An Approach for Easy Detection of Buried FRP Composite/Non-Metallic Pipes Using Ground-Penetrating Radar

Abstract

:1. Introduction

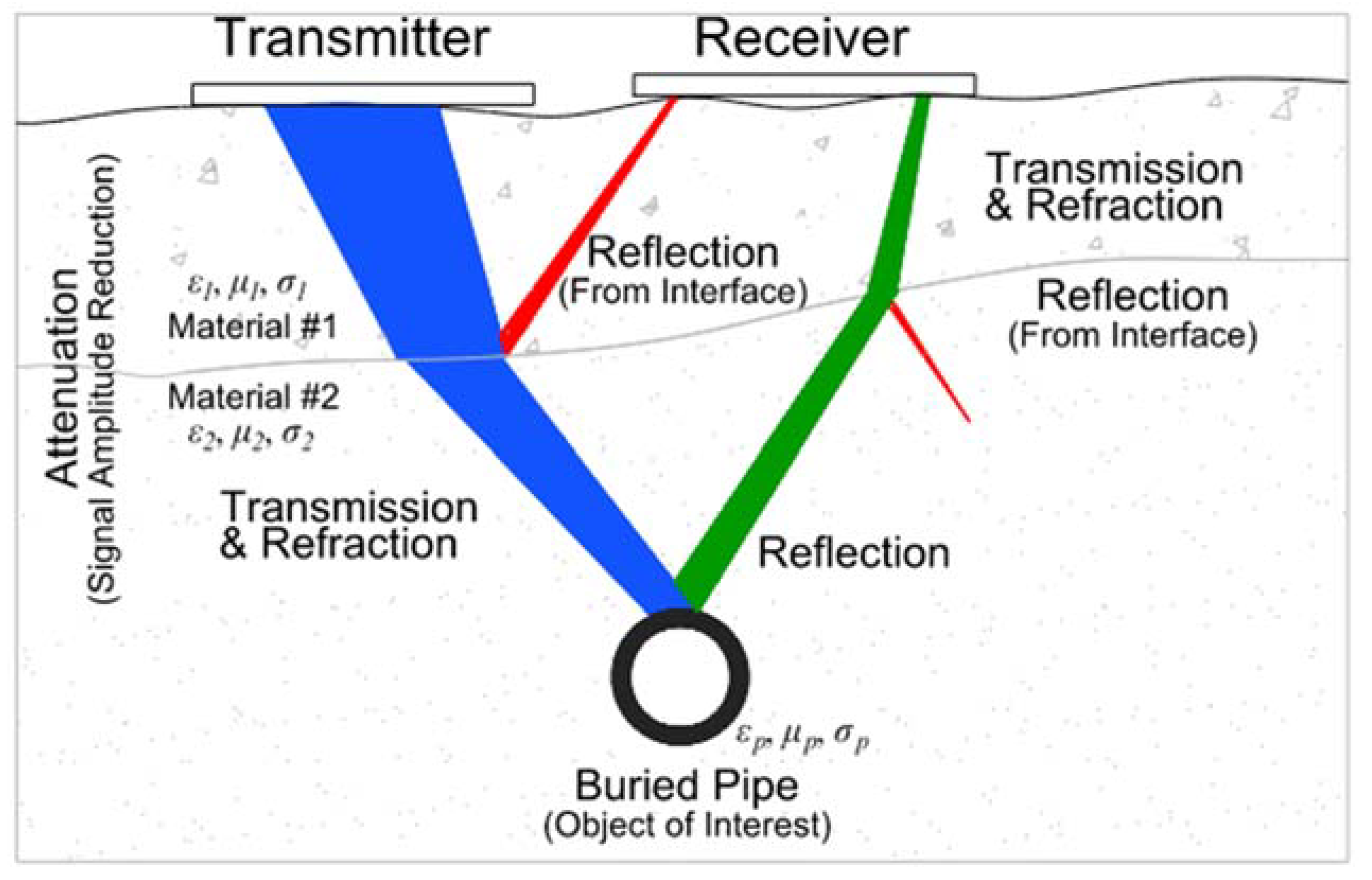

2. Transmission and Reflection of GPR Signals

- is the absolute magnetic permeability of the medium (H/m);

- is the absolute dielectric constant/permittivity (F/m);

- σ’ is the electrical conductivity (S/m);

- ω is the angular frequency of the radar wave (rad/s);

- i is the imaginary unit ().

- is the relative magnetic permeability of the medium;

- is the relative dielectric permittivity of the medium (also referred to as dielectric constant);

- μo = 4π × 10−7 H/m is the magnetic permeability of vacuum or free space;

- εo = 8.854 × 10−12 F/m is the dielectric permittivity of vacuum or free space.

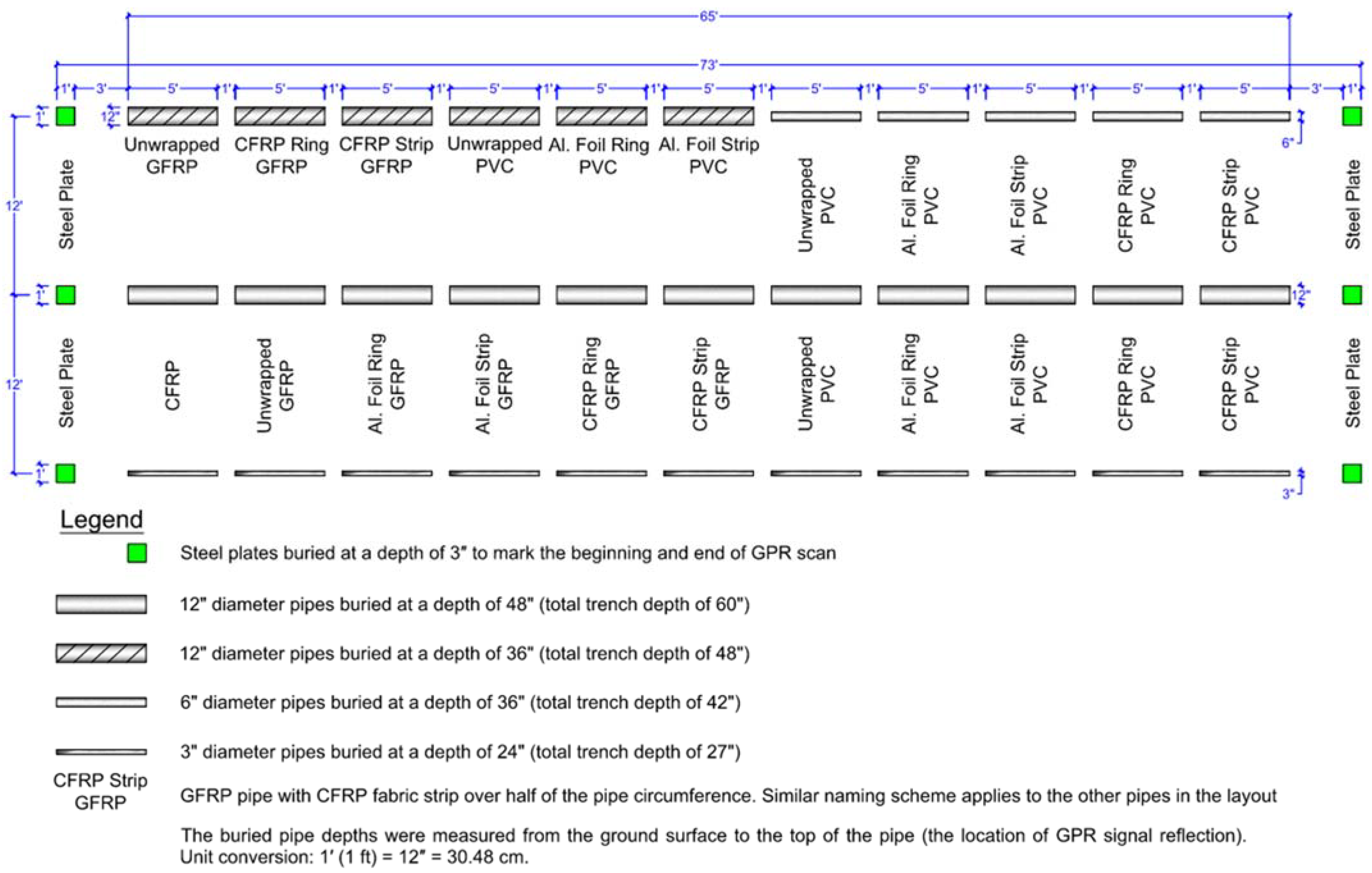

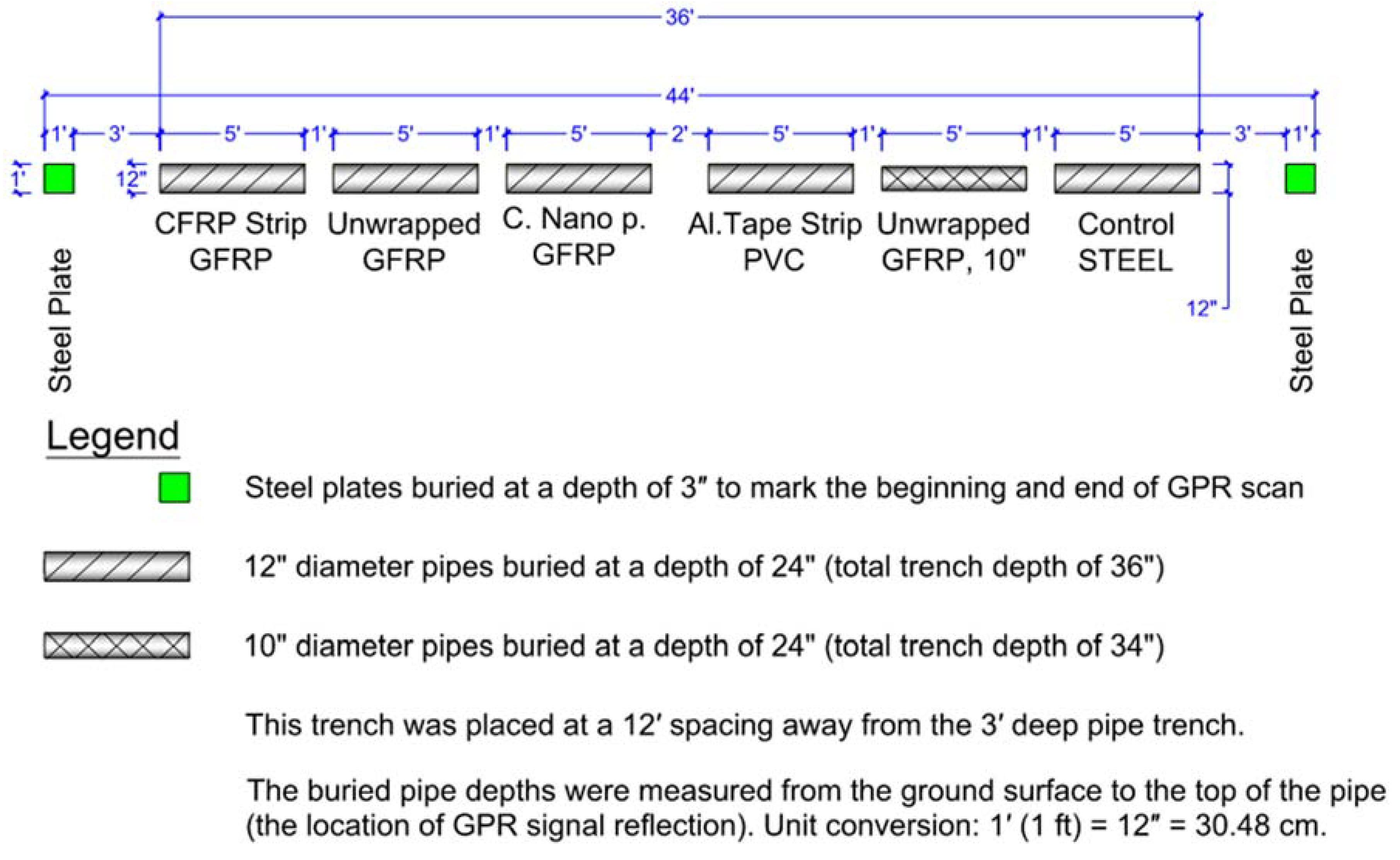

3. Experimental Program

3.1. Pipe Material Preparation

3.2. Creating Dielectric Contrast between Non-Metallic Pipes and Surrounding Soil

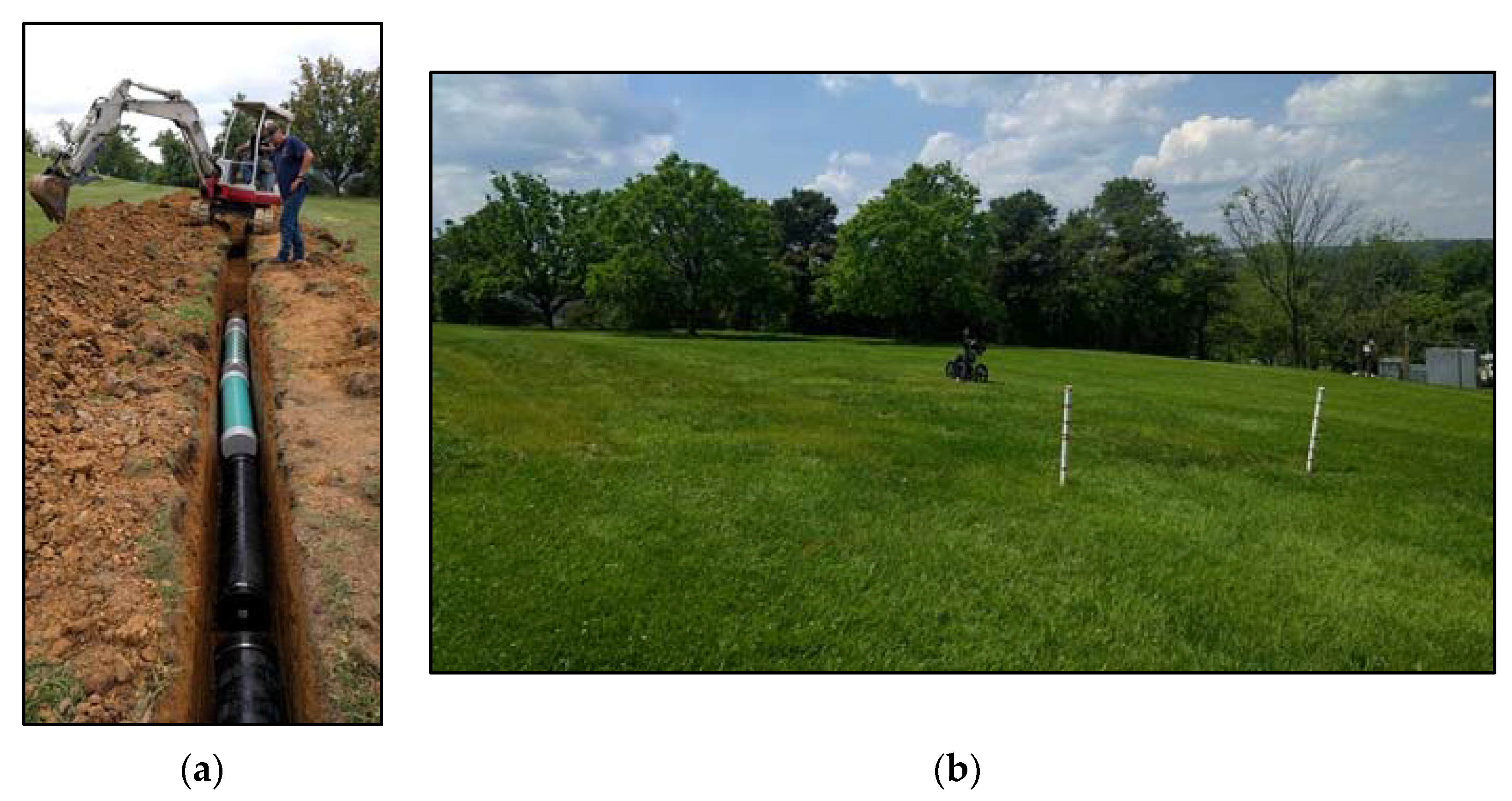

3.3. Pipe Setup and Burying

3.4. GPR Test Equipment and Data Acquisition Parameters

| Parameters | 900 MHz | 400 MHz | 200 MHz |

|---|---|---|---|

| Vertical Low-Pass Filter (MHz) | 2500 | 800 | 400 |

| Vertical High-Pass Filter (MHz) | 225 | 100 | 50 |

| Range (ns) | 30 | 30 or 50 | 50 |

| Samples per Scan | 512 | 512 | 512 |

| Bits per sample | 16 | 16 | 16 |

| Dielectric Constant | Varies, see Table 4 | Varies, see Table 4 | Varies, see Table 4 |

| Scans/in. | 12 | 12 | 12 |

| Scans per Second | 100 | 100 | 100 |

| Transmit Rate (kHz) | 100 | 100 | 100 |

| Depth Up to | Dataset I | Dataset II | Dataset III | ||||||

|---|---|---|---|---|---|---|---|---|---|

| cm (ft) | VWC, θ (m3/m3) | Diel. | Cond. σ′ (mS/m) | VWC, θ (m3/m3) | Diel. | Cond. σ′ (mS/m) | VWC, θ (m3/m3) | Diel. | Cond. σ′(mS/m) |

| 61 (2) | 0.290 | 13.42 | 10.94 | 0.473 | 26.77 | 17.08 | 0.343 | 16.60 | 12.47 |

| 91 (3) | 0.315 | 15.09 | 11.43 | 0.473 | 26.75 | 16.97 | 0.363 | 18.12 | 12.86 |

| 122 (4) | 0.341 | 16.76 | 11.92 | 0.473 | 26.73 | 16.85 | 0.383 | 19.65 | 13.25 |

3.5. Soil Moisture and Electrical Conductivity Sensor

4. Results and Analysis

4.1. Soil Dielectric Properties and GPR Experiments

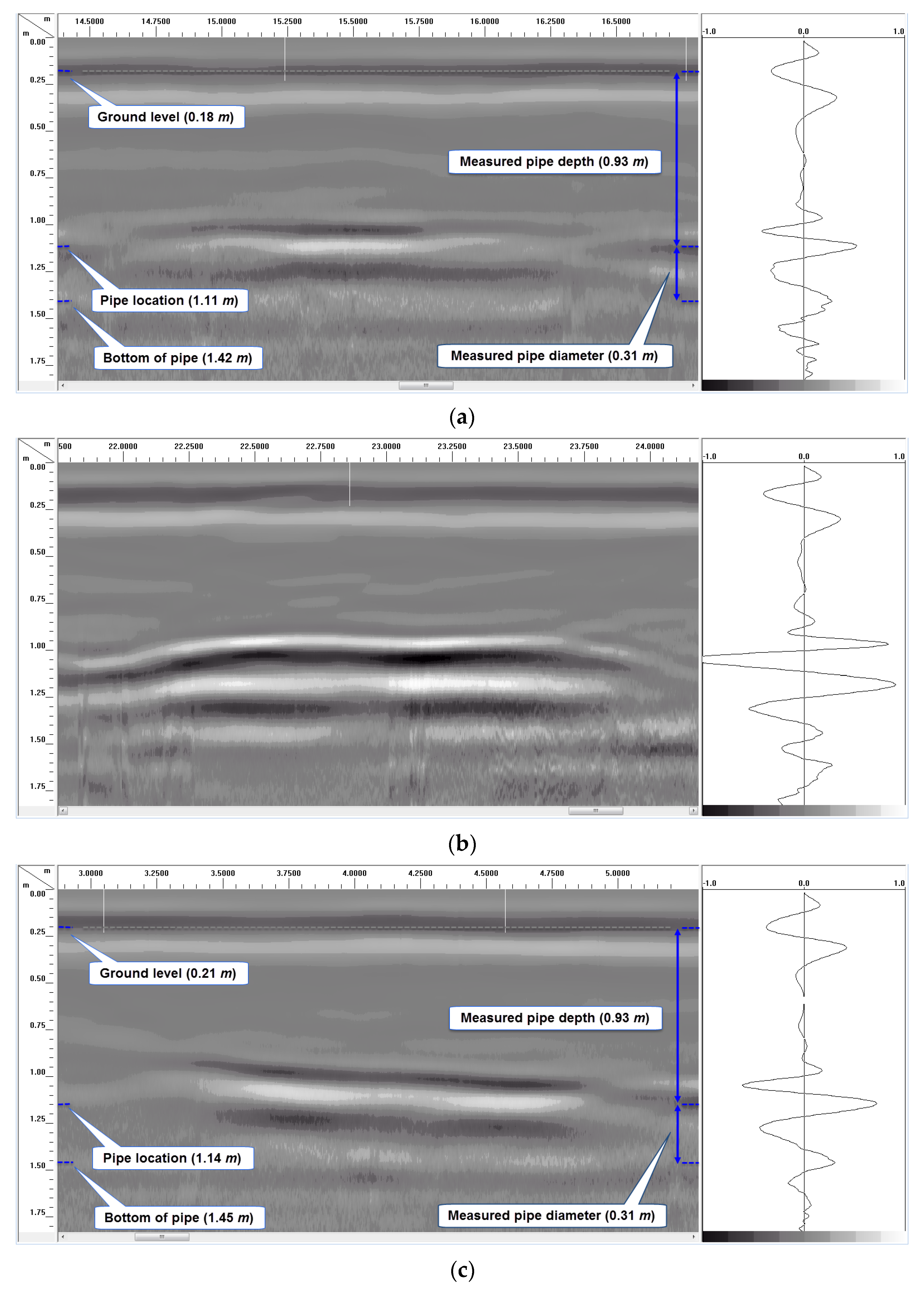

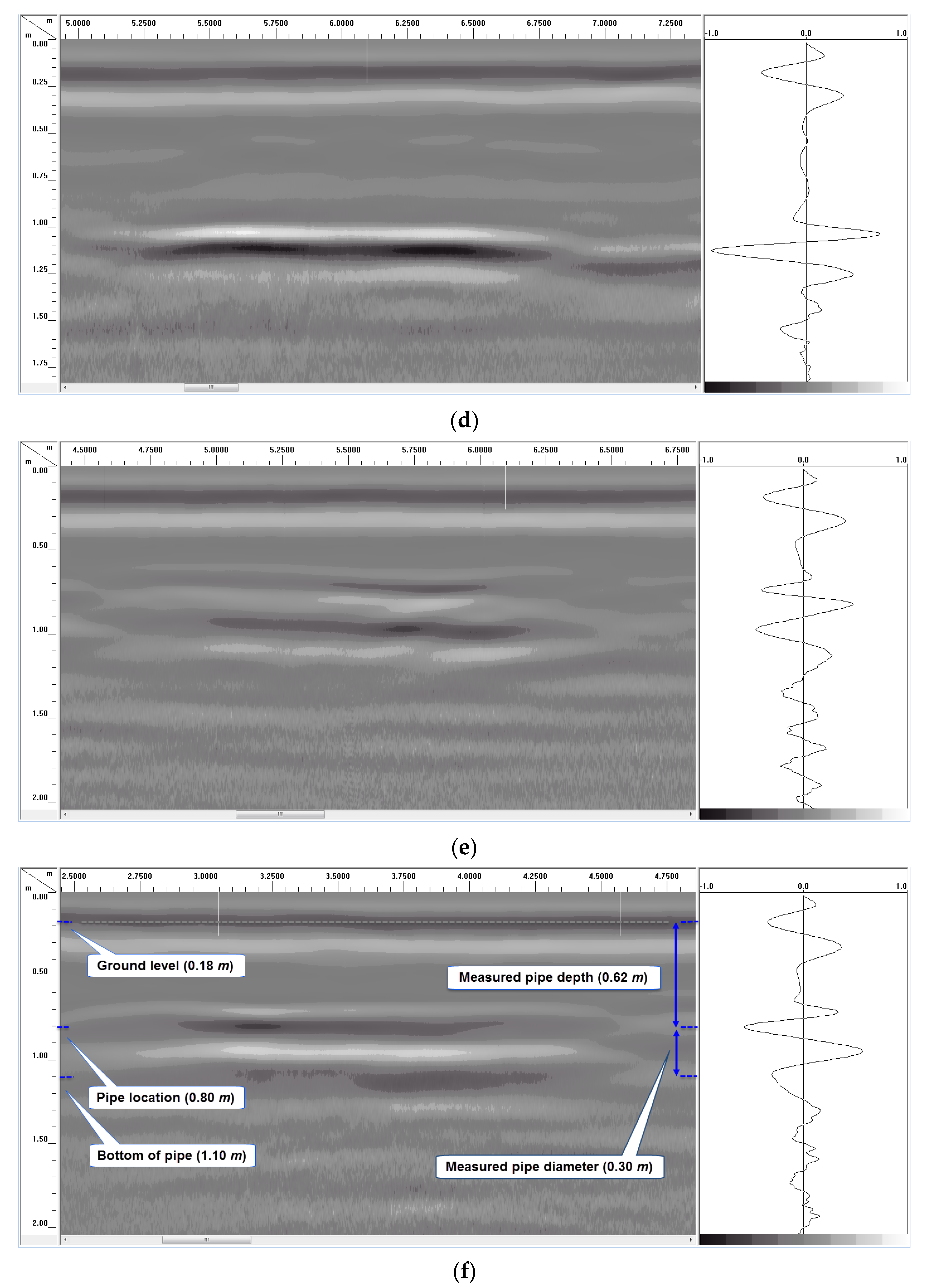

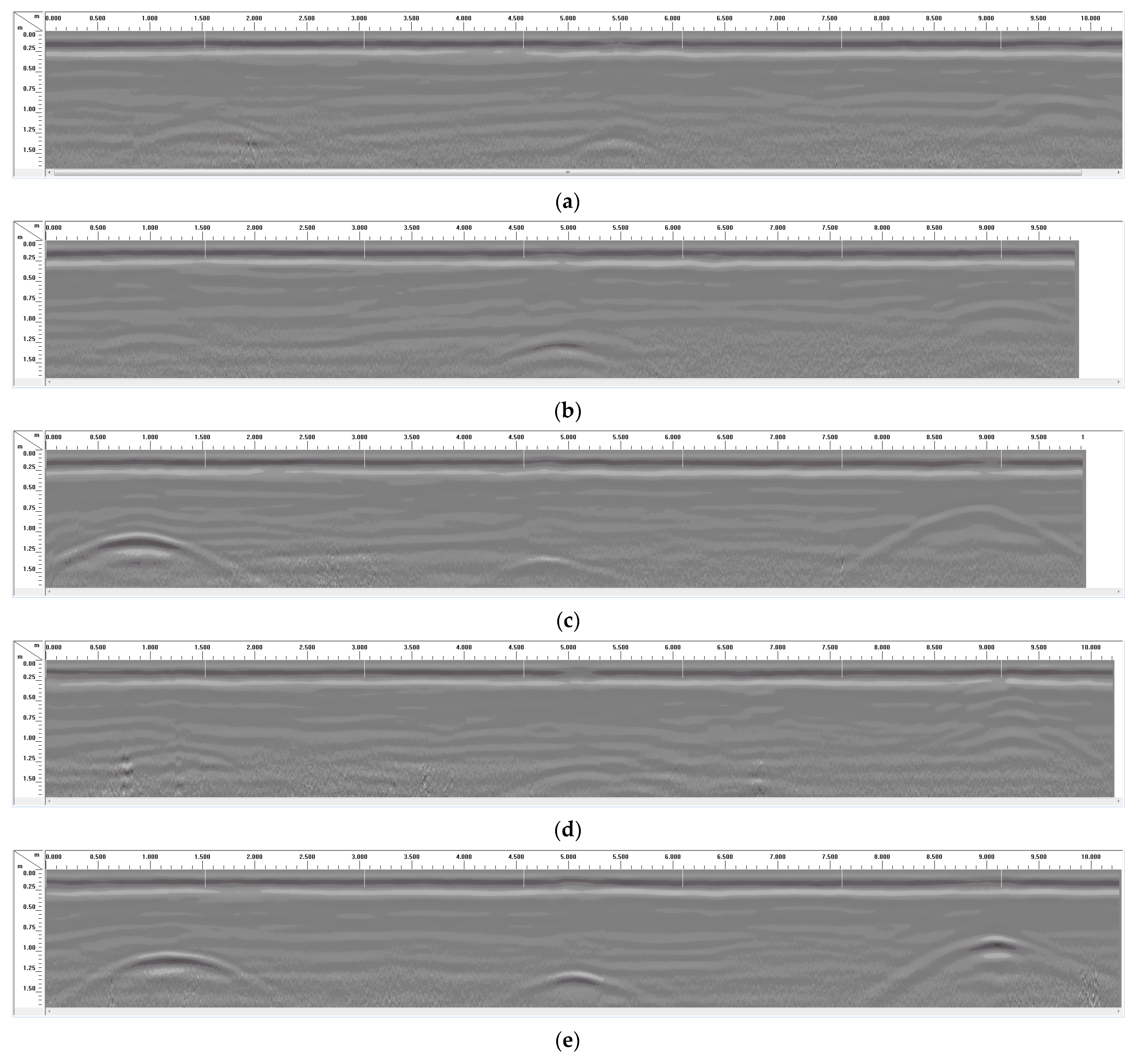

4.2. Results from GPR Experiments Using 200 MHz Antenna

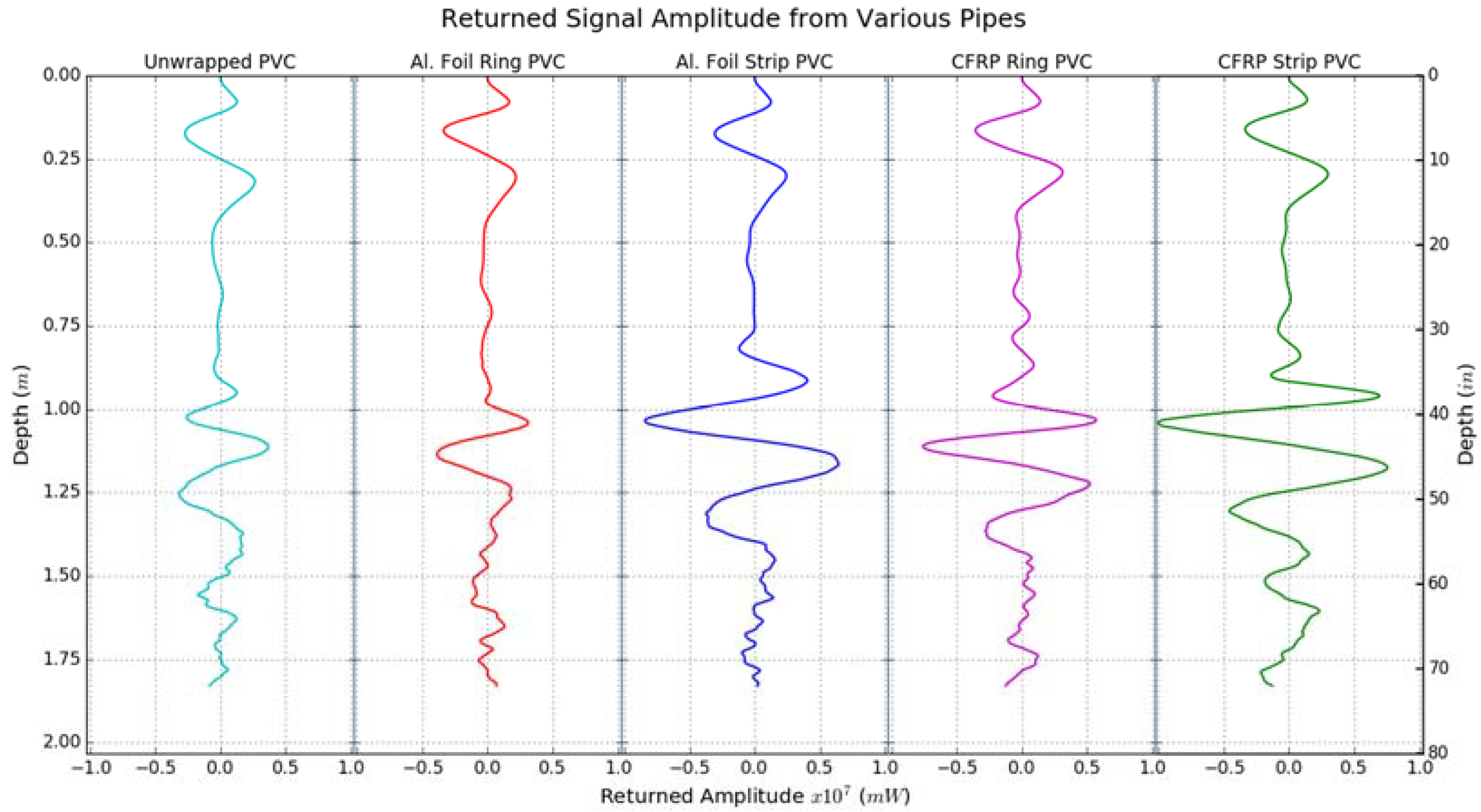

4.3. Results from GPR Experiments Using 400 MHz Antenna

4.4. Discussion on Performance of Surface Configurations

- Carbon fabric and aluminum foil overlays improved the detectability of buried non-metallic pipes using GPR.

- Carbon fabric and aluminum foil strips along the full length of the pipe performed better than carbon fabric and aluminum foil rings at a regular spacing of 3″ (7.62 cm) around the pipes.

- Carbon fabric overlays on pipes generally perform better than aluminum foil overlays.

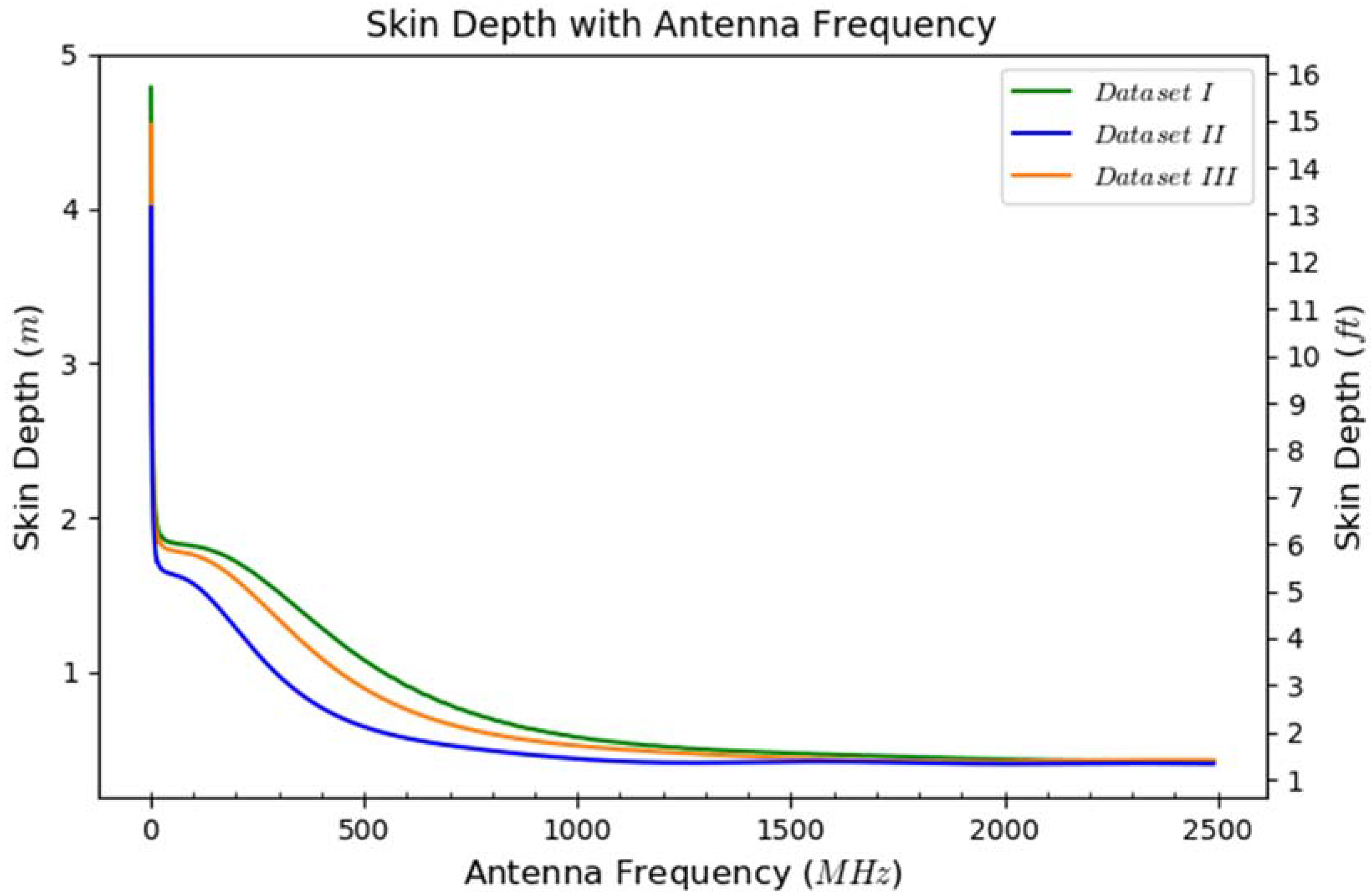

4.5. Signal Attenuation Modeling and Antenna Performance

- kI is the ohmic (material) attenuation coefficient (m−1);

- ω = 2πf is the angular frequency (rad/s);

- f is the frequency of the electromagnetic wave (Hz);

- is the absolute dielectric permittivity of the soil (F/m);

- is the absolute magnetic permeability of the soil (H/m);

- σ′ is the electrical conductivity of the soil (S/m).

- C is a constant;

- a is the radius of the scattering particle (m);

- f is the frequency of the electromagnetic wave (Hz);

- k is the wave number (m−1);

- μ, μ1 are the magnetic permeabilities of the soil medium and particle, respectively;

- N, N1 are the refractive indices of the soil medium and particle, respectively;

- λv, λ are the wavelengths of the electromagnetic wave in vacuum and in the soil medium, respectively (m).

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kavi, J. Detection of Buried Non-Metallic (Plastic and FRP Composite) Pipes Using GPR and IRT. Ph.D. Thesis, Department of Civil and Environmental Engineering, West Virginia University, Morgantown, WV, USA, December 2018. [Google Scholar] [CrossRef]

- GangaRao, H.V.S.; Halabe, U.B.; Zondlo, J.; Skidmore, M.; Imes, B.; Kavi, J.; Pacifico, A.; Alexander, R.; Cvetnick, A.; Sisler, P. Glass-Polymer Composite High Pressure Pipes and Joints—Design, Manufacture & Characterize, Final Report Submitted to USDOT-PHMSA. Contract No. DTPH5616HCAP02. 2018. Available online: https://primis.phmsa.dot.gov/matrix/FilGet.rdm?fil=12488 (accessed on 5 June 2023).

- Halabe, U.B.; GangaRao, H.V.S.; Zondlo, J.; Kavi, J.; Imes, B.; Cvetnick, A. Advancement in the Area of Intrinsically Locatable Plastic Materials, Final Report Submitted to USDOT-PHMSA. Contract No. DTPH5615HCAP09. 2017. Available online: https://primis.phmsa.dot.gov/matrix/FilGet.rdm?fil=11715 (accessed on 5 June 2023).

- Rawls, G. Fiber Reinforced Composite Pipelines. Presentation. 2015. Available online: https://www.hydrogen.energy.gov/docs/hydrogenprogramlibraries/pdfs/review15/pd022_rawls_2015_o.pdf (accessed on 5 June 2023).

- GangaRao, H.V.S.; Taly, N.; Vijay, P.V. Reinforced Concrete Design with FRP Composites; CRC Press: London, UK, 2007. [Google Scholar]

- Mallick, P.K. Fiber-Reinforced Composites: Materials, Manufacturing, and Design, 3rd ed.; CRC Press: London, UK, 2007. [Google Scholar]

- Wu, J.; Zhu, Y.; Li, C. Experimental Investigation of Fatigue Capacity of Bending-Anchored CFRP Cables. Polymers 2023, 15, 2483. [Google Scholar] [CrossRef] [PubMed]

- Pan, Y.; Yan, D. Study on the Durability of GFRP Bars and Carbon/Glass Hybrid Fiber Reinforced Polymer (HFRP) Bars Aged in Alkaline Solutions. Compos. Struct. 2021, 261, 113285. [Google Scholar] [CrossRef]

- Ellis, D.S.; Tabatabai, H.; Nabizadeh, A. Residual Tensile Strength and Bond Properties of GFRP Bars after Exposure to Elevated Temperatures. Materials 2018, 11, 346. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Jiang, Y.; Liang, H.; Yin, X.; Huang, Y. Study on Tensile Properties of CFRP Plates under Elevated Temperature Exposure. Materials 2019, 12, 1995. [Google Scholar] [CrossRef]

- Ananthkumar, M.; Mini, K.M.; Prakash, C.; Sharma, S.V.; Krishnaa, A.C.B. Study on the Efficiency of CFRP and GFRP in Corrosion Resistance of Rebar Embedded in Concrete. IOP Conf. Ser. Mater. Sci. Eng. 2020, 872, 012137. [Google Scholar] [CrossRef]

- Parvin, A.; Brighton, D. FRP Composites Strengthening of Concrete Columns under Various Loading Conditions. Polymers 2014, 6, 1040. [Google Scholar] [CrossRef]

- Rashid, S.M.P.; Bahrami, A. Structural Performance of Infilled Steel–Concrete Composite Thin-Walled Columns Combined with FRP and CFRP: A Comprehensive Review. Materials 2022, 16, 1564. [Google Scholar] [CrossRef]

- Qazi, A.U.; Khan, Q.S.; Ahmad, H.A.; Pham, T.M. Axial Behavior of FRP Confined Concrete Using Locally Available Low-Cost Wraps. Sustainability 2022, 14, 9989. [Google Scholar] [CrossRef]

- Bowders, J.J.; Koerner, R.M.; Lord, A.E. Buried container detection using ground-probing radar. J. Hazard. Mater. 1982, 7, 1–17. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Lahouar, S. Measuring layer thicknesses with GPR—Theory to practice. Constr. Build. Mater. 2005, 19, 763–772. [Google Scholar] [CrossRef]

- Alani, A.M.; Aboutalebi, M.; Kilic, G. Applications of ground penetrating radar (GPR) in bridge deck monitoring and assessment. J. Appl. Geophysics 2013, 97, 45–54. [Google Scholar] [CrossRef]

- Barone, P.M.; Bellomo, T.; Mattei, E.; Lauro, S.E.; Pettinelli, E. Ground-penetrating Radar in the Regio III (Pompeii, Italy): Archaeological Evidence: GPR Investigations in Pompeii. Archaeol. Prospect. 2011, 18, 187–194. [Google Scholar] [CrossRef]

- Barone, P.M.; Mattei, E.; Lauro, S.E.; Pettinelli, E. Non-destructive technique to investigate an archaeological structure: A GPR survey in the Domus Aurea (Rome, Italy). In Proceedings of the 2010 13th International Conference on Ground Penetrating Radar (GPR 2010), Lecce, Italy, 21–25 June 2010; pp. 1–4. [Google Scholar] [CrossRef]

- Butnor, J.R.; Doolittle, J.A.; Johnsen, K.H.; Samuelson, L.; Stokes, T.; Kress, L. Utility of Ground-Penetrating Radar as a Root Biomass Survey Tool in Forest Systems. Soil Sci. Soc. Am. J. 2003, 67, 1607–1615. [Google Scholar] [CrossRef]

- Butnor, J.R.; Doolittle, J.A.; Kress, L.; Cohen, S.; Johnsen, K.H. Use of ground-penetrating radar to study tree roots in the southeastern United States. Tree Physiol. 2001, 21, 1269–1278. [Google Scholar] [CrossRef]

- Dalrymple, G.A. Forensic Evaluation Techniques for Masonry and Concrete Construction. In Forensic Engineering 2009: Pathology of the Built Environment; American Society of Civil Engineers: Reston, VA, USA, 2010; pp. 617–626. [Google Scholar]

- Abouhamad, M.; Dawood, T.; Jabri, A.; Alsharqawi, M.; Zayed, T. Corrosiveness mapping of bridge decks using image-based analysis of GPR data. Autom. Constr. 2017, 80, 104–117. [Google Scholar] [CrossRef]

- Ékes, C.; Neducza, B.; Henrich, G.R. GPR goes underground: Pipe Penetrating Radar on Environmental. In Proceedings of the NASTT No-Dig Show, Washington, DC, USA, 27–31 March 2011. [Google Scholar]

- Hing, C.L.C.; Halabe, U.B. Nondestructive Testing of GFRP Bridge Decks Using Ground Penetrating Radar and Infrared Thermography. J. Bridge Eng. 2010, 15, 391–398. [Google Scholar] [CrossRef]

- Hirano, Y.; Dannoura, M.; Aono, K.; Igarashi, T.; Ishii, M.; Yamase, K.; Makita, N.; Kanazawa, Y. Limiting factors in the detection of tree roots using ground-penetrating radar. Plant Soil 2009, 319, 15–24. [Google Scholar] [CrossRef]

- Lamsters, K.; Karušs, J.; Rečs, A.; Bērziņš, D. Detailed subglacial topography and drumlins at the marginal zone of Múlajökull outlet glacier, central Iceland: Evidence from low frequency GPR data. Polar Sci. 2016, 10, 470–475. [Google Scholar] [CrossRef]

- Metwaly, M. Detection of metallic and plastic landmines using the GPR and 2-D resistivity techniques. Nat. Hazards Earth Syst. Sci. 2007, 7, 755–763. [Google Scholar] [CrossRef]

- Munk, J.; Sheets, R.A. Detection of Underground Voids in Ohio by Use of Geophysical Methods, FHWA/OH-97/010; US Department of the Interior, US Geological Survey: Washington, DC, USA, 1997.

- Najafi, M. Trenchless Technology Piping: Installation and Inspection; McGraw-Hill Education: New York, NY, USA, 2010. [Google Scholar]

- Paolo, F.D.; Cosciotti, B.; Lauro, S.E.; Mattei, E.; Callegari, M.; Carturan, L.; Seppi, R.; Zucca, F.; Pettinelli, E. Combined GPR and TDR measurements for snow thickness and density estimation. In Proceedings of the 2015 8th International Workshop on Advanced Ground Penetrating Radar (IWAGPR), Florence, Italy, 7–10 July 2015. [Google Scholar]

- Porsani, J.L.; Ruy, Y.B.; Ramos, F.P.; Yamanouth, G.R.B. GPR applied to mapping utilities along the route of the Line 4 (yellow) subway tunnel construction in São Paulo City, Brazil. J. Appl. Geophys. 2012, 80, 25–31. [Google Scholar] [CrossRef]

- Prego, F.J.; Solla, M.; Puente, I.; Arias, P. Efficient GPR data acquisition to detect underground pipes. NDT E Int. 2017, 91, 22–31. [Google Scholar] [CrossRef]

- Razinger, J. Utilization of Ground Penetrating Radar (GPR) to Detect Shear Bolts in Bridges—Colchester Bridges 77 & 76—US I-89, U2017-02, Report. 2017. Available online: https://vtrans.vermont.gov/sites/aot/files/highway/documents/materialsandresearch/completedprojects/Detection%20of%20Bridge%20Shear%20Bolts%20Using%20GPR%20%28Final%29.pdf (accessed on 5 June 2023).

- Sagnard, F.; Norgeot, C.; Derobert, X.; Baltazart, V.; Merliot, E.; Derkx, F.; Lebental, B. Utility detection and positioning on the urban site Sense-City using Ground-Penetrating Radar systems. Measurement 2016, 88, 318–330. [Google Scholar] [CrossRef]

- Takahashi, K.; Igel, J.; Preetz, H.; Kuro, S. Basics and Application of Ground-Penetrating Radar as a Tool for Monitoring Irrigation Process. In Problems, Perspectives and Challenges of Agricultural Water Management; Kumar, M., Ed.; InTech: Houston, TX, USA, 2012; pp. 155–180. [Google Scholar]

- Wijewardana, Y.G.N.S.; Galagedara, L.W. Estimation of spatio-temporal variability of soil water content in agricultural fields with ground penetrating radar. J. Hydrol. 2010, 391, 24–33. [Google Scholar] [CrossRef]

- Trela, C.; Kind, T.; Günther, M. Ground penetrating radar in reflection vs transmission mode for void detection in concrete structure. In Proceedings of the International Symposium on Non-Destructive Testing in Civil Engineering (NDT-CE), Berlin, Germany, 15–17 September 2015. [Google Scholar]

- Halabe, U.B.; Sotoodehnia, A.; Maser, K.R.; Kausel, E.A. Modeling the Electromagnetic Properties of Concrete. ACI Mater. J. 1993, 90, 552–563. [Google Scholar]

- Daniels, D.J. Ground Penetrating Radar. In IEE Radar, Sonar, Navigation and Avionics Series 15, 2nd ed.; The Institution of Electrical Engineers: London, UK, 2004. [Google Scholar]

- United States Department of Agriculture: Natural Resources Conservation Service—Web Soil Survey. Available online: https://websoilsurvey.nrcs.usda.gov/app/ (accessed on 8 September 2023).

- GPR Antennas from Geophysical Survey Systems, Inc. (GSSI). Available online: https://www.geophysical.com/antennas (accessed on 19 September 2023).

- Diamanti, N.; Elliott, E.J.; Jackson, S.R.; Annan, A.P. The WARR Machine: System Design, Implementation and Data. J. Environ. Eng. Geophys. 2018, 23, 469–487. [Google Scholar] [CrossRef]

- Ibraheem, A.E. Innovative Applications of Ground Penetrating Radar in Civil Engineering; M.S.C.E. Problem Report; Department of Civil and Environmental Engineering, West Virginia University: Morgantown, WV, USA, 2011. [Google Scholar]

- Sumlin, B.J.; Heinson, W.R.; Chakrabarty, R.K. Retrieving the aerosol complex refractive index using PyMieScatt: A Mie computational package with visualization capabilities. J. Quant. Spectrosc. Radiat. Transf. 2018, 205, 127–134. [Google Scholar] [CrossRef]

- Bohren, C.F.; Huffman, D.R. Absorption and Scattering of Light by Small Particles; Wiley: New York, NY, USA, 1940. [Google Scholar]

- Annan, A.P. Electromagnetic Principles of Ground Penetrating Radar. In Ground Penetrating Radar Theory and Applications; Jol, H.M., Ed.; Elsevier B.V: New York, NY, USA, 2009; pp. 41–72. [Google Scholar]

- Frezza, F.; Mangini, F.; Tedeschi, N. Tutorial: Introduction to electromagnetic scattering. J. Opt. Soc. Am. 2017, 31, 163. [Google Scholar] [CrossRef] [PubMed]

- Cassidy, N.J. Electrical and Magnetic Properties of Rocks, Soils and Fluids. In Ground Penetrating Radar Theory and Applications; Jol, H.M., Ed.; Elsevier B.V: New York, NY, USA, 2009; pp. 41–72. [Google Scholar]

- Goodman, D.; Piro, S. GPR Remote Sensing in Archaeology; Springer: New York, NY, USA, 2013. [Google Scholar]

- Davis, J.L.; Annan, A.P. Ground Penetrating Radar for High Resolution Mapping of Soil and Rock Stratigraphy. Geophys. Prospect. 1989, 37, 531–551. [Google Scholar] [CrossRef]

- Reynolds, J.M. An Introduction to Applied and Environmental Geophysics, 2nd ed.; Wiley: Bognor Regis, UK, 2011. [Google Scholar]

| Pipe Section | Wall Thickness, mm (in.) | Fiber Material | Fiber Mat (Fiber Orientation) | Fiber Weight, g/m2 (oz/yd2) | Resin (Matrix) Material |

|---|---|---|---|---|---|

| 30.48 cm (12″) GFRP | 9.525 (3/8) | E-Glass | 45°/90°/−45° | † | Polyurethane |

| 25.40 cm (10″) GFRP | 9.525 (3/8) | E-Glass | Filament wound | † | Vinyl Ester |

| 7.62 cm (3″) GFRP | ** | E-Glass | 0°/90° | 813.74 (24) | Vinyl Ester |

| 30.48 cm (12″) CFRP | ** | Carbon | 0°/90°/±45° | 949.36 (28) | Vinyl Ester |

| CFRP Strip/Ring | * | Carbon | 0°/90°/±45° | 949.36 (28) | Vinyl Ester |

| 7.62 cm (3″) CFRP | 7.938 (5/16) | Carbon | † | † | † |

| Pipe Diameters with Each Surface Configuration, cm | ||||||||

|---|---|---|---|---|---|---|---|---|

| Pipe Materials | Soil Cover Depth, m (ft) | Control (Unwrapped) | CFRP | Aluminum | Carbon Nano-Particle | Total | ||

| Strip | Ring | Strip | Ring | |||||

| CFRP | 1.22 (4) | 30.48 | 1 | |||||

| 0.61 (2) | 7.62 | 1 | ||||||

| GFRP | 1.22 (4) | 30.48 | 30.48 | 30.48 | 30.48 | 30.48 | 5 | |

| 0.91 (3) | 30.48 | 30.48 | 30.48 | 3 | ||||

| 0.61 (2) | 30.48, 25.40, 7.32 | 30.48, 7.32 | 7.62 | 7.62 | 7.62 | 30.48 | 9 | |

| PVC | 1.22 (4) | 30.48 | 30.48 | 30.48 | 30.48 | 30.48 | 5 | |

| 0.91 (3) | 30.48, 15.24 | 15.24 | 15.24 | 30.48, 15.24 | 30.48, 15.24 | 8 | ||

| 0.61 (2) | 7.62 | 7.62 | 7.62 | 30.48, 7.32 | 7.62 | 6 | ||

| Steel | 0.61 (2) | 30.48 | 1 | |||||

| Total number of pipes | 12 | 7 | 6 | 7 | 6 | 1 | 39 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kavi, J.; Halabe, U.B. An Approach for Easy Detection of Buried FRP Composite/Non-Metallic Pipes Using Ground-Penetrating Radar. Sensors 2023, 23, 8465. https://doi.org/10.3390/s23208465

Kavi J, Halabe UB. An Approach for Easy Detection of Buried FRP Composite/Non-Metallic Pipes Using Ground-Penetrating Radar. Sensors. 2023; 23(20):8465. https://doi.org/10.3390/s23208465

Chicago/Turabian StyleKavi, Jonas, and Udaya B. Halabe. 2023. "An Approach for Easy Detection of Buried FRP Composite/Non-Metallic Pipes Using Ground-Penetrating Radar" Sensors 23, no. 20: 8465. https://doi.org/10.3390/s23208465

APA StyleKavi, J., & Halabe, U. B. (2023). An Approach for Easy Detection of Buried FRP Composite/Non-Metallic Pipes Using Ground-Penetrating Radar. Sensors, 23(20), 8465. https://doi.org/10.3390/s23208465