Preparation and Performance Analysis of 3D Thermoformed Fluidic Polymer Temperature Sensors for Aquatic and Terrestrial Applications

Abstract

:1. Introduction

2. Materials and Methods

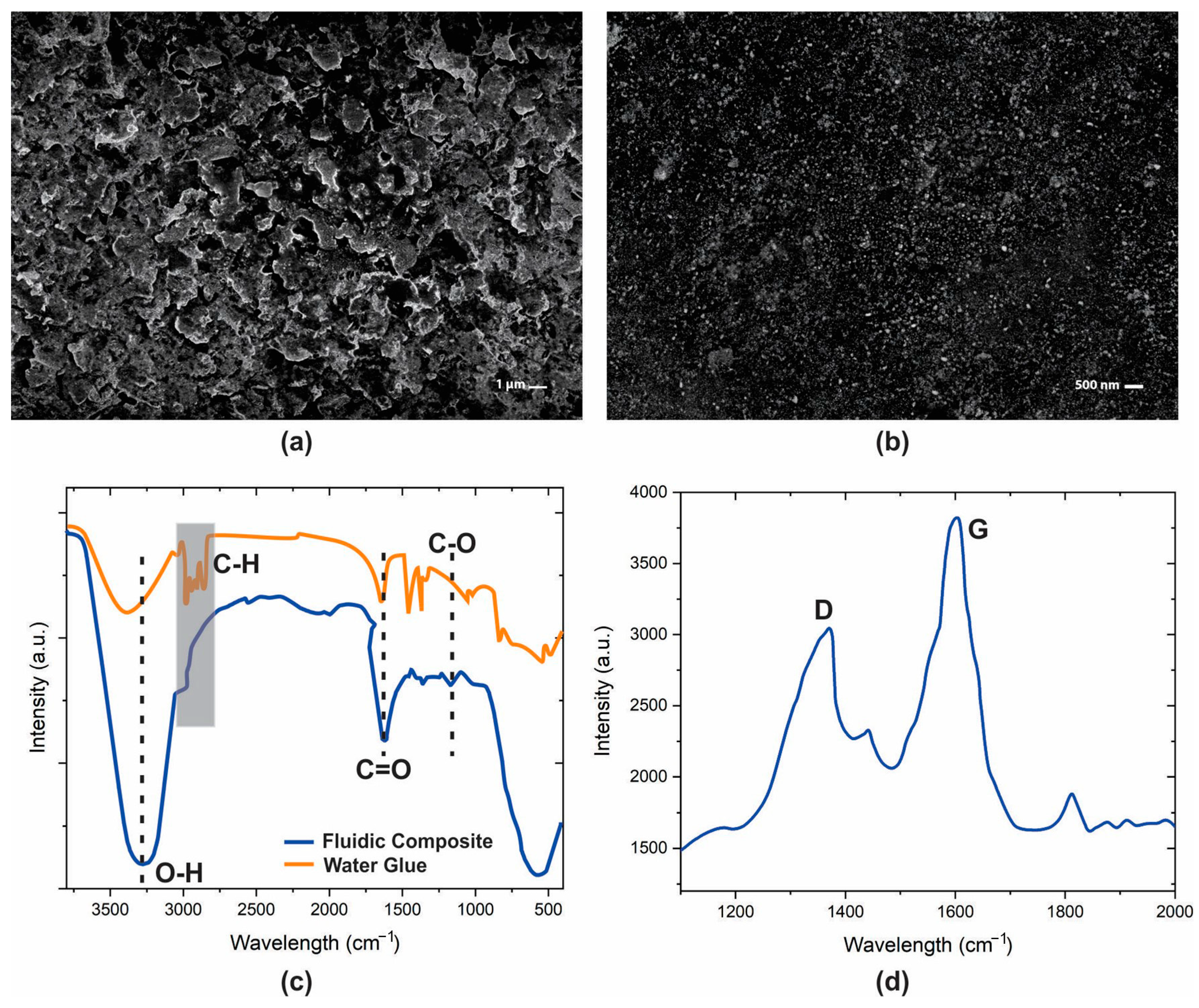

2.1. Preparation of Fluidic Composite

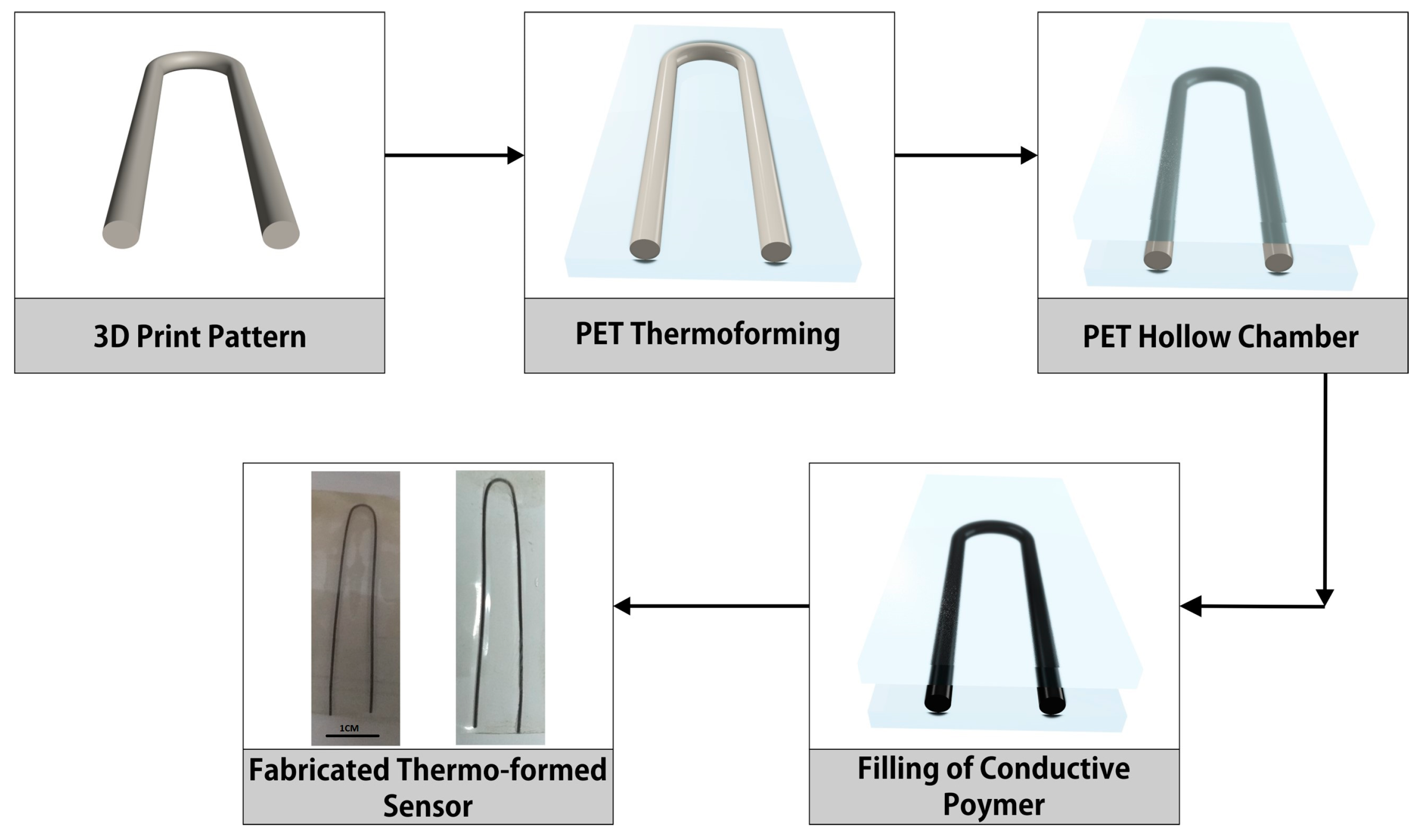

2.2. Sensor Fabrication

2.3. Experimental Setup

3. Results

3.1. Material Characterizations

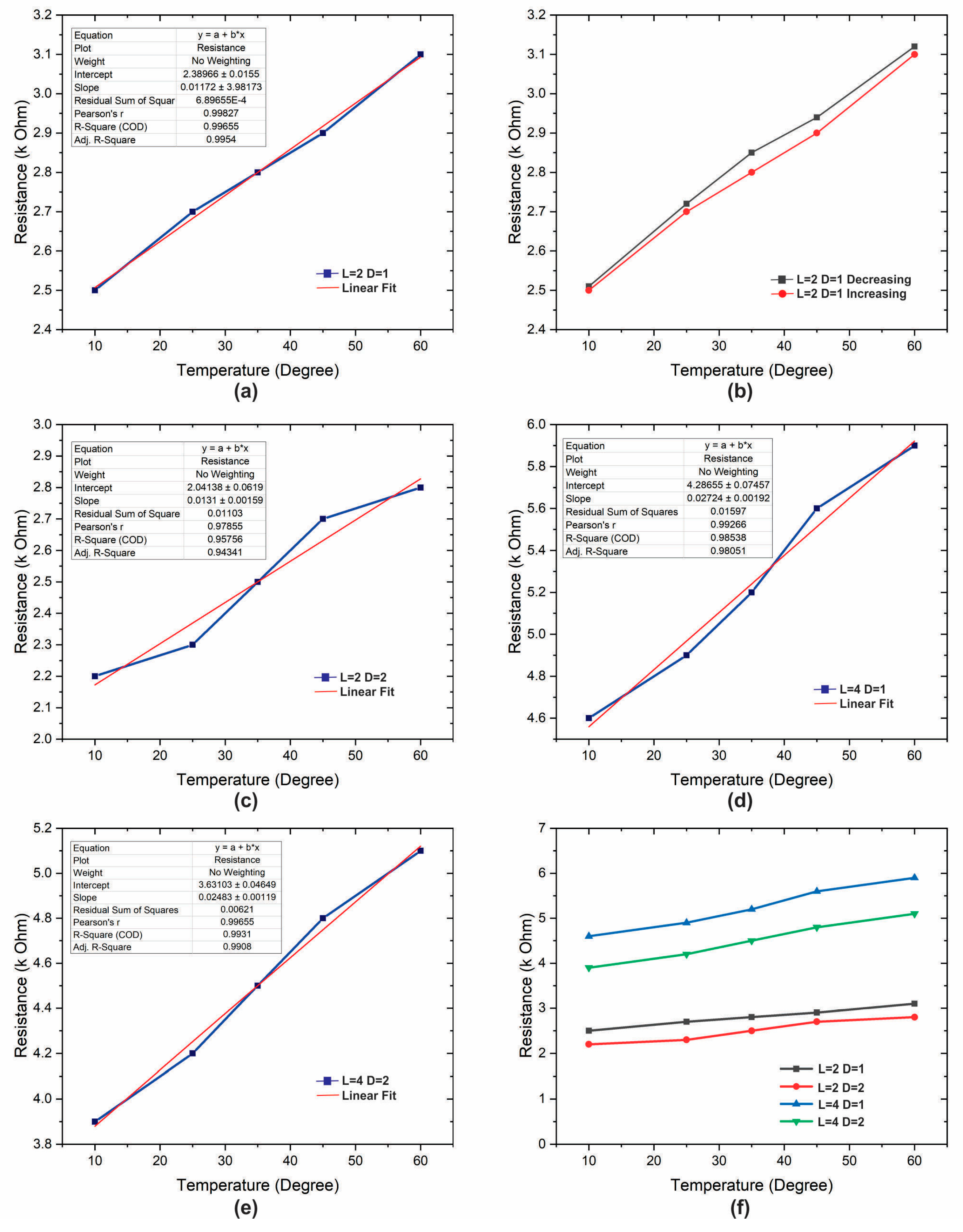

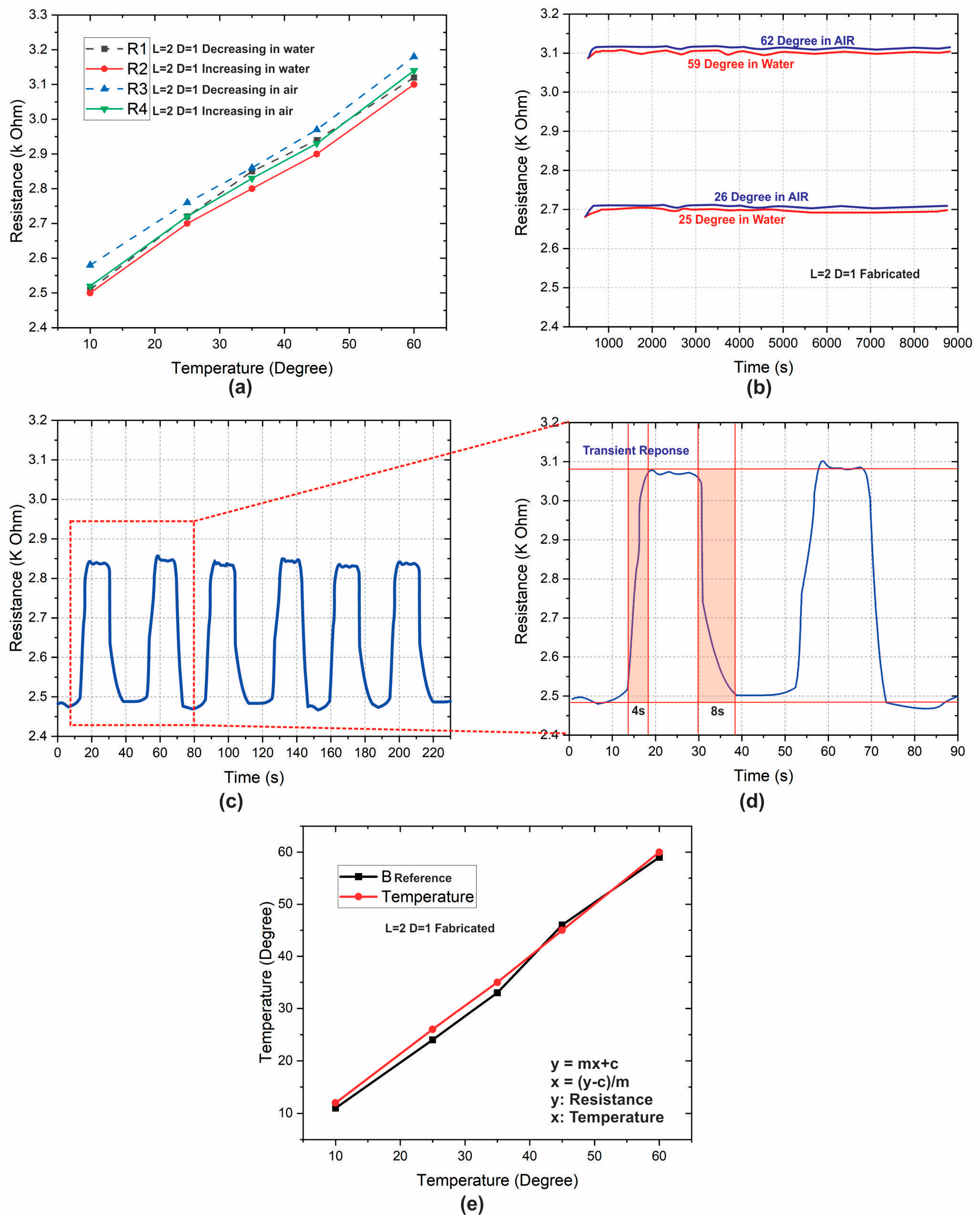

3.2. Electrical Characterizations

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xiao, Y.; Li, H.; Wang, C.; Pan, S.; He, J.; Liu, A.; Wang, J.; Sun, P.; Liu, F.; Lu, G. Room Temperature Wearable Gas Sensors for Fabrication and Applications. Adv. Sens. Res. 2023. [Google Scholar] [CrossRef]

- Lin, J.; Kilani, M.; Mao, G. Recent Advances in Integrating 1D Nanomaterials into Chemiresistive Gas Sensor Devices. Adv. Mater. Technol. 2023, 8, 2202038. [Google Scholar] [CrossRef]

- Xie, W.; Xiao, C.; Sun, Y.; Fan, Y.; Zhao, B.; Zhang, D.; Fan, T.; Zhou, H. Flexible Photonic Radiative Cooling Films: Fundamentals, Fabrication and Applications. Adv. Funct. Mater. 2023. [Google Scholar] [CrossRef]

- Jin, C.; Liu, D.; Zhang, L. An Emerging Family of Piezocatalysts: 2D Piezoelectric Materials. Small 2023, e2303586. [Google Scholar] [CrossRef]

- Cichosz, S.; Masek, A.; Zaborski, M. Polymer-based sensors: A review. Polym. Test. 2018, 67, 342–348. [Google Scholar] [CrossRef]

- Mei, X.; Ye, D.; Zhang, F.; Di, C. Implantable application of polymer-based biosensors. J. Polym. Sci. 2022, 60, 328–347. [Google Scholar] [CrossRef]

- Erk, N.; Mehmandoust, M.; Soylak, M. Electrochemical Sensing of Favipiravir with an Innovative Water-Dispersible Molecularly Imprinted Polymer Based on the Bimetallic Metal-Organic Framework: Comparison of Morphological Effects. Biosensors 2022, 12, 769. [Google Scholar] [CrossRef]

- Liu, X.; Zheng, W.; Kumar, R.; Kumar, M.; Zhang, J. Conducting polymer-based nanostructures for gas sensors. Coord. Chem. Rev. 2022, 462, 214517. [Google Scholar] [CrossRef]

- Ramanavicius, S.; Ramanavicius, A. Development of molecularly imprinted polymer based phase boundaries for sensors design (review). Adv. Colloid Interface Sci. 2022, 305, 102693. [Google Scholar] [CrossRef]

- Ramanavicius, S.; Samukaite-Bubniene, U.; Ratautaite, V.; Bechelany, M.; Ramanavicius, A. Electrochemical molecularly imprinted polymer based sensors for pharmaceutical and biomedical applications (review). J. Pharm. Biomed. Anal. 2022, 215, 114739. [Google Scholar] [CrossRef]

- Nambiar, S.; Yeow, J.T.W. Conductive polymer-based sensors for biomedical applications. Biosens. Bioelectron. 2011, 26, 1825–1832. [Google Scholar] [CrossRef]

- Khan, M.; Rehman, M.M.; Khan, S.A.; Saqib, M.; Kim, W.Y. Characterization and performance evaluation of fully biocompatible gelatin-based humidity sensor for health and environmental monitoring. Front. Mater. 2023, 10, 1233136. [Google Scholar] [CrossRef]

- Khan, S.A.; Saqib, M.; Khan, M.; Rehman, M.M.; Rahman, S.A.; Kim, W.Y. Wide-Range, Fast-Responsive Humidity Sensor Based on In2Se3/PEDOT:PSS Nanocomposite. ACS Appl. Electron. Mater. 2023, 5, 4473–4484. [Google Scholar] [CrossRef]

- Buga, C.S.; Viana, J.C. The role of printed electronics and related technologies in the development of smart connected products. Flex. Print. Electron. 2022, 7, 043001. [Google Scholar] [CrossRef]

- Yang, Y.; Wei, Y.; Guo, Z.; Hou, W.; Liu, Y.; Tian, H.; Ren, T. From Materials to Devices: Graphene toward Practical Applications. Small Methods 2022, 6, e2200671. [Google Scholar] [CrossRef]

- Wang, G.; Yang, Y.; Guo, M.; Zhu, K.; Yan, Z.; Cui, Q.; Zhou, Z.; Ji, J.; Li, J.; Luo, D.; et al. ThermoFit. Proc. ACM Interact. Mob. Wearable Ubiquitous Technol. 2022, 7, 1–27. [Google Scholar] [CrossRef]

- Balakrishnan, G.; Song, J.; Mou, C.; Bettinger, C.J. Recent Progress in Materials Chemistry to Advance Flexible Bioelectronics in Medicine. Adv. Mater. 2022, 34, e2106787. [Google Scholar] [CrossRef]

- Desai, S.M.; Sonawane, R.Y.; More, A.P. Thermoplastic polyurethane for three-dimensional printing applications: A review. Polym. Adv. Technol. 2023, 34, 2061–2082. [Google Scholar] [CrossRef]

- Hunt, C.J.; Morabito, F.; Grace, C.; Zhao, Y.; Woods, B.K.S. A review of composite lattice structures. Compos. Struct. 2022, 284, 115120. [Google Scholar] [CrossRef]

- Gul, J.Z.; Sajid, M.; Rehman, M.M.; Siddiqui, G.U.; Shah, I.; Kim, K.-H.; Lee, J.-W.; Choi, K.H. 3D printing for soft robotics—A review. Sci. Technol. Adv. Mater. 2018, 19, 243–262. [Google Scholar] [CrossRef]

- Hong, F.; Myant, C.; Boyle, D.E. Thermoformed Circuit Boards: Fabrication of highly conductive freeform 3D printed circuit boards with heat bending. In Proceedings of the 2021 CHI Conference on Human Factors in Computing Systems, Yokohama, Japan, 8–13 May 2021; ACM: New York, NY, USA, 2021; pp. 1–10. [Google Scholar] [CrossRef]

- Wicaksono, I.; Hwang, P.G.; Droubi, S.; Wu, F.X.; Serio, A.N.; Yan, W.; Paradiso, J.A. 3DKnITS: Three-dimensional Digital Knitting of Intelligent Textile Sensor for Activity Recognition and Biomechanical Monitoring. In Proceedings of the 2022 44th Annual International Conference of the IEEE Engineering in Medicine & Biology Society (EMBC), Glasgow, UK, 11–15 July 2022; IEEE: New York, NY, USA, 2022; pp. 2403–2409. [Google Scholar] [CrossRef]

- Götzelmann, T. CapMaps. In Computers Helping People with Special Needs; Springer: Berlin/Heidelberg, Germany, 2016; pp. 146–152. [Google Scholar] [CrossRef]

- Correia, V.M.G.; Pereira, N.; Perinka, N.; Costa, P.; del Campo, J.; Lanceros-Mendez, S. Printed 3D Gesture Recognition Thermoformed Half Sphere Compatible with In-Mold Electronic Applications. Adv. Eng. Mater. 2022, 24, 2200730. [Google Scholar] [CrossRef]

- Bauwens, P.; Bossuyt, F.; Deckers, J.P.; Vanfleteren, J. Vacuum Lamination of a Stretchable Sensor System in PolyPropylene. In Proceedings of the 2020 IEEE 8th Electronics System-Integration Technology Conference (ESTC), Tonsberg, Norway, 15–18 September 2020; IEEE: New York, NY, USA, 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Chtioui, I.; Bossuyt, F.; Bedoui, M.H. Thermo-plastically stretchable electronic and sensor circuits. In Proceedings of the 2016 17th International Conference on Electronic Packaging Technology (ICEPT), Wuhan, China, 16–19 August 2016; IEEE: New York, NY, USA, 2016; pp. 1396–1400. [Google Scholar] [CrossRef]

- Luan, C.; Yao, X.; Zhang, C.; Wang, B.; Fu, J. Large-scale deformation and damage detection of 3D printed continuous carbon fiber reinforced polymer-matrix composite structures. Compos. Struct. 2019, 212, 552–560. [Google Scholar] [CrossRef]

- Günther, D.; Erhard, P.; Schwab, S.; Taha, I. 3D Printed Sand Tools for Thermoforming Applications of Carbon Fiber Reinforced Composites—A Perspective. Materials 2021, 14, 4639. [Google Scholar] [CrossRef]

- Sajid, M.; Gul, J.Z.; Kim, S.W.; Kim, H.B.; Na, K.H.; Choi, K.H. Development of 3D-Printed Embedded Temperature Sensor for Both Terrestrial and Aquatic Environmental Monitoring Robots. 3D Print. Addit. Manuf. 2018, 5, 160–169. [Google Scholar] [CrossRef]

- Wu, L.; Qian, J.; Peng, J.; Wang, K.; Liu, Z.; Ma, T.; Zhou, Y.; Wang, G.; Ye, S. Screen-printed flexible temperature sensor based on FG/CNT/PDMS composite with constant TCR. J. Mater. Sci. Mater. Electron. 2019, 30, 9593–9601. [Google Scholar] [CrossRef]

- Katerinopoulou, D.; Zalar, P.; Sweelssen, J.; Kiriakidis, G.; Rentrop, C.; Groen, P.; Gelinck, G.H.; Brand, J.v.D.; Smits, E.C.P. Large-Area All-Printed Temperature Sensing Surfaces Using Novel Composite Thermistor Materials. Adv. Electron. Mater. 2019, 5, 1800605. [Google Scholar] [CrossRef]

- Xiao, Y.; Jiang, S.; Li, Y.; Zhang, W. Screen-printed flexible negative temperature coefficient temperature sensor based on polyvinyl chloride/carbon black composites. Smart Mater. Struct. 2021, 30, 025035. [Google Scholar] [CrossRef]

| Length (cm) | Dia (mm) | Min. Res (kΩ) | Max. Res (kΩ) | Sensitivity (Ω/°C) |

|---|---|---|---|---|

| 2 | 1 | 2.5 | 3.1 | 12 |

| 2 | 2 | 2.2 | 2.8 | 12 |

| 4 | 1 | 4.6 | 5.9 | 26 |

| 4 | 2 | 3.9 | 5.1 | 24 |

| Materials/Sensor Name | Fabrication Method | Max Detection Range (°C) | Sensitivity | Transient Response(s) | Operational Environment | Reference |

|---|---|---|---|---|---|---|

| TMP36 | Lithography | 120 | 10 mV/°C | 20 | DRY/WET | Commercial |

| LM35 | Lithography | 125 | 10 mV/°C | 8 s | DRY/WET | Commercial |

| DS18B20 | Lithography | 100 | 12-bit resolution | NC | DRY/WET | Commercial |

| TMP37 | Lithography | 100 | 10 mV/°C | NC | DRY/WET | Commercial |

| GNR + PLA | 3D Printing | 70 | 12 Ω/°C | 6 s | DRY/WET | [29] |

| Flake graphite/CNT/PDMS | Screen Printing | 80 | 0.028%/°C | NC | DRY | [30] |

| Mn2O3/NiO/Co3O4/CuO/ZnOPVDF, PDMS, CYTOP | Screen Printing | 140 | 91.76% | NC | DRY | [31] |

| Polyvinyl chloride/carbon black | Screen Printing | 44 | −0.148%/°C | NC | DRY | [32] |

| Graphite + Water Glue | 3D Thermoforming | 60 | 12 Ω/°C | 4 | DRY/WET | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gul, J.Z.; Khan, M.; Rehman, M.M.; Mohy Ud Din, Z.; Kim, W.Y. Preparation and Performance Analysis of 3D Thermoformed Fluidic Polymer Temperature Sensors for Aquatic and Terrestrial Applications. Sensors 2023, 23, 8506. https://doi.org/10.3390/s23208506

Gul JZ, Khan M, Rehman MM, Mohy Ud Din Z, Kim WY. Preparation and Performance Analysis of 3D Thermoformed Fluidic Polymer Temperature Sensors for Aquatic and Terrestrial Applications. Sensors. 2023; 23(20):8506. https://doi.org/10.3390/s23208506

Chicago/Turabian StyleGul, Jahan Zeb, Maryam Khan, Muhammad Muqeet Rehman, Zia Mohy Ud Din, and Woo Young Kim. 2023. "Preparation and Performance Analysis of 3D Thermoformed Fluidic Polymer Temperature Sensors for Aquatic and Terrestrial Applications" Sensors 23, no. 20: 8506. https://doi.org/10.3390/s23208506

APA StyleGul, J. Z., Khan, M., Rehman, M. M., Mohy Ud Din, Z., & Kim, W. Y. (2023). Preparation and Performance Analysis of 3D Thermoformed Fluidic Polymer Temperature Sensors for Aquatic and Terrestrial Applications. Sensors, 23(20), 8506. https://doi.org/10.3390/s23208506