WeMo: A Prototype of a Wearable Mobility Device Adapting to User’s Natural Posture Changes

Abstract

:1. Introduction

- (1)

- The device hardware design, which transforms according to the user’s natural posture change.

- (2)

- The user interface, which controls the device according to body movements.

- (3)

- The ability of the device in situations of daily life, including stair climbing.

2. Methodology

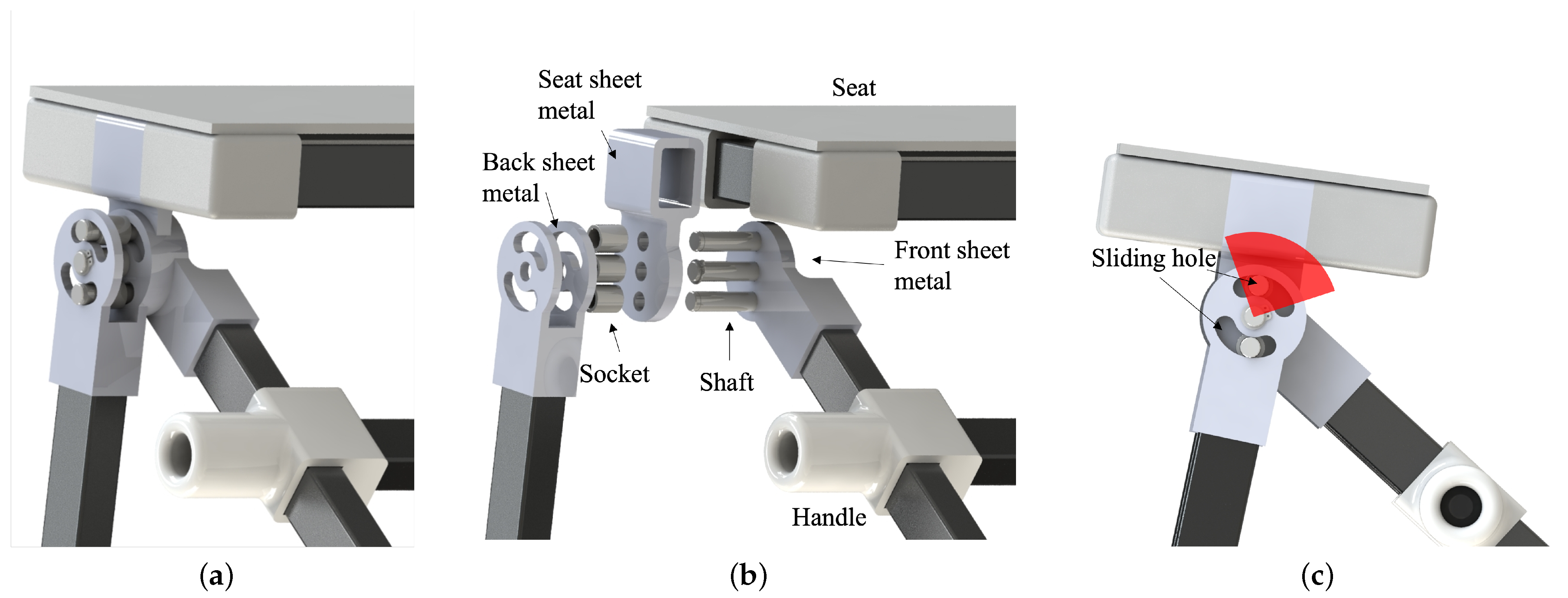

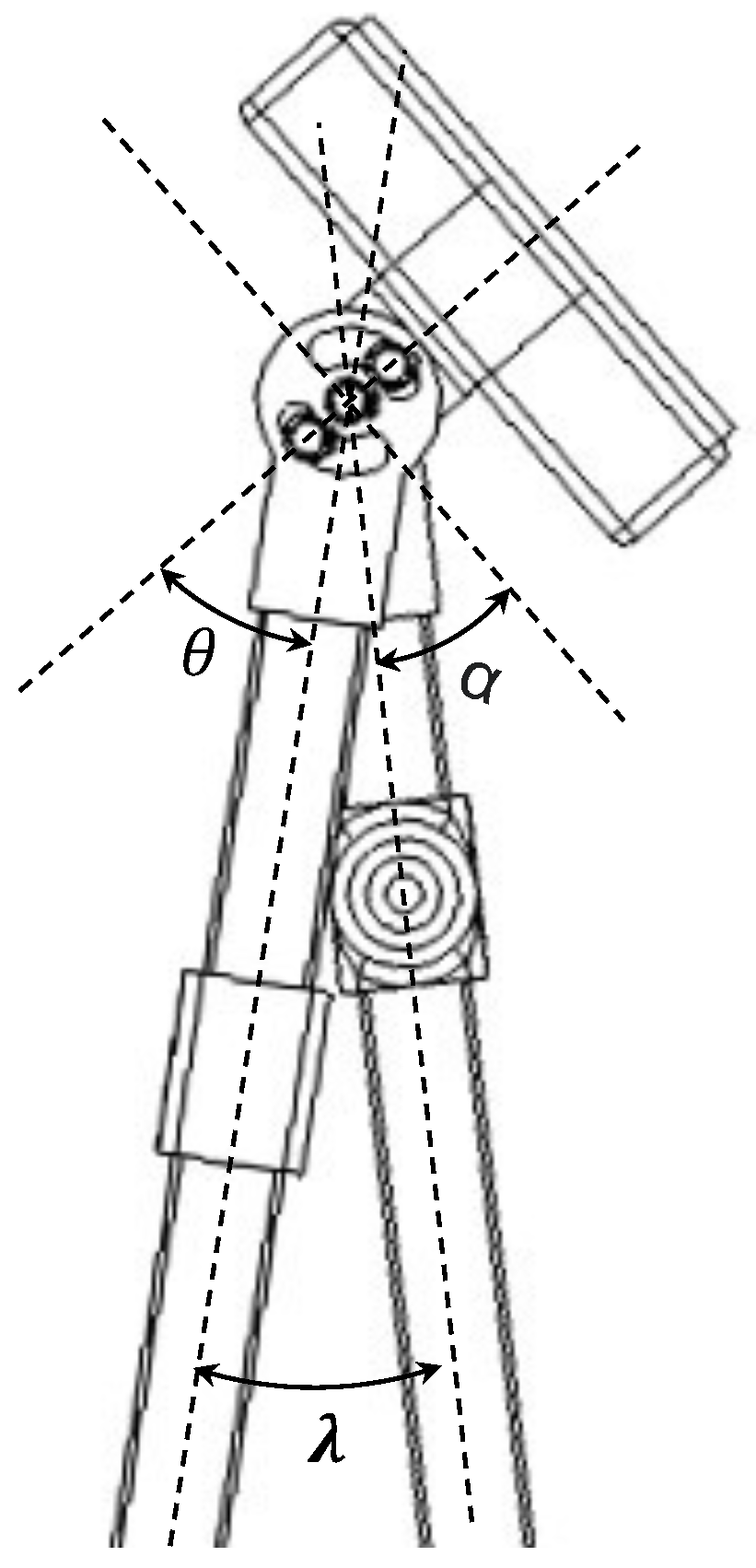

2.1. Hardware Design

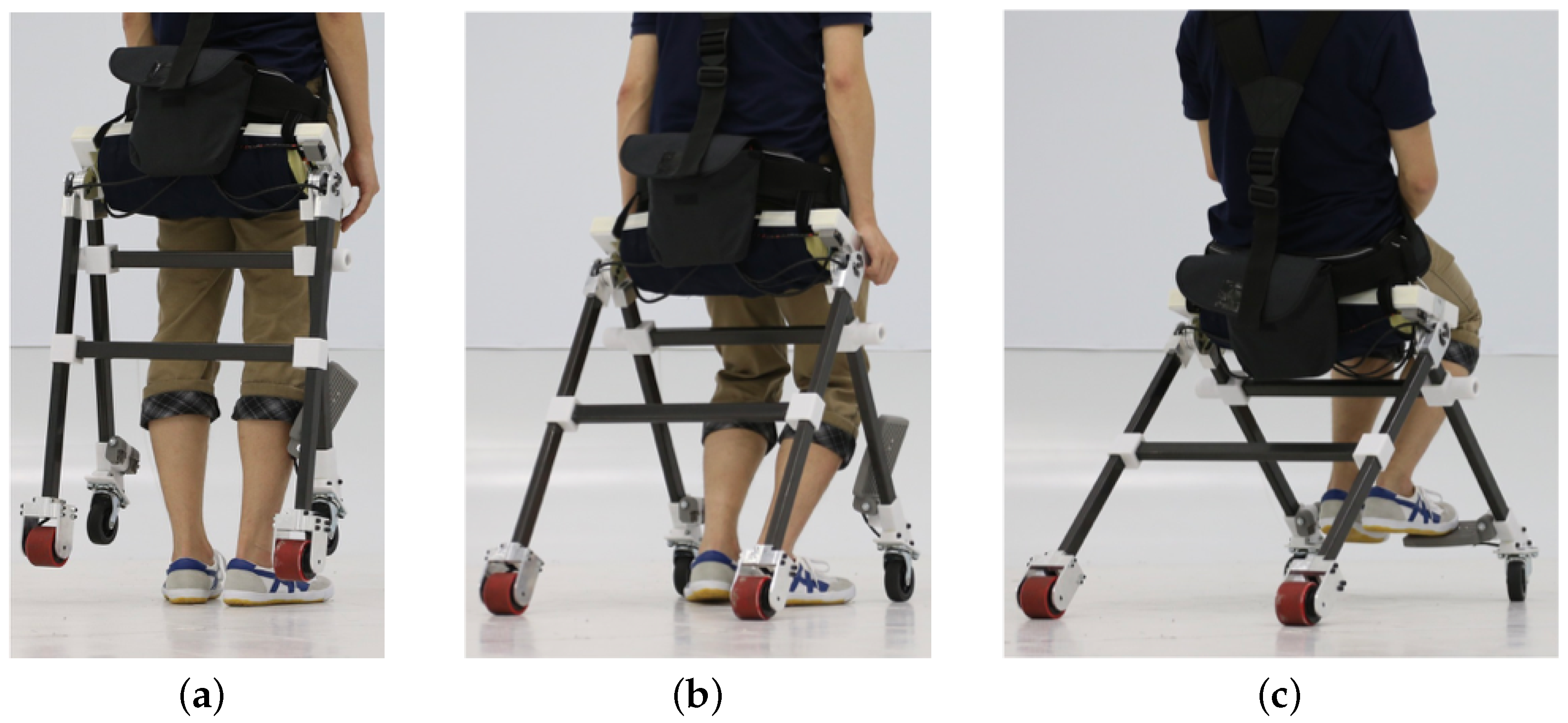

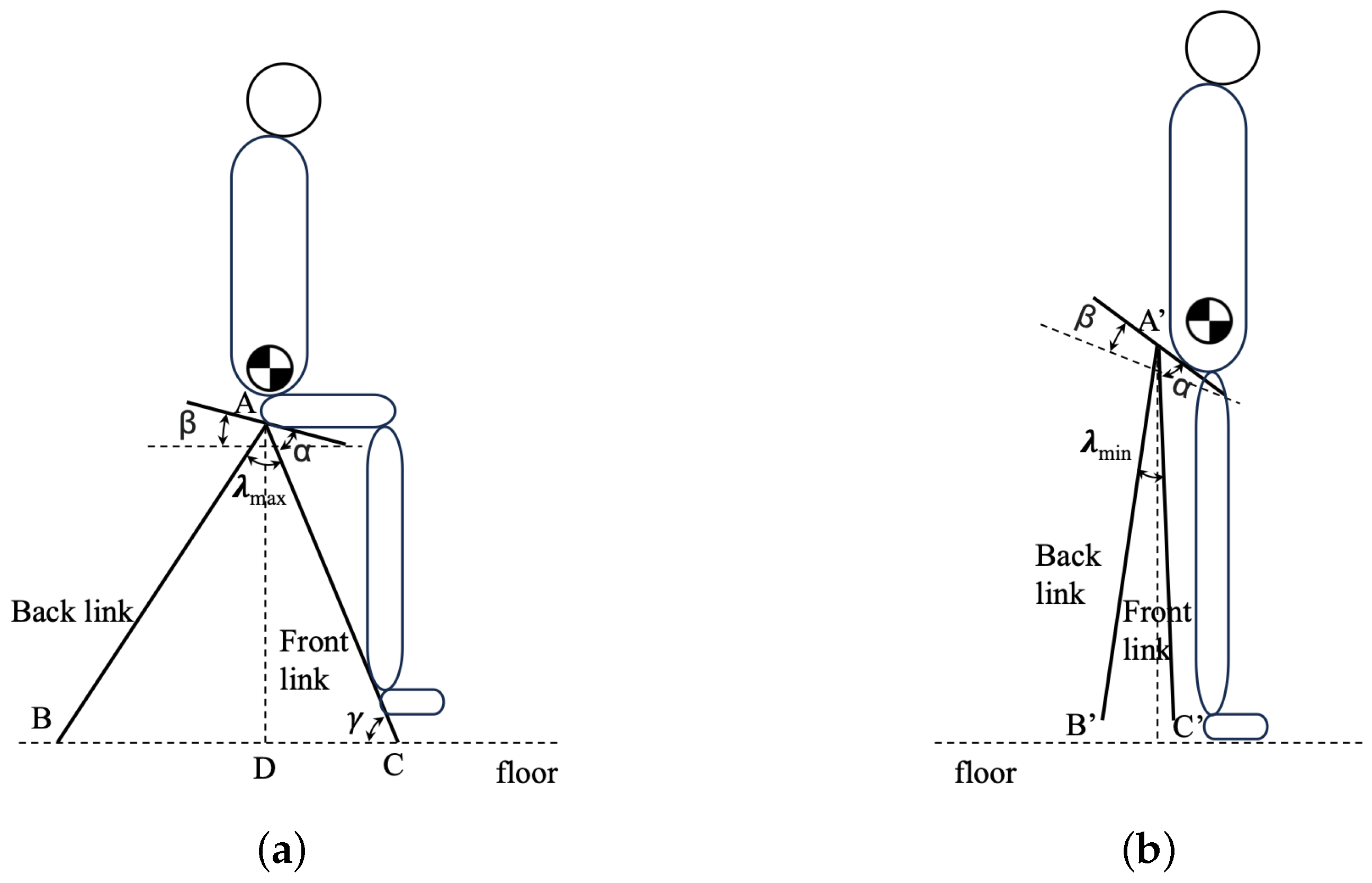

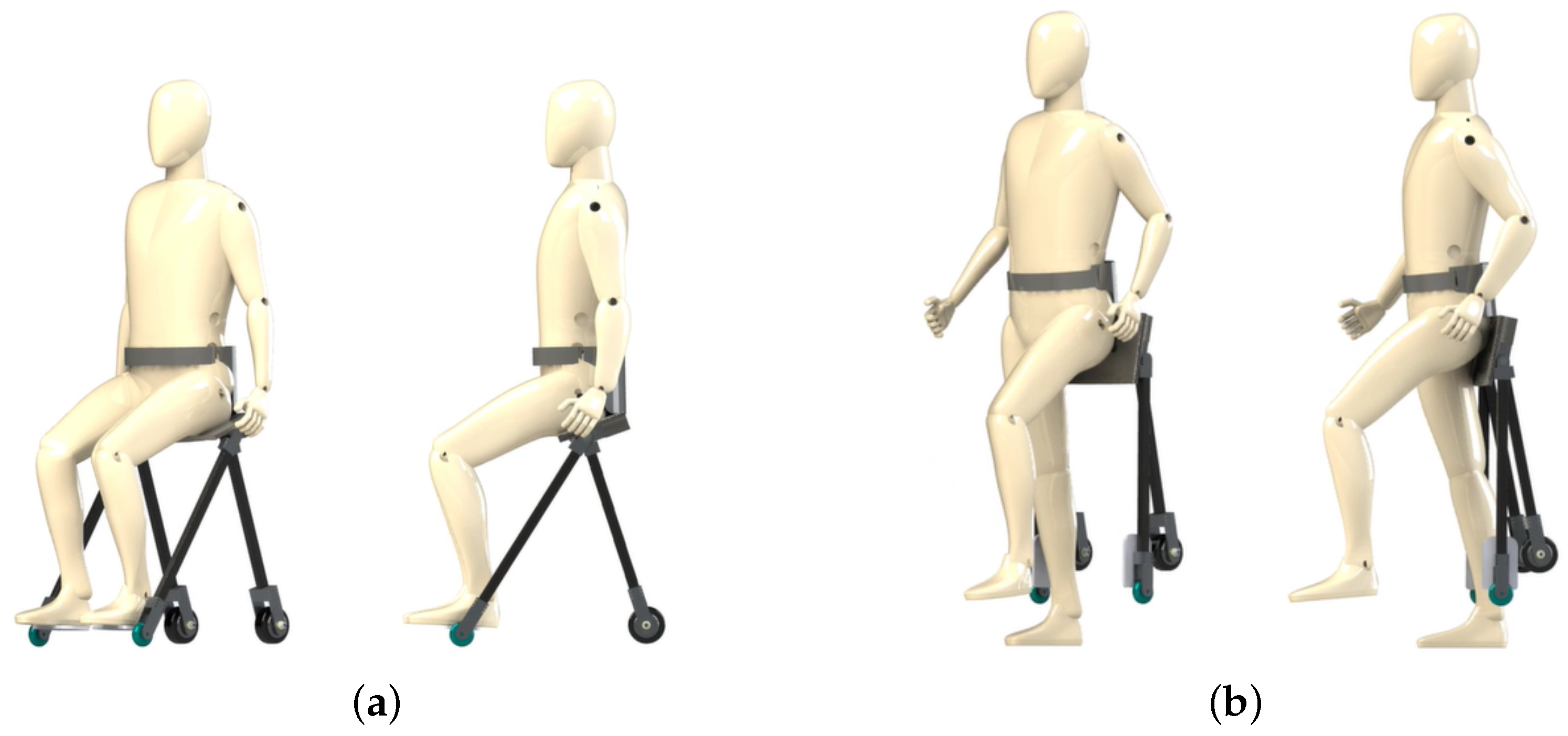

2.1.1. Driving Mode

2.1.2. Walking Mode

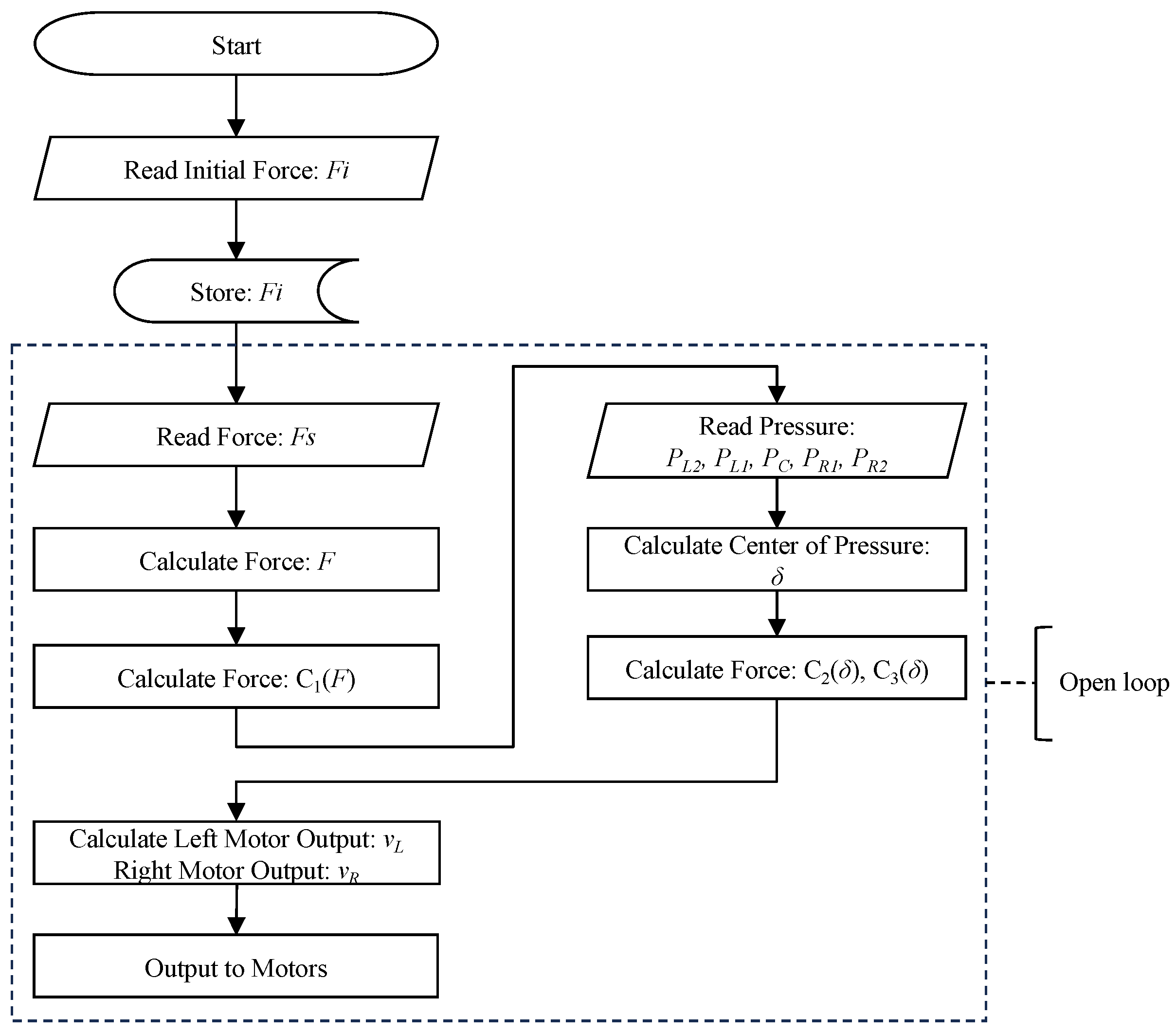

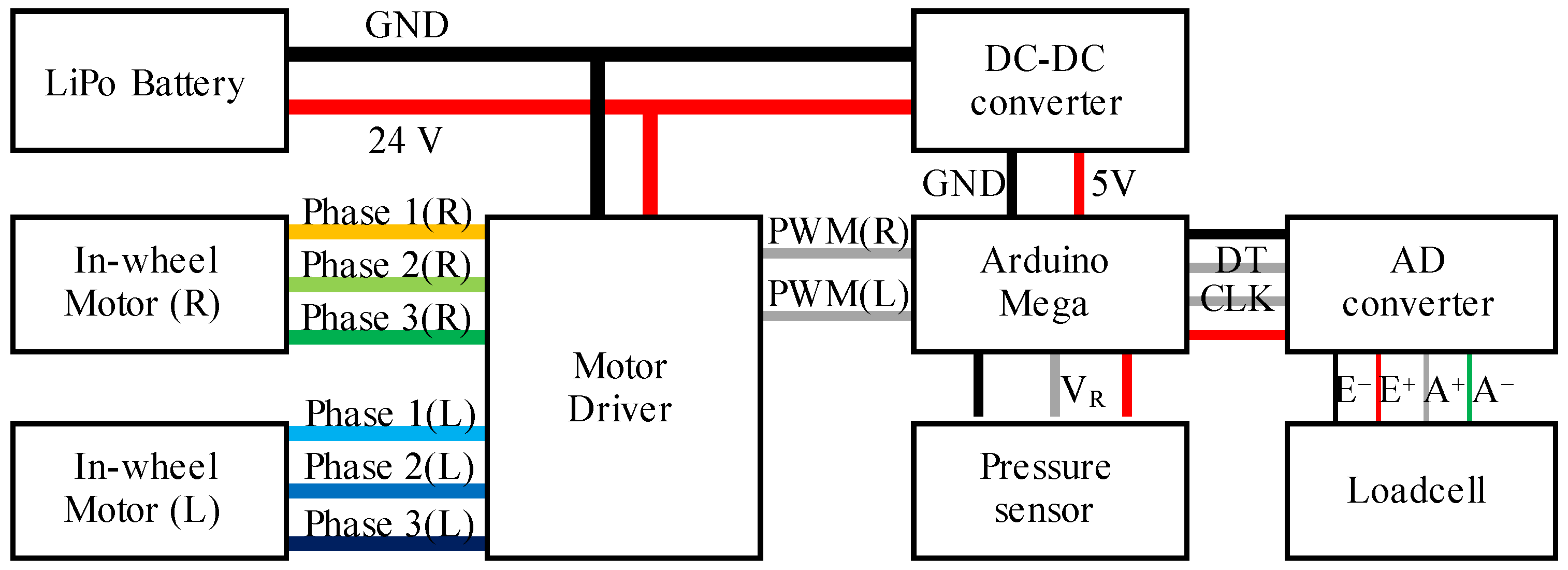

2.2. Sensing and Controlling

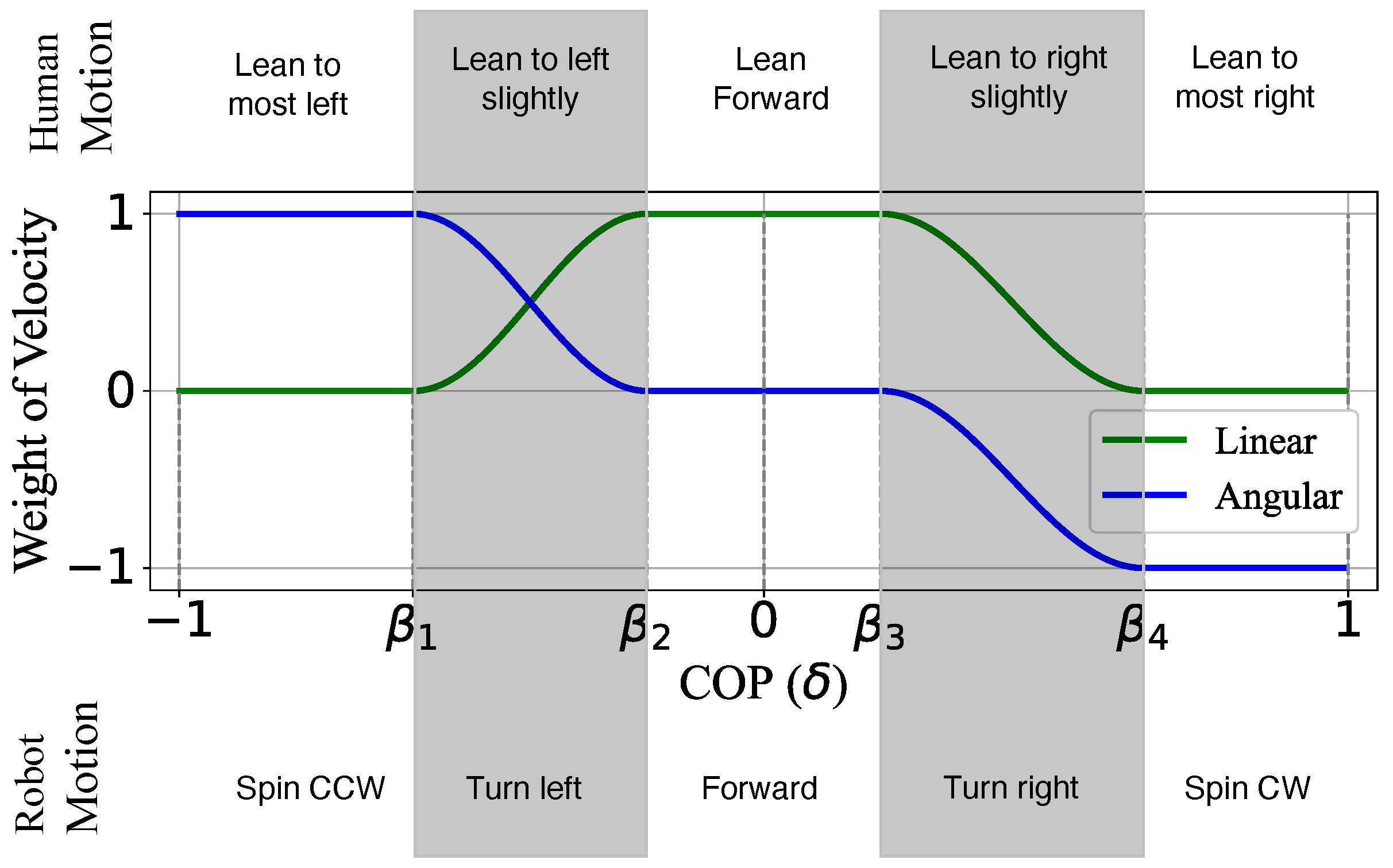

2.2.1. Pressure Sensors and Direction Control

2.2.2. Load Cell and Speed Controlling

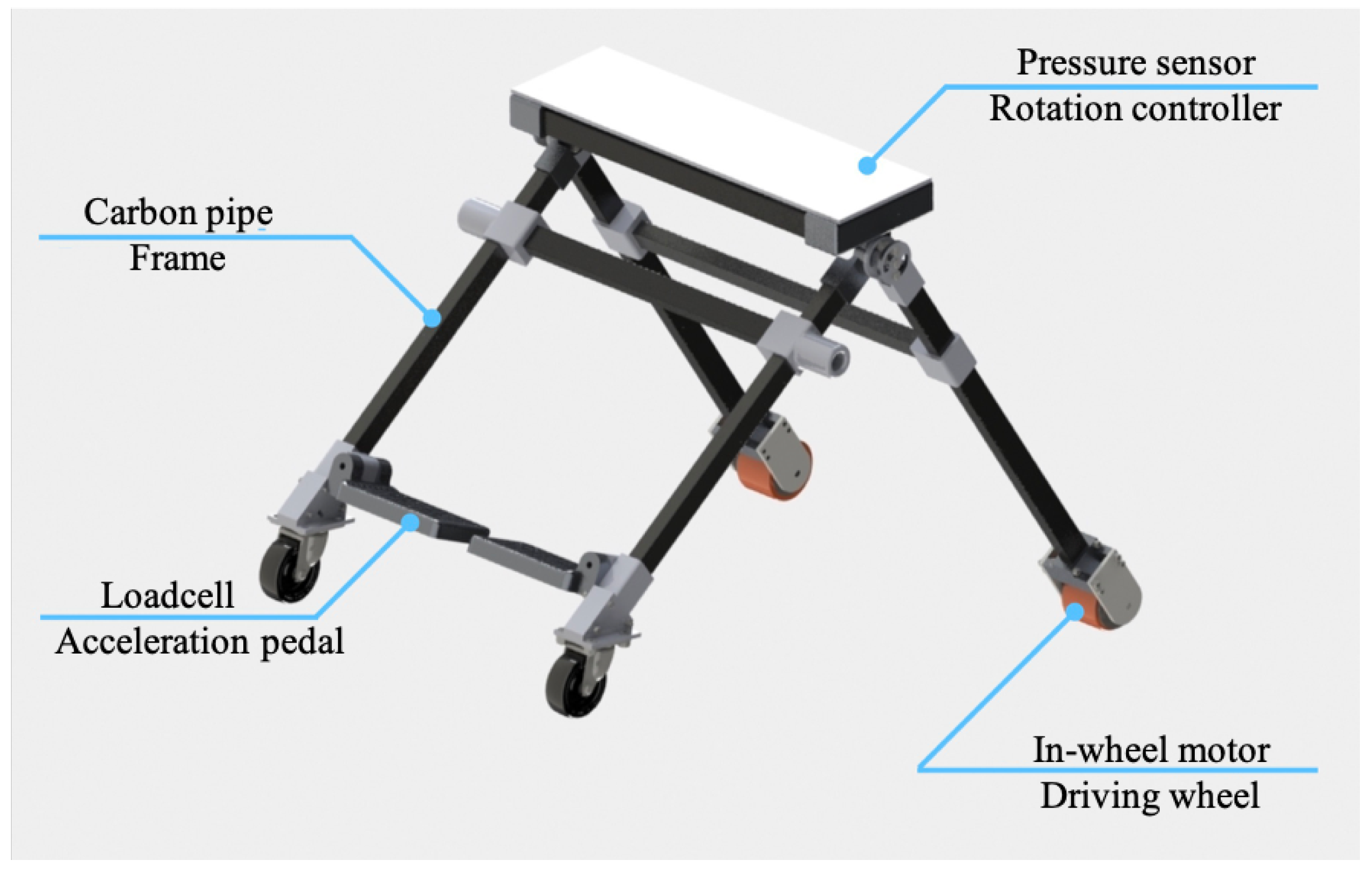

2.3. Developed Wearable Mobility Device

3. Experiments

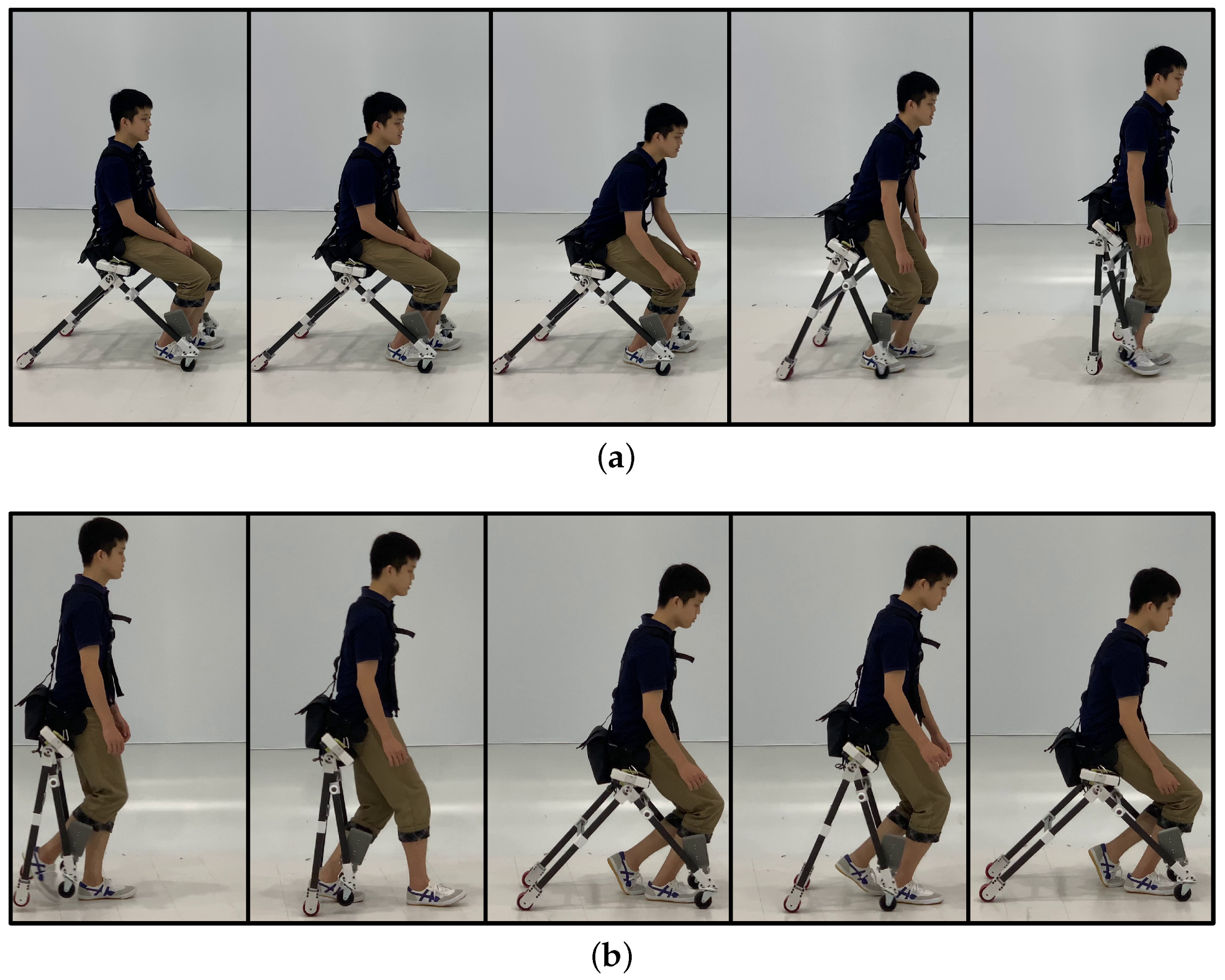

3.1. Frame Transformation Test

3.2. Control Test

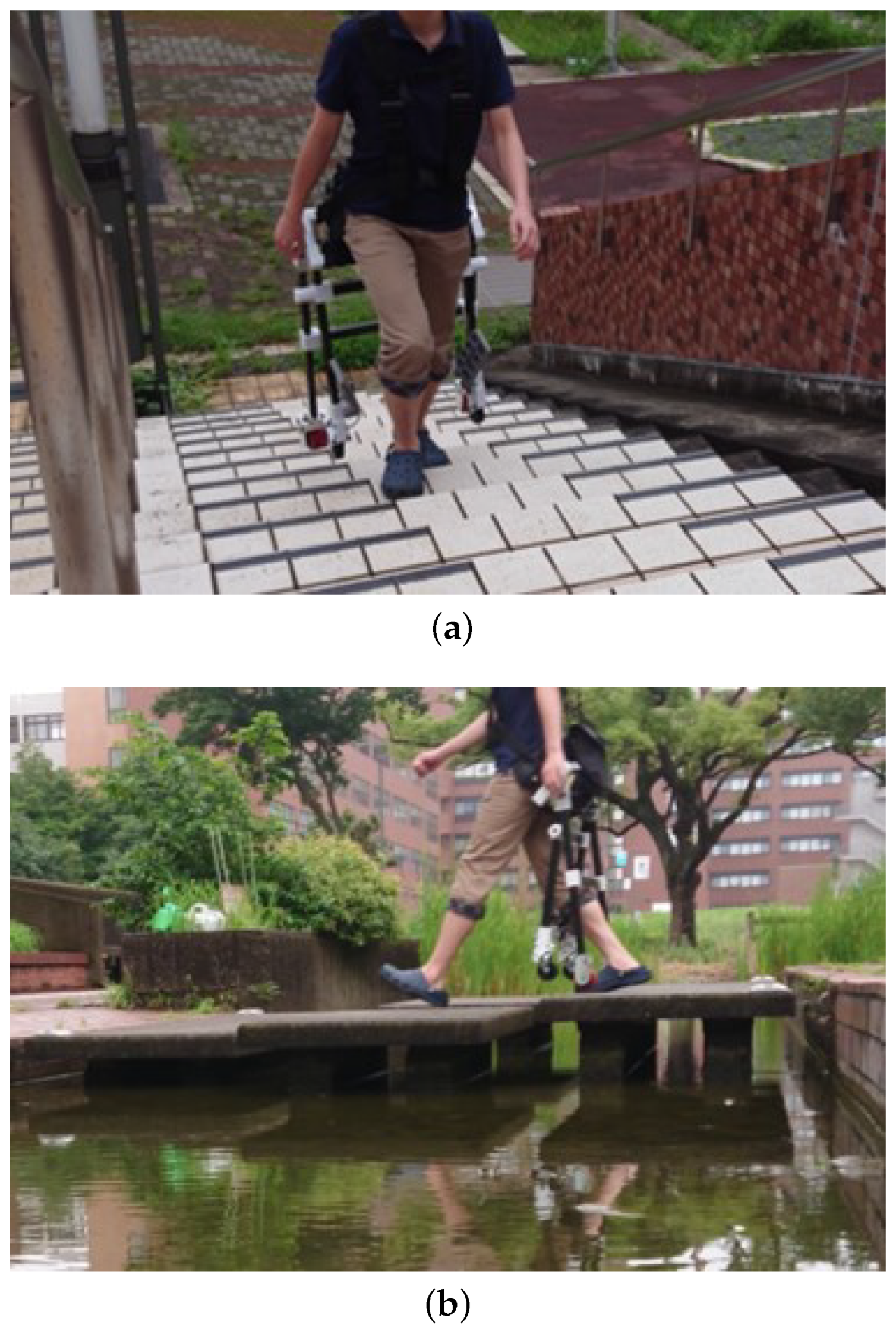

3.3. Walking and Climbing Test

3.4. Mobility Test

4. Discussion

Limitation

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ICT | Information and Communications Technology |

| WeMo | Wearable mobility |

| CFRP | Carbon Fiber Reinforced Plastics |

| PWM | Pulse width modulation |

| COP | Center of pressure |

References

- Batty, M.; Axhausen, K.W.; Giannotti, F.; Pozdnoukhov, A.; Bazzani, A.; Wachowicz, M.; Ouzounis, G.; Portugali, Y. Smart cities of the future. Eur. Phys. J. Spec. Top. 2012, 214, 481–518. [Google Scholar] [CrossRef]

- Medical Dictionary. Personal Mobility Device. 2009. Available online: https://medical-dictionary.thefreedictionary.com/personal+mobility+device (accessed on 20 July 2023).

- Akter, S.; Mamun, M.M.H.; Mwakalonge, J.L.; Comert, G.; Siuhi, S. A policy review of electric personal assistive mobility devices. Transp. Res. Interdiscip. Perspect. 2021, 11, 100426. [Google Scholar] [CrossRef]

- Tzouras, P.G.; Mitropoulos, L.; Koliou, K.; Stavropoulou, E.; Karolemeas, C.; Antoniou, E.; Karaloulis, A.; Mitropoulos, K.; Vlahogianni, E.I.; Kepaptsoglou, K. Describing Micro-Mobility First/Last-Mile Routing Behavior in Urban Road Networks through a Novel Modeling Approach. Sustainability 2023, 15, 3095. [Google Scholar] [CrossRef]

- Nguyen, H.G.; Morrell, J.; Mullens, K.D.; Burmeister, A.B.; Miles, S.; Farrington, N.; Thomas, K.M.; Gage, D.W. Segway robotic mobility platform. In Proceedings of the Mobile Robots XVII. SPIE, Philadelphia, PA, USA, 29 December 2004; Volume 5609, pp. 207–220. [Google Scholar]

- Shin, G.W.; Lee, K.J.; Park, D.; Lee, J.H.; Yun, M.H. Personal mobility device and user experience: A state-of-the-art literature review. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting; SAGE Publications Sage CA: Los Angeles, CA, USA, 2018; Volume 62, pp. 1336–1337. [Google Scholar]

- Sasaki, M.; Yanagihara, N.; Matsumoto, O.; Komoriya, K. Steering control of the personal riding-type wheeled mobile platform (PMP). In Proceedings of the 2005 IEEE/RSJ International Conference on Intelligent Robots and Systems, Edmonton, AB, Canada, 2–6 August 2005; pp. 1697–1702. [Google Scholar] [CrossRef]

- Takei, T.; Matsumoto, O.; Komoriya, K. Simultaneous estimation of slope angle and handling force when getting on and off a human-riding wheeled inverted pendulum vehicle. In Proceedings of the 2009 IEEE/RSJ International Conference on Intelligent Robots and Systems, St. Louis, MO, USA, 10–15 October 2009; pp. 4553–4558. [Google Scholar] [CrossRef]

- Podobnik, J.; Rejc, J.; Slajpah, S.; Munih, M.; Mihelj, M. All-terrain wheelchair: Increasing personal mobility with a powered wheel-track hybrid wheelchair. IEEE Robot. Autom. Mag. 2017, 24, 26–36. [Google Scholar] [CrossRef]

- Sugahara, Y.; Yonezawa, N.; Kosuge, K. A novel stair-climbing wheelchair with transformable wheeled four-bar linkages. In Proceedings of the 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18–22 October 2010; pp. 3333–3339. [Google Scholar]

- Maeda, K.; Nakajima, S. Human machine interface to provide a driver with information on a next motion of personal mobility vehicles. In Proceedings of the 2021 60th Annual Conference of the Society of Instrument and Control Engineers of Japan (SICE), Tokyo, Japan, 8–10 September 2021; pp. 1227–1232. [Google Scholar]

- Morbidi, F.; Devigne, L.; Teodorescu, C.S.; Fraudet, B.; Leblong, E.; Carlson, T.; Babel, M.; Caron, G.; Delmas, S.; Pasteau, F.; et al. Assistive Robotic Technologies for Next-Generation Smart Wheelchairs: Codesign and Modularity to Improve Users’ Quality of Life. IEEE Robot. Autom. Mag. 2022, 30, 24–35. [Google Scholar] [CrossRef]

- Chen, Y.; Paez-Granados, D.; Kadone, H.; Suzuki, K. Control interface for hands-free navigation of standing mobility vehicles based on upper-body natural movements. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 24 October–24 January 2020; pp. 11322–11329. [Google Scholar]

- Maruno, Y.; Dan, Y.; Zengin, A.T.; Okajima, H.; Matsunaga, N. Maneuverability analysis of front drive type personal vehicle STAVi using modeling error compensation system. IFAC Proc. Vol. 2013, 46, 837–842. [Google Scholar] [CrossRef]

- Sankai, Y. HAL: Hybrid assistive limb based on cybernics. In Proceedings of the Robotics Research: The 13th International Symposium ISRR; Springer: Berlin/Heidelberg, Germany, 2011; pp. 25–34. [Google Scholar]

- ReWalk Robotics. ReWalk Personal 6.0 Exoskeleton. Available online: https://rewalk.com/rewalk-personal-3/ (accessed on 21 July 2023).

- WIRobotics. ReWalk Personal 6.0. Available online: http://www.wirobotics.com/en/wim.php (accessed on 17 July 2023).

- Asbeck, A.T.; De Rossi, S.M.; Galiana, I.; Ding, Y.; Walsh, C.J. Stronger, smarter, softer: Next-generation wearable robots. IEEE Robot. Autom. Mag. 2014, 21, 22–33. [Google Scholar] [CrossRef]

- Takashima, R.; Kuwahara, T.; Imahori, M. A Novel Wearable Mobility Device Adapting to Posture of Wearer and Environments with Steps. In Proceedings of the HCI International 2019—Posters: 21st International Conference, HCII 2019, Orlando, FL, USA, 26–31 July 2019; Springer: Cham, Switzerland, 2019; pp. 528–532. [Google Scholar]

- Courtine, G.; Schieppati, M. Human walking along a curved path. I. Body trajectory, segment orientation and the effect of vision. Eur. J. Neurosci. 2003, 18, 177–190. [Google Scholar] [CrossRef] [PubMed]

- Shikdar, A.A.; Al-Hadhrami, M.A. Smart workstation design: An ergonomics and methods engineering approach. Int. J. Ind. Syst. Eng. 2007, 2, 363–374. [Google Scholar] [CrossRef]

- Azizi, M.; Ashaari, R.; As’arry, A.; Hafiz, M. Design and Development of Stabiliser for Electric Unicycle. J. Soc. Automot. Eng. Malays. 2020, 4, 288–306. [Google Scholar] [CrossRef]

- Olabi, A.; Wilberforce, T.; Obaideen, K.; Sayed, E.T.; Shehata, N.; Alami, A.H.; Abdelkareem, M.A. Micromobility: Progress, benefits, challenges, policy and regulations, energy sources and storage, and its role in achieving sustainable development goals. Int. J. Thermofluids 2023, 17, 100292. [Google Scholar] [CrossRef]

- Kim, S.H.; Lim, H.; Kim, J. Exploring countermeasures from a psychological perspective to create a safe driving environment for personal mobility devices. Sustainability 2021, 13, 5450. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Kuwahara, T.; Nishimura, Y.; Suzuki, K. WeMo: A Prototype of a Wearable Mobility Device Adapting to User’s Natural Posture Changes. Sensors 2023, 23, 7683. https://doi.org/10.3390/s23187683

Chen Y, Kuwahara T, Nishimura Y, Suzuki K. WeMo: A Prototype of a Wearable Mobility Device Adapting to User’s Natural Posture Changes. Sensors. 2023; 23(18):7683. https://doi.org/10.3390/s23187683

Chicago/Turabian StyleChen, Yang, Takashi Kuwahara, Yuki Nishimura, and Kenji Suzuki. 2023. "WeMo: A Prototype of a Wearable Mobility Device Adapting to User’s Natural Posture Changes" Sensors 23, no. 18: 7683. https://doi.org/10.3390/s23187683

APA StyleChen, Y., Kuwahara, T., Nishimura, Y., & Suzuki, K. (2023). WeMo: A Prototype of a Wearable Mobility Device Adapting to User’s Natural Posture Changes. Sensors, 23(18), 7683. https://doi.org/10.3390/s23187683