1. Introduction

In a wide range of cases, from microelectronics and nanoelectronics to nanomedicine, the precise determination of the local temperature at the nanometer scale is essential to achieve control of the physical, chemical and biological processes involved. Large experimental initiatives are underway in the field of nanothermometry [

1,

2,

3], from the generation of new materials, to the implementation of analytical techniques and prototypical tests of real devices, with the final aim of obtaining high sensitivity and good spatial resolution in the detection of the local temperature over a wide range of temperatures, in particular that of biological interest (293–323 K). The achievement of these objectives is the driving force for the generation of new materials to be used in nanothermometry. The determination of the local temperature of microscopic or nanoscopic objects can be carried out using different techniques [

1,

2,

4], which are divided into contact techniques, mainly based on scanning microscopes [

5,

6,

7], and contactless techniques, which exploit optical properties, such as luminescence [

8,

9,

10] or diffusion [

11,

12]. Interesting features in the exploitation of Raman spectroscopy as a thermometric technique are the high spatial resolution, of the order of the diffraction limit of the laser probe (<1 μm), and good temperature resolution (1–10 K) over a wide wavelength range. Moreover, Raman is a non-destructive technique that can be applied to a wide range of samples and experimental conditions—it does not require complex sample preparation, requires small volumes of material, and can be applied in a wide range of environments, even during the course of chemical reactions or under extreme conditions of pressure and temperature [

1,

2,

13].

The temperature can be measured from Raman spectra by determining the degree of shift in the position of a defined peak at different temperatures, by evaluating the broadening of its linewidth, or by measuring the peak intensity ratio of the anti-Stokes signal to the Stokes signal [

12].

Nanoparticles’ unique characteristics have been extensively explored for use in the nanothermometry field to detect the local temperature [

2]. The synthesis of nanoparticles with an appropriate and homogeneous size, structure, and morphology is an essential purpose to be achieved. In particular, the particle size and distribution are fundamental for their use in the biomedical field [

14,

15,

16,

17,

18]. For practical applications, nanoparticles and nanostructures ranging from 5–10 nm [

19,

20] to 100–600 nm [

21,

22,

23,

24] have been tested.

Titanium dioxide, particularly the anatase polymorph, possesses all the characteristics that define a suitable material for Raman nanothermometry—it has a large Raman scattering cross-section, an intense and clearly distinguishable peak at low Raman shifts, and low absorbance at the wavelengths of excitation in the visible and NIR, which limits the heating of the sample due to the laser source. Moreover, it also has interesting chemical characteristics, such as high chemical stability and non-toxicity in biological environments. Lastly, commercial TiO

2 NPs have already shown good properties as Raman active nanothermometers in the visible range [

25,

26].

The possibility of synthesizing pure anatase nanoparticles of well-defined dimensions and suitably functionalized to increase their solubility in biological media would open the way to the use of this material in the biomedical field. In the literature, numerous sol-gel syntheses of titania have been reported; however, they often require a calcination step at temperatures above 500 °C. Some articles report sol-gel methods combined with the use of ultrasound treatments [

27] or the use of reflux conditions at 70 °C [

28], while others adopt solvo/hydrothermal treatments, taking advantage of mild reaction conditions [

29]. Sol-gel and solvothermal syntheses, both based on mild synthesis conditions, allow controlling of the shape, size, structure, and composition of NPs by optimizing parameters, such as the temperature, reaction time, and the amount and ratio of reactants, additives, and ligands.

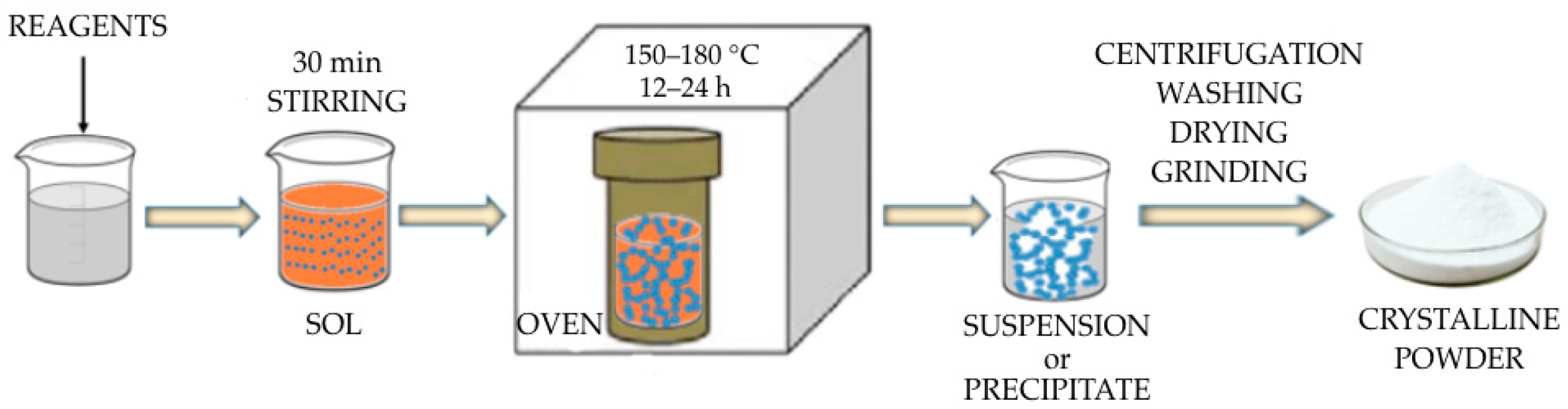

In this work, titanium dioxide NPs, as an anatase polymorph, were synthesized, employing an optimized combination of sol-gel and solvothermal synthetic approaches to obtain samples of pure anatase, with defined crystallite dimensions and a bipyramidal morphology characterized by a high Raman signal. The synthesis process of anatase nanoparticles was optimized and fine-tuned in compliance with sustainability criteria from a green perspective (i.e., low temperature, non-hazardous solvents and chemicals). The TiO2 NPs were characterized by SEM, XRD and Raman techniques to investigate their morphology and microstructure, respectively. In particular, their nanothermometer properties were evaluated in the visible region at 514.5 nm by anti-Stokes (aS) and Stokes (S) Raman measurements collected in the 293–323 K range.

3. Results

All the synthetized samples were structurally, morphologically and optically characterized to choose the best-performing ones, in terms of size, crystallinity and Raman signal intensity. These were used as test materials for the temperature measurements.

An example of the complete characterization of the sample TP22.10, prepared with acid synthesis with

r = 3.32,

= 105, at 150 °C for 24 h, is presented in

Figure 2 and

Figure 3.

From the SEM images, it was possible to observe the morphological characteristic of the nanocrystals, which depend on the synthesis conditions used. The elongated and tapered nanostructures were the result of specific growth mechanisms under hydrothermal conditions. The image in

Figure 2b shows a single small particle with a nanorod shape, with a major axis around 700 nm and a minor one around 300 nm.

The XRD pattern of the sample TP22.10 showed the presence of a pure anatase phase in the sample: no spurious phases were found in the XRD patterns, as reported in

Figure 3a. The diffraction peaks were indexed with powder diffraction standard data using the Crystallography Open Database. The crystallite size of TiO

2 NPs was estimated from the broadening of the anatase (101) reflection, deconvoluted with a Lorentzian function to determine the full width at half maximum (FWHM). Using the Debye formula [

32], the calculated crystallite size for the TP22.10 nanoparticles was found to be 13 nm.

The Stokes Raman spectrum of the TP22.10 sample recorded at room temperature is reported in

Figure 3b. The spectrum shows an intense peak centered at 147 cm

−1, with a shoulder at 197 cm

−1, and three peaks at 397, 515 and 640 cm

−1 with lower intensity, which are comparable to data reported in the literature [

33]. The corresponding Raman active modes are also indicated in the figure. The uniformity, in terms of the positions and intensity of the Raman signal acquired at the various positions of the sample, clearly indicates the homogeneity of the synthesized sample tested over a wide spatial range.

The more interesting results, with ethylene glycol synthesis, were obtained at 150 °C. They are summarized in

Table 2. The optimal molar ratio of 1,2-ethanediol:TEAOH was established to be 60:4.5; the hydrolysis ratio was increased from a minimum value of 68.5, corresponding to the water present in the 35% (by weight in water) TEAOH solution, to 1431. Only using these conditions, it has been possible to obtain a powder sample. At low hydrolysis ratio values, the samples were observed to be amorphous (TP23.1 and TP23.2), while in the hydrolysis ratio range of 100–175, anatase was obtained as the only pure phase. When the ratio was further increased, the formation of an anatase/rutile mixture (TP26.4) and rutile (TP26.5) was observed.

The parameters obtained from the fitting of the E

g(1) Raman mode in the spectra, such as the Raman intensity normalized for the excitation input power, the peak position and FWHM, are also reported in

Table 2 and shown in

Figure 4, together with the results of the XRD, in terms of the crystallite size.

Figure 4a shows that, as the hydrolysis ratio increased in the range 100–175, the crystallite diameter decreased by approximately 50%, from 49 nm large crystallites (TP23.3,

r = 100) to 26 nm crystallites (TP23.6,

r = 175). This can likely be ascribed to a faster hydrolysis and condensation process, leading to the rapid nucleation of the NPs [

34,

35,

36]. Furthermore, the size of the crystallite did not seem to be correlated with the intensity of the Raman peak E

g(1): the samples had high intensities, with the exception of the sample synthesized with

r = 100 and

r = 708 and 1450. The width at half-height (FWHM) of the Raman peak decreased only at a high hydrolysis ratio due to the presence of a rutile phase together with anatase. The center of the peak moved to higher Raman shifts.

As can be understood by comparing the SEM images reported in

Figure 5 and the

Supplementary Materials with the Raman data, the most intense Raman signals were obtained when the nanoparticles were of homogeneous morphology (TP23.6, TP9), or when ellipsoidal elongated particles were obtained, or when particles appeared to have fused together to form rods (TP23.4). Nanostructures with dimensions ranging from 30 to 300 nm were obtained with glycol synthesis.

The acid synthesis always led to the formation of crystalline anatase, and only in a few cases (outlined in the

Supplementary Materials) did the XRD patterns indicate the co-presence also of an amorphous component in such amounts as not to visibly alter the Raman properties of the material. The results of the characterizations of samples prepared with the acid synthesis are shown in

Figure 6. In the images, the correlation diagrams were drawn between the diameter of the crystallite, the position, intensity, width at half height of the Raman peak E

g(1) of the anatase, and the hydrolysis ratio used. The diagrams also show the characterization data of the samples synthesized twice, with

r = 3.32 or with

r = 16.6, to evaluate the reproducibility of the synthesis.

The crystallite size and the intensity of the Raman signal decreased as

r increased, while both the shift and the amplitude of the Raman peak E

g(1) decreased with increasing hydrolysis ratio. We can easily explain the decrease in crystallite size as a function of the hydrolysis ratio because the hydrolysis rate was increased using a larger amount of water in the reaction mixture, producing smaller crystallites. On the other side, the Raman peak position and the width behavior were different from what has been observed in the literature, as they shifted at lower values with increasing hydrolysis ratio, i.e., with decreasing crystallite size. This discrepancy may be attributed to the presence of structural defects in the material, which may have broadened the diffraction peak and consequently the crystallite size [

37,

38]. The highest intensities of the peak E

g(1) were obtained at low

r values and a low hydrolysis ratio.

The crystallite dimensions estimated from the XRD measurements were between 10 and 30 nm; with this synthesis, crystallites with dimensions smaller than the ones obtained with the glycol synthesis were obtained, indicating a lower size limit of the NPs. Moreover, the SEM images, reported in

Figure 7 and

Supplementary Materials, confirmed the capability of tuning and reducing the dimension of the nanostructures obtained by changing the experimental parameters—the morphological control of the material with the acid synthesis seemed to depend substantially on the hydrolysis ratio.

At higher dilutions (r ≤ 4.15, TP22.10) the formation of larger nanoparticles was favored, with hydrolysis and condensation occurring more slowly in this case; a slow nucleation of a few nuclei is hypothesized to occur with different sizes incorporating other nuclei during the hydrothermal treatment. The results obtained in terms of shape and size were similar to those obtained with the glycol synthesis.

At small dilutions (r = 150, TP25.5), a fast nucleation of numerous nuclei, with a narrow size distribution, followed by slow growth during the hydrothermal phase, was probably obtained; faceted morphologies were obtained. When the hydrolysis ratio was further increased, more aggregated nanoparticles smaller than 20 nm were obtained; micrometer sized aggregates could also be seen.

Regarding the properties of the Raman signal, its variability seemed to be linked to the diameter of the crystallites; the more intense signals (around 200,000 and 300,000 counts/mW) were obtained with low

r values (in between 1.66 and 3.74), while a good signal was observed in all the other conditions (see

Supplementary Materials for details). The maximum variation of the position of the E

g(1) peak and of its FWHM was 3 and 4 cm

−1, respectively, reflecting the presence of nanoparticles with different dimensions.

The XRD patterns and Raman spectra of the samples synthetized under basic conditions also revealed the presence of brookite in a negligible amount (0.04–0.07% wt) with respect to anatase. The presence of these traces did not influence the Raman Eg(1) peak of anatase, and was, therefore, not a problem for thermometry purposes.

The correlation diagrams for the basic synthesis are reported in

Figure 8. Over the whole range of the hydrolysis ratios, the basic synthesis led to more reproducible results: the size estimate of the crystallites was always around 20 nm.

For this synthesis, the properties of the Raman signal varied little as r varied; the maximum variation in the position of the Eg(1) peak and of its FWHM were 0.6 cm−1 and 1.1 cm−1, respectively.

The SEM images of these samples (TP21.1 is reported in

Figure 9a as an example) showed nanoparticle aggregates of faceted shape with a narrow size distribution centered around the values of 25–50 nm. The basic synthesis seems not to have been affected by the variation in the hydrolysis ratio.

The signal intensities were, on average, lower, but comparable with those obtained from the other syntheses. As can be seen from the diagrams in

Figure 10, the intensity values also varied little as a function of both the diameter of the crystallites and throughout the range of variation of the hydrolysis ratio. This effect may be attributed to the crystallinity of the sample obtained [

39].

A comparison between the samples obtained with the different syntheses is shown in

Figure 10, where the intensity of the Raman peak is reported both as a function of the size of the crystallites (a) and as a function of the hydrolysis ratio. The acid synthesis allowed modulation of the dimensions of the crystallites and of the NPs together with the intensity of the Raman signal, while the synthesis with glycol allowed modulation of the dimensions of the crystallites, but not of the Raman intensities, and the basic one maintained a constancy in the two parameters.

The determination of the local temperature was obtained from Stokes and anti-Stokes Raman spectra of anatase collected over a defined temperature range on selected samples. From the first Raman characterization performed on all the synthetized materials, a set of samples prepared with the three different syntheses was selected on the basis of the most intense and homogeneous Raman signal to be exploited for nanothermometry. These samples were TP9 for glycol synthesis, TP22.10 and TP25.1 for acid synthesis, and TP21.3 and TP26.9 for basic synthesis (see

Supplementary Materials for details on intensity).

Figure 11a reports the Stokes and anti-Stokes Raman spectra of the E

g(1) peak of TP9 sample collected in the temperature range between 293.2 and 323.2 K. All these peaks were interpolated with a Lorentzian function to determine their area and intensity (

and

). The values of the ratio between the peak intensities (

), together with the corresponding absolute uncertainty, were obtained and are reported in

Figure 11b as a function of the temperature. Equation (1) was used to fit these data as a function of the sample temperature, which has an almost linear trend in this interval, starting from the experimental parameters reported in

Table 3.

The instrumental constant was considered as a free parameter of the fitting and determined through calculation iterations.

Figure 11b shows the fitting curve, and

Table 3 reports the value of the constant A and the relative sensitivities as a percentage.

The obtained value was in agreement with the one obtained in the literature using a commercial TiO

2 powder [

26], confirming the quality of the synthetized nanomaterial. The figure also reports the relative sensitivities, which decreased as the temperature increased [

26,

40]. The thermal resolution (absolute uncertainty in determining the temperature), as well as the percentage accuracy, varied according to the calibration temperature.

Regardless of the type of synthesis used to produce the anatase and the intensity of the Raman signal at room temperature, it can be seen that in all cases it was possible to obtain a nearly linear relationship between the calibration temperature and the intensity ratio aS/S. The graphical representation of the response curve of the nanothermometers tested, obtained by fitting the experimental data with Equation (1), is shown in

Figure 12. It shows that the response data of the nanothermometers tested followed the same increasing trend with the calibration temperature: the intensity ratio grew as the probability of aS events increased with the temperature, with a similar speed in all cases.

The calibration procedure of the nanothermometers enabled obtaining the value of the calibration constant A, reported in

Table 4, together with the characteristics of the material, such as the Raman peak position, XRD crystallite and SEM nanoparticle dimensions.

The difference in size between the crystallites, highlighted with XRD, and the nanostructures, clearly visible with the SEM images, was due to the fact that the NPs were formed by several crystallites.

All the tested materials performed well in the temperature range 298–323 K, and, for Raman thermometry purposes, had comparable performance with commercial anatase, the data for which were taken from [

26]. This work confirmed that, at a laser power of 1 mW, there is no self-heating of the sample; for the Raman shift E

g(1) mode close to 143 cm

−1, the calibration constant assumes values close to the reference value.

For the different nanothermometers synthesized, the relative error in determining the temperature was calculated using the formula:

where

Tmeasured is the value obtained from the signal of the nanothermometer, while

Treal is given by the thermostat at the different calibration temperatures. The relative error, depicted in

Figure 13a, can also be given in percentage terms, as reported in

Figure 13b.

4. Discussion and Conclusions

The need for and importance of using biocompatible nanosystems which allow the determination of local temperature in the biomedical field is the main thrust of this research work. From this point of view, two important purposes should be carefully considered. The first is the control of the dimensions and the dispersity of the nanomaterial; only small dimensional structures, in the range of tens of nanometers, can be suitably incorporated into biological systems. The second is the concomitant maintenance of the optical properties in terms of the quality and intensity of the detectable signal. From these requirements the need arises to synthetize anatase nanoparticles with dimensions modulated in the nanoscopic range, which can be used as active Raman materials for the determination of the local temperature. Control over the size, morphology and optical properties can be achieved through bottom-up synthesis. A green method was adopted which was sustainable both from an energy point of view and from the point of view of the toxicity and hazard of the reagents. The materials were synthesized by a sol-gel process combined with hydrothermal treatment, following three different syntheses: the first using a mixture of ethylene glycol and water as solvent, with tetraethylammonium hydroxide as a peptizer; the second using an aqueous solution of acetic acid as a catalyst; the third using a buffered ammonia solution at pH 9.5. The precursor used in all three cases was titanium tetraisopropoxide, which is very reactive and has low toxicity.

All three syntheses, optimized in term of reaction time and hydrothermal treatment temperature, were effective in obtaining anatase of different dimensions by varying the hydrolysis ratio, a parameter that was accurately controlled within the same range of values. Nanostructures having dimensions ranging from tens of nm to hundreds of nm were obtained, as underlined also by the SEM measurements presented in

Figure 14. The results of seven different samples are reported in the diagram of

Figure 14 as examples: TP22.10 and TP25.5 samples for the acid synthesis, TP21.1 and TP21.4 for the basic synthesis and TP7, TP9 and TP23.6 for the glycol synthesis. Within each synthesis, two different samples made with different hydrolysis ratios are reported: around the lowest and the highest probed for the synthesis to highlight the size of the NPs obtained. For the synthesis with glycol, a sample synthesized at 180 °C is also reported (TP7), which is identical to its correspondent, synthesized at 150 °C (TP9). On each box of the diagram, the central line represents the median of the size distribution, and the bottom and top edges of the box indicate the 25th and 75th percentiles, respectively. The whiskers extend, instead, to the most extreme data points in the distribution that are not considered outliers. Adopting the synthesis in an acid environment, the morphology and the size were modulated, from tens of nm NPs to hundreds of nm NPs, by regulating the hydrolysis ratio. Concerning the basic synthesis, within the range of variability of the hydrolysis ratio, it was possible to obtain nanostructures of faceted morphology and constant size of around tens of nm. With the glycol synthesis, nanostructures with dimensions in the range of hundreds of nm were obtained.

The average size of the crystallites was calculated using the Scherrer formula. It can be seen that the materials synthesized with the basic synthesis were made up of smaller crystallites, of around 20 nm. This dimension reflects what could be observed from the SEM images—for the basic synthesis, the choice of the hydrolysis ratio seems to have had little influence on the nanoparticle dimensions and morphology, therefore it represents a more repeatable synthesis. The synthesis with glycol yielded materials with larger crystallites, of around 40 nm. The acid synthesis appeared to provide more control over the nanoparticle morphology than over the crystallite size.

The intensity of the Raman signal was highly modulated with the hydrolysis ratio of the acid synthesis, reaching more than one order of magnitude higher at a low hydrolysis ratio with respect to the higher. The Raman intensities of the samples obtained with the basic synthesis were comparable with those obtained with samples prepared with acid synthesis with high hydrolysis values. The samples prepared with glycol synthesis, on the other hand, had intensity values intermediate between the two extremes. In any case, the intensity values obtained were such as to allow their use for local temperature determination using anti-Stokes and Stokes measurements, as demonstrated with the measurements performed in the temperature range 293–323 K.

For the practical use of TiO2 nanoparticles in biological systems, such as cells, a narrow and centered size distribution at dimensions in the range 10–50 nm will allow direct NP uptake. This dimensional range is easily achieved with the basic synthesis, which has been proved also to be the most reproducible, being less affected by variation in the reaction conditions. It can also be obtained with the acid synthesis working at high values of the hydrolysis ratio. Larger NPs can still be useful after proper functionalization.

The characterization of the optical properties through Raman spectroscopy has highlighted, within a given type of synthesis, the materials with the best signal-to-noise ratio, as regards the Eg(1) peak characteristic of anatase. This signal underwent variations in the Raman shift and in the amplitude at half height, which, according to the literature, were ascribable to the size of the crystallites and to the presence of lattice defects of a compositional type or derived from mechanical or thermal stress. The record of the Stokes and anti-Stokes branches of the Raman spectrum enabled performing Raman nanothermometry through the relationship between the intensity ratio aS/S of a peak and the temperature. It was possible to calibrate the Raman thermometer at different temperatures between 293 and 323 K to obtain the calibration constant. The calibration constants, estimated on a selected set of samples, were, in all cases, comparable with those determined for a commercial anatase powder described in the literature. The performance of the nanothermometer was, therefore, comparable through the relative sensitivity, which decreased as the calibration temperature increased. The synthesis of anatase of different dimensions and morphology opens the way to the possibility of preparing materials with well-defined characteristics in terms of dimensions, for example, and surface functionalization, and is the first step for the creation of composite materials. Only by controlling the dimensions and suitably functionalizing the external surface of the nanostructures will it be possible to internalize and localize them in biological systems. Moreover, it will open the way to the preparation of composite materials in which the nanothermometer, anatase, can be combined, for example, with a plasmonic material capable of amplifying its thermometric sensitivity and, at the same time, functioning as a local nanoheater. Finally, the use of anatase, as a Raman active material, enables monitoring of the local temperature over a wide wavelength range, from the visible to the near-IR range.

An important point will be to study the nanothermometry performance of the synthesized nanoparticles, not in the form of powder pressed on KBr tablets, but directly in aqueous suspension. Preliminary tests have shown encouraging results—the Raman signal of the colloidal suspension is high enough to be recorded even with attenuated power. In this regard, it will be important to ensure the dispersion of the nanoparticles through an electrostatic barrier (pH-dependent): the nanoparticles synthesized at acid or basic pH were found to be less aggregated.

The results obtained are very encouraging in view of the use of titania NPs as local temperature probes in biological systems. The use of a biocompatible material, combined with the possibility of modulating the dimensions of the NPs between the tens and hundreds of nm, and the excellent Raman signal of the nanosystems, pave the way for their practical use. There are good prospects in the future for the use of these nanoparticles in the in vitro and/or in vivo study of local temperature within living tissues to investigate cellular metabolism with good thermal resolution and excellent spatial resolution.