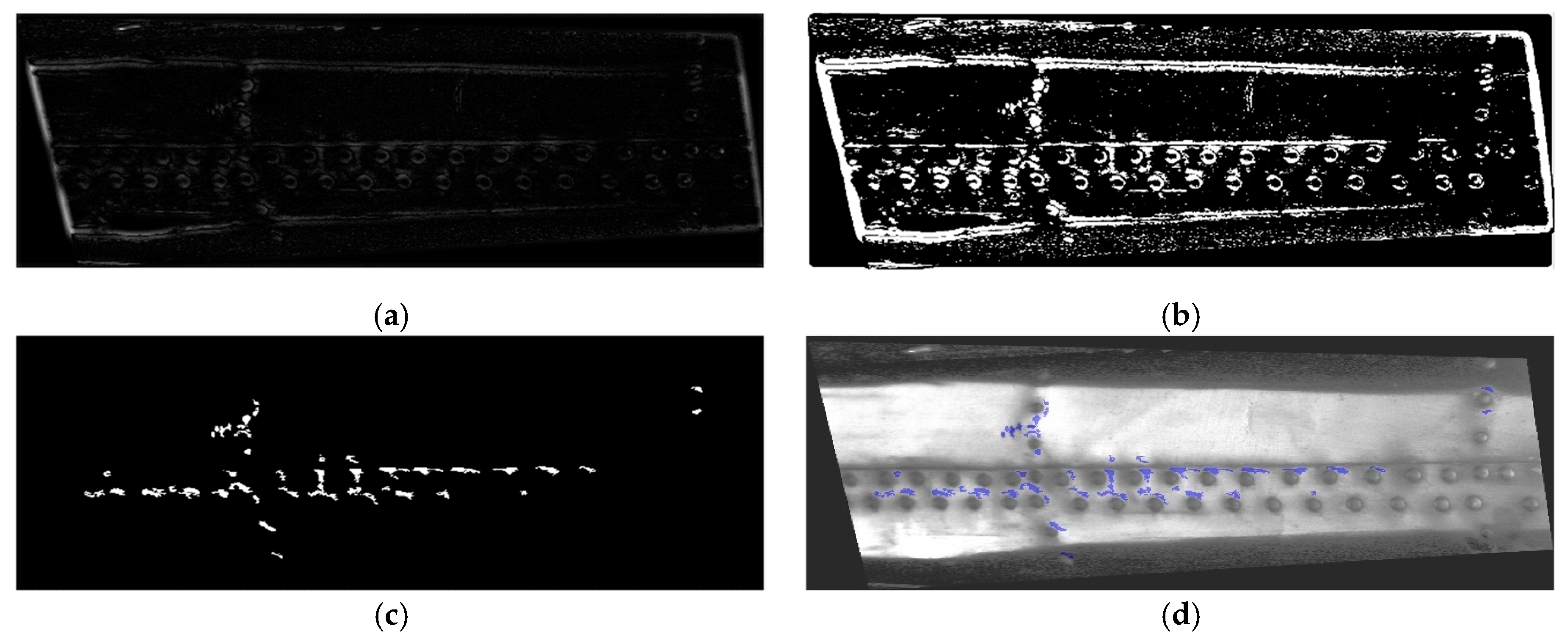

3.1. Data Preparation and Processing Algorithm

3.2. Evaluation of Hidden Corrosion

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Komorowski, J.P.; Forsyth, D.S. The role of enhanced visual inspections in the new strategy for corrosion management. Aircr. Eng. Aerosp. Technol. 2000, 72, 5–13. [Google Scholar] [CrossRef]

- Liao, M. Corrosion damage atlas for aircraft corrosion management and structural integrity assessment. In Proceedings of the NATO RTO STO-MP-AVT-303 Corrosion Management, Athens, Greece, 10–14 December 2018. [Google Scholar]

- Li, L.; Chakik, M.; Prakash, R. A review of corrosion in aircraft structures and graphene-based sensors for advanced corrosion monitoring. Sensors 2021, 21, 2908. [Google Scholar] [CrossRef] [PubMed]

- Nusser, J.K.; Herzberg, E.; Stimson, D.J.; Babish, C.A. Data-driven corrosion prevention and control decisions for the USAF. In Proceedings of the Society for Protective Coatings 2017 (SSPC 2017) Conference, Tampa, FL, USA, 30 January–2 February 2017. [Google Scholar]

- Cassidy, M.; Waldie, J.; Palanisamy, S. A method to estimate the cost of corrosion for Australian Defense Force aircraft. In Proceedings of the AIAC16 Sixteenth Australian International Aerospace Congress, Melbourne, Australia, 23–24 February 2015. [Google Scholar]

- Corrosion Control for Aircraft, Advisory Circular no. 43-4B; U.S. Department of Transportation, Federal Aviation Administration: Cambridge, MA, USA, 2018.

- Cole, G.K.; Clark, G.; Sharp, P.K. The Implications of Corrosion with Respect to Aircraft Structural Integrity; DSTO Aeronautical and Maritime Research Laboratory: Melbourne, Australia, 1997. [Google Scholar]

- Benavides, S. (Ed.) Corrosion Control in the Aerospace Industry; Woodhead Publishing: Cambridge, UK, 2009. [Google Scholar]

- Cardinal, J.W.; Burnside, H. Damage tolerance risk assessment of T-38 wing skin cracks. In Proceedings of the 2005 USAF Structural Integrity Program (ASIP) Conference, Memphis, TN, USA, 29 November–1 December 2005. [Google Scholar]

- Knight, S.P.; Salagaras, M.; Trueman, A.R. The study of intergranular corrosion in aircraft aluminum alloys using X-ray tomography. Corros. Sci. 2011, 53, 727–734. [Google Scholar] [CrossRef]

- Ciężak, P.; Rdzanek, A. Corrosion monitoring of aircraft based on the corrosion prognostic health management (CPHM) system. J. CONBiN 2020, 50, 205–216. [Google Scholar] [CrossRef]

- Komorowski, J.P.; Bellinger, N.C.; Gould, R.W. The role of corrosion pillowing in NDI and in the structural integrity of fuselage joints. Fatigue in New and Aeging Aircraft. In Proceedings of the 19th Symposium of the International Committee on Aeronautical Fatigue, Edinburgh, UK, 18–20 June 1997; pp. 251–266. [Google Scholar]

- Heida, J.; Bruinsma, A. D-Sight technique for rapid impact damage detection on composite aircraft structures. In Proceedings of the 7th European Conference on Non-Destructive Testing, Copenhagen, Denmark, 26–29 May 1998; NDT.net: Copenhagen, Denmark, 1998. Volume 4. [Google Scholar]

- Reynolds, R.L.; Karpala, F.; Clarke, D.A.; Hageniers, O.L. Theory and applications of a surface inspection technique using double-pass retroreflection. Opt. Eng. 1993, 32, 2122–2129. [Google Scholar] [CrossRef]

- Hageniers, O.L. D Sight for large area aircraft inspection. Proc. SPIE 2001, 1993, 248–256. [Google Scholar]

- Bellinger, N.; Komorowski, J.; Benak, T. Residual life predictions of corroded fuselage lap joints. Int. J. Fatigue 2001, 23, 349–356. [Google Scholar] [CrossRef]

- Komorowski, J.P.; Bellinger, N.C.; Gould, R.W.; Marincak, A.; Reynolds, R. Quantification of corrosion in aircraft structures with double pass retroreflection. Can. Aeronaut. Space J. 1996, 42, 76–82. [Google Scholar]

- Bellinger, N.C.; Komorowski, J.P. Corrosion pillowing stresses in fuselage lap joints. AIAA J. 1997, 35, 317–320. [Google Scholar] [CrossRef]

- Forsyth, D.S.; Komorowski, J.P.; Gould, R.W. Use of solid film highlighter in automation of D sight image interpretation. Proc. SPIE 1998, 3397, 50–56. [Google Scholar]

- Katunin, A.; Dragan, K. Qualitative to quantitative non-destructive evaluation: A concept for D-Sight inspections of aircraft structures. Appl. Mech. Mater. 2022, 909, 69–74. [Google Scholar] [CrossRef]

- Xiong, G.; Li, X.; Gong, J.; Chen, H.; Lee, D.-J. Color rank and census transforms using perceptual color contrast. In Proceedings of the 2010 11th International Conference on Control Automation Robotics & Vision, Singapore, 7–10 December 2010; pp. 1225–1230. [Google Scholar]

- Simone, G.; Pedersen, M.; Hardeberg, J.Y. Measuring perceptual contrast in digital images. J. Vis. Commun. Image Represent. 2012, 23, 491–506. [Google Scholar] [CrossRef]

- Palma-Amestoy, R.; Provenzi, E.; Bertalmío, E.; Caselles, V. A perceptually inspired variational framework for color enhancement. IEEE Trans. Pattern Anal. 2009, 31, 458–474. [Google Scholar] [CrossRef] [PubMed]

- Beghdadi, A.; Larabi, M.-C.; Bouzerdoum, A.; Iftekharuddin, K.M. A survey of perceptual image processing methods. Signal Process. Image Commun. 2013, 28, 811–831. [Google Scholar] [CrossRef]

- Brandoli, B.; de Geus, A.; Souza, J.; Spadon, G.; Soares, A.; Rodrigues, J., Jr.; Komorowski, J.; Matwin, S. Aircraft fuselage corrosion detection using artificial intelligence. Sensors 2021, 21, 4026. [Google Scholar] [CrossRef] [PubMed]

- Zuchniak, K.; Dzwinel, W.; Majerz, E.; Pasternak, A.; Dragan, K. Corrosion detection on aircraft fuselage with multi-teacher knowledge distillation. In Computational Science–ICCS 2021; Lecture Notes in Computer Science; Paszynski, M., Kranzlmüller, D., Krzhizhanovskaya, V., Dongarra, J., Sloot, P., Eds.; Springer: Cham, Germany, 2021; Volume 12747, pp. 318–332. [Google Scholar]

- Katunin, A.; Nagode, M.; Oman, S.; Cholewa, A.; Dragan, K. Monitoring of hidden corrosion growth in aircraft structures based on D-Sight inspections and image processing. Sensors 2022, 22, 7616. [Google Scholar] [CrossRef] [PubMed]

- Katunin, A.; Lis, K.; Joszko, K.; Żak, P.; Dragan, K. Quantification of hidden corrosion in aircraft structures using enhanced D-Sight NDT technique. Measurement 2023, 216, 112977. [Google Scholar] [CrossRef]

- Aircraft Accident Report–Aloha Airlines, Flight 243, Boeing 737-200, N73711, near Maui, Hawaii, April 28, 1988, NTSB/AAR-89/03; National Transportation Safety Board Bureau of Accident Investigation: Washington, DC, USA, 1989.

| Year of Inspection | 2009 | 2012 | 2014 | 2017 | 2022 |

|---|---|---|---|---|---|

| Value of quantitative measure | 13.1842 | 12.6146 | 14.0894 | 39.7338 | 52.5461 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Katunin, A.; Synaszko, P.; Dragan, K. Automated Identification of Hidden Corrosion Based on the D-Sight Technique: A Case Study on a Military Helicopter. Sensors 2023, 23, 7131. https://doi.org/10.3390/s23167131

Katunin A, Synaszko P, Dragan K. Automated Identification of Hidden Corrosion Based on the D-Sight Technique: A Case Study on a Military Helicopter. Sensors. 2023; 23(16):7131. https://doi.org/10.3390/s23167131

Chicago/Turabian StyleKatunin, Andrzej, Piotr Synaszko, and Krzysztof Dragan. 2023. "Automated Identification of Hidden Corrosion Based on the D-Sight Technique: A Case Study on a Military Helicopter" Sensors 23, no. 16: 7131. https://doi.org/10.3390/s23167131

APA StyleKatunin, A., Synaszko, P., & Dragan, K. (2023). Automated Identification of Hidden Corrosion Based on the D-Sight Technique: A Case Study on a Military Helicopter. Sensors, 23(16), 7131. https://doi.org/10.3390/s23167131