1. Introduction

The automotive industry has experienced rapid development in recent years, with continuous transformation and upgrading of cars. The development of automobiles toward intelligence, electrification, networking, and sharing has greatly improved transportation and people’s daily lives [

1,

2,

3]. The autonomous vehicle represents the most advanced technology in the industry’s development. It encompasses three main components, including environmental perception [

4], path planning [

5], and tracking control [

6]. The first part relies on various sensors to detect the external environment and input this information into the autonomous vehicle system [

7,

8,

9], thereby establishing the foundation for subsequent planning and control [

10]. The objective of planning is to determine the most optimized path for intelligent vehicles using appropriate algorithms [

11]. The function of control involves using suitable controllers to guide the vehicle along the planned path [

12,

13]. This study primarily focuses on the study of path planning and tracking control [

14].

Path planning is one of the important aspects of intelligent vehicles. It includes two major parts, global path planning and local path planning. Global path planning is carried out throughout the entire map range, planning a rough route for vehicles from the starting point to the endpoint. The classification of common global path planning methods is as follows, graph search-based algorithms such as A* [

15] and Dijkstra [

16], intelligent algorithms such as the genetic algorithm [

17] and particle swarm optimization [

18], and machine learning-based methods such as reinforcement learning [

19] and deep learning [

20]. Local path planning is carried out in the environment surrounding the vehicle’s current location. It is used to plan a local collision-free path in detail.

Common local path planning algorithms include potential-based methods such as the APF method and the minimum potential energy method, rule-based methods such as the discrete method and the continuous method, and sampling-based methods such as Monte Carlo sampling [

21] and inverse sampling. Most of the improved A* algorithms can effectively plan a collision-free path, as global path planning is already very mature. However, local path planning algorithms have problems such as local optima, an inability to adapt to dynamic environments, and poor security. Therefore, this study focuses on local path planning. Among them, the APF method has the advantages of simplicity, high real-time performance, and adaptability to complex environments. Therefore, the most widely used APF method was chosen for improvement.

At present, the APF method has drawbacks such as local minima, unreachable target points, and poor adaptability to traffic environments. Scholars have made a series of improvements to the APF method. Li et al. [

22] proposed a minimum safe distance model for overtaking and lane-changing scenarios. The length of overtaking routes was controlled to a minimum by setting a minimum safety distance. However, only considering the minimum route ignores the dynamic constraints of the vehicle, which may result in the turning radius of the vehicle not reaching that large. Yao et al. [

23] proposed a fusion method of the black hole potential field and reinforcement learning to solve the problem of local minima. Their method found target points in a multi-objective environment. At the same time, the trained autonomous vehicle quickly adapted to the scene containing new obstacles in real time. However, setting the threshold is not very easy to grasp. If the threshold is set too high, multiple gravitational fields will overlap. On the contrary, if the threshold is too low, it cannot be detected. Xie et al. [

24] proposed an improved APF algorithm, which introduced the concepts of the velocity difference potential field and the acceleration difference potential field. They also proposed an optimization algorithm based on the stability of vehicles. Their experimental results demonstrated that the improved algorithm successfully enabled the safe overtaking of multiple-lane fleets. Although the generated path can meet the road constraints, dynamic constraints, and kinematic constraints in the environment set in the text, it cannot adapt to complex environments such as multiple obstacles. Duan et al. [

25] proposed an improved APF method for local minima in the safe distance model. They introduced a second virtual target gravitational field. Their experiments showed that the improved APF method could effectively solve the problem of local minima. Although the safety and stability of cars were improved, they did not take into account the issues of unreachable goals and constraints of the traffic environment. Feng et al. [

26] put forward a model for lateral lane changing and a model for longitudinal braking distance in order to avoid collisions. They also integrated the safety model into the APF algorithm. This allowed them to plan a collision avoidance path that satisfied stability requirements. However, their study did not consider the dynamic environment, which is too simplistic and limited in its adaptability. Yuan et al. [

27] proposed lateral and longitudinal safety distance models to analyze the braking process and limit the sideslip angle. Building on these models, they improved the APF algorithm. Their simulation results demonstrated that obstacle avoidance could be achieved within a short period of time. However, they did not address the issue of unreachable targets and insufficient adaptability to different environmental conditions. These algorithms have made significant progress in enhancing planning efficiency, reducing computational costs, and complying with kinematic constraints. Nevertheless, further research and improvement are required to achieve a more efficient, accurate, and secure autonomous vehicle path planning system.

Table 1 lists the methods, merits, and drawbacks of the improved APF methods mentioned in the above references.

Path tracking control is based on the planned path at the upper level and uses a specific control algorithm for tracking control [

28]. Existing issues in vehicle path tracking primarily include inaccuracies in path tracking and control instability [

29], as well as the presence of dynamic and kinematic constraints in the vehicle [

30]. To address these concerns, researchers from both domestic and foreign backgrounds have implemented various improvement strategies for enhancing path-tracking performance. In response to the aforementioned concerns, scholars have implemented a range of measures to enhance path tracking. Chen et al. [

31] proposed a hierarchical dynamic drift controller for achieving smoother tracking of general paths. The controller is divided into three layers. The first layer determines the state of the system. The second layer combines drift and typical turning control using a dynamic drift inverse model. The third layer implements a steering system and controls wheel speed. This controller can successfully achieve high tracking accuracy in real time. Wang et al. [

32] improved the LQR algorithm and designed a discrete LQR controller with both feedforward and feedback components. They utilize fuzzy control methods to dynamically adjust the weight coefficients of the LQR controller. The update mechanism, based on cosine similarity, achieves the objective of reducing computational complexity. This control algorithm effectively enhances path-tracking accuracy but exhibits relatively weak steering stability. Sliding mode control(SMC), a well-established nonlinear control strategy, generates discontinuous control signals that compel the system to follow a predetermined sliding mode trajectory [

33]. Nevertheless, traditional fuzzy control encounters a significant issue when the system reaches the sliding mode surface, as it leads to chattering. Hence, scholars have used diverse techniques to mitigate chattering and improve the effectiveness of the controller. Terminal sliding mode control is one such technique that suppresses chattering and reduces the convergence time in comparison with traditional SMC [

34]. Ao et al. [

35] introduced a super twisted sliding mode control algorithm, and with the application of backstepping techniques and experiments, they successfully demonstrated the stability and robustness of the system. Similarly, Sabiha et al. [

36] developed an integral terminal SMC approach that not only guarantees finite time convergence but also enhances the convergence speed. Building upon these advancements, Wang et al. [

37] proposed an adaptive integral terminal SMC method, which offers several advantages over other sliding mode controllers. While the previous enhancements demonstrated promising results, there is still room for further improvement in terms of control accuracy and stability. Consequently, this study introduces an improved sliding mode controller with error fusion based on the aforementioned SMC method to ensure accurate and stable path tracking.

Table 2 shows the methods, merits, and drawbacks of the improved path-tracking methods mentioned in the above references.

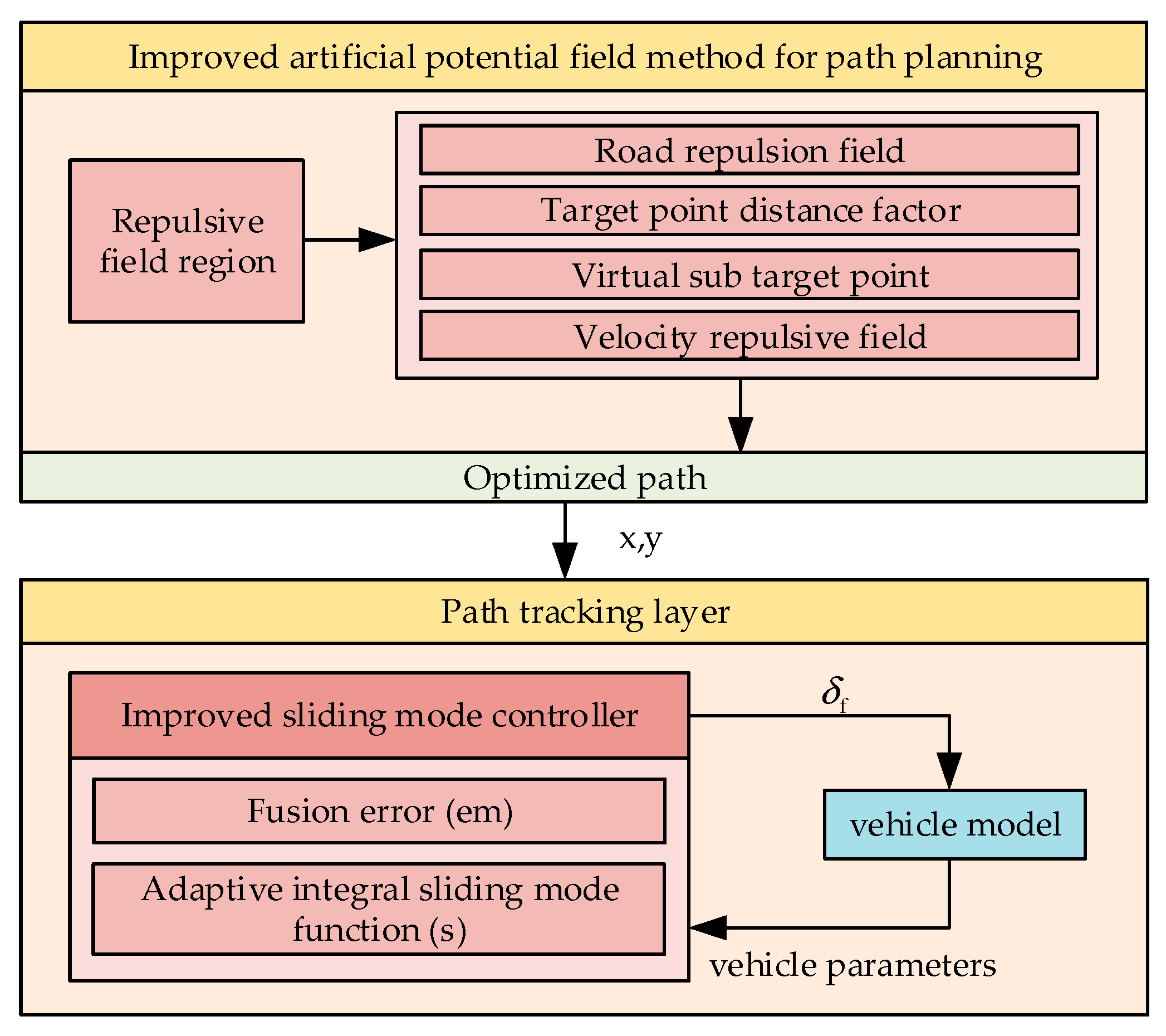

Figure 1 is a block diagram showing the path planning and path tracking system designed in this study.

Path planning in the upper layer uses an improved APF method. Initially, the range of the obstacle repulsion field is determined. Subsequently, improvements are implemented in four aspects, including the road repulsion field, target point distance factor, virtual sub-target point, and velocity repulsion field. These enhancements lead to the generation of an improved path. The optimized path is then smoothed using a cubic Bessel curve and fed into the lower layer for path tracking. In the lower layer, an improved sliding mode controller is used for trajectory tracking. This controller incorporates fusion error and improves the sliding mode function, resulting in high-precision trajectory tracking. This validates the upper layer’s ability to generate traceable optimized paths. The main contributions of this study are as follows.

- 1.

This study presents a method for setting the action area of a repulsive force field by analyzing the change in obstacle velocity. The detection process is divided into two areas. First, within a 120° range in front of the vehicle, a forward detection radius function is formulated based on the relative velocity between the closest obstacle and the vehicle. This function determines the detection area for obstacles in front. Similarly, a rear detection radius function is developed to cover a 240° range behind the vehicle for rear detection purposes. By considering only obstacles within the detection range, it saves computational time by ignoring irrelevant obstacle repulsion fields. This approach ensures both the accuracy and real-time performance of the path planning process.

- 2.

In response to the problem of unreachable targets and local optima in traditional APF methods, this study introduces the concept of virtual sub-target points and a target point distance factor. These sub-target points are randomly generated within a certain radius around the target point to replace the original target point when the resultant force becomes zero during obstacle movement. By doing so, the resultant force is always maintained as non-zero, preventing the vehicle from becoming stuck in local minima. Additionally, the distance factor for the target point is included in the formula to ensure that the total force becomes zero when the vehicle reaches the target point.

- 3.

This study presents an improved sliding mode controller that incorporates error fusion to ensure vehicle driving stability and tracking accuracy, taking into consideration both lateral and heading errors. By utilizing the improved APF algorithm, an optimized path is computed, incorporating vehicle kinematics and dynamics, which is then utilized as input for the lower controller responsible for path tracking. This aims to verify the feasibility of the planned path and evaluate the effectiveness of the enhanced tracking controller.

- 4.

To verify the effectiveness of path planning and tracking, this study uses the Carsim–Simulink joint simulation platform. The experiment encompasses both static and dynamic scenarios. The static scene involves designing an environment with obstacles and two lanes ahead and utilizing an improved APF method to devise secure routes for vehicles. A vehicle with moving obstacles is placed in the dynamic scene, and the improved APF proposed in this study is used to generate an optimized and safe path for the autonomous vehicle. The experimental results demonstrate that the planned driving path is fully compliant with safety and road constraints, allowing for the vehicle to smoothly reach the endpoint.

5. Conclusions

This study proposes an improved APF algorithm to solve a series of problems. Firstly, the range of the repulsive field is determined, allowing the range to change in real time depending on the obstacle’s speed. In addition, a road repulsion field function is incorporated. Moreover, a target point distance factor and virtual sub-target points are introduced to resolve the problems associated with unreachable targets and local minima. Furthermore, the inclusion of a velocity repulsion field enables the vehicle to adapt not only to static obstacles but also to dynamic ones. To validate the feasibility of the proposed path, an improved SMC controller is designed, which integrates both lateral and heading errors effectively. The optimized path from the planning layer is fed into the controller. The controller’s results are then compared to those obtained using the traditional SMC controller’s tracking results. Conclusively, the controller examined in this study effectively tracks three different paths in high-speed and low-speed states. Moreover, it exhibits minimal lateral and heading errors while maintaining high tracking accuracy.

In this study, we primarily explore the local path planning method for autonomous vehicles. We utilize an enhanced sliding mode controller, based on the improved artificial potential field algorithm, for trajectory tracking control. However, it is important to note that there are certain limitations associated with this approach. Firstly, our path planning methodology involves a two-degree-of-freedom ideal vehicle model, neglecting the consideration of multiple degrees of freedom. Secondly, we do not comprehensively accounted for external factors like road conditions and weather in our analysis of traffic scenarios. In future research, we aim to investigate various operating conditions and conduct more extensive studies on unexpected events such as adverse weather and other vehicle interventions, thereby making our algorithm more robust. Additionally, it should be noted that the improved artificial potential field method proposed in this study has certain computational speed drawbacks. Therefore, in the future, we intend to explore ways to simplify the calculation process. Currently, our experimentation remains limited to the simulation phase. However, we plan to validate the effectiveness of our proposed method using real vehicle experiments in subsequent research.