High-Sensitivity Temperature Sensor Based on Fiber Fabry-Pérot Interferometer with UV Glue-Filled Hollow Capillary Fiber

Abstract

:1. Introduction

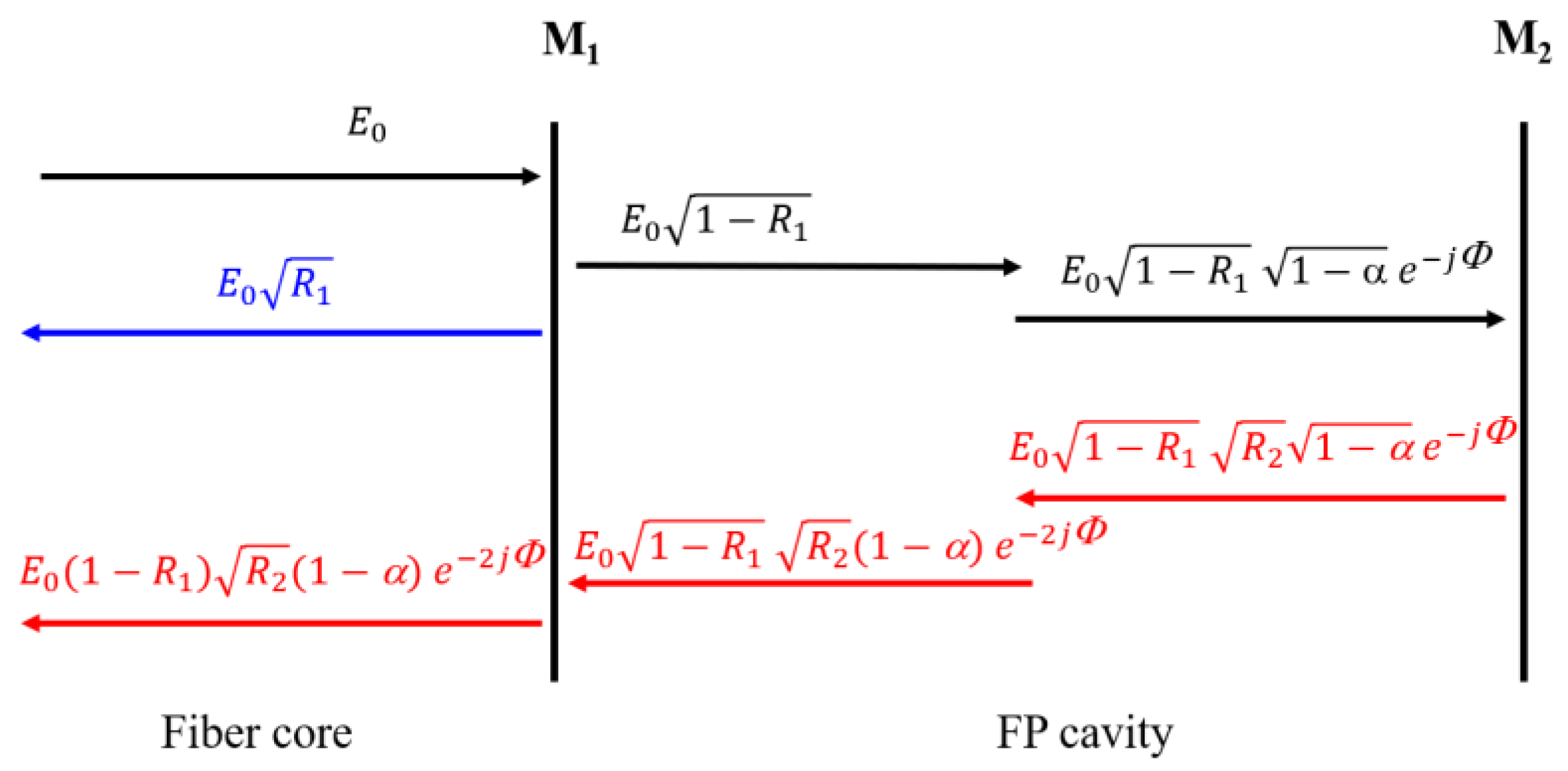

2. Sensor Configuration and Principle

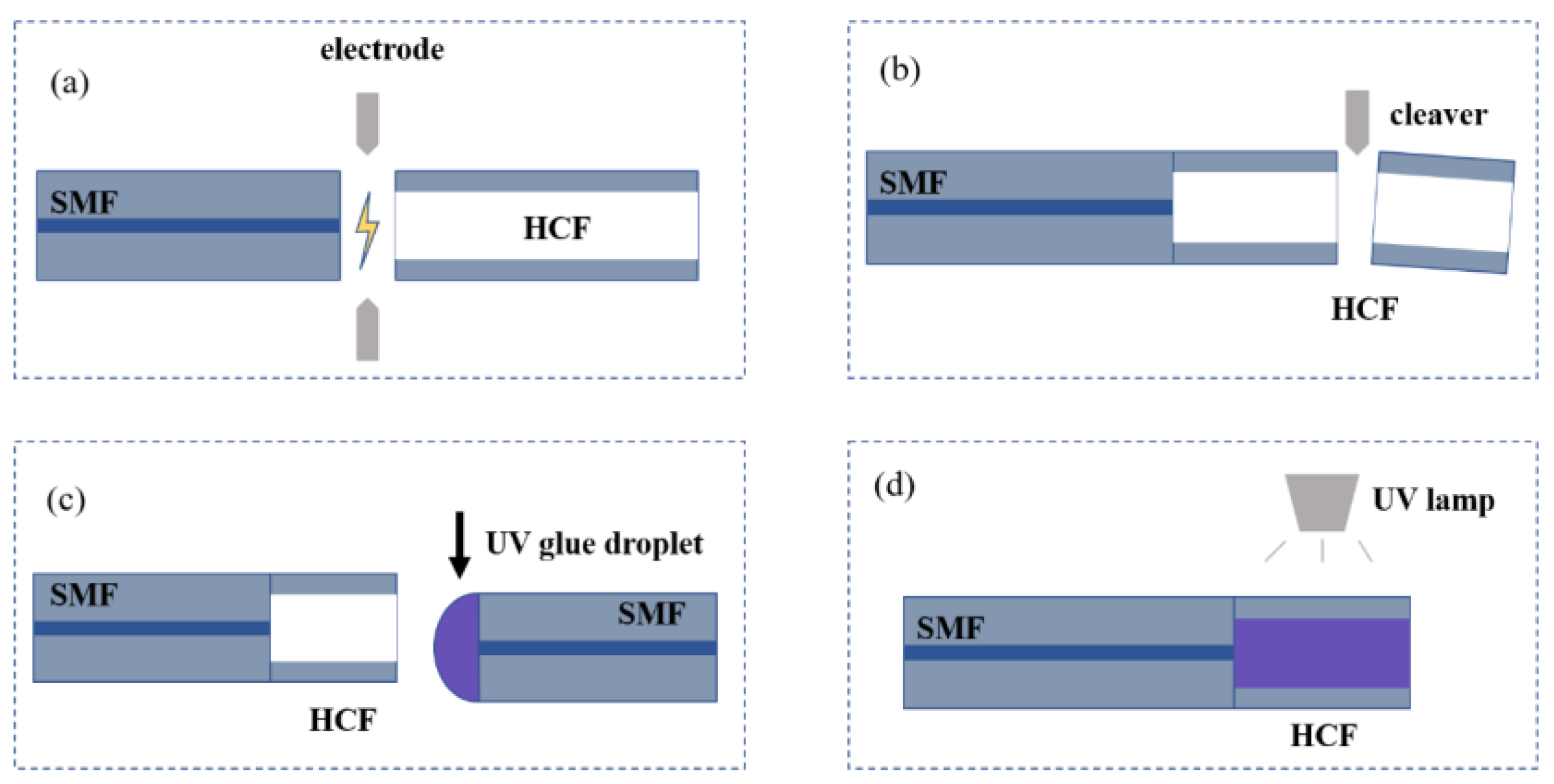

3. Sensor Fabrication

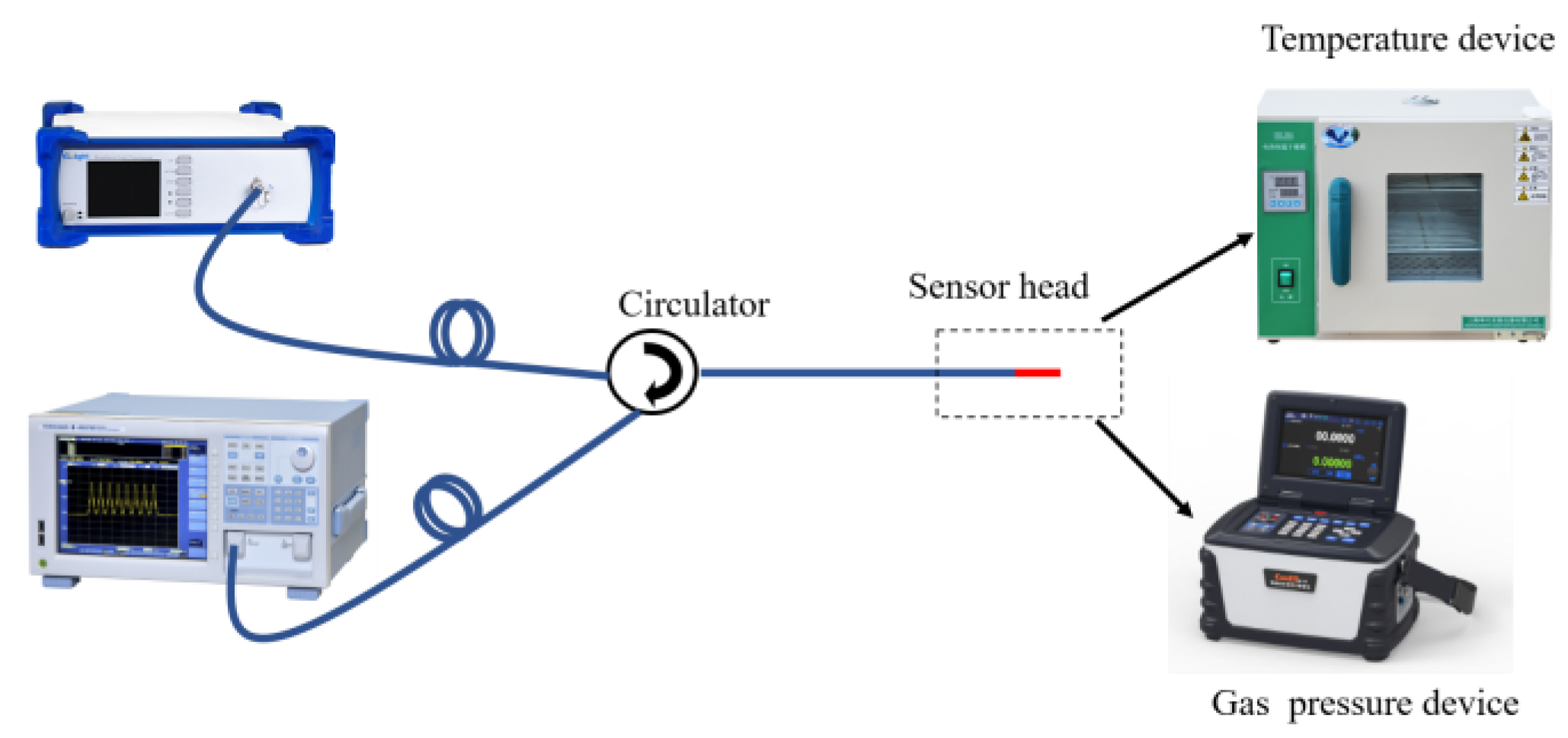

4. Results and Discussion

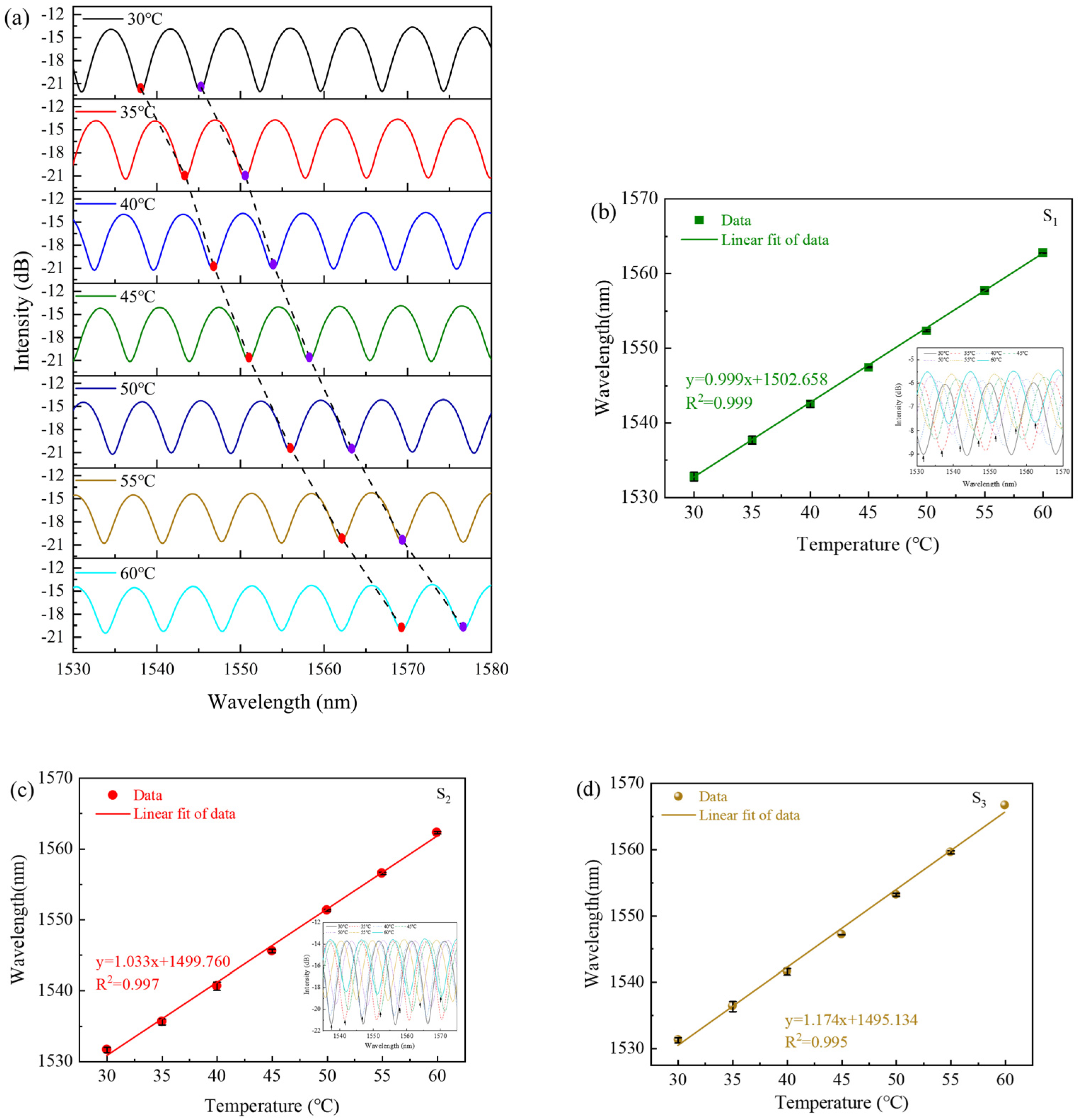

4.1. Temperature Performance

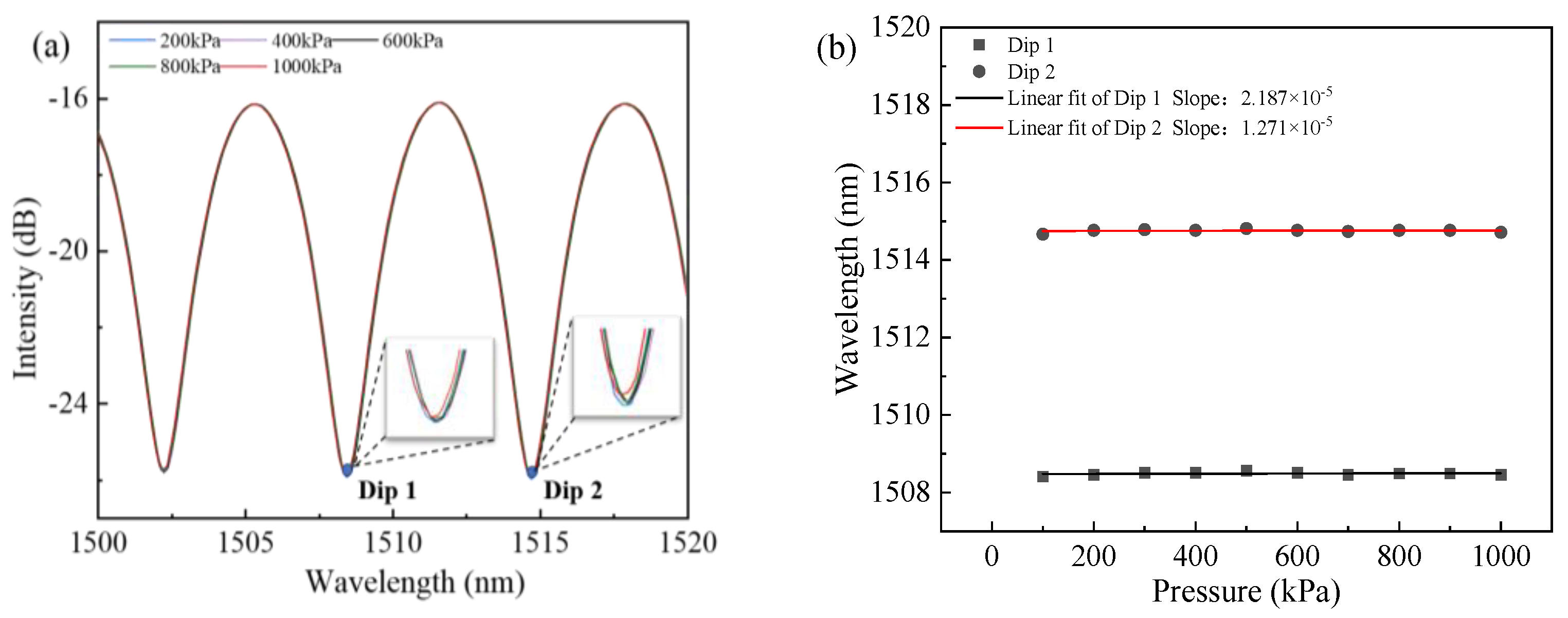

4.2. Pressure Performance

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, B. Review of the present status of optical fiber sensors. Opt. Fiber Technol. 2003, 9, 57–79. [Google Scholar] [CrossRef]

- Sahota, J.K.; Gupta, N.; Dhawan, D. Fiber Bragg grating sensors for monitoring of physical parameters: A comprehensive review. Opt. Eng. 2020, 59, 060901. [Google Scholar] [CrossRef]

- Liu, Y.; Yuan, L.B. Ultrasensitive temperature sensor based on a urethane acrylate-coated off-axis spiral long period fiber grating. Optik 2020, 223, 165557. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, X.G.; Cai, L.; Zhang, Y.N. Measurement of RI and temperature using composite interferometer with hollow-core fiber and photonic crystal fiber. IEEE Trans. Instrum. Meas. 2016, 65, 2631–2636. [Google Scholar] [CrossRef]

- Mollaha, M.A.; Islamb, S.R.; Yousufalia, M.; Abdulrazak, L.F.; Hossaine, M.B.; Amiri, I.S. Plasmonic temperature sensor using D-shaped photonic crystal fiber. Results Phys. 2020, 16, 102966. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Zhang, X.Q.; Chu, S.C.; Fan, Z.K. A highly sensitive photonic crystal fiber temperature sensor based on Sagnac interferometer with full liquid filling. Opt. Quantum Electron. 2023, 55, 371. [Google Scholar] [CrossRef]

- Ma, J.W.; Wu, S.; Cheng, H.H.; Yang, X.M.; Wang, S.; Lu, P.X. Sensitivity-enhanced temperature sensor based on encapsulated S-taper fiber modal interferometer. Opt. Laser Technol. 2021, 139, 106933. [Google Scholar] [CrossRef]

- Fu, X.H.; Ma, S.Y.; Zhang, R.J.; Liu, F.; Fu, G.W.; Jin, W.; Bi, W.H. Refractive index insensitive triple cladding quartz specialty fiber temperature sensor with D-type microcavity structure. IEEE Sens. J. 2021, 21, 24098–24105. [Google Scholar] [CrossRef]

- Li, A.W.; Shan, T.Q.; Gou, Q.; Pan, X.P.; Liu, S.R.; Chen, C.; Yu, Y.S. Research progress of optical fiber Fabry-Perot interferometer high temperature sensors. Chin. Opt. 2022, 15, 609–624. [Google Scholar]

- Wang, B.T.; Niu, Y.X.; Zheng, S.W.; Yin, Y.H.; Ding, M. A high temperature sensor based on sapphire fiber Fabry-Perot interferometer. IEEE Photon. Technol. Lett. 2020, 32, 89–92. [Google Scholar] [CrossRef]

- Yang, T.Y.; Feng, Y.; Tang, M.D.; Liu, C.; Liu, X.; Zhang, J.M.; Shen, T. MZI interferometric fiber optic temperature sensor based on MFC. Microw. Opt. Technol. Lett. 2022, 65, 1208–1214. [Google Scholar] [CrossRef]

- Gong, J.Q.; Shen, C.Y.; Xiao, Y.K.; Liu, S.Y.; Zhang, C.; Ding, Z.Y.; Deng, H.T.; Fang, J.H.; Lang, T.T.; Zhao, C.L.; et al. High sensitivity fiber temperature sensor based PDMS film on Mach-Zehnder interferometer. Opt. Fiber Technol. 2019, 53, 102029. [Google Scholar] [CrossRef]

- Bao, L.F.; Dong, X.Y.; Shum, P.P.; Shen, C.Y. Compact temperature sensor with highly Germania-doped fiber-based Michelson interferometer. IEEE Sens. J. 2018, 18, 8017–8021. [Google Scholar] [CrossRef]

- Shao, L.P.; Hu, J.H.; Lu, H.L.; Du, J.; Wu, T.Y.; Wang, Y.P. High-sensitivity temperature sensor based on polarization maintaining fiber Sagnac loop. Photonic Sens. 2019, 9, 25–32. [Google Scholar] [CrossRef]

- Lebarck, J.P.; Schmidt, C.E.; Leal-Junior, A.G. Highly sensitive temperature sensing based on a birefringent fiber Sagnac loop. Opt. Fiber Technol. 2022, 72, 102949. [Google Scholar] [CrossRef]

- Kou, J.L.; Feng, J.; Ye, L.; Xu, F.; Lu, Y.Q. Miniaturized fiber taper reflective interferometer for high temperature measurement. Opt. Exp. 2021, 18, 14245–14250. [Google Scholar] [CrossRef]

- Chen, M.Q.; Zhao, Y.; Xia, F.; Peng, Y.; Tong, R.J. High sensitivity temperature sensor based on fiber air-microbubble Fabry-Perot interferometer with PDMS-filled hollow-core fiber. Sens. Actuator A Phys. 2018, 275, 60–66. [Google Scholar] [CrossRef]

- Ge, M.; Li, Y.; Han, Y.H.; Xia, Z.H.; Guo, Z.Y.; Gao, J.M.; Qu, S.L. High-sensitivity double-parameter sensor based on the fibre-tip Fabry–Pérot interferometer. J. Mod. Opt. 2017, 64, 596–600. [Google Scholar] [CrossRef]

- Deng, H.C.; Jiang, X.W.; Wang, R.; Xu, R.H.; Teng, C.X.; Chen, M.; Zhang, W.T.; Yuan, L.B.; Deng, S.J. Real-time monitoring of UV curing by fiber-integrated Fabry-Perot sensor. Opt. Commun. 2021, 496, 127143. [Google Scholar] [CrossRef]

- Meng, J.; Ma, J.N.; Li, J.; Yan, H.; Meng, F.L. Humidity sensing and temperature response performance of polymer gel cold-spliced optical fiber Fabry-Perot interferometer. Opt. Fiber Technol. 2022, 68, 102823. [Google Scholar] [CrossRef]

- Liu, Y.G.; Yang, D.Q.; Wang, Y.X.; Zhang, T.; Shao, M.; Yu, D.K.; Fu, H.W.; Jia, Z.N. Fabrication of dual-parameter fiber-optic sensor by cascading FBG with FPI for simultaneous measurement of temperature and gas pressure. Opt. Commun. 2019, 443, 166–171. [Google Scholar] [CrossRef]

- Zhang, J.; Liao, H.; Lu, P.; Jiang, X.Y.; Fu, X.; Ni, W.J.; Liu, D.M.; Zhang, J.S. Ultrasensitive temperature sensor with cascaded fiber optic Fabry-Perot interferometers based on Vernier effect. IEEE Photon. J. 2018, 10, 6803411. [Google Scholar] [CrossRef]

- Li, B.W.; Liu, Y.G.; Song, X.Y.; Fu, H.W.; Jia, Z.N.; Gao, H. High-sensitivity temperature sensor based on ultraviolet glue-filled silica capillary tube. J. Mod. Opt. 2020, 67, 1327–1333. [Google Scholar] [CrossRef]

- Lee, C.L.; Lee, L.H.; Hwang, H.E.; Hsu, J.M. Highly sensitive air-gap fiber Fabry–Pérot interferometers based on polymer-filled hollow core fibers. IEEE Photonic Technol. Lett. 2012, 24, 149–151. [Google Scholar] [CrossRef]

- Chen, J.H.; Huang, X.G.; Huang, Z.J. Simple thin-film fiber optic temperature sensor based on Fabry-Perot interference. Opt. Eng. 2010, 49, 412–414. [Google Scholar] [CrossRef]

- Huang, Y.W.; Xu, J.T.; Huang, G. Research progress on F-P interference-based fiber-optic sensors. Sensors 2016, 16, 1424. [Google Scholar] [CrossRef]

- Zhou, C.; Zhou, Q.; Wang, B.; Tian, J.J.; Yao, Y. High-sensitivity relative humidity fiber-optic sensor based on an internal–external Fabry–Perot cavity Vernier effect. Opt. Exp. 2021, 29, 11854–11868. [Google Scholar] [CrossRef]

- Sakhabutdinov, A.Z.; Morozov, O.G.; Anfinogentov, V.I.; Tunakova, J.A. Applicability limits of the end face fiber-optic gas concentration sensor, based on Fabry-Perot interferometer. Karbala Int. J. Mod. Sci. 2022, 8, 339–355. [Google Scholar]

| Parameter | Explanation |

|---|---|

| n0 | RI of air |

| ns | RI of SMF core |

| n | RI of the UV glue |

| R1 | reflectivity of reflected surface M1 |

| R2 | reflectivity of reflected surface M2 |

| L | FPI cavity length |

| α | transmission loss at the M1 |

| λ | wavelength of incident light |

| Φ | phase difference in FP cavity |

| λm | wavelength of m′th-order interference dip of FPI |

| E0 | input electric field |

| Er | total electric field reflected from the FPI sensor |

| Ir | total reflected light intensity |

| T | temperature |

| ST | temperature sensitivity of the proposed FPI |

| αTEC | the TEC of UV glue |

| σTOC | the TOC of UV glue |

| m, j | positive integer |

| Sensor Structure | Sensitivity | FPI Cavity Length or Structure Size | Range | Fabrication | Cost | Ref |

|---|---|---|---|---|---|---|

| PDMS-filled air-microbubble | 2.7035 nm/°C | the air-microbubble length of 26.5 μm | 51.2–70.5 °C | Easy | Low | [17] |

| SU-8 and PDMS polymer-capped | 0.6897 nm/°C | the SU-8 film thickness of 18.7 μm the PDMS film thickness of 7.7 μm | 20–75 °C | Easy | High | [18] |

| UV glue-capped with FBG | 0.223 nm/°C | the UV glue cap thickness of 48 μm | 30–110 °C | Complicated | High | [21] |

| UV glue/Air cavity | 67.35 nm/°C | the sensing air cavity length of 77.59 μm the reference air cavity length of 81.52 μm | 20–24 °C | Complicated | Low | [22] |

| UV glue and Capillary | 0.963 nm/°C | the UV glue cavity length of 90 μm | 42–50 °C | Easy | Low | [23] |

| UV glue and Air Cavities | −1.7 nm/°C | the air cavity length of 20 μm the UV glue cavity length of 70 μm | 20–75 °C | Easy | Low | [24] |

| UV glue-filled HCF | 1.174 nm/°C | the UV glue cavity length of 118.85 μm | 30–60 °C | Easy | Low | Our work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Y.; Chen, Y.; Zhang, Q.; Tang, Q.; Zhu, Y.; Yu, Y.; Du, C.; Ruan, S. High-Sensitivity Temperature Sensor Based on Fiber Fabry-Pérot Interferometer with UV Glue-Filled Hollow Capillary Fiber. Sensors 2023, 23, 7687. https://doi.org/10.3390/s23187687

Zheng Y, Chen Y, Zhang Q, Tang Q, Zhu Y, Yu Y, Du C, Ruan S. High-Sensitivity Temperature Sensor Based on Fiber Fabry-Pérot Interferometer with UV Glue-Filled Hollow Capillary Fiber. Sensors. 2023; 23(18):7687. https://doi.org/10.3390/s23187687

Chicago/Turabian StyleZheng, Yiwen, Yongzhang Chen, Qiufang Zhang, Qianhao Tang, Yixin Zhu, Yongqin Yu, Chenlin Du, and Shuangchen Ruan. 2023. "High-Sensitivity Temperature Sensor Based on Fiber Fabry-Pérot Interferometer with UV Glue-Filled Hollow Capillary Fiber" Sensors 23, no. 18: 7687. https://doi.org/10.3390/s23187687

APA StyleZheng, Y., Chen, Y., Zhang, Q., Tang, Q., Zhu, Y., Yu, Y., Du, C., & Ruan, S. (2023). High-Sensitivity Temperature Sensor Based on Fiber Fabry-Pérot Interferometer with UV Glue-Filled Hollow Capillary Fiber. Sensors, 23(18), 7687. https://doi.org/10.3390/s23187687