Multi-Channel Gating Chip in 0.18 µm High-Voltage CMOS for Quantum Applications

Abstract

:1. Introduction

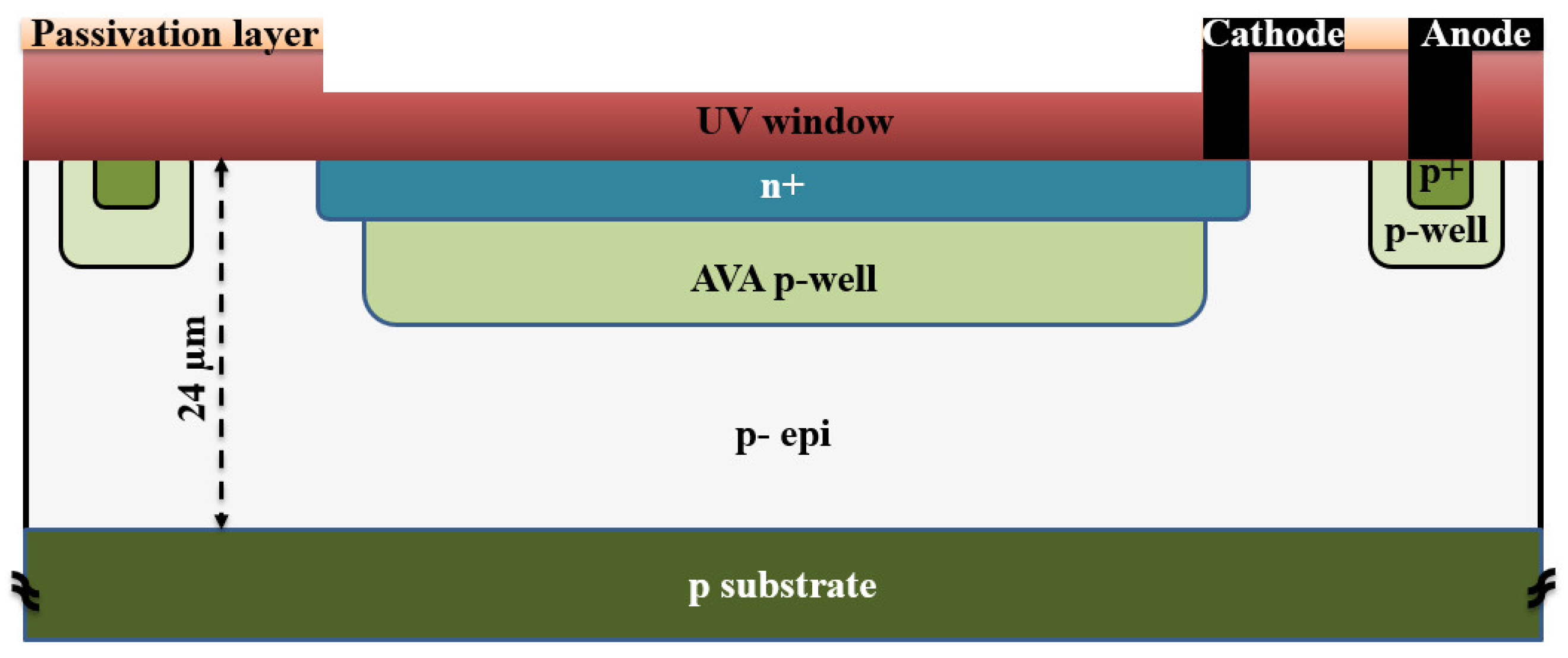

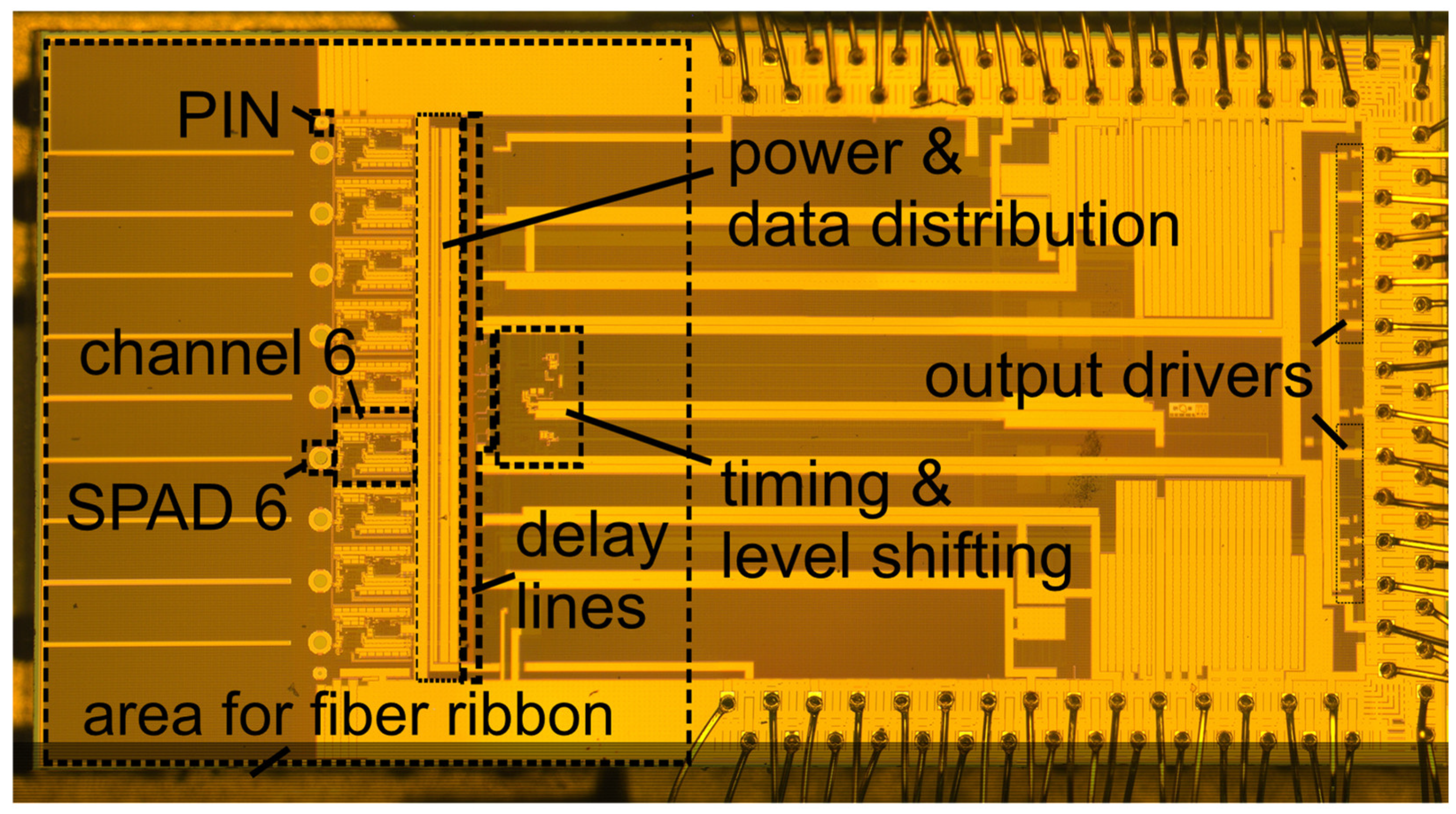

2. Gater Chip

3. Structure of SPAD

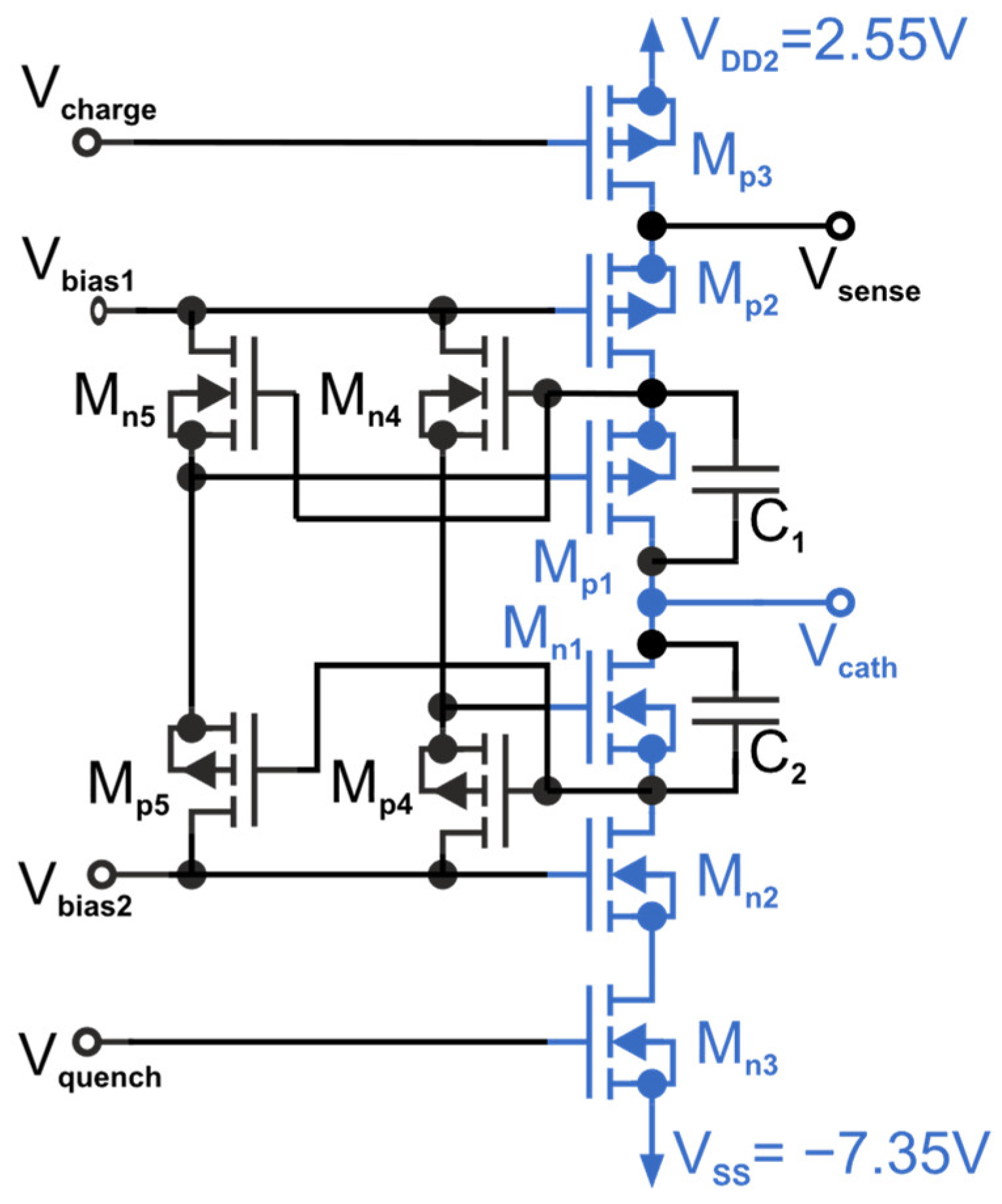

4. Gating Circuit

4.1. High-Voltage Cascode Switch

4.2. Sample and Hold and Comparator

4.3. Layout

4.4. Post-Layout Simulations

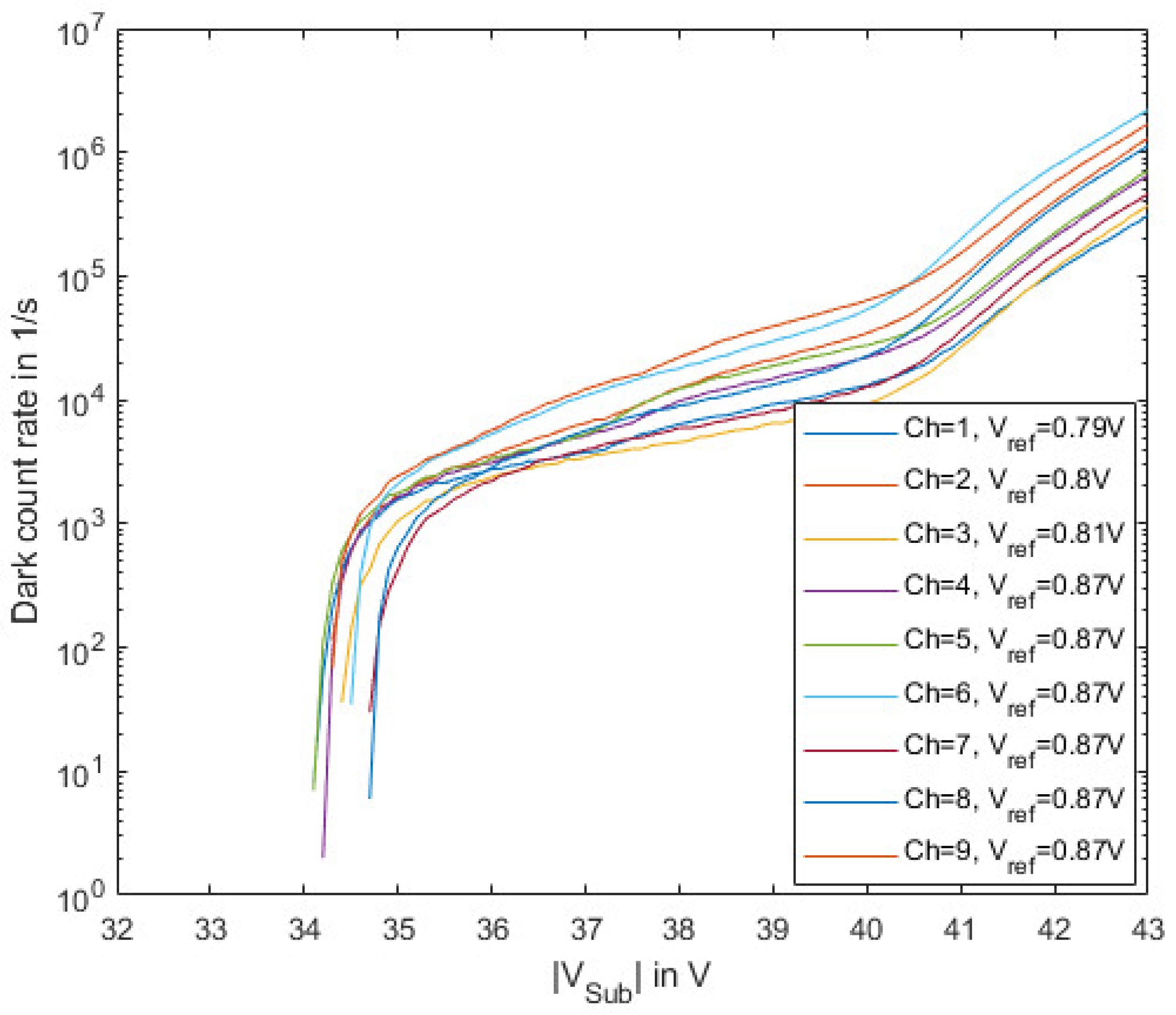

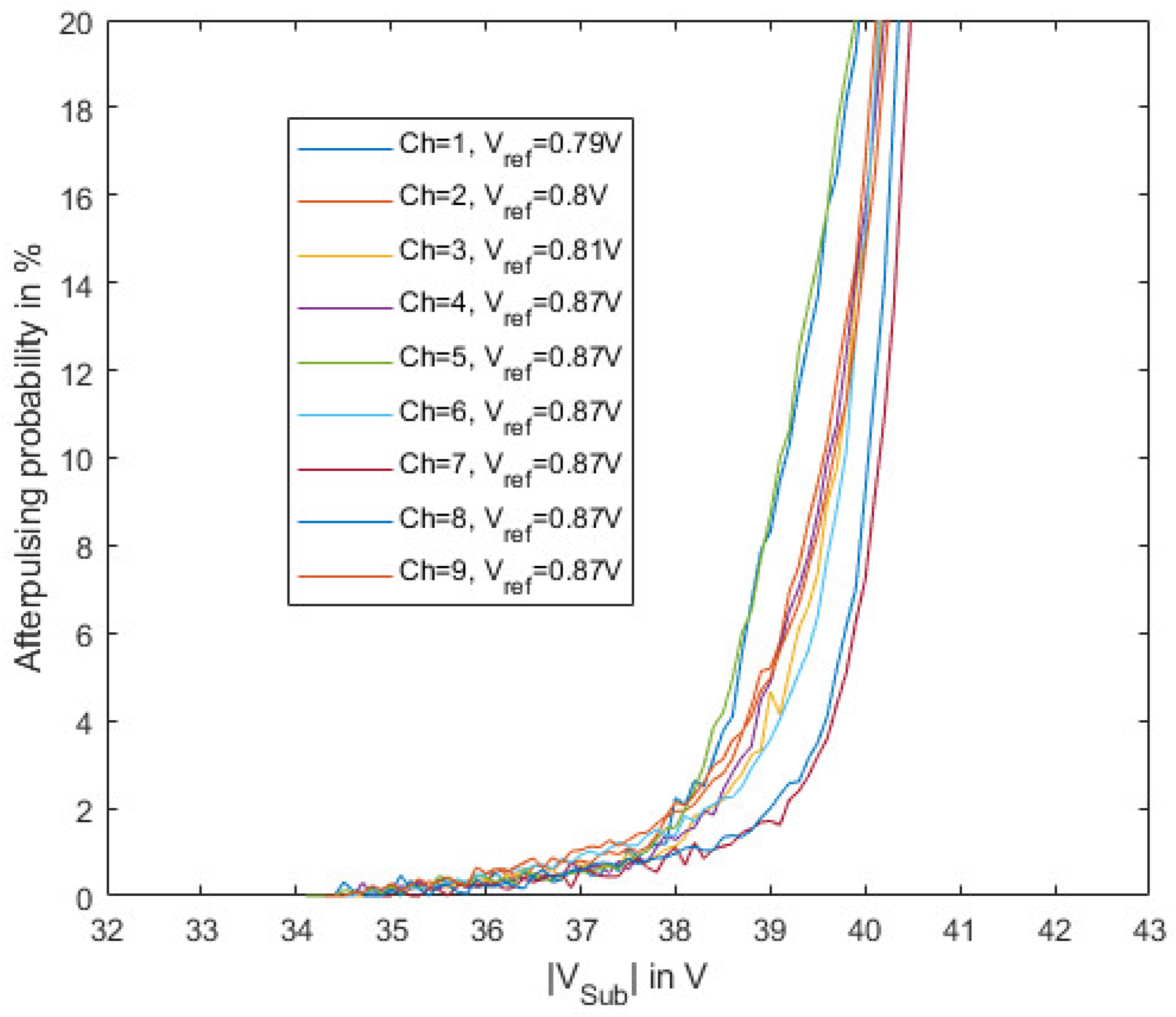

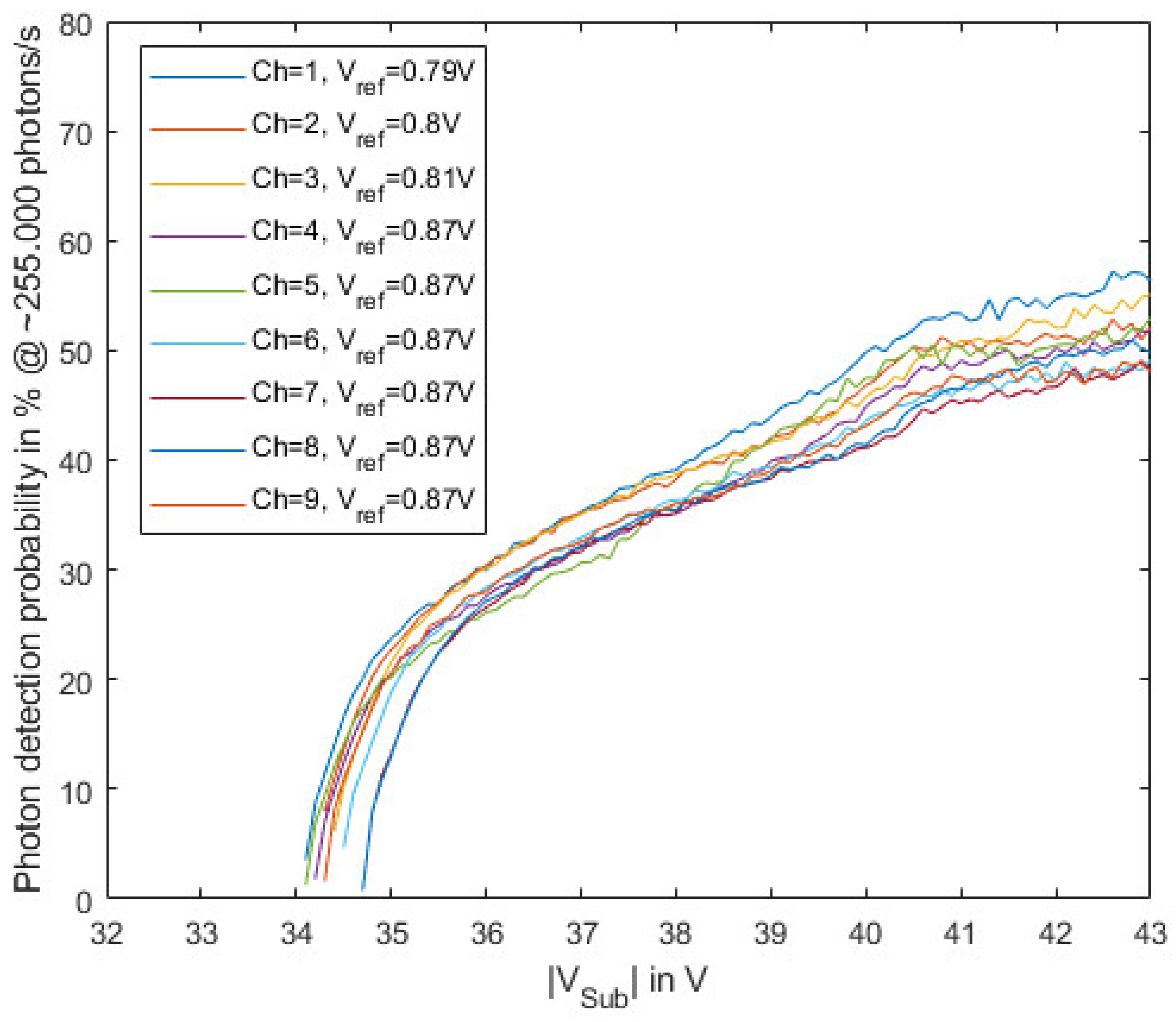

5. Characterization of SPAD

6. Comparison and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviation

| SPAD | single-photon avalanche diode |

| ASIC | application-specific integrated circuit |

| PDP | photon detection probability |

| CMOS | complementary metal-oxide semiconductor |

| MOSFET | metal–oxide semiconductor field-effect transistor |

| APP | after-pulsing probability |

| HVCS | high-voltage double-cascoded switch |

| MIM capacitor | metal insulator metal capacitor |

| DCR | dark count rate |

| PCB | printed circuit board |

| PDP | photon detection probability |

References

- Cova, S.; Ghioni, M.; Lacaita, A.; Samori, C.; Zappa, F. Avalanche photodiodes and quenching circuits for single-photon detection. Appl. Opt. 1996, 35, 1956–1976. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Jiang, W.; Kumar, S.; Deen, M.J. Time-Controlled SPAD Receivers in Optical Wireless Communication System. IEEE Photonics J. 2023, 15, 7304113. [Google Scholar] [CrossRef]

- Gallivanoni, A.; Rech, I.; Ghioni, M. Progress in Quenching Circuits for Single Photon Avalanche Diodes. IEEE Trans. Nucl. Sci. 2010, 57, 3815–3826. [Google Scholar] [CrossRef]

- Bronzi, D.; Tisa, S.; Villa, F.; Bellisai, S.; Tosi, A.; Zappa, F. Fast Sensing and Quenching of CMOS SPADs for Minimal Afterpulsing Effects. IEEE Photonics Technol. Lett. 2013, 25, 776–779. [Google Scholar] [CrossRef]

- Tosi, A.; Mora, A.D.; Della Frera, A.; Shehata, A.B.; Pifferi, A.; Contini, D. Fast-gated SPAD for ultra-wide dynamic range optical investigations. In Proceedings of the 2010 23rd Annual Meeting of the IEEE Photonics Society (Formerly LEOS Annual Meeting), Denver, CO, USA, 7–11 November 2010; pp. 185–186. [Google Scholar]

- Nissinen, I.; Nissinen, J.; Holma, J.; Kostamovaara, J. A TDC-based 4128 CMOS SPAD array for time-gated Raman spectroscopy. In Proceedings of the ESSCIRC 2014—40th European Solid State Circuits Conference, Venice Lido, Italy, 22–26 September 2014; pp. 139–142. [Google Scholar]

- Conca, E.; Cusini, I.; Severini, F.; Lussana, R.; Zappa, F.; Villa, F.A. Gated SPAD Arrays for Single-Photon Time-Resolved Imaging and Spectroscopy. IEEE Photonics J. 2019, 11, 6803910. [Google Scholar] [CrossRef]

- Renna, M.; Ruggeri, A.; Sanzaro, M.; Villa, F.A.; Zappa, F.; Tosi, A. High Detection Rate Fast-Gated CMOS Single-Photon Avalanche Diode Module. IEEE Photonics J. 2020, 12, 6802312. [Google Scholar] [CrossRef]

- Liu, J.; Jiang, W.; Deen, M.J. Time-Gated Circuit for SPAD-based OWC. In Proceedings of the 2022 IEEE Photonics Conference (IPC), Vancouver, BC, Canada, 13–17 November 2022; pp. 1–2. [Google Scholar]

- Aspuru-Guzik, A.; Walther, P. Photonic quantum simulators. Nat. Phys. 2012, 8, 285–291. [Google Scholar] [CrossRef]

- Wang, H.; Li, Y.-H.; Su, Z.-E.; Li, B.; Huang, H.-L.; Ding, X.; Chen, M.-C.; Liu, C.; Qin, J.; Li, J.-P.; et al. High-efficiency multiphoton boson sampling. Nat. Photonics 2017, 11, 361–365. [Google Scholar] [CrossRef]

- Webster, E.A.G.; Grant, L.A.; Henderson, R.K. A High-Performance Single-Photon Avalanche Diode in 130-nm CMOS Imaging Technology. IEEE Electron Device Lett. 2012, 33, 1589–1591. [Google Scholar] [CrossRef]

- Nam, H.; Ahn, Y.; Roh, J. 5-V buck converter using 3.3-V standard CMOS process with adaptive power transistor driver increasing efficiency and maximum load capacity. IEEE Trans. Power Electron. 2010, 27, 463–471. [Google Scholar] [CrossRef]

- Enne, R.; Steindl, B.; Hofbauer, M.; Zimmermann, H. Fast Cascoded Quenching Circuit for Decreasing Afterpulsing Effects in 0.35-μm CMOS. IEEE Solid State Circuits Lett. 2018, 1, 62–65. [Google Scholar] [CrossRef]

- Dervić, A. High-Voltage Active Quenching and Resetting Circuit for SPADs in 0.35 μm CMOS for raising the Photon Detection Probability. Opt. Eng. 2019, 58, 040501. [Google Scholar] [CrossRef]

- Goll, B.; Hofbauer, M.; Steindl, B.; Zimmermann, H. A Fully Integrated SPAD-Based CMOS Data-Receiver with a Sensitivity of −64 dBm at 20 Mb/s. IEEE Solid State Circuits Lett. 2018, 1, 2–5. [Google Scholar] [CrossRef]

- Silvaco Atlas User’s Manual. Available online: https://www.silvaco.com (accessed on 21 November 2023).

- Zach, F. Leistungselektronik Ein Handbuch, 5. Auflage; Springer: Berlin, Germany, 2015; ISBN 978-3-658-04898-3. [Google Scholar]

- Goll, B. Clocked, Regenerative Comparators in Deep-Sub-Micron CMOS. Ph.D. Thesis, TU Wien, Vienna, Austria, 2007. [Google Scholar]

- Fiber Ribbon, LaseOptics Corp. LF-SM-SC-01/2-780-HP-8CH/127-VG-FC/APC. Available online: https://www.laseoptics.com/Lensed-Tapered-Fibers-Description-2017.pdf (accessed on 10 September 2023).

- Hofbauer, M.; Steindl, B.; Zimmermann, H. Temperature Dependence of Dark Count Rate and After Pulsing of a Single-Photon Avalanche Diode with an Integrated Active Quenching Circuit in 0.35 μm CMOS. J. Sens. 2018, 2018, 9585931. [Google Scholar] [CrossRef]

- Poushi, S.S.K.; Mahmoudi, H.; Hofbauer, M.; Steindl, B.; Zimmermann, H. Photon Detection Probability Enhancement Using an Anti-Reflection Coating in CMOS-Based SPADs. Appl. Opt. 2021, 60, 7815–7820. [Google Scholar] [CrossRef]

- Ruggeri, A.; Ciccarella, P.; Villa, F.; Zappa, F.; Tosi, A. Integrated Circuit for Subnanosecond Gating of InGaAs/InP SPAD. IEEE J. Quantum Electron. 2015, 51, 4500107. [Google Scholar] [CrossRef]

- Signorelli, F.; Telesca, F.; Conca, E.; Della Frera, A.; Ruggeri, A.; Giudice, A.; Tosi, A. Low-Noise InGaAs/InP Single-Photon Avalanche Diodes for Fiber-Based and Free-Space Applications. IEEE J. Sel. Top. Quantum Electron. 2021, 28, 3801310. [Google Scholar] [CrossRef]

- Madsen, L.S.; Laudenbach, F.; Askarani, M.F.; Rortais, F.; Vincent, T.; Bulmer, J.F.F.; Miatto, F.M.; Neuhaus, L.; Helt, L.G.; Collins, M.J.; et al. Quantum computational advantage with a programmable photonic processor. Nature 2022, 606, 75–81. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ribisch, C.; Hofbauer, M.; Kohneh Poushi, S.S.; Zimmer, A.; Schneider-Hornstein, K.; Goll, B.; Zimmermann, H. Multi-Channel Gating Chip in 0.18 µm High-Voltage CMOS for Quantum Applications. Sensors 2023, 23, 9644. https://doi.org/10.3390/s23249644

Ribisch C, Hofbauer M, Kohneh Poushi SS, Zimmer A, Schneider-Hornstein K, Goll B, Zimmermann H. Multi-Channel Gating Chip in 0.18 µm High-Voltage CMOS for Quantum Applications. Sensors. 2023; 23(24):9644. https://doi.org/10.3390/s23249644

Chicago/Turabian StyleRibisch, Christoph, Michael Hofbauer, Seyed Saman Kohneh Poushi, Alexander Zimmer, Kerstin Schneider-Hornstein, Bernhard Goll, and Horst Zimmermann. 2023. "Multi-Channel Gating Chip in 0.18 µm High-Voltage CMOS for Quantum Applications" Sensors 23, no. 24: 9644. https://doi.org/10.3390/s23249644

APA StyleRibisch, C., Hofbauer, M., Kohneh Poushi, S. S., Zimmer, A., Schneider-Hornstein, K., Goll, B., & Zimmermann, H. (2023). Multi-Channel Gating Chip in 0.18 µm High-Voltage CMOS for Quantum Applications. Sensors, 23(24), 9644. https://doi.org/10.3390/s23249644